by B.B. Pelletier

Today we’ll look at my .177 Diana model 27 rifle after the piston seal and breech seal have been soaked in oil. I told you I put petroleum oil down the air transfer port because my gun is a low-powered springer with leather seals. Leather seals need lots of oil to keep them fresh and pliable, and a low-powered springer doesn’t generate enough compression to detonate the oil. So, petroleum-based oil is fine for guns on this category.

The way to know for certain that you’ve oiled the piston seal enough is to move the barrel through the first few inches of cocking and then relax it. Do that several times and listen carefully to the air transfer port. When you can hear a slurping sound coming from the port, the piston seal is soaked with enough oil to rejuvenate it.

My .22-caliber model 27 that I tuned about 10 years ago with lithium grease on the mainspring still slurps when I test it, despite never having been re-oiled all that time. The excess lithium grease has soaked the seal from the back, making that tune a very long lasting one. However, I did use so much grease on the spring that I gave up some power with that rifle. I think when I tune this one I’ll use black tar grease on the mainspring and oil the piston seal conventionally.

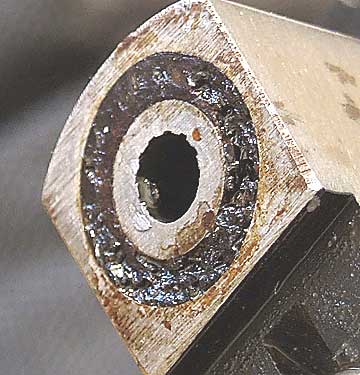

When I oiled the leather breech seal on this 27, it started to disintegrate. I took a closeup photo to show you what that looks like. This seal doesn’t look too good to me, but looks can be deceiving. The chronograph test should tell us for certain if the seal still works. I cannot feel a blast of air coming from the breech joint when the rifle fires, which is one test for an air leak. But a chronograph test should be conclusive.

You can see the disintegration of the breech seal in this photo. Bits of leather are sloughing off, leaving pits where there should be a raised surface. An oil spray can be seen rising from the breech with every shot. Even though I can’t feel anything, that oil spray confirms the fact that the breech seal is shot.

I also felt the barrel on this rifle deserved to be cleaned with J-B Non-Embedding Bore Cleaning Compound. Even though the velocity is not high enough for leading to be a problem with any pellet, we don’t know the history of this rifle. If there’s anything in the bore that could hurt velocity or accuracy (probably accuracy more than velocity), I want to clear it out. We’ll start with a fresh new bore.

The bore seemed easy to clean, and there’s a definite choke at the muzzle end. The breech was very dirty. After cleaning, all pellets loaded easier than they did during the first test. Now, let’s see how the velocity is affected after oiling both the piston seal and the breech seal.

Eley Wasps

Before oiling Wasps averaged 444 f.p.s. After oiling and some sloughing of the breech seal, the average is 225 f.p.s. The breech seal is visibly leaking.

RWS Basic

RWS Basic pellets had averaged around 475 f.p;.s. before (they were very bi-modal, so I recorded two averages) and 212 f.p.s. after. The breech seal has failed.

Crosman Premier 7.9-grain pellets averaged 580 before and 321 after. In fact, only RWS Superdomes held anywhere close to their former average of 412 f.p.s., coming in close at 393 f.p.s.

Well, that wasn’t a very big surprise, given the shape of the breech seal. The big question now is what does the piston seal look like. In my experience, leather breech seals fail sooner than piston seals, but we’ll have to tear the rifle apart to know for sure.

The firing behavior has become rougher, which is the piston slamming into the end of the compression chamber because the air is leaking so badly at the breech. I hope I can save the piston seal, but a new breech seal is mandatory.

I adjusted the trigger, which is the rear screw only. The front screw is just a locking screw, and the rear screw controls how crisp and light the trigger pull is. I screwed it down pretty far, which made the second-stage pull very crisp. The drawback is a longer first-stage pull, but there’s no way around it if you want a crisp second stage.

This photo is worth a lot to vintage Diana owners. The rear screw (at right) is down nearly all the way, and the front screw is tight. This gives a model 27 a crisp two-stage pull.

The next report will be either a disassembly of the powerplant or the repair of the breech seal, whichever comes first.

BB, might I suggest doing the breech seal first? That way you’ll be better able to quantify the improvement derived from fixing that one problem. If you dive into the powerplant and do the breech seal at the same time you’ll not be sure how much improvement came from fixing the seal and how much might have come from anything you did to the internals.

And you might find that the breech seal fix is all it needs.

As I mentioned earlier, if the seal grove is the same as my ’25 of comparable vintage (and from scaling the photo you posted it looks like it is) a standard RWS Diana breakbarrel seal or a Buna-N #109 O-ring should work just fine. I got a zillion of them if you need any, but they should be available locally.

B.B.

Is the picture of the breech face deceptive, or is there nearly no wear…indicating very little use?

twotalon

hi BB

Is the .25 Theoben Eliminator more accurate than the .25 Webley Patriot ?

thanks

B.B.,

Is there something wrong with the pellet chamber on the gun?

It looks like I can see lands and groves in the barrel in the upper portion, but nothing on the lower right. It looks like the pellet chamber is cut off center…or is this an optical delusion?

Herb

Vince,

Yes to the breech seal first. After I wrote that I figured it out.

B.B.

Twenty-five cal.,

I think an Eliminator MIGHT be a little more accurate than a British-made Patriot, but there are a lot of Patriot owners who would argue that.

Twenty-five caliber airgun are the least accurate in any model. The Whiscombe proves that, because the same rifle can be barreled in the other three. .177 and .22 are the best — followed closely by .20 Twenty-five is always at the bottom of the pile.

B.B.

Herb,

That’s just the camera angle.

B.B.

Good Morning B.B.,

It looks like Vince will be busy for awhile longer… I just bought a Hy-score 809 (Diana 35).. The trigger looks just like the 27 in your photo.. The seller says it shoots .22 cal 14.3 at 520fps, so maybe it's ok.. so I'll start out here with it Vince.. But if it's not up to snuff, you'll be getting it soon..

I solved my practice problem.. I showed the S&W 586 CO2 revolver to Randy… He shot it all afternoon, allowing me my USFT practice time.

B.B. your pistol training system, is perfect. Randy was shaky at first, but I started him at 15 feet.. also a good time to use shots after 50.. you get another 25 low power shots, that are fine up close, for learning. He's totally in love with that pistol. After about 5 Co2 cartridges he was grouping 10 shots in 2" from 25 feet, with many in the 1/2" center of the 3" dot…

That is a high quality pistol!! Built very well..

Well if the weather permits me getting over the pass, I might make it down to compete in the Field Target contest at Prado Olympic park in Chino CA. on Sunday… My first contest.. I'm sure I won't do well, but one has to start somewhere… better get stuff together.. if I'm lucky, I'll be gone a few days..

Wayne,

Ashland Air Rifle Range

Wayne,

That Diana 35 sounds about right.

Don't forget to shoot that new S&W yourself. It's a wonderful air pistol.

Good luck in your first FT match.

B.B.

I onder if the slight additional volume from Vince’s suggested use of an O-ring might impair performance. I would go with a square-section seal like the original, even if I had to carve it. Just a guess, and I am sure BB has already tried it both ways and measured the results.

BB,

With the breech seal looking that way, I would assume everything else is SNAFU also. My concern with shooting it too much in that condition — even if the breech seal only restores normal operation — is that if the piston seal disintegrates like the breech seal has done, the cylinder could be scored badly. Small chance, but risk outweighs reward, in my opinion.

Are you going to use a leather or synthetic seal to update it?

BG-Farmer,

My experience with leather breech seals is they fail much sooner than leather piston seals. I think that is because they are cut to expose the grain.

I will attempt the seal first. I haven’t looked at seal possibilities yet, but leather is on my mind. I have plenty of thick belt leather to replace it.

B.B.

BB,

Just wanted to let you know that I got a Maccari spring for my HW50S (for xmas) and my father and I installed it today following your instructions on the blog. Everything seemed to go fine. Thank the lord you have all that info up. The HW seems to have really come to life now. Man, that old spring was crooked. Thank for all the info:-)

Al in CT

BB,

Please do try the leather seal first. If nothing else, it’s “period correct” for the gun.

Of course, it would be more interesting if you did an o-ring seal first then a leather for velocity comparison, but I think there would be virtually zero difference between the two as it’s just a static seal.

tedne

Al,

You make me proud. I hope your new spring keeps your rifle running for many years.

B.B.

Derrick,

I will look at doing a leather seal first, as it is period. The only thing that would sway me is if I found an exact fit with a synthetic seal I had on hand. I have a few.

But I’d like to keep the rifle period, if possible.

B.B.

BB,I can’t wait to hear about precision cutting a small leather seal from thick belt stock.will you sharpen some tubing?,or maybe dremel diamond holesaw?It sounds like a good excuse for a trip to harbor freight….lol..FrankB

Frank,

Keep guessing. After I hear something plausible, I’ll claim it as my own idea. I had planned to use a simple X-Acto knife, but you give me ideas.

B.B.

Evening B.B., something plausible…JC Whitney Catalog had a punch thing, notice my technical tool vocabulary, for cutting different size holes in light gauage metal might do the same in a leather belt. Sorta like making a shim for the breach seal.

Mr B…do you mean a whitney hand punch?

Mr. B.,

Thanks for the lead.

B.B.

BB,

Yeah, this is a job for a hollow punch set. They’re dirt cheap ( $5 whole dollars) and do a much better job than you could ever do freehand with a knife. You can make a half dozen in 2 minutes and they’re perfect.

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=3838

Derrick

BB, do you or anyone else know if the globe front sight for the RWS rifles 34, 45 ect. (in my case the mod 34) with the interchangable inserts is the same ht., or slightly higher, than the standard stock globe sight? Thanks in advance Robert.

Good Morning B.B. & All,

Well, I got stuck fixing a plumbing problem, and moving a bed yesterday, then it started snowing… so I didn't make it over the pass to LA for the Field Target Contest.. The Prado was canceled anyway, it turned into just a club shoot. Tim, said come on down.. but it wasn't worth putting chains on, and, 12 extra hours of driving slow..

But.. once again, Tom, thanks for a tip, I used the high tech "leather belt with a pipe wrench" on the finished shower head pipe. Worked great for not scratching.

So, maybe Randy will let me shoot the S&W 586 revolver today.. He is really hooked on that one.. He said he won't stop until he can get 1" groups at 20 feet.. He's got half the 50 shots there now.. the rest are in 2" and a little in 3"..

I've got an old crossman mark I on the way too.. I don't know if it works, Vince..

Well, I've got to get a load of firewood in and get the fire stoked up.

Wayne,

Ashland Air Rifle Range

Derrick,

Thanks for that lead.

I will visit their website.

B.B.

Robert,

I believe the globe sight that accepts inserts is slightly higher than the standard Diana globe sight.

B.B,.

BB,

The Mendoza peep sight I got for Christmas is a mixed bag, at least for me. It is mechanically sound and cosmetically acceptable, and it fits the rail of my QB36-2 nicely. The peep is much lighter and lower in profile than a scope, so it looks pretty good aesthetically, also.

I noticed I wasn’t using that rifle much since I put the scope on to test the tune, and the factory rear sight is of dubious construction given my heavy use. Also, that rifle has a front sight that accepts inserts.

One problem in mounting was that the hex bolts securing the sight to the rail are a somewhat odd size, some PA reviews say 9/64″; I haven’t verified that but none of my fairly complete collection of english or metric hex keys fit it. I found an odd driver head laying around that worked well enough to get it mounted, though.

Once mounted, the height of the sight made it impossible to sight in at 10M, despite a generous range of elevation adjustment. The rifle has a fairly elevated front sight globe and a low rail machined into the tube, also, so I was surprised by this. It’s about 1/2″ high at 30M with the sight at its lowest setting. The rifle’s barrel droop confuses the issue, although it seems to be in line with what Leapers expects to correct with the RWS scope mounts.

Anyway, its too bad that I can’t think of any way to fix this, because the sight itself is nice for a sporting aperture with nice precise clicks and little slop.

The aperture itself is big but that is fine for a sporter and makes target acquisition easier; a smaller aperture could be made easily, as well. In conjunction with the post and bead front sight insert, the sight picture does make bullseye targets easier to handle than using a six-o’clock hold with open sights.

I did, however, remember why I prefer open sights when trying to adjust elevation and windage for different ranges and conditions. This is probably not an issue for the new generation of “click-setting” shooters, but for those of us accustomed to make windage and elevation adjustments with the sight picture, a peep feels crippling, although I’ll admit it is perfect for bullseye shooting at fixed ranges.

In conclusion, I don’t know what to do with the sight at this point. I may go through the hassle of returning it or may keep it figuring it will work on something at some point. I might also get it to sight in a a reasonable range by using heavy pellets. Suggestions welcome.

BG_Farmer,

You can either raise the front sight or lower the rear. Since you mention the rear won’t lower any more, then raising the front seems to be the solution.

Did you see my report on the AirForce front sight, and will that possibly work for this gun?

/blog/2008/11/the-airforce-match-sight-set-part-2/

B.B.

hey B.B.

its Jason again , with all my questions , so i do not own a chrono etc. and i am wondering if you could give me a general idea of how many fps. and ft. lbs. etc. that my rws 850 is putting out in the general terms of 14.9 gr. up to .25 eun jin pellets . yes i know you would have to do a whole report to give me real precise answers , but that is not what i am asking for , i am only looking for general terms , so being off by 100 fps or so is not tht big of a deal . i am more trying to figure out what to compare my feelings of the gun to and how much more power i need to be looking for to be happy etc. , as i find that depending on what web site i go to , the estimated fps. on the rifles is not always the same , so i was wondering what is the general true fps and power range of these RWS 850’s in .22 cal … thanks again in advance for all my questions that you answer…

BB,

Thanks for the suggestion, but as far as I can tell, the front sight assembly and lever clip is one piece of metal, so raising the front sight or replacing it isn’t an easy proposition. Its no big deal, just wanted to run the situation past you to make sure I wasn’t missing something.

BB,

I had a thought on why my 1911 was jamming up so often. Could it be the recoil spring is too light for my +p and P+ loads? What does +p, p+, and +p+ even mean? The only bullets I can find in .38super are +p and p+ loads. What is a fully supported chamber?

Shadow express dude

BB,

I just broke a small spring in the trigger unit of my Storm XT. It’s the flexible piece of wire that rests on the adjustment screw. my trigger now goes off under a few ounces. I just might keep it broken:)It now has no first stage.

Shadow express dude

SED,

Yes, the soft spring could very well be the problem as it will allow the gun to cycle faster than it should by not providing enough resistance.

A fully supported chamber means just that. The cartridge case (except the case rim) is completely enveloped inside the chamber. The steel of the barrel thereby supports the soft brass case during firing.

Some chambers (Glock being the most well-known) have a groove or relief spot near the rim where the brass case must hold the pressure w/o being backed up by the steel. Fired cases from Glocks (.40’s especially ) often exhibit a bulge at the base just above the rim. A fully supported chamber would not(could not) display that kind of pressure mark on the fired case.

+P, +P+ etc. are all higher powered or “hotter” loads and are designed for high performance, self-defensive ammunition. They are NOT suitable for NON +P rated guns. Typically this means older handguns as these hot loads didn’t exist when the older guns were designed.

+P and +P+ loads are generally recognized to shorten the life of guns and their components.

+P+ is a higher power load than a +P. Firing even +P loads in a non-fully supported chamber is a potential disaster. Firing +P+ in a non-fully supported chamber is almost certainly going to result in a ruptured case and injury to the gun and the shooter and possibly people standing nearby.

Why do we have +P and +P+? They were developed to give better terminal ballistics from short-barreled revolvers–“Snub-nosed”. The shorter barrel gives up hundreds of fps compared to a longer–but harder to carry–version. The +P and +P+ allow for better penetration and expansion at the expense of more recoil and “Boom!”

SED,

The Storm XT may fire unexpectedly without that spring pressure holding the first stage of the sear.

Thanks derrick, I just found my SW .40 sigma to have a fully supported chamber, still unsure about the 1911 in .38 super. The way I see it, it should handle the loads because it was built on a .45acp platform. I read an article about the RIA .38, he had the same jamming problems. He sent it to the factory and the did something (he didn’t specify) to the barrel and magazine. Worked flawlessly afterwords.

BB,

I just went hunting with my Remington 77 thumbhole. I got a 4lbs squirrel at 52yards (range finding scope) on 6pumps with premier heavies. He crawled a foot then went down.

Shadow express dude

SED,

Good hunting! Sorry to tell you this, but you can't assume that the 1911 is safe just because it's a 1911 frame.

A +P .38 Super can have as much as 36,500 psi of pressure. It's actually rated higher than a .44 magnum by 500 psi. You need to find out if that barrel is fully supported or not. A STANDARD 1911 type pistol barrel is NOT fully supported. Of course a standard .45 auto round (only) develops a max of 21,000 psi. (.45 +P will push about 23,000 psi)

That's 15,500 psi of difference between a .38 Sup.+P+ and .45 ACP. I'm not trying to scare you. OK, yes, I am–because I want you to be OK!

If you want to continue to shoot +P+, and cannot determine if the gun is +P+ rated please take it to a competent gunsmith.

And–IF it's rated +P, it is NOT necessarily safe for +P+.

Shooting games: IPSC uses a major and minor power classification. It's a combination of bullet weight and velocity. The .45 makes "major" classification because the 230 grain bullet is so heavy even though it only goes 850 fps. A 158 grain 9mm won't quite make the power factor at even at 1100 fps and so has to be driven to much faster speeds to qualify. Think foot pounds here and it makes sense.

http://findarticles.com/p/articles/mi_m0BTT/is_154_25/ai_78870840

Anyway, when IPSC was in it's early years, a lot of interest occurred in making a smaller diameter round go (.38 and 9mm) fast enough to make "Major" classification. And many shooters found out just what happens when you shoot a +P .38 Super through a partially supported barrel. Damaged guns and occasionally shooters were a not so uncommon occurrence.

Google ".38 Super +P+ power" and you'll find guys worried about cracking the forcing cones and stretching the frames of older S&W revolvers

So I'm just saying…

Derrick

SED, the trigger in the Quest (and Gamo and QB57 and QB25 and QB88 and all variants) has two springs. The important one works on the intermediate lever and is not all that obvious.

The more visible one – the one that rests near the adjustment screw – is a trigger return spring only. It does not work on the sear or the intermediate lever at all. In fact, if you upgrade one of these triggers with the Rich in Mich insert or the GRT you would be instructed to leave the spring out.

Generally I yank ’em out even if I don’t upgrade the trigger mechanism. It shouldn’t be a problem unless the trigger blade itself doesn’t move freely through the range of its travel. If it is not binding or sticking it should be fine, and as you found it does lighten the trigger pull quite a bit. Although if you put a pull gage on it I think you’d find that it isn’t really releasing with just a few ounces. In reality, it’s probably a bit heavier than that.

That trigger never really had a functional ‘first stage’ like the AR1000’s or the B20/B26. What they call a first stage is nothing more than some spring-loaded slop built into the mechanism.

Jason,

The RWS 850 Air Magnum is a 12-foot-pounds airgun. So you can figure out the velocity without my help. Just use the velocity calculator on this website and plug in the weight of the pellets you are interested in.

/article/What_is_Muzzle_Energy_August_2003/5

Figure the energy will ALWAYS be LESS than 12 foot-pounds, and sometimes MUCH less.

So a 21-grain Beeman Kodiak will produce about 475-500 f.p.s. in that rifle That’s all there is to it.

B.B.

SED,

Several readers have already responded regarding the +P+ ammo and supported chambers. I will just add this. While your feeding problem COULD be a spring, I’m inclined to suspect the extractor, which is a major culprit in feeding problems. Magazines are also suspect until you know better.

B.B.

SEWD,

Listen to Derrick on the safety of your handgun. The 1911 is not inherently an overly- strong pistol. It simply shoots a cartridge – the .45 ACP – that operates at very low breech pressure. The cartridge give great performance on humans, but it doesn’t generate as much pressure as many weaker rounds such as the 9mm Luger.

As for your shot with the AirMaster 77, that was pretty lucky. The gun only generates minimum energy at that range. It’s more of a 25-yards gun.

B.B.

All,

A bit off topic… which seems to be the norm for our weekend blogs Q&A.

Santa got me a new plastic stock for my 12GA 870 shotgun. It is a great upgrade if comfort is more important than looks. It is a Knoxx SpecOps with LOP adjustment and (best of all) recoil reduction.

It really reduces recoil. Makes the 12GA shooting slugs feel like a 20GA. Looks are not that good but it functions well. Hope it holds up over time.

DB

Random, but I’m a newbie looking to buy my first pistol. After a lot of research I’m between the Walther CP Sport and the Crosman 1088 and their accuracy seem pretty comparable for target shooting and plinking. Any advice? Thanks.

Random,

The CP99 Sport is for pellets only, while the 1088 also shoots BBs. That may mean the CP99 Sport is a trifle more accurate.

The CP99 Sport will feel more realistic. But both guns shoot well.

It’s a hard decision.

B.B.

DB,

You aren’t kidding about ugly, huh:)? I’m sure there’s a lot of people who prefer its looks to the factory wood, though.

Glad it works for you.

BB,

That shot was amazing. Still thinking about it today. It was a perfect chest shot on a mid sized squirrel. That’s about the longest shot to date for me (I’ve had some great 100+ yard shots, but thats at the range). On just 6 pumps (I only ever pump to 7), it goes 530fps with premier magnums.

Shadow express dude

Shadow express dude, Thanks for sharing your shot on the squirrel with us. It got me thinking about my unbelievable shots. Lots of smiles flitting through my brain including two grays and two red squirrels.

Please listen to what the others have said about +P+, etc. Bad things can and do happen with it when used improperly. A question for you please: isn’t a 38 Super pretty much a 357 Magnum for a semi auto? Thanks.

I like the way the weekend topics bounce all over the place. We never know what’s coming next.

Mr. Gaylord

I own four Diana 27s.

They will diesel if lubricated with petroleum oil.

Petroleum oils oxidize over time; by dieseling or exposure to oxygen, bacteria, heat and time.

The oxidation produces acids.

My daughter’s engineering thesis topic was “Biodegradation of diesel fuel and petroleum based lubricants”.

When your petroleum lubricant oxidizes it will produce acids which will pit cylinder walls and decompose the leather piston seal.

You appear to know air guns.

Perhaps you should do some research on lubricants.

Ross,

What you say may be true, but I have never encountered a rusted compression chamber in a gun oiled with petroleum oil.

All these oils burn off as you shoot the gun. They diesel. That’s not a powerful explosion. We call that a detonation. But these guns are supposed to diesel with every shot.

B.B.

B.B.

Since your still up..

I’ve been testing the Crosman premium heavy 10.5 vs the 10.2 heavy JSB and 8.4 JSB at 45 yards back to 25 yards today in the wind… to see which one drops the least between that distance.. and preforms best in the wind…

At 12 ft lbs with the USFT or the AAS410, it looks like the 8.4 JSB is a very close second to the 10.2 JSB Heavy, which does better if there is a wind.

But with the AAs410 on full power, at 55 yards, the CPH preforms best by a good percentage.. and is a tie at 55 yards with the 10.2 JSB heavy in the 12 ft lb USFT… The CPH have the rep of getting the barrels dirty???? As much as I hate to shoot the dirty CPH (they really get my fingers black quick.. I have to wear gloves).. but their knocking down the targets better at 50 yards.. especially in the wind..

If I shoot them say 25% of the time, will I still need to worry about cleaning?

Wayne,

Ashland Air Rifle Range

oopps!

I meant: “but “They’re” not “their” … knocking down the targets better”….

Wayne

Wayne,

Hope you had a Merry Christmas!

Glad to see you haven’t abandoned the AAS410 completely for the USFT. “You” haven’t taken my money yet?!! Thought you were lubing your crossman premiers with whiscombe honey?

Volvo,

Very perceptive of you. Wayne and I have to wear the “Same outfits”. Did I lose a bet?

kevin

Ditto on the oils, BB. I’ve got a Slavia 619 that my Dad bought (I believe) in the 50’s. It spent quite a bit of time alternating between being shot and sitting for several decades. Its been lubed on and off through the years with nothing but ordinary motor oil, with no visible ill effects on its innards.

Isn’t oxidation primarily driven by getting hot? I suspect that the bulk of the lubricant in a springer never sees much more than ambient temperatures. Even the lubricant clinging to the cylinder walls ahead of the piston – and thus exposed to high pressures – I believe will be kept cool by the tube wall. I think that the only oil that gets hot is that tiny bit that gets atomized, and much of that gets expelled with the pellet anyway. I can’t imagine enough oxidized oil being in contact with sufficient surface area (seal and cylinder) for a long enough time to do real damage.

Wayne,

Was shooting CP pellets myself today. Thumb and finger were dark grey.

Not sure what the last rule number was… but maybe we could say something like.

You know your and airgun addict if your thumb and finger have a permanent lead stain.

BG_Farmer,

Yep function over form. It is getting more and more difficult to deal with the recoil of a 12GA especially slugs.

DB

Wayne and everyone,

Crosman Premiers make your fingers dirty with the graphite anti-oxidant they are coated with. They are not dirty pellets.

The reason they make the bore dirty is they rub off lead because of the antimony in their alloy. That lead then rubs off more and more lead from successive pellets. The result is a leaded bore.

Velocity is what makes them rub off the lead. At lower speeds they don’t rub off lead very fast.

Clean the bore whenever the accuracy drops off. It’s the only way to tell.

B.B.

Eveyone,

RossB wasn’t saying that petroleum oils cause rust, he was saying the as it degrades it makes an acid. The acid can pit the metal without rust.

.22 multi-shot

B.B.

I was wondering if shooting the JSB would “clean” the barrel after shooting the CPH.. if I shot 300 JSB after shooting 100 CPH..

Wacky Wayne idea..

Wayne,

I think that’s a great idea to try out.

B.B.

ross b…perhaps you should research manners.

Your’re post seems a little ‘terse’, directed at someone who has helped so many.

B.B.

Well then, we will see how it comes out over time. The only time I want to shoot the CPH is when it’s long distance, 40 to 60 yards, and windy.. otherwise the JSB heavy are as good, or better… they are better for sure at 12 ft lbs.. and under 25 yards, the JSB 8.4 are best.. so, that’s my normal shooting… so we shall see, if I ever have to clean my barrels on the USFT or AAs410 .177.

I don’t know what pellets Billy LO was shooting in the USFT before I got it, but she is perfect now with either pellet. I’ve been practicing with the JSB 8.4 indoors mostly, so the cleaning process, if it happens, has been going on..

Wayne,

Ashland Air Rifle Range