by B.B. Pelletier

It’s too cold to shoot CO2 outdoors, so the accuracy test of the Crosman 1088 is postponed until we get some warmer days. So, I thought I’d clean up a couple of jobs that I’m working on and show them to you as I go. First, I removed the leather breech seal from the Diana 27 rifle.

Derrick found an inexpensive set of leather punches for me at Harbor Freight, so I ordered them to use in the Diana 27 breech seal project instead of just carving the seal from a leather belt with a sharp knife. There are nine graduated punches in the set for less than $5, so even with shipping I figured it was well worth the investment. I’ll probably have to trim the seal to final size, but the punches will get me most of the way there.

Today I decided to remove the old seal for you, so you can see what the job looks like. Several months ago, I bought a set of dental picks to use on the Walther Falcon Hunter breech seal I replaced during that test series, and they worked well for this seal, as well.

These picks were inexpensive, and they make handling breech seals easy. On this job, I had to break the seal into pieces and scrape it out of the channel.

Old seal was brittle

The old seal came out in chunks instead of a whole seal. That happens only

when the leather has lost all its sealing properties and has transformed into a waxy mass of dark stuff. It should have hung together, but the leather was shot. That happens when there’s no lubrication for a long time–maybe decades.

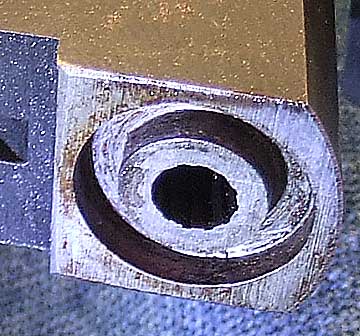

When the old leather seal is completely removed from the Diana 27 breech, you can see the groove the new seal must fit. This photo is like an Escher print until you decode it in your mind. We’re looking at a breech that’s pointing up–away from us. The groove for the seal is wide and flat and there is a stub of the barrel in the middle. Notice that this shot shows more of the rifling, though a couple lands and grooves at 9 o’clock are invisible.

Weihrauch breech seal possible

Just for fun, I pressed a Weihrauch synthetic breech seal into the groove and it fit. It’s about double the height it has to be for this gun, so I would have to divide it in half before installing, but I think it would work. But I want to try to fit a new leather seal to keep the rifle looking vintage.

I cleaned out the breech seal groove with the picks, so the groove is fresh for a new seal. A toothbrush was used to remove the smaller pieces of disintegrated leather.

That project is now on hold until the punches arrive, so I shifted over to the Career Infinity project. You’ll remember that I replaced the inlet seal on my test gun, but then that seal started leaking, too. Boris made a Teflon seal to replace the brass seal holder in the gun.

Boris made the Teflon inlet seal on the left to replace the three-part inlet seal assembly that came with the rifle. Less mass may keep the seal from deforming too much.

The new seal is lighter and moves very smoothly inside the valve body. Being Teflon, it’ll deform and take the exact shape of the valve seat. Hopefully, that’ll fix the problem of the inlet valve dumping all the air after a fill.

When I filled the gun it held perfectly, but it also did that after the last seal replacement. The proof of the fix will be if the seal continues to hold after repeated fills, which I will be doing as we move into the velocity part of the test. Boris thought that the Teflon seal would be so light that it wouldn’t get pushed out of shape like the brass carrier did to the factory seal. We shall see!

From what I can tell in the picture, the groove looks to have about the same depth as the Model 25 I worked on, so I suspect that the RWS 34/350 seal or the regular #109 O-ring would work as well.

A side note – just got finished working on a couple of older BSA Meteors, and they certainly are a bit different. The PISTON seal is an ordinary O-ring, and is carried on a separate piece that fits to the front of the piston. There’s a synthetic spacer between the O-ring carrier and the piston that disintegrates with time (as does the breech seal). The trigger is almost identical to the Chinese built TS45/B4-1/TF41 or B3 models, but the parts are made better. Overall it’s a mixed bag with some neat features and some disappointing shortcuts.

I’ve seen parts diagrams of the newer Meteor’s, and it looks like many of the mechanicals have been replaced with Gamo-type stuff (trigger, piston seal, spring retainer, cocking link, etc.). I guess this helps with standardization, but it sorta does take away from the personality…

Hey Vince, not sure if you will see this or not being an old blag comment. I believe that I need to replace the piston seal on my Diana 25. Dating is difficult on these but most likely a 60’s or 70’s gun. Are you saying that the 28mm seal for the Diana 34/350 will fit? If not, can you point me in the right direction to source a proper seal? Thanks,

Bob

Bob,

https://twchambers.co.uk/airgun-spares/

BB

Thanks BB!!

I don’t have a repair/cleaning kit for the Chinese B2-2 on hand but they do have leather breech and leather piston seals in the kit, would have to measure to see if they would fit, cost is around $10, just another source for parts on the older rifles….

Mike,

That’s a good suggestion.

B.B.

Good morning B.B., I have to agree with Vince on sorta like loosing personality with standardization of stuff. Can be a good thing though if the bean counters are kept under control.

Getting ready to head to NC for the week to be with number one son, his wonderful wife and my two beautiful grandchildren. He’s got access to 40 acres for us to go shooting on. Number two son is looking fwd to exercising his Glock. I’m going to enjoy the Talon SS with it’s 24″ barrel and shroud 😀 while number one wants to try the M1 carbine.

HAPPY NEW YEAR to one and all. Be careful and lookout for the rookie drinker/drivers if you’re out and about.

A bit off topic BB, but do you or anyone here know how long a BB gun barrel will last?

I have a Daisy 499 on back order and have read on some forums that anything but the use of the Avanti shot for it can ruin the barrel. I guess they say that the lower quality steel shot has less tolerance and tends to bounce down the barrel somewhat. Over time it’s supposed to ding up the barrel and cause accuracy to fall off. I only plan on using the Avanti shot in it, but was curious if even that would have an effect on the barrel over time since steel on steel is a lot harsher than lead on steel.

Al in CT

Al, I’m not a BB gun expert but I don’t know how true that is. Even though cheaper BB’s might bounce around a bit, they can still only move a few thousands of an inch in the direction perpendicular to the shot tube. I can’t see their building up enough momentum in that short distance to ding the tube.

I would think that a bigger issue might be the surface finish of the BB – if it’s a little rough it might tend to abrade the shot tube and gradually wear the bore.

BB, please correct me if I’m wrong.

B.B.,

Greatly appreciate you sharing the progress of making an old gun shootable again. Applies to many older airguns that deserve to be brought back. The 27 is certainly one of these. I respect you wanting to keep the gun “correct”. I have the same obsession for vintage when possible.

I acquired a winchester 427 that had a breech seal problem. Don’t have a chrony, yet, but put baby powder over the the top of the barrel, above the breech seal/o-ring, and shot it. Puff! Seal was gone. When I took out the old leather seal I found a thin shim under it. Did you find a shim under your leather seal after you dug it out? I think your solution to make a new leather seal using two correct sized punches (one for exterior diameter and one for interior diameter) will work great!

I ordered the aftermarket replacement parts for the diana 27. Diana Part number (german “artikelnummer”) for the 27breech seal is 300312 and part number for the 27 shim is 300313. This is where I obtained them:

http://www.sportwaffen-schneider.de/advanced_search_result.php?keywords=300312

I ordered several of each. Used one shim and the new breech seal. Oiled the piston seal, like you advise, and the gun shoots fine. Not as strong as my diana 27 but I’m not ready to tear into the 427 yet. Maybe this process will give me the confidence to do that. I’m sure your method of the breech seal replacement will work fine too.

kevin

B.B.,

I’ve been enjoying your blogs for a month or so now and I just realized you have become an extension of my morning newspaper. I like to sit down with a nice hot cup of coffee and read the newspaper while my computer is warming up then start in on your blogs. There are so many I don’t see how I’ll ever catch up.

I do want to compliment you on the amazing optical illusion you included in your October 28 2008 blog on Reading Targets – Part 2. The target graphic for “Calling Your Shots” at the end of the blog looked to me like the center of the line under the dark circle is bent upward and the ends of the line are lower than the edge of the dark circle. However, placing a straight edge along the line clearly shows it is not bent and is indeed a straight line tangent to the dark circle.

I do have a question for you. After reading your blogs on oiling air rifles, why did I buy a bottle of Beeman’s Metalophilic MP-5?

-Chuck

Al,

For crying out loud — stop reading the forums. Regular BBs WILL NOT harm the 499 barrel! What utter nonsense some people post when they can’t think of anything else to say.

BB guns are known to have passed to 10 million shot mark when used in military programs like Quick Kill. Of course there they received a lot of abuse and little care. The barrels, being a replaceable part, have no definite track record, but I’m confident a few of them have lasted that long.

Al, I’m not angry with you. I’m frustrated by the forums, where anybody can say anything. When I helped coach youth programs I saw a lot of 499s being shot with Wal-Mart BBs.

The reason you want to use Daisy Precision Ground Shot is for the final edge in accuracy. I have shot my 499 with both Daisy and Crosman BBs and found that it’s almost as accurate. But both of those BBs roll down the barrel in less time than it takes a Daisy No. 515 Precision Ground Shot to do the same thing, so you know the latter fits the bore better.

B.B.

BB,

Funny you mention accuracy test of the 1088. I was shooting my 2 1088’s yesterday, we had a 70 degree day in VA. I found a small, rather impractical way around the side of the pellet contacting the barrel wall. Reset the cylinder so a pellet looks ready to take off straight down the barrel. The close the action and pull the trigger slowly once. for the remaining shots, set the cylinder to the last emptied chamber, close, then slowly pull the trigger. After doing this I was able to hit quarters at 10yards, and 1inch silhouettes at 50yards.

P.S. I always run the Co2 under slightly warm water for about 3 seconds before starting.

Shadow express dude

BB

Sorry for the typo, I meant to say “6inch silhouettes at 50 yards”.

Shadow express dude

No offense taken at all, reminded me of my dad for a second:-) Thanks for laying that to rest.

Thanks for your answer too Vince.

Al in CT

Kevin,

Thanks for that information. I could have gone to John Groenewold and bought the right breech seal, but since you can’t do that for a lot of obsolete guns I decided to make one from scratch.

No, I didn’t find a shim under my seal, so it may have been a replacement. Knowing that you did find one I will allow the seal to extend up more than I planned to.

The trick to seal replacement is to first fit the new seal to the groove — THEN oil it. It will swell, but by keeping the breech closed, it should end up with a perfect compression fit. At least that’s the theory.

Leather is very forgiving, which is why it makes such a good seal material. I still plan to overhaul the powerplant of this rifle. This is just a side excursion to see how much power loss the old seal caused.

B.B.

SED,

Hand-indexing is the name for your method. Elmer Keith wrote a lot about the importance of a cylinder being aligned with the forcing cone of the barrel (the breech) for best accuracy.

B.B.

Chuck,

You can use Beeman’s MP-5 Metalophilic oil in place of Birchwood Casey’s Sheath — as a metal protectant.

B.B.

How thick is the new leather seal in your diana 27. Also does the breech seal have to be flush the seal groove?

Jsh

Josh,

Have patience. All will be revealed.

B.B.

I hope everyone here had a good Christmas.

Christmas as our house was as expected. The boys (7&5) were up at 5:30 to see if Santa had been there.

Of course he had.

The 5 year old already had a strong suspision that there would be Red Ryder under the tree as he had been adamant that Santa bring one like his brothers all year long.

Gwydion (the 7 year old) was completely surprised and totally blown away when he opened the Marksman 1010.

They opened the rest of their presents and we were down in the basement trying out the new guns before breakfast.

Gotta get a bigger backstop!!

Right now we have a good commercial bb and pellet trap, with a piece of plywood behind that to stop the odd flyer from embedding into the drywall.

But the 5 year old, though he can hit a tree no problem (his favorite target), misses the pellet trap regularily. And the 7 year old is finding a pistol harder to aim than his Red Ryder, so is also hitting the backstop.

Though everyone wears shooting glasses…mom was not to happy with the ricochets.

I figure a 4X6 foot piece of drywall should cure the problem.

One thing that surprised me. The Marksmans shoots low (by about 5 inches at 20 feet), but actually groups 10 shots in a 4 inch circle. Seems once you have the sights figured out it will easily be accurate enough for plinking (this with bbs).

Also, Santa left some cash in an envelope under the tree for daddy.

So BB, my question to you is…would the Camo Compact be a good addition to the Walter CP99 and PPK.

CowboyStar Dad

CowboyStar Dad,

Well, those boys are off to a good start! Now let’s get dad pointed in the right direction, as well.

The Gamo Compact is quite the target gun. I hope you have read the entire report, which compared it to the IZH 46:

/blog/2008/7/gamo-compact-vs-izh-46-part-6/

The one drawback is a trigger that’s heavier than I think it has to be, but if that doesn’t scare you I’d say go for it.

B.B.

BB,

That picture of the breech reminds me of how craters on the moon are often mistaken for domes. Given the condition of the old one, I will go out on a limb and predict there will be a significant improvement with a new breech seal:).

CowboyStar Dad,

Sounds like your five year old is happy. Mine was hoping (among other things) for a Red Ryder and a pump action shotgun, but since I don’t believe in giving kids anything for their own that they can’t be totally responsible for, he got neither…He’s happy with a pop gun he can carry around all the time and shoots my Red Ryder when he can talk me in to it.

For the record, the pump action shotgun was never a viable possibility:), although I bet he would be a better wingshooter than I.

CowboyStar Dad,

How about a sheet of insulation board from the lumberyard, it comes in 1" or 2" thick..

Thanks for sharing the mental picture of the kids… for us old guys without grandkids yet.. Catch 22.. my son is working long hours making a new website, for the raised garden business.. but I want him out there finding a wife, too.. And my daughter is focused on school and teaching preschool.. so..

Count your blessings those of you with grandchildren…

Consider the S&W 586 revolver too.. Randy still won't put it down.. and his groups have gotten down to 2" at 30' with more than half of the 50 shots in 1" and a maybe 25% in the 1/2" center dot..

The JSB 8.4 are doing best for him now..

Wayne,

Ashland Air Rifle Range

bg farmer…I know what you mean.

The only reason I felt comfortable for the time being with the Red Ryder and the Marksman are both are too hard for them to cock unaided…this was the only reason they got past mom.

For this reason the CO2 pistols are kept in locked pistol cases. I don’t think they could really figure how to get the cartridge in and the magazines loaded, but I’m not taking a chance.

Years ago (like the 60’s through 80’s) CIL (a munitions maker in Canada) sponsored a shooting training course. By the time I was 7 I had my bronze pin in .22LR prone.

It’s a different world today.

That photo of the Diana seal groove is a great optical illusion. At first viewing I couldn’t make it out, but when I read your desciption of it, it instantly became clear. Very cool.

BB – Do you know of any bb guns which have a barrel ideally suited to Gamo round lead balls? I’m thinking of Barnes’ pictures of recovered lead balls from his big bores which show rifling marks, and am wondering if one can achieve the same result in .177.

Airdog,

Not any BB guns, because their bores are too small, but you can shoot round balls in pellet rifles. They work the same as larger caliber round balls.

B.B.

CowboyStar Dad,

Glad you’re taking safety training seriously.

Waynes idea of pressed foam sheet (pink sheets from Home Depot) does sound better for ultra low power BB rounds. It is lower cost than drywall. The mess it will make will be easier to clean up. And lastly it is just about the right density if you use a double layer of 1/2″ you could discard the front sheet when used up and put a new one behind the old one. Kind of a rotation method.

BB’s should not bounce off the foam insulation sheets and there would be almost no noise created. The down side is foam makes very wonderful crack when broken so the boys may be tempted to snap away the corners. Boys will be boys.

Just my thoughts.

The mental image of you and the boys plinking away was quite grand. Thanks for bringing back old memories of my own children shooting BB guns and learning gun safety in the process.

DB

Hi B.B.

I wonder if you could help me with a project?

I want a Crosman 2240 with standard rear sight, the 14+” bbl, trigger shoe, extra, long receiver. I want to make it into a carbine (I have the stock) and I want t o use it with open and telescopic sights, at my discretion.

Crosman’s custom shop only offers it without the rear sight (I don’t want or need the MIM sight they offer, and they don’t offfer a configuration with the standard rear sight). PA doesn’t offer it standard with the 14″ bbl. I read that the 14″ bbl is quieter than the standard 10″.

Who should I go to to get this?

Thanks,

Joe B.

Also, do I want the 2260 with the larger air cylinder?

Joe B.

Al, I guess the only thing you need to avoid is using rusty BB’s! BB’s right about the forums, though – they are very fertile ground for all sorts of baseless theories and rumors.

Some time ago BB reviewed the QB18 air rifle (specifically the TF49 variant), and mentioned that it had power comparable to the Beeman R7. Next thing you know, some forum guys are claiming that the QB18 is a clone of the R7, which is about as laughable as saying that a 1985 Mustang is a clone of a 1984 Ferrari 308 because the 0-60 times are similar.

Not sure if that was any sillier than the guy spreading the story that the Mendoza RM600 was a clone of the RWS350. Apparently he was extremely impressed with some guy who claimed that his .22 RM600 did 1100fps with 30gr pellets.

Thanks for the idea of the foam. I was concerned about drywall powder possibly being breathed in by the boys.

CowboyStar Dad

BB(&Vince if you've got time),

I noticed my 36-2 was sending a good number of Hobbies supersonic after a couple thousand shots on the "tune"/rebuild, which is remarkable considering I tuned specifically for smoothness and never put more than a drop of chamber oil in it. I usually shoot heavier pellets, but wanted to waste the Hobbies, which don't work as well as Basics for me in anything.

Is it the seal seating better? No noticeable dieseling nor any detonations, and the firing cycle is as good as ever.

Maybe I should take some preload off — should be smoother than the Hammerli, then:).

Airdog,

I was shooting 22cal lead round balls at 20-yards through my Discovery yesterday; they shot just as well as JSB pellets and better than CP round nosed. Plus they are so much easier to load.

If I recall accuracy falls off at longer ranges. Did not test that yesterday. BB would likely know for sure though… he did some testing a year or so ago. Do a search for that blog. You might find it useful.

Not contradicting BB. But many BB pistols with smooth bores are rated for both BB and pellets. My 177 AutoAir II feeds and fires lead balls very well. BB’s sure do cost less though.

DB

BG_Farmer,

Do you hear a whistle when you shoot Hobbies?

They produce a fairly loud whistle when shot from my Discovery. They also whistled when shot from a high powered Beeman springer.

DB

lol…crosman custom shop…been there a few times.

I ended up with a 2260 with 14 inch barrel, muzzle brake, trigger shoe, cocobolo pistol grips with the lazer engraving of AJVENOM on it. Well, at least unil I come to my senses, turn off the computer and go down stairs and shoot the several airguns I do own now. If only the Discovery came about a year earlier.

I am saving up for either a PCP or very nice springer. It will be interesting to see what the Discovery has in store for us in Febuary. Good deals on later models would be nice too.

Well the weather’s warmed up a bit, now’s a good time to go get some fuzzy bunnies. I wonder if you can make pepperoni sticks or jerkey out of them. I’m still waiting on my deer meat. Have to go pick it up sometime.

DB,

Yes, a high whining whistle…not so sure about a crack now that I think about it, but they were doing something weird, for sure. My experience with those pellets runs contrary to the mainstream every time:).

Joe B,

I have been putting together my own custom 2240 similar to what you describe buying through the Crosman website. I purchased the Crosman long steel breech and a 2250 barrel from my local airgun shop. I cut the barrel down about 1.5″ on the breach end so the little set screw divot would line up with the 2240 barrel band. I did purchase the Lsa Mim sight from Crosman and would recomend you consider it. It’s very nice. The stock 2240 plastic rear sight does not fit the steel breach well without some cutting/filing.

I have my old one that you can have if you want it. Another option is to call Crosman direct and ask for the parts dept. If you look online you will find the 2240 parts diagram, and you can order mist all of the parts that way. By the way, I asked them why you can’t buy thecwood grips, muzzle breaks, trigger shoes individually off the Crosman website anymore. The person I talked to said they couldn’t build the custom gun orders in a timely manner because the individual part orders where using up the parts they needed.

Joe,

That was going to be my answer, too. Buy the gun you want and then buy the sight as a part.

B.B.

Vince,

Thank you for that answer about the forums.

B.B.

Joe,

Okay, I’ll bite.

Do you want the larger 2260 cylinder?

B.B.

BG_Farmer,

Duane Sorenson who used to work at Compasseco claimed that the TF 97 (your 36-2) would break in and go faster after several thousand shots. I never shot one that much, but apparently your did. Your explanation of the piston seal fitting tighter is the same thing Duane said. He is the guy who advocated using corn oil in the compression chambers of Chinese spring-piston guns because he said the waxy buildup from the dried oil would correct the machining flaws in the walls of the compression chamber.

Removing preload should reduce the piston speed.

B.B.

DB,

Of course you are right about the bore sizes of guns rated for both BBs and pellets. When I said BB guns, I was thinking of those that are strictly BB guns, only. I should have said so.

B.B.

Hello BB,

I am brand new to this forum/blog, but like to say that I am happy to find a forum with a focus on Airguns and all details related. I’ve been wanting a Diana for close to 8 years now, and my wife finally got me a model 34 for Christmas. (I had been using a Crosman 2100 Classic, don’t ask me why.) As a beginner in this wholly beautiful new realm of airgun accuracy, I have couple questions to ask of you.

With this new gun, what iron/aperture sights would you recommend for it? My intentions are to join a club, and possibly get trained up for some 10 meter competition. I’m not sure how easy that will be since I live in Western Maine,and may have an arduous search for one of these groups. Maybe you can help with that too.

AccuracyNut,

First let me tell you that your wife has give you a wonderful air rifle in the RWS Diana model 34. Over several decades that rifle has evolved into a real world-beater of a spring piston sporting rifle.

Now for the bad news. The 34 is unsuited for 10-meter competition. It generates far too much velocity to be allowed in a formal match, where muzzle velocities are usually under 600 f.p.s. You might be allowed to submit a target shot by yourself in a postal match but now match director will ever permit you to shoot in a formal match. The pellet traps cannot stop your rifle safely. It will shoot through the backstop within a remarkably low number of shots. It is especially dangerous since you will be impacting in the same spot on the trap, time after time.

However, that shouldn’t stop you from using your new rifle for practice. It is certainly good for that. I would look at the new AirForce aperture sight listed here:

/product/airforce-adaptive-rear-target-sight-fits-most-10-meter-3-position?a=2237

If that’s too much take a look at the Beeman Sport Aperture sight

/product/beeman-sport-aperture-sight?a=717

B.B.

I don’t think a 2250 plastic grip/shoulder carbine stock will attach to a Crosman 2260 unless you buy a new grip/trigger assembly from a 2240 or 2250 first, then attach it to the gas tube. Isn’t the stock trigger assembly different on the wood stocked 2260 rifle from the 2240/50?

B.B. / Everyone

Does anyone have some numbers on cocking effort for the Walther Falcon Hunter (either caliber) after some more break in time than reported in the initial reviews? Even just a sense of whether it will keep dropping from the mid-40 lb range would be helpful.

I have some raccoons to get rid of but have had no luck getting close enough to them to feel comfortable using anything less than .22 cal and 20 ft-lbs to ensure a humane kill— you see, one of my neighbors thought it would somehow work to kill them with an underpowered BB gun, and now they retreat quite a ways when anyone comes out to shoo them away. (Of course they just come right back once they hear a frustrated sigh and a door closing!).

I’ve also been looking into hunting larger animals like raccoons with an airgun, and it seems like the Falcon Hunter is the best bet for me given my buying power (or lack thereof). But unfortunately I don’t have the arms of a gorilla, and unless that cocking effort is getting beneath 40lbs, it’s probably not a good rifle for me. They really should start shipping things like the Patriot and Talon Magnum with ibuprofen and protein powder, don’t you think..?

Thanks in advance.. EJ

BB, please forgive my nitpicking – but TF97 = QB36, TF99 = QB36-2. The -2 variant is larger and more powerful, and is the one you tested a while back.

Corn oil in the compression chamber? Oy! That stuff must be pretty good, if it corrects some of the defects I’ve seen…

EJ,

You want to get a PCP. Then you get the power without the effort.

B.B.

Vince,

You’re not nitpicking. Of course I got it wrong. I even know that, now that you mention it.

Duh!

Yes, Duane said the wax from the corn oil would build up in the scratches in the wall and eventually you would have a smooth chamber. He swore by it and I still have a half-gallon of Wesson Oil in my cabinet.

B.B.

B.B.

BB,

No corn oil in mine, thanks. I did work on the cylinder, of course, before putting in the new spring and apex seal, which fit pretty tightly when new. It was rougher than the recommended grit, though, so wear-in is likely.

Ditto on Vince’s correction. I would not even have trouble believing some .177 36-2 somewhere could achieve 1100fps (factory says 900) consistently, especially if fortified with a combustible:)…mine whacks the target with authority, even after being toned down. The problem is, it took a bit of work to get there and most of them might even require more.

B.B. (or others)

Can you advise what I should use to lubricate the shaft of my Axsor hand pump.

It got a bit contaminated in the field, and needed to be cleaned, but I recall you advising never to wipe the shaft clean. So now I’m a bit stuck…will diver’s grease work?

Ed Pikor

All,

Just found an old steel frame Weaver Marksman 4x scope that was made in the USA on our Christmas tree. We decorate with vintage toys instead of ornaments. Looks better then you’d think and it is always food for discussion.

Anyway… was wondering if it has any value. Most likely is from my childhood… though I really can not recall how it came into my possession.

It has a straight tube except for the eye piece.

DB

All,

Pounded out some CP round nosed pellets again today. Ran them through the Disco.

The reason was to test an old Tasco 3-7×20 scope that was given way some time back. The new owner claimed he couldn’t get it zeroed and gave it back. Took me several shots to zero it but then dropped 20 consecutive shots in a 1” circle at 30 yards. Guess the scope still works. Likely could have done better with JSB pellets.

What I really learned is the Leapers scope I’ve been using on my Disco has some kind of problem. It is a 1.5-6×44 SWAT IR scope which should outperform the low end Tasco. Yet I can not duplicate that shooting with the Leapers. I’m thinking it is a parallax issue because there is often two different POI groups.

DB

DB,

You probably hit the nail on the head when you said parallax. The old-school Tasco has a much slower (higher) f/ratio and is more particular about your eye location than the big-glass Leapers, so parallax will not be such an issue. That’s my theory, anyway.

BG_Farmer,

Agreed. Have been having trouble with it all along. And I work real hard to keep eye placemnt the same every time.

My next scope will have an AO adjustment. Hoping that will help with the problem. Do love the bright sight picture the large lens offers.

DB

Tom, the O-ring is the best bet for the 27 breech seal. The same size used in Diana’s current barrel-cockers works perfectly in the older models with leather seals. You may need to shim under it to tweak sealing and barrel angle.

Hi BB,

I am considering purchasing a .22 TX200 MKIII for pest control of furry critters 40 – 60 yds.

I have never owned a fixed barrel before, so what is your recommendation to clean the barrel? A rod, or a flexible snake?

Eric

CowboyStar Dad,

Shamed by your good example, I let my boy talk me into shooting the Red Ryder this afternoon. We’ve discussed aiming many times, but I’ve never been sure he listens. Today, he hit a soda can 2x at roughly 25 feet in about 5 tries. This is not astonishing marksmanship, but I think he must be aiming properly and his hold looks as good as I can expect for a boy shooting a gun almost as long as he is:). We only shot a few times because he insisted on cocking the gun himself, which is not an easy process, as you know. Thankfully, it was the “new” one (1938B), which won’t break your fingers if you lose control of the cocking lever:).

DB, on the old Weaver scope you have. I have bought the old 1/2″ J-series and 1/2″ and 7/8″ ( 7/8″ tube were the Weaver V-series, from the seventies) rimfire scopes I see in pawn shops and flea markets. Mostly they go for less than five dollars. The larger Weaver 1″ tube scopes are starting to show some collector interest.The range seems to be in the $25 to $40 dollar range for a nice clean 1 1/2 to 6x fixed power scope. However, I just buy them for use as working scopes on my own guns and do not collect them. The old 1/2″ Weavers, look nice and still perform well on vintage CO2 and pneumatic air guns and twenty- two firearms. They had real glass lenses, and were well made, compared to the cheap plastic seen today. Hope this helps ,Robert.

Ed,

The best lube for a hand pump is Parker Super O Lube. Be very careful after applying it because it attracts and holds dirt.

A better lube for general use might be Beeman M-2-M moly grease. Don’t use much of it.

B.B.

DB,

The two different groups you get with the Leapers scope are indicative of a parallax problem, like you mentioned. Head placement is critical with a scope that has a broad exit pupil, like that Leapers. It don’t force a certain head placement, so you have to take care to do it the same every time.

Those scopes are good because they acquire the target fast, but they should be used on guns that fit us well.

B.B.

Mike,

Thanks for your suggestion. Again, I am trying to retain the vintage look of this model 27. Velocity isn’t that important to me. However, if I botch the leather seal, I will try a modern O-rings like you suggest.

B.B.

Eric,

Since I never clean airgun barrels unless the accuracy falls off, I have no recommendation. I never cleaned my first TX 200 and I have never cleaned my current one, either.

If I had to, I would use a solid rod and go in from the front. A brass brush is the only real cleaning tool when a barrel gets leaded, which is the only bad thing that ever happens to airgun barrels.

B.B

Hi BB,

I have a few quick stupid questions for you:

“How does the Diana 25 compare to the Diana 27? A predecessor, but with less power perhaps? Ia it any good?”

Thank you.

Dave

RAFB, GA

P.S. Does the Diana 25 have that same cool trigger as the 27 like you showed in that close up pic?

Thanks, man.

Dave

RAFB

Dave ,

There are several different versions of the Diana 25. The top one has the same trigger as the 27. Power is slightly lower (maybe 50-75 f.p.s. less) but in this day and age it’s hardly noticeable. The state of the individual gun’s tune is more important than the potential power.

B.B.

Thanks, BB! =)

Robert,

Thanks for the scope info. Guess the old scope will remain a Christmas tree ornament.

DB

B.B.,

About the scope problem we were discussing yesterday. Is there another scope that offers less parallax problems? Does the AO adjustment help a lot?

DB

DB,

The lower-powered scopes will always have larger exit pupils and therefore more shooter-induced parallax. It’s built into their design. They are for rapid target acquisition where the last half-inch of shot placement isn’t important.

The more powerful scopes have smaller exit pupils, and therefore force you to place your head in the same spot.

The parallax correction on the scope does help a little, but it doesn’t solve the head-placement problem. So to be accurate, you have to have and do both things — scope adjustment and head placement.

B.B.