by B.B. Pelletier

Lots of interest in this story! I should have told it long ago. One of our readers may have actually seen the rifle at the recent airgun and firearm show in Frederick, Maryland.

With the last report, we left off with an external examination of the rifle. Naturally, as a red-blooded airgunner, I put it through the chronograph first thing. The cocking effort was 53 lbs., compared to a Beeman R1 that cocks with 36-41 lbs. of force. So, while the rifle isn’t the heaviest-cocking springer I’ve ever tested (that distinction belongs to a Hatsan 135 that took 75 lbs. to cock), it certainly wasn’t built for casual plinking.

The firing behavior was harsh. There was a huge lunge forward plus lots of vibration. The big lunge means a heavy piston, and the vibration usually means a canted mainspring. I said last time that the barrel was an Anschutz, but I found that Steve Vissage told me he thought he remembered putting a Webley Ospry barrel on the gun.That would have had the proper dimensions for a .22 caliber pellet.

The velocity I got with 14.5-grain Eley Wasp pellets was 755 f.p.s. I checked with the two .22 caliber R1 rifles I used in the R1 book, and they averaged 725 f.p.s. and 751 f.p.s. after 1,000-round break-ins. Steve Vissage remembered a velocity of around 800 f.p.s. with this gun, but that could have been with a different pellet.

Then, I disassembled the rifle. I was all set to use a mainspring compressor, but Steve told me the mainspring was under about a half-inch of preload. So, I removed those three machine screws and the one triggerguard screw, and the end cap popped up by less than a quarter-inch. I guess over time the spring had scragged (taken a set length from which it will never diminish until it wears out).

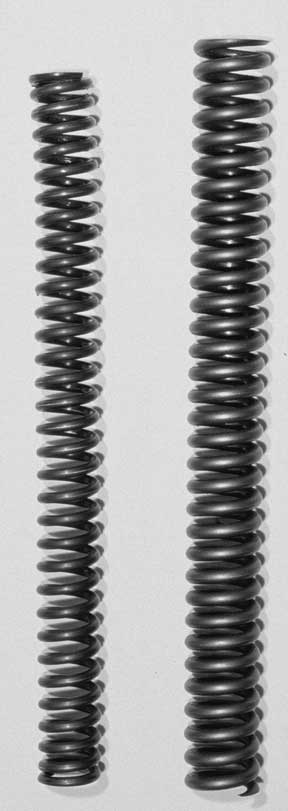

With the end cap off, the mainspring came out, and it’s a monster! Its 32.5 coils are made from 0.190″ ASTMA 410 silicone chrome wire. The compressed length is 6.175″, which must be a record for spring rifles. The mainspring weighs 12.2 oz.

An R1 mainspring weighs 6.3 ounces, in comparison, or just over half what this one weighs. Look at the photo for a comparison.

The piston came out next. It weighs 18.2 oz. and is 1.30″ in diameter, while an R1 piston weighs 12.6 oz. and is 1.147″ in diameter. Vissage had the piston tempered and shot-peened to relieve stress. The piston rod was hardened and drawn to a dark straw color. That should make it file-hard. The spring guide is also proportionately larger than the R1 guide.

A close examination of the piston seal revealed several flat spots, which are burn marks from excessive friction. Vissage told me he put a lot of effort into the selection of material for the piston seal. He was looking for high-lubricity and tolerance for high-temperatures from the heat of compression. Those flat spots told me the seal was too dry and was wearing from the friction with the chamber.

After seeing the massiveness of these parts, I felt that some velocity was lost by a slowdown in acceleration of the piston. The weight of the piston told me where the rifle’s powerful forward lunge was coming from. However, before you start criticizing Vissage, let me tell you that Jim Maccari once made a plastic piston for a TX200 to accomplish just the opposite – faster acceleration from lighter weight. That gun vibrated like a jar full of mad hornets, so you can go too far either way.

The piston seal is not a parachute design. Perhaps there’s some loss of pressure around the sides, where the high-pressure air has nothing to confine it. A parachute seal would inflate and push its sealing edges against the cylinder walls, but this seal can’t do that.

I lubricated the piston seal with Beeman M-2-M moly grease before installing it again. The mainspring received a coat of Maccari’s black tar to cut the vibration. All friction points received a coat of M-2-M grease. The thin washers at the pivot point had never been lubricated. Steve counted on the Armaloy plating to self-lubricate, but I found it mostly scraped away when I disassembled the rifle. So, I used moly paste on the washers, and the cocking got smoother.

When the gun was back together, it felt like the cocking effort had diminished, when in fact it had actually increased by 2 lbs.! It was smoother but also a little harder to cock. The velocity with Wasps averaged 776 f.p.s., but that dropped to 767 pretty fast. I imagine the rifle will sink back to 755 in time. It vibrated much less this time, though there was still some present.

Sorry to say that I never shot the Vissage rifle for accuracy. I was more interested in how the powerplant performed; and, as we saw, it was about like a factory R1.

When I tuned a standard Beeman R1 with a Venom Mag 80 Laza kit, the average velocity with Eley Wasps jumped to 840.8 f.p.s., and the firing behavior was as smooth as glass. The Venom kit was the first to offer Delrin button bearings to float the piston in the spring tube. It took 50 lbs. of effort to cock, but the return was a much more powerful air rifle.

That’s the tale of a man and his quest for speed. The other two rifles he built were a .177 and a rifle with both .177 and .22 barrels, which he kept for himself. Vissage never went supersonic in .22 caliber, but I bet he knew a lot more about what goes into a powerful spring rifle after this project was over! And, now, we all know a little more.

BB –

Yes, after organizing my memories, I did indeed see the serial number “0001” Vissage at the Frederick, MD show. I wish I had known of its history before the show; I would have spent more time looking the rifle over.

Thanks for an informative an interesting series!

Phil

B.B.,

Just great. Really enjoy your history lessons.

kevin

B.B.

I love that he tried!! And that you shared the story with us, giving him a little piece of history he rightfully deserves..

A super lesson for us novices about the basics of spring gun power plants and what makes them do what we want, smooth firing.. at any fps

Super interesting! And little, by little, I’m learning about taking one apart, it’s not as scary as before, but still quite a bit.. I bought a rusty old Winchester 422 on gunbroker, with the intent of tearing into it. just to see what I might learn.. certainly not with the hope of making it better, it will probably not even make it back together..

Wayne,

Ashland Air Rifle Range

bb,so much effort to make a better mousetrap.can you say anything about the transfer port?that piston seal didn’t look up to par with the task at hand.thank you for this opportunity to “monday morning quarterback” steve’s creation.credit to him for pursuing excellence.frankb

Morning B.B. Thank you Sir from another of your students. You know that this gives our creative brain cells something to do while stuck in traffic. Perhaps,we could get a senator to attach an ear mark to the bail out bull suspending some of the laws of physics for all of us air gun people–just think of what we could build then.

Very interesting tpoic. I foun dit interesting that with such large, robust components, it still is about the same (or even less) power as a more practical gun. I wonder though, with the heavy piston, would this gun do better with very heavy pellets than the smaller guns?

jajajajj great comment Mr. B…….

B.B.:

Excellent story… I really enjoyed reading about this rifle… I was disappointed to see that it performed the same as or even less than the R1… I was hoping for higher power using a .22cal…….. but……… A question, do you have any more tails like this one??? Anyone else like Vissage dedicates to this kind of projects??? Just curious to see if anyone has really done any REAL improvement… LOL… Anyway, great story sir…..

Cheers,

Jony

tales* (correction)… sorry

Cheers,

Jony

B.B.

Interesting review. However the rife would score low on my shoot-ability test.

UPS tracking tells me I have a package arriving this Monday with I believe a single shot Webley Raider.

I could only find a review from you on the Webley Raider 10. With that rifle you were only able to get 10 good shots before refilling. Any experience with the single or two shot model?

I wanted to try a PCP without diving in head first, so a used rifle and hand pump seemed to make sense over a high dollar gun and scuba gear to start. Hopefully it was not too bad of a decision. I discovered the rifle late at night or would of asked you first. The “yellow” guys said it was a good value. Pd $395 for it – supposed to be 95% +. No picture, very short description. I am guessing the single shot beech based on the price.

I will try and not let my Springer’s see her when she arrives. I know the purists take a dim view of the PCP’s.

Since this is my first, any advice?

Thanks,

Volvo

Yeah Volvo!!

Under no circumstance, let the springers know!!!… you might as well put them away for awhile, if your experience will be like my first PCP, the Discovery. The longer you go without shooting them, the harder it will be to go back, especially the ones that recoil very much..

To me, high power springers are for those poor souls who can't afford, (but the Discovery really limited that group), do pumping or deal with the scuba tanks, getting them filled easy..

PCPs, at least the Air Arms S410 are very hard to beat for accuracy and ease to shoot, I have to really be motivated to want to shoot anything else, like a contest with Matt61..

I think you'll find the PCP is a one way road to happiness!!

But that is just me, remember Gino's guest blogg (I think it was Gino), sold his PCPs, in favor of the TX200 in .177 and .22

There are some great deals out there on used PCPs, I only paid $365 for a BSA Lonestar, that looks like new, and $390 for a like new 10 year old Air Arms S310, the first version of my beloved S410.

Wayne,

AARR&R

Wayne,

Nothing wrong with having budget constraints, but that is not what really kept me from PCP’s.

A quality spring gun like my HW97K that has more than just an advance tune breaks the $900.00 mark when all is said and done.

I believe simplicity and durability are the principal spring gun advantages. I favor a recurve bow over a compound bow for the same reason.

But…I can’t resist at least giving one a try.

Here is an old PA link on the one I purchased:

/product/webley-raider?m=104

Looking in my crystal ball I’m not sure if that is a AA S410 or…

Volvo

Volvo,

Any progress report on the break in of the fwb 124?

kevin

B.B.

That’s pretty intense. So what was the reason why the more powerful spring did not produce greater power? Was it just that the greater mass slowed the acceleration of the piston? Then perhaps the answer is a titanium spring. Bob Lee Swagger, the fictional Marine Corps sniper in the Stephen Hunter books uses a titanium firing pin in this Remington 700 to decrease the lock time…all on a $14000 Marine Corps pension.

The B30 has returned complete with a new stock. Everything is in place and working, and I believe that I have scored a tune job out of this. The cocking effort is noticeably lighter and smoother. The discharge sound has a slightly higher timbre, more of a “crack” than a “thunk” but is as smooth as ever. I’m in business again and all for the B30. I get the feeling that this one will be good for the duration. Great job, Stacey and PA.

Wayne, you’re doing a great job selling the S410 which, for a man of my budgetary outlook, is really saying a lot. But “one-way road to happiness” sounds like the movie, The Apostle with Robert Duvall, about a renegade preacher who runs the One Way Road to Heaven church. It’s quite entertaining. After clobbering his wife’s adulterous partner with a baseball bat he says that he believes he’s “sent him to glory.”

The following is one of those stories that many have heard and many have not, so I thought I would post it.

http://darwinawards.com/

stupid/stupid1998-11.html

I had heard it before myself but what caught my attention this time is that the guy used a pellet gun to pop his helium balloons at 16000 feet up. The model which he used seems lost to history. Had I been doing this (which I’m not likely to), I would have packed my trusty Crosman 1077 and been up the creek with the temperatures at that altitude. What seems lost in the laughter about this escapade is that the guy’s crazy plan actually worked and even more or less as planned–just too well.

Matt61

Monday morning QB,

I did a whole chapter in the R1 book of different-sized transfer ports and their effects on the velocity of the R1.

If you ask real nice…

B.B.

UW Hunter,

‘

Like you, I surmised the Vissage gun needed something to resist that big piston, which is why I tested it with 5.6mm Eley Wasps.

Although it wasn’t borne out in the tests I did, I do think the gun would do better with heavy pellets than with light ones.

B.B.

BB,

if a tuner can get 800fps out of a .22 R1, maybe your vissage needs a tuner! They may find it benefits from a lighter (or heavier) piston. 1000 fps may be as simple as drilling a few holes.

Now that we have very powerful PCPs it wouldn’t make any sense, but maybe this guy should have expanded a Benjamin.

Jony,

I do have a few more stories like this one. I told Monday morning quarterback I might tell you all how changing the air transfer port changes power in a springer.

B.B.

Volvo,

I tested the 2-shot FX (which is the Webley Rapier, too) years ago for The Airgun Letter. I forget how many powerful shots it got, but I will try to research it for you.

No Benjamin Discovery? I designed it for guys in your situation.

B.B.

Matt61,

That doesn’t sound like a very happy road to happiness…

Not anything like the joy I get shooting the s410..

As far as selling them, I wish I could, but with the magazine issue. I don’t want to. I still advise buying one, from PA, with their great customer service, but there is a good chance you’ll have to send it back, or fix it yourself, or just shoot it by turning the mag manually, which is very easy and quick. While you wait for the parts like I am..

So, I’m not selling them, I’m “just calling them as i seees em”

The Air Arms S410 is the cream of the crop of my inventory of air rifles.

Wayne,

Ashland Air Rifle Range

Tuner,

Yeah, and what were the ’49ers thinking by taking covered wagons across to California, when a plane can make the trip in a few hours?

In 1982, all Benjamin made were gas guns and multi-pumps.

B.B.

Kevin,

My overall impression of the FWB 124 is that it is an extremely accurate mid powered rifle that’s biggest draw back is its trigger. While not a bad trigger, the Rekord on the HW rifles or even the trigger on my BSA Lightning XL out shines it.

It is at about 762 fps with CPL’s. But the tune is still not broken in. I’m sure higher power springs exist for it, if that is important to you.

I can shoot it very well from a rest, but not as good off hand. That is certainly a subjective point- but my observation.

It could fill the role of an only Springer if that is what you are looking for even with the trigger. For 10 meter, plinking, and small pest control you could do much worse.

Since it is a classic, numerous reviews of it exist, including expert information from B.B.

Are you contemplating purchasing one? As B.B. stated the piston seals were made of a brittle material. While my rifle was obviously use very little if at all, the seal still exploded after ten shots. So keep in mind any original gun could have this issue. Easy fix but more $$.

Thanks for asking,

Volvo

B.B.

I considered the Discovery, but I guess that would have been too easy. Getting the rifle, pump, and the fittings in one box certainly makes a lot of sense!

The Raider just seemed attractive to me. Most larger purchases are made base on emotion and filling a need, then justified afterwards. I am working on that last part right now.

If I had been on the Disco forum at the time, with all the passionate owners, I am sure that is what would be coming instead.

Volvo

The way to go, if you want REAL POWER for the 21ST CENTURY, of course, is to use very small, ultratlightweitht and fast springs and pistons…NANOspirngs and nano pistons. hunerds of thousands of the li’tl buggers, and ther u go!

Volvo,

Your so wise.. that’s how it works for me, for sure..

So let me help you justify, you’ll have to help me later..

HHMMM, this is tough, because I don’t have a Raider… but who cares.. It built tougher, more accurate, more powerful, and it can leap tall buildings in a singe bound. It will be worth as much as you paid or more, in the near future.. The joy you get shooting it is priceless, think of all your saving on medical bills..( when your in joy your immune system is working over time, making you healthier than any drug, food or supplement)

So don’t waste one thought in regret, ever.. call it a lesson and move on. But I know you knew that.. and that’s not whats going on here, you made the deal of the century..

hows that for a pile of bull shi..

but you do feel better, right?

Wayne

Hey Everyone,

What is your opinion of the Marlin 336 in 30-30 as an all around rifle, deer hunting out to 100 yards, and the like.

Wayne

BB,

If it wasn't a boutique item and therefore expensive, I would love to get the Vissage — it seems like there is a lot of margin for increased efficiency and better firing behavior. Maybe Industry will copy it:). I know there's not much point in a supersonic .22 pellet rifle, but it would be fun to play with.

Wayne,

Glad you're giving the 336 a look.

Wayne & Matt,

Go for offhand, otherwise you're just testing rifles not contesting primary shooting skills:).

Wayne,

I sense a need. : )

Volvo

Volvo,

Not to worry, the “King of justification” is here for you. No one has done more of it than me..

Just go right ahead, it will be fine..

Wayne

hell just buy a fire arm if want to take deer, thats not what air guns are about, if you ask me its waste of time and money spendin hundreds tryin to make a boost in power to an air rifle,

so lets say your springer can kill coons now with ease instead of just rabbits, the issueis you spent tons of work, and probably $1000 to do it.

The real question is why? I own air guns and fire arms, and takin rabbits and squirrels and rabbits with the air rifle is fun.

But when I’m goin hog huntin and deer hunti, I don’t bring the air rifle!

Don’t bring air rifles into somethin they aren’t made for.

I mean come on, you can get a VERY nice and accurate hunting rifle that can take deer immediate kill at .277 cal for maybe 300 or 400.

Air gund are fun, but use them for what they are meant for, once you go beyond that, it ruins the point of air gunning.

Anyone else agree?

Wayne

Is that rumor true that you are selling your S410? I know you are very passionate about it 🙂

Do you have any magazine problem with s410?

Also what scope you use for s410?

Walter

floridawoodsman,

I agree with you in general, but the Marlin 336 is one of the most powerful airguns available, especially if you use the plasic pellets from Gamo.

Walter,

That’s the thing about rumors, you can’t trust them.. I will never sell my walnut stock Air Arms S410 .177 period. That is my personal favorite and from the sounds of it does things that some others might not do, like 130 shots per tank, with out loss of POI to any degree that counts for accuracy.

Yes, I have had three S410 and each one had a problem advancing the magazine, two I sent back for credit and the walnut stock I have and won’t sell. The problem is not serious to me, because I can advance the mag by taking it out and using my finger, it takes 2 seconds longer. PA is sending me replacement parts for free, but I’m not bothered waiting.

I’m a “horse trader” from way back in the family line, but this one breaks my pattern.

I have a leapers 6-24x50AO on it now. That is a very nice scope for the money, especially on a PCP.

Thanks, annon, I was just going to say that about my Marlin 336 question.. Doesn’t anyone have one, who wants to tell about it?

Wayne,

Ashland Air Rifle Range

bg farmer,

Thanks for the belly laugh.

But I think the new Beeman gold pellets in the Marlin336 would be best for penetration. The Gamo’s just don’t expand.

Volvo

Wayne

20mm vulcan would be good for deer. If you want something lighter, use a Grizzly ot T-Rex.

twotalon

Wayne,

Sorry for the digression, but the Marlin 336A is the number two all time selling rifle, only the Winchester 94 is higher.

The Marlin is easier to scope.

The 30-30 round is fine, they even have some new polymer tip rounds for better ballistics.

Buy it now.

Volvo

Twotalon,

HHHMMMM, I’m new to this so “bear” with me, I just bought a WWII Arisaka, and I hope it’s the 6.5mm

So, your saying I need a 20mm vulcan, whatever that is…. Oh I get it, It’s a joke..

What I’ve heard about the Marlin 336 is that the heavy receiver is great for scope mounting and “smothering” the report, as well as the side ejection, light weight, balance and size. And it’s real easy to pull out and shoot quick while your on horesback. (If I could ride one)..

Volvo, where is my help with the justification? I’m drowning here..

Wayne

Volvo,

Look at that, you were there for me before I asked, how cool we were typing at the same time.. “air gun bros”

Wayne

floridawoodsman…I think you’ve missed the point.

It’s kinda along the lines of:

“why risk your life climbing Everest?”

A: “because it’s there”.

Or if you want to go real fast why spend all that cash on an Indy car when an F-16 will go a hell of lot faster.

Some people just want the biggest, fastest, bestest.

cowboydad

Wayne,

Bro, kind of sad that that you didn’t offer the S410 to me first since I see you’re selling it.

Imagine yourself on horseback with your trusty Marlin and a Ruger SA with CB caps.

You need one of both, best way to finance them is by selling me that nothing but trouble S410.

I got your back,

Volvo

Volvo,

It feels good I’ll lean back…

I can only imagine the horseback thing, I might be able to ride a goat or a donkey, if they had training wheels.

What S410, oh that one, I sold it last week for $10 at a garage sale…. piece of junk you wouldn’t have wanted it.

Wayne,

B.B.

Found this in cyber space:

… while FX Airguns builds the FX2000 rifle for Webley & Scott, they have no part in the production of the Raider/Viper. In fact, Webley & Scott builds the Raider/Viper themselves. FX Airguns does, however, produce their own two shot rifle, named the Timberwolf…

Also found a 30 shot string with a median of 800fps. Extreme spread was 40 fps.

Volvo

All,

Has anyone looked at a Crosman Raven?

Looking for a youth gun that can kill a rabbit or squirrel at close range. The Raven looks good and seems rated at the edge of the power needed and most importantly it is on sale right now at PA.

Thanks in advance,

DB

Wayne, how about, since you won’t sell us your “beloved S410 in the walnut stock”, send it off to B.B. so he can take her all the way down and figure out why she has so many shots w/o loosing POI. This will allow all of us to have ours blue printed to her exact specs, thus releaving you from our whinning and crying. Thanks Mr.B

DB,

Most of the youth air rifles are a little shy on power for rabbits and squirrels.

The Crosman 2260 is very light and CO2 or the Daisy 22 SG is a pump rifle with good energy.

Both are considered adult guns, but scaled on the smaller side. The Crosman is less $$ but will need CO2, the Daisy more $$ to start but less to run.

Good luck,

Volvo

Just got some grips for my Talon from Steve Corcoran yesterday. They are the walnut with stippling grips. They feel much better than the factory pistol grip and short thin forward grip. The stippling makes it very grippy and easy to hold. The finish is flawless and they fit the gun perfect.

jeff

DB

I know nothing of the rifle you ask, but….

What is your budget? The Discovery is also the size of a youth rifle, at least pretty close, and has the accuracy and power for the job. Or a Benjamin 392 pump.

It might be best to consider the long term, a first gun can be something to grow into, if you supervise, which is a must at any level you start them anyway.. give them the tool that can really get the job done, and show them how to do it. It will be a bonding experience as well.

Wayne,

Ashland Air Rifle Range

Mr. B.

You know that is a pretty good idea, but what if B.B. falls in love with it too. Then I would have to decide who loves it more.

I’m not sure if I want to go there..

I’ll think about it real hard.

For the long term advancement of the sport, it sounds like a great idea!!!

B.B. is the guy to figure it out, and turn the info into a product we could all afford, instead of the $1,000 plus Air Arms wants for it.

lots to think about.

Wayne,

Ashland Air Rifle Range

Volvo & Wayne,

Thank you for the input. Those are excellent choices… as are the others on BB’s blog about youth guns.

Have considered both your recommendations. The 22SG is reliable and fairly accurate and the 2260 is practically a legend. But not really wanting CO2 and the 22SG is just about 40% more in price.

I have a Disco myself (and love it) and that is way more power than this particular youngster needs. Not all children are equally skilled. And then there is the $500 price tag. Budget is $50 to $75.

Last year I got him a Crosman 1377 and he loves it. So was thinking of getting a rifle this year (for Chrismas).

OK it was the price tag on the Raven that attracted me. Was hoping that being a low powered springer it would be reasonable accurate. Both pistol and rifle in 177 would keep his ammo needs simple. And you know the Raven just looks cool.

I have time… someone will review it.

Thank you,

DB

B.B. (Vissage low power)

Very interesting.

Do you think the piston and spring are so heavy, and therefore their acceleration is so slow, that the pellet is out of the barrel before the piston ever reaches the end of the chamber? A lot of wasted high pressure air going out of the barrel after the pellet is long gone.

The swept volume of the piston appears to be about 1.7 times that of the stock R1. I bet this power plant would really wail on a snug fitting .30 cal pellet and barrel like the custom Maccari R1 you talk about in your book. I don’t think the Vissage gun is getting 10% of its power into the pellet. A slow accelerating .30 cal might be a better match.

What do you think?

Thanks,

Lloyd

Tuner here.

I know what Benjamin made; their manuals had a catalog. If I could pump a .22 as a kid, then a man could pump a bigger one. Have you ever felt maxed out pumping a benjamin?

B.B.,

Off subject update: I sent the leaky Daisy 22SG back to Pyramyd; it’s a shame it didn’t work.

However: Today its replacement arrived, a Sheridan .22 cal and a Williams peep sight for it. I tightened all the screws and then test-fired about 50 rounds through it, then added the Williams sight. This time, the original rear sight came off without taking any paint with it.

I performed a shoot-off between it and the .20 cal Sheridan. Even though the .22 has a better trigger, I shot better groups with the CB9. The peep sights make an enormous difference for me, and I’m delighted with both guns.

Also, after reading some of your comments, I got the Crosman 850 pellet trap. I managed to shoot and destroy the interior curtain-hanger almost immediately. Not good, but there were benefits; first, I found a package with Crosman targets inside the trap, and second, I found out that a 1/4″ wooden dowel cut to length makes a suitable replacement for the plastic hanger.

–Witt

Wayne,

You had magazine problems with all of your S410s?! Okay, that’s a cold shower to hear about for that kind of money. I’ll stick with the B30 while they’re straightening that out. Let me know if and when you get the mag fixed.

BG_Farmer, I’m afraid that benchresting will involve a test of my benchresting skills which have a ways to go.

Witt, the interior of my Crosman 850 trap didn’t last any time at all. But the shell has withstood a hurricane of lead with the help of some duct seal inside.

Matt61

Matt61,

No big deal, don’t let it hold you back, really PA will stand behind it as you well know. I don’t care if I ever get mine fixed. Like I said, it takes 2 seconds more. You can still get 3 shots in 10 seconds, doing it manually. What’s a little work for your index finger going to hurt you. You have to pull the cocking lever back regardless, the only extra is, while it is back you slide out the mag, rotate it with your index finger, slide it back in, close the cocking lever, shoot the gun. (no auto safety) Only difference, no slide out, no slide in. no biggy…

But if you look at everything else about the gun. It’s still the cream of my crop of 50 plus tested air rifles..

Wayne,

Ashland Air Rifle Range

B.B.

(another thought on Vissage low power)

My previous comment was that I believe a .30 cal (or possibly .28) would be able to capture a lot more of the energy that this power plant can deliver.

I am also thinking that in this particular case, a longer barrel would have proved helpful. The volume is way too big for the pellet and barrel. I’m guessing this gun was very loud?

All that extra volume makes this a little bit like my ongoing experiments (and I promise to write a blog this winter) with my big bore pcp setup. My project has demonstrated that with an unlimited constant high pressure air supply (not the conventional knock-open Nelson valve) ME will increase linearly with barrel length while the MV increases only at the square root of the increase in barrel length. However, the longer the barrel length and the higher the velocity, the larger the deviation between theoretical and empirical performance, in other words the returns diminish quickly.

My thought is that on the Vissage, with all that spare volume, the point of diminishing returns regarding barrel length has not been reached.

On another note, I will be attending the Roanoke show in 2 weeks and very much hope to make your acquaintance. I stumbled upon your blog a couple of years ago and since then, I have you, and this great group of bloggers, to thank for an exciting and stimulating new hobby.

Best regards,

Lloyd

B.B. Please tell us more about the time you tuned that R1. From SavageSam.

SavageSam,

I’ve tuned so many R1s. Can you narrow it down a bit?

B.B.

Volvo,

I was referring to the 2-shot Webley RAPIER, not the Raider. It was around in the 1990s.

B.B.

Lloyde,

According to tests done by the Cardews, a spring gun barrel doesn’t need to be very long. In the 1970s when they tested it was 6 inches, I believe. Today it’s probably 9 inches – the length of the TX 200 barrel.

So, no, I don’t think the Vissage barrel is too short.

B.B.

Tuner,

Well, Daystate made the Sportsman Mark II, a five-pump multi pump that developed 25 foot-pounds.

Trouble was, pumps 4 and 5 both required 77 pounds of effort to close the handle. Many adult men could not do it.

B.B.

Witt,

See if you can buy some Kevlar fabric to replace the ballistic curtains.

B.B.

Lloyd,

Please look me up at Roanoke. I want to meet as many blog readers as possible.

B.B.

Good Morning B.B. & All

I won a RWS Diana 45 on Gunbroker, it's on the way…I'm hoping it shoots in that 700 to 800fps area I like so much. Anyone have one? Do you like it? This one looks like new, and is called excellent by the seller.

Meanwhile the Slavia 634 seems to be similar size to the Diana 45, it's doing the 750fps I like with the JSB Exacts, I put another couple hundred shots through her last night, maybe up to 350 shots now. She is breaking in so fine. No more occasional loud shots at 850fps, from left over shipping oils, or whatever causes that. The cocking must be 25 lbs or less, the trigger was great out of the box, but has now smoothed out so much, it's as good as my TX200 or S410, I guess under 2 lbs and crisp as glass when it breaks.

I sure wish I had another 4-16x50AO in stock, I can't fit a larger one and the leapers 3-9×40 is doing perfect, but my old eyes need more power, I've gotten too use to the centerpoint 6-24x50AO on the S410 and my other favorites.

Matt61, I ran a test with the 634 while breaking it in last night. I put a row of 2" orange dots and a row of 1" dots under them, testing your idea about focusing on smaller targets.. Unlike the boards I had saved that showed your idea a good one, this was more of a tie, with the best group of 9/16" (20 yrds indoor lazyboy off knee) on the two inch dot, and second best 5/8" also on a two inch dot. This isn't a fair test, because the gun is still breaking in. I'll do it again when we compete, hey you should as well.

Let's set up a row of 3" – 2" – 1" and 1/2" dots and use that as the contest and test of your idea as well…

I have to get my batteries charged up on the camera before I can put some photos in the photo bucket.. later today..

Wayne,

Ashland Air Rifle Range

B.B.,

Just want to say thank you. I’ve really enjoyed reading your blogs. You are a “straight shooter” in more ways than one!

Herb

Air Gun Shoppers,

The Blue light is flashing at Gunbroker…

My new, far away friend, Billy Lo, is selling most of his collection to pay for medical bills for his wife, and now his Dad.. Real tough for him right now. I bought the HW-55 T B.B. is blogging now, and I’m buying his USFT he won in the 2005 nationals for winning the event. He will be posting a whole lot of hand picked and custom tuned very nice air rifles…

Kevin,

Right now, is the FWB 124 you want, it’s the one I bought from him, but I told him to resell it and apply it to the USFT. Here is the link:

http://www.gunbroker.com/Auction/ViewItem.asp?Item=111986454

He also has a brand new Weihrauch HW-100 14 shot Sporter .177 with a hand picked Curly walnut stock, comes with an extra 14 shot mag. it’s beautiful..

here is that link:

http://www.gunbroker.com/Auction/ViewItem.asp?Item=111991037

If you plan to buy a quality air rifle soon, consider helping this great person through these tough times.. He has a lot more he will be listing: a Steyr LG100ZM, Brian Johnson’s Pro-Target, a Ripley FT rifle, Daystate Huntsman .22, FX Revolution, FX Tarantula, R9, R7, HW97’S (.177-.22) and a couple of FWB 124’s, and a Webley Xocet TK from Jim Maccari.

So go to the links and contact him before he lists, and get the best deals, and save him the trouble of listing, he is very busy going in and out of the hospital right now..

Thanks in advance fellow air gunners..

Wayne,

Ashland Air Rifle Range

B.B.

Sorry for the misunderstanding. I thought the Webley model name was a typo like I make all the time. I should have known better.

Wayne,

I’ll let you know what I think of the PCP world next week. The rifle will be here Monday, the pump on Wednesday. Not sure if everyone knows this, but PA has quite a few owners manuals you can download. So I have been reading up and hopefully will get underway quickly.

Volvo

BB,i’m thinking about this gun in drag racing terms…the pellet fit is similar to traction. 5.6 mm is maximum available.spring energy is horsepower.more than enough!barrel is track length.piston weight is torque.if the race is over before we are at max hp we need a lighter flywheel.decreases torque,but gets rpm’s up reaching peak hp sooner[before pellet moves]even with a pcp if a valve did flow the same volume from shot to shot velocity should run paralell to pressure alone.if the piston seal was a parachute design,and the piston was tuned for less mass a bit at a time and chrono’ed,i’m convinced,barring part failure,this could perform much better!?frankb

Wayne,

I don’t know if the effect of the smaller target is something that you could see so dramatically; I suspect it is something that will show up over time. You might consider greater differences in target size. I shoot at basically marks on paper which have almost no area at all–maybe a square eighth of an inch that I can barely see at 20ft. And ultimately, the sight picture is individual I suppose. Elmer Keith and Clint Fowler, high master shooter, don’t like the 6 o’clock hold while most of the target shooting world does.

It looks like I’m rained out of the shooting range this weekend, so let’s point towards next week. We can certainly try the different dot sizes for experimentation. But for the showdown, how about this. If The American Rifleman is the ultimate gun magazine, then why not go with their testing protocol of five 5 shot groups? We could take their average. This actually would work to the advantage of the killer consistency that you showed in one of your photos.

Matt61

BB,PLEASE tell us what you know about transfer ports,you’ll notice in the above post I left a huge omission in my proposed solution,[though i did open the window mighty wide!!!SINCERELY..frankb

Frank,

As for tuning the Vissage for higher velocity, it is certainly possible. Yes to all your thoughts about it.

As for the transfer ports – next week.

B.B.

B.B.

Your work load just got lighter by 25%…. I got my “Blue Book of Airguns, seventh Edition… I love it. I just found out that the Benjamin model G (200) 1910 to 1935, I got for $77 is worth more like $180. But I paid $60 too much for my Benjamin 312. The BSA Meteor about right as well as the Diana 45, that just arrived, but I see that it is shooting a little slow at 780fps instead of the 1000fps the books says.. I also see that the Slavia 634 is so new, it’s not in it yet, but the 631 is. This is too fun..

And thanks to you as well Volvo for the lead.. But now when I’m buying, I’ll be shooting fish in a bowl, like the rest of you… too easy…

Wayne,

Ashland Air Rifle Range

thank you,for everything BB,I needed something to look foreward to right now.frankb

Matt61

In general, my best groups seem to be on the 1″ orange dots, that have a 1/8″ black dot with cross hair lines. Between the lines and the very small dot that looks very big through my 6-24×50 Centerpoint, it’s pretty easy to dial in. (I just got a 8-32×56 30mm tube, with the book, guess where it’s going)

So your right, I’m just focusing on the dot and lines make it that much easier.. I’m sure I could make a paper target with 1/8″ dots and cross hairs, without the 1″ orange dot and do as well. The dots stick to the lumber scraps and that is very easy for me.. The lumber also gives a look at the penetration of the pellet, or in the case of the IZH61 the bouncing off of the pellet.. just another reason I like 650fps to 750fps, unless out doors at 50 yards, then I’ll crank up the S410 to 900fps, which is still only 3/4 on the power adjuster.

Yes, 5 shots per group it is..

Say Matt, are you having any trouble uploading pics to your Photo bucket, for some reason I went to mine, and there is no place to upload anymore, just view whats already there. Is there a limit to how many you can post? I can’t delete any either.

Wayne,

Ashland Air Rifle Range

I hate it when this happens:

Today as I was shifting some open pellet tins from one place to another, I dropped a whole can onto two others and they spilled and intermixed; .177, .20, and .22. A big mess, and as Kenny used to say, “I could just scream.” It looked like a tedious job to get them all sorted—it was—but I was able to simplify the process by using a decimal drill-bit gauge to do it.

The following pellets fit through the corresponding drill bit holes:

.177 cal = .189

.20 cal = .209

.22 cal = .228

–Witt

Witt,

Good thinking!!!

Turning adversity into ….. into

…..into…. something,

oh well I thought I had one going..

Wayne

My Hammerli 490 Express combo arrived today and I got a few rounds through it. These are observations on this one rifle.

The first surprise I got was when I popped he breech open and discovered the rifle was cocked and the bore wasn’t passing any light. Apparently there was a styrofoam bead from the packing in it or I wasn’t holding the barrel at the right angle, because blowing into the breech and looking again showed clear.

So to speak.

This rifle needs — nay, *demands* — JB bore paste on a bronze brush. Apparently the plugs that were supposed to keep the bluing salts out of the bore leaked. Lacking the brush, I just started shooting after I lubed the piston.

The rifle honked when I decocked it, so I put two drops of Crosman’s chamber oil in the transfer port and let it sit for a couple of minutes then broke the action open and checked the seal’s sound again. It was still making a racket so I put two more drops of chamber oil in the transfer port and tried it again. No more sound, so I grabbed a tin of Gamo Match pellets and headed for my basement shooting range.

The first thing I wanted to try was penetration tests, so I cocked the rifle and loaded a Gamp Match pellet into the breech and fired it at the 2×4 that has been catching the pellets from my Walther Falcon Hunter. The pellet bounced off of the wood. So did the next three or four. Penetration is lacking, but hunting is not a priority for this rifle. That is what I got the Falcon Hunter for.

I set up the pellet trap then went across the basement and fired a few groups. The Gamo pellets went a little wild at first, which I am inclined to blame on the bluing salts in the bore. They settled down a little, but not a whole lot. Next came the Crosman premium-grade wadcutters in the tin. The rifle liked them. They ripped one raggedy hole from 30 feet over the iron sights. The rifle also liked the Beeman laser sports I put through it, but the Crosmans took the cake, at least on this particular day.

The iron sights are eminently usable, with adequate amounts of room either side of the front post when viewed through the notch. It was easy to keep equal amounts of light on either side of the post. I did notice the front sight seemed to catch the light behind me, turning it a dark gray instead of black. I may be squirting it with matte black spray paint to change that.

This may be the ideal basement-shooting air rifle. The sound of the pellet’s impact in the trap was louder than the sound the rifle made when it fired. I suspect a little blob of RTV on the deflector in the trap may serve to dampen its vibration and quiet the major noise source involved with shooting the rifle in the basement.

My original intent was to get a basement shooter and sparrow controller. It certainly appears to have the accuracy for head shots on those bluebird-killing sparrows, but I must admit I am a little concerned about its apparent lack of penetration. I may have to get something else to kill sparrows with — but that’s just an excuse for another air rifle, right?

–WFH

WFH,

I have almost 2000 pellets through my 490 and it keeps getting better. My barrel was extremely clean on arrival, however. Mine likes Meisterkugeln 8.2(?) best, but it will shoot almost anything believably; RWS Basics work well. The trigger can be a little heavy, but I found a little moly makes it lighter and still crisp. Your unit may differ.

I don’t think it will ever penetrate 2×4’s:). Mine usually goes through one side of a steel can.

For some reason it does require chamber lubrication more often than you would think, but since a drop of silicone always brings it back to life, I haven’t bothered to open it up and see what the issue is.

Anyway, I hope you enjoy yours as much as I have mine.

Oops…make that almost 2500 pellets. You know these clunks just don’t hold up:).

Wayne,

My photobucket account works fine. If the problems persist, why not just create another account. I’m sure it’s nothing personal. 🙂

That new scope sounds like a real beast. Since you’re building such a huge collection, have you thought of getting a real high-end rifle like the Air Arms EV2 field target rifle or a Feinwerkbau target rifle–the sort of things that visitors to the range would probably never otherwise see in their lives? I bet even the S410 would be outclassed.

Matt61

B.B.,

Sorry, but I can’t resist asking another off the wall question. Would it be possible to use two springs joined in middle so that one spring has a left hand twist and the second a right hand twist? It seems you’d probably need a bushing of some sort in center to join them.

In the olden days there was a spring balance that used a Jolly spring that had such a twist. It was to keep the spring from twisting as it stretched. (the spring was also conical in shape so that it lengthened in direct proportion to added mass. Conical shape was needed since spring itself had mass.)

Anyway it just seems that two “opposite” springs would “tune” better on a springer.

Herb

Wayne,

The Blue Book is just a guide. In many places the pricing is unrealistic and you have to adjust based on the market. That’s a big reason I go to airgun shows.

B.B.

Walther Falcon Hunter guy,

Plugs in the barrel to avoid bluing solution is what a custom barrel-maker does. Not even Lothar Walther does that with production barrels. They ALL get blued inside and out. What the better makers do afterward is what makes the difference.

At AirForce, I was in charge of cleaning thousands of Lothar Walther barrels after bluing. I used an industrial rust preventive compound, and STILL some people found rust in their barrels of their new guns. That’s why I advise the cleaning of every new airgun barrel with JB paste.

I think your 490 is a little weak for hunting. I’d like you to finds something with at least 650 f.p.s. velocity for that.

B.B.

Herb,

The two-spring counter-wind approach has been done. Notably, the FWB 65 Mark I has one spring inside of the other.

B.B.

B.B.

So your saying that I’m not done bugging you with questions yet….

Or, I should go the the air gun shows with you…

That sounds fun, and expensive…and fun…. and expensive…and fun..

HHHMMMM I’ll think about that too..

It may seem like I have a lot of free time, and I do, but that’s as long as I’m pretty close to the office, which is also my indoor practice range. But a long journey to a show would be too much time away at this point in the business.. So I’ll continue to bug you with questions, just not quite as many as before, now that I have the Blue Book of Airguns…

Matt61,

Well I’m surprised you haven’t noticed I’ve got the USFT that Billy Lo won in the 2005 national field target contest, on the way..

If that is not a special one to come see, and shoot, then I don’t know what is.. Billy said it also went to the world championship with Paul Cray, when Billy couldn’t go, he won 12th place, because it was so windy, and it’s a 12 foot lb gun, which it has to be to compete there, and we use 20 ft lb guns over here, and were not use to the 12 ft lb in the wind like the guys over there that shoot the 12 foot lb guns all the time, because that’s all they’re allowed.. It’s going to be tough to get that world cup back for the USA. But my new gun is tuned and as ready as any in the US.

I already told Billy that he and his friends can borrow it any time they want to go for it again. Just leave me a 20 ft lb USFT to play with.

B.B. did a blog on the USFT in 2005 I think.. or check out Mac1 airguns and read a little of Tim’s story.

Wayne,

Ashland Air Rifle Range

Wayne,

Please leave the internet address or phone # for the AARR or for it’s owner.

Thank you.

– Dr. G.

dr.g.

I'm the major owner of the Ashland Air Rifle Range and Rentals. It's an LLC.

wayne.burns@naturlayards.com

or 541-552-1441 but I'll be out most of the rest of today.

Wayne

AARR&R

I came to that conclusion too, B.B. While my WFH is definitely up to the task, the fact that I would be shooting with my muzzle elevated at least part of the time leads me to believe that at least some of my pellets would fall on the seven or eight houses within a quarter mile of mine. That was one of the reasons I got the 490 — limited velocity with wadcutters should keep the pellets fairly close to where I let them go.

Ah well. At least I now have one air rifle I can shoot in the basement without sending the cats fleeing in terror and another I can use to kill chicken killers and garden raiders. The search for a sparrow rifle continues . . . .

–WFH

B.B.

Back after the lake, but off to moms' for Sunday dinner soon..

You were right again.. I need you again..

Here is one that I couldn't find in the Blue Book of Airguns… A Beeman 1783 Silver Bear .177

http://www.gunbroker.com/Auction/ViewItem.asp?Item=112145064

Wayne,

AARR&R

Wayne,

This is a cheap Marksman gun with the Beeman name.

As the Marksman 1790, it’s worth $30-40.

B.B.

Hey BB,

Do you know if crosman will ever bring back the 357 kit? do you know where i could get one?

crittercontroller

More pellet gun stuff:

I have been incorrectly calling my new .22 gun a Sheridan when it is in fact a Benjamin 392. My confusion has been because both it and the Sheridan are basically the same gun, but in different calibers. I prefer the .20 caliber primarily because it shoots the unique “cylindro-conodial” 14.3gr pellet. Originally it was a 16gr pellet.

A friend of mine loaned me a book, “Complete Book of the Air Gun” by George C. Nonte, Jr, published in 1970. I have had a chance to scan it and it has some interesting information and pictures.

Two of the pictures show the Sheridan 5mm with the Williams peep sight on it, and in a section called “Today’s Airguns” it says the Blue Streak or Silver Streak are available “with Williams receiver sight or scope and mount. About $39 to $59.” [!!!] There is also a drawing of a Sheridan that has been fitted with a stock and forearm “of standard Winchester dimensions.” It has a scope rail and scope mounted on it and the front sight is missing. I don’t know how they removed it; my gun’s sight appears to be brazed on.

There are also drawings for making a “Ball Seater” for inserting pellets “to the proper depth.” It makes the pellets engage the rifling rather than having the nose of the bolt do it.

One gun discussed is the Daisy/Heddon V-L System, Model 002. This gun used caseless ammunition, a pellet with a chemical propellant extruded on the rear. It was .224” diameter. The propellant was ignited by the compressed air, which reached approximately 2,000 degrees. Daisy claimed a 1150 fps muzzle velocity with a 30.3 grain projectile. The article says the gun went into “volume production in 1969.” B.B., have you ever heard of or seen one of these? BTW, a favorite of yours, the Daisy Model 25 notes, “Open sights; plastic stock; gold-filled engraving; 50-shot tubular magazine. About $17.”

Fantastic stuff!

–Witt

B.B.

Thanks for that info on the marksman…

OHHHH…. I ate too much… I better shoot a few hundred rounds with the s410 in the lazyboy to work them off…

Just kidding, maybe after a walk..

Wayne

Critter Controller,

Crosman doesn’t tell me their business plans. If you want a kit, start watching the classified ads. Find them here:

http://www.airguninfo.com

B.B.

Witt,

I have owned a Daisy VL. Nice idea, but no longer supported. I would stick with .22 rimfire.

B.B.

thanks tom

I have been shooting and repairing air rifles for a long time and achieving more velocity on springers isn’t hard if any one is interested in finding out how to really increase your piston air rifles power without using oils or light pellets contact me at illlaw7@yahoo.com

my will not work it wont shot in its a rs7

Anonymous "my will not work it wont shot in its a rs7",

What are you saying?

You have a Beeman R7 and it won't shoot?

kevin