by B.B. Pellitier

This report comes to you courtesy of reader Jim Grossman, who generously shipped his Relum Supertornado to me to test. The last rifle I tested that Jim had worked on was the Haenel Model 1, which I bought earlier this year from an internet ad. You can read about it here.

I may have mentioned in that report that Jim is a careful airgun packer. I’m sure I did, because his packaging impressed me a lot. So, this time, I captured the details of the packing for you–as well as making a visual record for when I have to send the gun back.

The first step in airgun packing is when Jim selects the box he’s going to fashion into an airgun shipping box. Usually, the little box is so thrilled that he runs out to the playground to tell all the other little boxes that he’s going to be one of Jim’s airgun shipping boxes. They all then share what stories they have heard about Jim’s boxes before the bell rings and they have to come in for their afternoon nap.

Some boxes, however, don’t receive the news with joy. These are the delinquent boxes. Some of them smoke, and most of them curse. They all wear leather jackets and black boots. They don’t care that they could end up on the floors of garages, under cars soaking up dirty motor oil or be cut into pieces and used to light fires on cold winter evenings. They just don’t want anyone telling them what they are going to do.

Jim has a program for these obstinate boxes. He doesn’t give them Ritalin or send them to “Scared Straight” encounters. No, he simply starts fashioning them into the containers he needs. They complain loudly, but what else can they do? They’re boxes, after all. Most of the time, before he’s halfway through the box-making task, the box starts to transform after seeing that it’s about to become a very useful member of society. Almost 98 percent of the boxes Jim works with go on to achieve self-actualization, which for a box is pretty hard to do. Their new owners are so impressed with them that as many as 79 percent of them are stored away in a dark, cool, dry space, awaiting the day they may be called into service again. Perhaps future archaeologists will examine these boxes and try to reconstruct what they might have held.

Outer box (although, at this point, I didn’t know there was an inner box) awaits opening.

Inner box says “Open other side.” You bet I will!

It’s a wonderful, if somewhat humbling thing, to receive an airgun packed by Jim Grossman. On the other hand, if you’re expected to return the gun to Jim, and there’s no documented instance where this has ever happened before now, then it’s downright scary. You feel exactly like a private pilot student at the moment their first solo flight begins. As you unpack the box, you feel like, “Oh, my gosh! The wheels just left the ground! I’m now flying. There’s nothing I can do except land the airplane by myself, because I’m the only one in this cockpit!”

As each braced part of the gun is removed from its carefully fitted cushioned cutout and you see that is is actually cross-braced in its center on both sides and on the bottom, as well, you feel like you’ll never be able to remember where everything goes. “Let’s see, the head bone is connected to the…to the….Oh my gosh, Spock! I don’t remember how it goes!”

Inside the second inner box that was braced inside the outer first box and annotated on the outside to instruct me which side I should open, I discovered a letter. Letters in airgun boxes are a lot like socks at Christmas. Yes, you’ll eventually get to them; and yes, you probably need them–but they shouldn’t get in the way of your fun! However, after carefully deconstructing this double-boxed bank vault to this point, I was hardly going to ignore a set of instructions from the maker! They might begin with, “If the large part begins to tick when you lift it from the foam, quickly retire from the room and seek shelter.”

Flip side of inner box says “Open this side.” We’re getting closer!

Inside the inner box, a letter laid on top of everything. I read it first. Each part has a form-fitted compartment in the dense foam, with shims and cushions on all sides. The stock screws are pressed into the foam and taped in place. Large parts, such as the stock, are inside sacks made from nylons (kinky) to prevent rubbing from the padding. I’m sure there’s a radiological dosimeter in here; I just didn’t find it.

Thankfully, it wasn’t anything like that. It provided the background of the gun, which I will slip into the report as I feel you need it.

Yes, this is an airgun blog, and, no, I’m not just wasting your time. We’ve got the Michaelangelo of airgun packers here, and it’s worth turning aside for a moment to appreciate a masterpiece. Now, drink your coffee, and I’ll get on with the report!

Relum Supertornado is an odd-looking underlever.

The Relum Supertornado is a spring-piston underlever that loads through a tap. It was made in Hungary at a time before the fall of the Iron Curtain. So, it has a lot of Communist in it and looks a bit crude. It probably works like a champ–kind of like that Mosin Nagant rifle that seems to set me off whenever anybody criticizes it.

The overall form of the rifle is boxy and a bit on the cobby side. Things that would be neatly tucked away in other air rifles stick out on the Supertornado. The angles of the stock and the triggerguard are too sharp, and the forearm feels just like a two-by-four. The beechwood stock is stained an uneven, muddy dark brown. The metal parts are evenly covered with black oxide over a surface that’s about on par with what China was putting out in the 1990s.

It sounds like I’m setting you up for a poor report, but that’s not my intention. From what Jim has told me, I sense that there’s a silk purse inside this hog’s ear. Jim made some repairs and modifications to the rifle, so let’s look at those.

The trigger housing was welded onto the spring tube on a slight cant, which caused the trigger bar to contact the sear on an angle. Eventually, it let go, and Jim was the lucky owner when it happened. He tried to source a replacement, but Relums aren’t exactly mainstream, so he wound up having a machinist make the part by examining the broken pieces and the hole it left in the trigger housing. What had been a stamped steel part is now machined from solid stock and should prove many times stronger and more reliable.

Silver part at the top of the trigger housing is the part made to replace the trigger bar. Silver at the bottom is a piece of feeler gauge cut to fit the trigger and held in place with JB Weld. The pivot pin hole broke out of the trigger, but the hard feeler gauge provides a new place for the hole to be drilled.

When he assembled the trigger again, he broke out a pivot hole on the sheetmetal trigger blade, but a piece of feeler gauge held on by JB Weld has fixed it. The trigger had an adjustment screw, but Jim opted to leave it out because it changed the depth of sear engagement. He felt that with all the trigger had been through, a little erring on the side of safety was appropriate.

The original front sight was a hooded post on a dovetailed base held fast with a setscrew. Jim replaced it with a Diana model 28 front sight that accepts inserts. He installed a clear aperture that would be found on a target rifle.

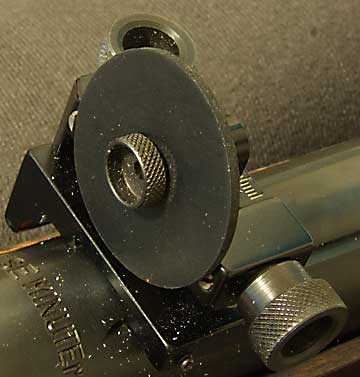

The rear sight was a crude but complex folded-metal unit that Jim replaced with a Beeman Sport aperture rear sight. He cleverly uses a rubber fender cushion washer as a disk to enlarge the small Beeman eyepiece for light reduction.

Rubber fender washer makes a nice light shield for the Beeman Sport Aperture sight.

That’s all for today. Next time, I’ll complete the tour and we’ll get to know the rifle.

BB,

If it wasn't for the excessive cheek piece, it would be perfect. What is the piece that looks like a flapper (on a vertical exhaust) on the receiver above and just a little behind the cocking lever pivot?

BG_Farmer,

I think you are looking at the tap handle. I was saving that until next time.

B.B.

Volvo,

Nice find with the Izh61. That's exactly what I was looking for. I guess I'll have to be more diligent if I want to get the drop on one of you guys.

Kevin,

Nice tarantula. Hope she's everything advertised.

B.B.,

I never cease to be amazed at the number of vintage airguns and the variations that exist. It's very enjoyable to me to see what airguns have evolved from. The first ones to walk on land. LOL!

Looks like Lasso was alot of fun!

Yesterday, with the family in tow, off we went to the largest bookstore in town (whatever happened to newstands?) to find the latest Shotgun News Magazine. Drove a long ways across our snowy landscape and then walked 5 blocks over snow drifts to our destination.

At the entrance of this fine bookstore a tall, lanky gentlemen was entering in front of us. We paused in the vestibule and promised to meet at the checkout counter in 20 minutes before going our separate ways to peruse publications on our favorite topics.

The tall, lanky gentleman had made it to the magazine area of the bookstore just ahead of me and was holding the last copy of the November 30th Shotgun News. I muttered under my breath before meandering over to the architecture rack of magazines and acting like I was interested. Several minutes passed before he finally put the last copy of Shotgun News back on the stand.

I snatched it up and thumbed through to make sure there was an article on airguns by Tom Gaylord. Yep, there it was and it was mine.

I'm subscribing to Shotgun News today so this is the last story in this vein you will ever read written by me. Ever.

I sure like your writing style and your latest "Silence is GOLDEN, The Truth About Quiet Airguns" didn't disappoint.

The article I'm very interested in reading is the review you mentioned about the FX Revo that would be published in Shotgun News. Will this be published in the future or has it already been published?

A side note. It's amazing how Shotgun News has evolved. It's been years since I subscribed. Shotgun News seems almost paramilitary now.

kevin

Slinging Lead,

This is my second FX Tarantula purchase. The first has grade 4 turkish walnut and is not only a looker but a shooter.

Yesterday's tarantula has the synthetic stock.

In my opinion, the FX Tarantula is an oft overlooked and undervalued pcp. Great fit, excellent woodwork (especially the grade 4 that are more common than you might think), multi-shot (that I like but some others don't ;-), adjustable power (top end is 33-34 fpe in .22 caliber), good shot count and the accuracy you would expect from a Lothar Walther match grade barrel that is fitted on all Tarantula's.

The cocking action isn't as smooth as an AA S410 SL and the tarantula's need some extra help to be very quiet. What wasn't mentioned in the ad on the tarantula I bought yesterday is that it has a full custom shroud built by Dave R. Luckily, I knew the gun from Roald's collection.

kevin

Kevin,

The Revolution article is supposed to be in the November 20th issue. Are you telling me that it isn't there?

B.B.

Kevin,

One other thing,

I was unable to photograph or film the LASSO event because I was too busy filming the television segment.

LASSO was larger this year that both previous years combined. Next year I am hopeful there will be a smallbore event to attract smallbore shooters, as well. The event could easily double in size again.

B.B.

I've always wondered what a "normal" life was like for the average family under a Communist regime. The kind of people who didn't give one kapok how the govt was run so long as they left them alone and there was food on the table and a safe environment for their children to grow up in. Were they actually allowed to have fun with these air rifles or is this how they were allowed to get food?

-Chuck

RE: Lasso

Photo-album picked up from the yellow forum.

http://s158.photobucket.com/albums/t99/rbva/Lasso/?albumview=slideshow

Good point. I've heard a few horror stories involving airgun shipments using non original packaging.

Double boxing and good packing material are two popular things I hear a lot about nowdays.

Chalk one up for original packaging. As for my Discovery, it was used, but it was mailed to me in the original packaging. I was pretty amazed how everything fit into the styrofoam block and was well protected. As for collectors, it probably good to have the original packaging also.

Kevin,

When you start remarking on the paramilitary look of shotgun news, you're showing your age:). No offence intended, its the same for me: Most months I have to look hard through American Rifleman to find the one story about a "civilian" rifle or activity. Too many AR's, pistols and shotguns. I remember back when they used to do interesting, informative articles about shooting and rifles.

Boy, do I agree with that! Too many mall ninjas, too few real firearms.

B.B.

B.B.

Well, I thought I was the only one with an interest in cardboard boxes for internet shipping. Does anyone have a method for removing the brass staples that come with PA boxes? They're great for protecting the shipment but a pain to remove. I end up levering them out with a scissors and worry and mutilate the box a good deal in the process.

Thanks to all for the glue recommendations.

Regarding the Mosin Nagant, Tunnel Engineer, did you manage to get the sights adjusted to point of aim at 100 yards? If so, how? I've read about all sorts of creative solutions to do this, but it doesn't seem to happen by itself. B.B., thanks for the vote of confidence on this rifle. There are conflicting reports about it–sort of like the Russian airguns. Nice to know that it is reliable but requiring a special technique for loading doesn't sound "soldier-proof."

Volvo, please do review your all-metal IZH 61 when you have a chance. I'm always interested in reports on this rifle.

The last time I looked through Shotgun News a long time ago it looked like a place for advertisements. Most of the articles on the website are not accessible, so I haven't formed a new opinion. 🙁

Matt61

B.B.,

Last two published dates of Shotgun News were (Monday) November 16, 2009 and (Monday) November 30, 2009. The ninth annual Shotgun News Treasury is also on the stands. I bought all 3.

There isn't an article by Tom Gaylord in the November 16th issue. The article by Tom Gaylord in the November 30th issue is titled, "Silence is GOLDEN, The Truth About Quiet Airguns". Good article. The article by Tom Gaylord in the Shotgun News Treasury is titled, "The Story of Wham-o's Guns".

BTW the November 16th issue is Number 32 and the November 30th issue is Number 33.

So, the cats ate your homework?

kevin

In middle school, I used to smuggle in Field and Stream, Popular Mechanics, Consumer Reports and Road and Track magazines into the class. If you read Gun and Ammo, some people would considered you a "gun nut" and felt that you may pose some kind of threat.

Later in highschool, a lot of students had hunting and fishing gear in their vehicles and posed no theat to one another. Most major disputes were settled the old fashion way, with our fists.

Also, going out fishing was just a nice way to unwind and have a few beers with the girls on a nice summer night.

BG_Farmer,

No offense taken. I think Shotgun News is a fairly new rag at least compared to Sports Afield and Field and Stream. I didn't subscribe to Shotgun News until much later.

They covered a wide array of guns but Shotguns were front and center. I remember one terrific articles on Purdy's. Still have it around here somewhere.

I think a more appropriate name for the magazine now would be Mercenary Times.

No offense intended.

kevin

Matt61,

Try levering those pesky staples out with channel lock pliers. Works great.

The soldier proof Mosin Nagant is as follows: those that figure it out became soldiers while those that don't became casualties.

Mr B.

Kevin,

I just emailed the editor of SGN to see what the problem is. I submitted that article back in September.

B.B.

Kevin,

I had a subscription to Shotgun News in the 1960s. That would be more recent than Sports Afield or Field & Stream, but it'd not new.

B.B.

B.B.,

No big problem. You sold another subscription. ;^)

Shame about not having time to shoot pictures at Lasso since I also assume you didn't have time to shoot any of the wonderful guns that were there. Heard the EDGE was there and everyone that had a chance to shoot it wants one.

Hollywood and stardom are major commitments. Wait til people start stopping on the street asking for autographs.

kevin

Kevin,

I have an Edge and am testing it right now. I will blog it when PA is ready to get theirs to sell.

B.B.

bb

would like your advise on which crosman m1 i should buy, the wood or the croswood. i would like the one that looks and feels like the real m1' that'sn the one i was trained on

thanks vin

Vin,

I have owned both and the Croswood stock feels more real to me than the wooden one. The wood stock is flat on both sides, instead of being rounded like the carbine. You'll also save a lot of money going with the plastic stock.

B.B.

Kevin et. al.,

Regarding the feature article on the FX Revolution rifle, I was supposed to finish that article and submit it after returning from New York after the last filming in August. Instead I had my gallbladder attack and in the ensuing confusion forgot about the article entirely. In eight years of contributing to Shotgun News this is the first deadline I have ever missed, let alone forgot.

Kevin, I'm asking to get it published as soon as possible. It's color, so they only do six issues like that a year. The next is Jan 20.

I am so sorry about this. I really thought it was covered.

Tom Gaylord

B.B.,

Relax. Not the end of the world.

Had no intention of this turning into more pressure on you.

Hope you and Mrs. Gaylord have scheduled some extended time away from the internet and film crews. Always helped to know there's a decompression period scheduled when things get too hectic.

We'll be here when you get back.

kevin

ps-i still like the "cat ate my article" excuse better

Kevin,

I do, too, but right now it feels like the cats ate me.

I still have to apologize to Airguns of Arizona for forgetting their article. 🙁

B.B.

AJ,

Those were the days. Fishing can be the ultimate redneck social:). I don't believe there was actually any rule against guns in our cars, and we often had them unintentionally (left over from squirrel hunting or camping). Believe it or not, there was never a single incident of gun violence. The only thing that was considered weird was the kid (there was always one or two) reading "Soldier of Fortune", although we all wanted the Freon powered BB machine gun advertised therein:).

TwoTalon,

I didn't get .495 balls yet, but I decided to try increasing my charge to 70 gr. — accuracy (relative) restored. I'll still try the .495's, but I think you may have been on to something when you said the pressure is less when the bore wears in. From the look of the patches — one solid ring around the pouch where the ball sits — it seems like 70 is better as well. I couldn't use the bench this morning, so I haven't done exhaustive load testing, but the improvement was noticable over last week.

BG_Farmer

The whole thing is a balancing act . There are a lot of possible combinations that will give you good results.

Here you have changed only one variable (increased charge). If you change patch/ball fit, you would probably have to change charge as well.

Some rifles are touchy about what they really like while some are not…even though pressure may be ratty.

I have had some rifles that almost defy any attempt to get an accurate load worked up….and some don't care too much as long as the patch does not blow out.

twotalon

BB,

I thought I remembered reading that you only publish an article in SN the fourth issue of the month. Did I read that correctly? The reason I'm asking is that I too went to the book store and I actually found, in addition to the Nov 30 issue, an Oct 5 edition with an article by you on airgun bore cleaning. I felt like I struck gold.

-Chuck

At last the Tornado makes it to Pyramid Air Report! Theres a bit of a cult following (if you can call it that as the Tornado in its many variants was/is a pretty ropey rifle) here in the UK for these. They were the first air rifle for many, cheaper than Webley or BSA, and the factory fitted double concentric spring promised, but rarely delivered, high power.

Made by FEG in Budapest (now I believe sadly gone a few years back) there were some five variations including a very rare 'baby' tornado, a miniature copy of the full size gun in .177 calibre.

i love them, almost pre-war in their odd styling, rebuilding and tuning a Tornado or Super Tornado is a challenge (though thisis the first time I've ever seen decent open sights fitted to one).

Ollie

Chuck,

SGN only publishes three issues each month and I am always in number three. That is my column.

Any feature articles I write are always in the color editions that come out 6 times a year.

B.B.

Ollie,

Then you can watch over my shoulder and fill in the blanks as we go through this interesting rifle.

B.B.

Matt,

Re: Mosin Nagant.

Funny you should ask. I got the Mosin, aimed and fired three big KABOOMS aimed 6 O'clock at bullseye at 100 yd. Rear sight was set at 100.

All shots were 3.5 inches right of bull. I then aimed 3.5 inches left of bull and did six careful KABOOMS which landed right around bullseye, some high, some low, some right , some left. It was a 5-inch group if I remember correctly (Dirty Bird target where I can read group sizes easily)

So, I did not adjust the front sight as it was not grossly out of adjustment. If I were to adjust it, I guess I would need to tap it about 0.02 inches to the right but I will not go into that right now. I am just happy it looks like my Mosin can shoot. I will only worry about the extractor and the type of ammo for now. I just ordered surplus. Hopefully, this wednesday I will go to the range again with some more Wolf ammo and do some more testing.

It is really fun to first shoot the Whisper or Disco in a crowded range, and then pull the big Kaboom…

T.E.

B.B.

Where or in what should an air rifle be stored in? (such as a case, on a stand, just laying on the ground or table, etc.)

Thanks

B.B.

Yes, the Edge, the Edge. And you know the natural question when the time comes for the review: How does it compare to the Crosman Challenger? Also the production delay would be interesting to address. It seems like we heard about the Edge far in advance of the Challenger, but it still hasn't come out. It's hard to construe this as a good sign.

Tunnel Engineer, so the Mosin Nagant surprises again. I've heard that they shoot quite high at 100 yards. You're in luck.

Regarding Soldier of Fortune Magazine, I read a newspaper article describing their first official convention many years ago. The reporter described one tough guy as someone who looked like he "would put syrup on a grenade and call it breakfast." This fellow approached another conventioner and said, "I love your cammies."

Matt61

BG_Farmer……yep those were the days..

https://www.youtube.com/watch?v=znrjbo9QRLk&feature=related

For BB…I uusually find myself too having trouble with carpentry work…..kinda like this man has with mechanical work….

https://www.youtube.com/watch?v=w4D6cHLRLUk

AJ,

In my case, it was a LeSabre instead of a LaSalle, but close:).

AJ,

That was too funny!!

I got a kick out of how stayed so cool and kept sniffing all the time.

-Chuck

ajvenom,

Loved the video. In fact, Tom & I are big fans of Red Green. Last Xmas, I gave him the entire Red Green Show collection. When we lived in Maryland, we saw the Red Green movie, "Duct Tape Forever," in the theater on the first day of its showing. Tom was one of the few men in the theater not wearing red & green suspenders.

Edith

ajvenom,

Like Edith said, we like Red Green a lot. And I don't see anything wrong with how he changed that light except he forgot to tape a flashlight to the fender after he destroyed the original light.

B.B.

Ryan,

Store airguns in a cool, dry place. I have a closet devoted to my collection. You can start with one standing in the back of your closet.

B.B.

Will you post the article, or a condensed version of it on the FX Revolution here a month or so after the Shotgun News issue comes out? Difficult to get to a store that has them… 90 miles away is the closest.

Am very interested in what you have to say on it.

The FX Revolution article missed the November issue, so it will be in the March issue.

I won't publish a report on it here, but I will tell you right now that it works as advertised. Fully capable of 10-shot one-inch groups at 50 yards and a surprising number of shots per fill.

Believe the advertising.

B.B.