by Tom Gaylord, a.k.a. B.B. Pelletier

Last week, I made reference to a heavy top hat affecting performance in a spring gun, and blog reader Joe asked this question:

“You wrote ‘…weighted top hat inside the piston, or the piston itself is heavy. Either way, the rifle should shoot medium and heavyweight pellets better than lightweight pellets.’

What is a ‘top hat’? Why would a heavy piston or top hat shoot medium to heavy pellets better?”

Joe, thank you for asking this question. This blog is now in its 10th year, and I forget that the readership has changed over that time. If one person asks a question, it means that many other readers are wondering the same thing and not writing in. Today, I’d like to review the main parts of a spring-piston airgun powerplant and discuss how they affect performance.

Piston

The piston is the most recognizable part of the powerplant. When the gun fires, it’s propelled forward by some kind of spring. It may be a coiled steel spring or it could be some kind of gas under pressure — whatever the source of energy is, it pushes the piston. And before anyone asks — yes, there have been guns with springs that pull the piston.

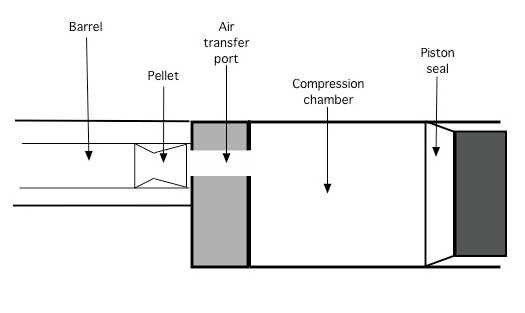

The piston compresses air in front of it as it goes forward. There is some kind of seal on the piston that keeps most of the air contained, so it compresses air very well.

The piston seal (this one is a parachute type, whose sides flare out and seal the chamber better) seals the air in front of the piston.

Tuning tip

Removing excess tolerance makes a spring gun shoot smoother. The top tuners put Teflon or nylon bearings (called buttons) around the rear of the piston skirt to hold it steady and away from the spring tube walls. The piston seal does the same thing for the front of the piston. In a well-built airgun, the metal piston should never touch the walls of the spring tube.

These small white nylon bearings on the Benjamin Nitro Piston 2 are part of the reason that rifle is so smooth when it fires!

Compression chamber

Let’s talk about something that’s dirt-simple, yet confuses a lot of people — the compression chamber. It’s the end of the spring tube, which has been closed off by a metal cap. A hole through the cap, called the air transfer port, allows the compressed air to move from the compression chamber to the barrel. If there’s a pellet in the barrel, the air cannot get past it and has to shove the pellet out of the way. This doesn’t happen until the air reaches a high pressure, which is at the heart of today’s discussion. Essentially, the pellet stays put until the piston has come to almost a full stop, then the compressed air blows it forward, like the cork from a champagne bottle.

The spring-piston powerplant is so simple that it confuses people.

Spring

We all know what the spring does. It pushes the piston, which compresses the air. A spring can be either coiled steel or compressed gas; but for the remainder of this report, I’ll be talking about a coiled steel spring because it’s the thing that relates to the top hat.

Thanks to a generous cocking slot, we can see the mainspring inside this piston’s body.

Spring guide

The spring guide does what the name says — it guides the spring. What it actually does is keep the coiled spring from twisting or bending too much as it’s compressed.

This is the spring guide. It’s hollow to allow the piston rod to pass through when the gun is cocked. The metal one is an older Beeman R1 guide, the white plastic (probably nylon) one is what they use more often these days. A lot of vibration can be eliminated by very closely fitting this guide to the inside of the spring.

When the gun is cocked, the piston comes back and compresses the spring. The spring fits up inside the piston, so it’s contained by the piston skirt as the piston comes back over it. The spring guide is a hollow tube at the rear of the spring that the spring fits over. As the spring is compressed, it tries to bend to the side, but the spring guide prevents it. The piston skirt keeps it from bending at the front.

Tuning tips

When a tuner wants to smooth the performance (the shot cycle) of a spring gun, getting rid of excess clearance is a great way to eliminate vibration. The outside of the mainspring is fitted to the inside of the piston skirt very closely. Here’s something you may not have guessed. When the spring is compressed, it also expands just a little (measured in thousandths of an inch), so the internal fit to the piston skirt has to take that into account.

The spring guide is also fitted to the inside of the mainspring. In the best-tuned airguns, the guide cannot be put on the spring unless the spring is twisted against the guide counterclockwise. Airgunsmith Jim Maccari calls that a guide that’s “nailed on.” The mainspring grows in diameter as it’s compressed. When the gun is cocked, the spring loosens a little and slips down the guide.

Top hat (forward spring guide)

Okay — here it is. You had to wade through lot of blather to get to this point, but I hope it’ll be worth it. A top hat is a spring guide that is on the front side (the piston side) of the spring. It fits inside the piston and slides on the central piston rod. Obviously, the mainspring fits over this guide, too, just like it fits the guide in the rear.

Two top hats (forward spring guides). The heavier one at the bottom was made by airgunsmith Jim Maccari for a special Beeman R1 tune that worked for heavier pellets. I wrote about it in the “Beeman R1” book.

Tuning tip

Joe — this is the answer to your question. A top hat adds weight to the piston. A heavy top hat adds a lot of weight.

When the piston compresses the air in the chamber, it can reach very high pressure before the pellet starts moving. When the pellet begins to move, the air pressure drops rapidly. Although the pressure is very high, there’s not a lot of it — pressurized air.

If the pressure in the chamber is too high and the pellet hasn’t started moving, either because of its size, weight or both, the piston can rebound off the compressed air cushion and travel backwards a few hundredths of an inch before the pellet starts to move. Heavier pellets will resist moving longer than lighter pellets — I hope that’s obvious.

By adding a lot more weight to the piston, it can resist rebounding to a greater degree (because of its greater inertia). Heavier pistons usually do better with heavier pellets. And top hats are one way to make pistons heavier. That’s why I said what I did.

Whew!

That was a quick and dirty look at the spring-piston powerplant and some of its subtleties. Don’t think this makes you an expert — there’s a whole world of things like this that I haven’t addressed.

I tend to knock up up delrin/PTFE top hats that just act as a slip washer in older 70’s air rifles, i find this works a treat. Though if i need the extra weight for the piston i will add a lead washer, these are all things i can make on my rudimentary lathe.Yet again another corker of a blog, thank you Mr B.B. Gaylord esquire for reminding me of the basic stuff i keep forgetting.

Could this teaser indicate another book from Gaylord Publishing perhaps titled airgun tuning secrets?

Maybe released immediately after the 2nd edition of the R1 super magnum?

Since they’re both semi-retired I remain guardedly optimistic about the odds of this happening.

Have a great weekend everyone.

Kevin

This would be a great idea!

Thanks, you have a great weekend yourself. Mines only just started and it’s been wicked so far, i did some busking in Cheltenham (UK) during the the gold cup race week and made enough money to buy a new chroney. Which i have to get as the old one slipped off my pile of airgun stuff in the corner of the kitchen and fell on to the hot plate of the cooker and incinerated it self, hey s~~t happens and i get to go out with my Meteor and my SMK B45-3 multi pump for the rest of the weekend.

TTFN

Wing Co Tetlington-Smythe

Old time follower but first time responder.

The tolerances that the spring tuners adhere to are incredible. I have shot TXs that have been tuned and to an inexperienced spring shooter like me the differences seem minimal. The dedicated springer shooters are quite easily able to detect the slightest twang, buzz or “harsh” reaction that would be undetected by someone like myself.

Anyone who has shot a stock TX would deem the mods. unnecessary but such is the nature of the spring fundi.

I love the blog! Learned much over the past year, as well as the archives. So… mabey in line here…

Does the transfer port determine this also. I.e. a smaller/ longer port will act as a type of spring / valve, and create a load or bounce for the piston on my .22 españia sproinger?

Meaning, would a smaller port with a heavy piston give you the kind of air pulse I get from my multi-pump or a PCP / vs. Deiseling or explosives. ( I shot black powder as a kid). My springer jumps around like my 12 lbs .54 hawken.

A total shot in the dark here, but most of the recoil of your sproinger is from the mass of your piston being accelerated to a very high speed very quickly and then slamming to a halt at the end of tube. If you pay real close attention you can feel a slight rearward recoil when you pull the trigger as the piston starts it’s journey, but most of the recoil is forward. The heavier the piston in relation to the rifle (or pistol) the more recoil.

You actually do want just a tiny bit of rebound off of the compressed air so that your piston seal is not slamming into the end and getting all buggered. There is a very distinct impression of a screw head in the end of the compression chamber of my 1906 BSA where someone was shooting it with a bad seal.

As far as the transfer port goes, it can have a major effect in the rebound, or not. That compressed air has to go somewhere. Too small of a port and you get greater rebound. Too large and your piston slams into the wall.

Some of your “recoil” can also come from spring vibration. As BB pointed out, that is one of the reasons for the tight fitting spring guide. Also, the proper lubrication of the spring helps in that respect also.

And just to make things more confusing, the weight of the pellet is a factor. If the pellet is too light for the “tune” of your air rifle, it will start forward down the barrel too soon and allow the piston to bang it’s head against the wall. If it is too heavy, it will rebound more. If it is too loose or too tight, it will also have an affect.

Did somebody ask a question?

And I love the fact that someone else has picked up on the word, sproinger!

What, you’re not confused enough? How about the location of the transfer port?

Erick,

Yes, and that’s not all. The shape of the port also affects performance. Jim Maccari did some experimenting with different shapes back in the ’90s.

Here is a 3-part report I did on them:

http://airgun-academy.blogspot.com/2008/11/air-transfer-port-part-3.html

B.B.

Great articles. I did not realise that a violent burst is better than a more controlled air pulse. In a spring riffle. My thinking went the opposite way. A small port would give a longer pulse. And give more cushion to slow the piston at the end of its stroke.

Thereby reducing the forward recoil.

Things are not always as they seem.

I love learning. 🙂

Ok BB time to pull out the Whiscombe and experiment with the transfer ports.

chris in ct,

I thought he already did that:

http://airgun-academy.blogspot.com/2010/02/changeable-air-transfer-ports.html

/blog/2008/10/the-air-transfer-port-part-1/

http://airgun-academy.blogspot.com/2008/10/air-transfer-port-part-2.html

http://airgun-academy.blogspot.com/2008/11/air-transfer-port-part-3.html

Edith

I missed that sorry. I got a example that relates to transfer port issue. My 22cal Beeman Crow Magnum doesn’t like 21grain Kodiaks/barracudas, I can feel a grunt when I shoot these, but 16grains or less it feels smooth. Same thing with my 177cal Beeman R1 it doesn’t like 16grain eunjins pellets I feel the same grunt, but 10.6grain Kodiaks are smooth. Two different power plants one gas spring one steel spring. I’m thinking that the air is getting by the piston seal and shaking the piston as it blows by.

And while BB did a thorough test to prove that enlarging the port does not give more power. he did not record the firing cycle of different weight pellets with different size ports.

My introduction to sproingers started with a little bitty break barrel a friend stumbled across somewhere. with cracks on both sides of the stock and a barrel that obviously didn’t line up with the stock. It turned out to be very accurate but under powered. Not really knowing what I was doing, I tore it down, filled the cracks painted it matte black,deburred, cleaned, polished, lubed the spring and soaked the leather seal. When I got it all back together I was astounded! While the gun still felt weak to me, it was ‘birdseye’ accurate @20m. I was putting 3 outta 5 shots inside the mouth of a 16 oz soda bottle @ 50′. I’ve been bouncin’ around the state of Texas for about 10 years now and I truly regret that it got away from me. Sure do miss that little old 618!

Another great blog on the inner workings of a spring powerplant B.B. After looking at that last photo of the extra large top hat it seems to me that in not only adds mass to the piston, but its longer length also causes more compression of the spring. Do tuners have to use shorter springs to accommodate?

It also seems like adding or removing washers between the spring and top hat could be a simple way ti provide similar tuning effects. The more washers the more the piston mass and the greater is the spring compression. I think Goat boy was referring to this when he mentioned his lead washer. You would have to be careful not to add too much spacing to cause the spring coils to bind up in the cocked position. Is this how manufacturers produce different power versions of the same gun?

I’ve read a number of times that when compressed the spring should be as close to full compression as possible and any modifications should accommodate to either shortening the spring or a longer spring if adding or removing respectively. Sounds to make sense.

Feinwerk,

Like I said, a lot of things were not in this report. Yes, that top hat does compress the spring more and the length of the spring does have to be taken into account when using it. Maccari made a spring for that top hat to go into the R1 that I was testing for my book.

Here is another report I did that includes info on measuring a mainspring:

/blog/2012/02/the-spring-piston-powerplant/

B.B.

BB, when its said not to use bbs in a rifled barrel would you say that includes the copper coated bbs? They would be a bit gentler on rifled bores no?

Off topic

RDNA,

The copper plating on steel BBs is just a flash coat, so there is no protection from the steel.

B.B.

Great link and refresher, B.B. I have a Beeman R1 ‘laser’ .20 cal from the early 90’s. Was that laser lube just copper filled anti-seize paste? I didn’t know at the time but a few years ago I acquired a can of copper formula anti-sieze paste for a job at work and it looked just like what I remember seeing inside my R1.

Good question, in my opinion. Pros- Doesn’t attack rubber, sticks to everything, slick like graphite, waterproof. Just a guess, noncombustible(Is that really a word?). Anybody got any cons? OK, besides it being everywhere.

BB, would you please explain pumpers in the same way…lots of detail but easily read. If you have have do so, would you provide the link? As well, I could use greater explanation of the various trigger mechanisms. How does pulling that one or two stage trigger get the ball/pellet in motion…given the intermediate effects on the sear,/etc? And what are the peculiarities of those few parts? Again, if you’ve already done so, a link to your previous articles would be fine.

You provide some of the nicest, clearest…and entertaining technical writing I’ve ever read. Image what you might have done for Microsoft or NASA. We would all be blooming computer and rocket scientists.

Rob

Rob,

I will look around, but all you have to do is type your question into the address bar of your browser and the search engine will find whatever exists.

For example, type in:

How does a pneumatic air rifle work

and see what comes up. I just did it and my report was ranked number 2.

/blog/2008/7/how-does-a-pneumatic-airgun-work/

B.B.

B.B.

That’s great. Sorry, didn’t think of google to find your past reports.

I’ll have a look and see if I have any qestions after reading them.

Rob

BB, if you will ever consolidate your knowledge into a single repository, I’m sure we’d all love it and want to buy it. I’m not speaking about reviews and tests, but the general knowledge and tuning ideas. I’d pop down 20 bucks quick if I could make it relevant to my own guns. I guess you’d need to throw all of that PCP info; I, unfortunately don’t have one yet, but I’d like one in the next year.

Anyway, I’m just asking you for what you probably hear everyday.

Thanks much.

Rob.

Rob,

I have been working on such a book, but I am finishing another book right now that will get priority treatment.

B.B.

Book!!

What book??

Please don’t say Kindle version only.

Inquiring minds want to know.

CSD,

Not a Kindel file — a real paper book!

B.B.

Air or powder?

I’ll buy either.

I know you’ve a wealth of knowledge on the 1911 platform…and service rifle competition as well.

CSD,

It’s about airguns.

B.B.

BB You will be the author of the most comprehensive airgun bible. Can’t wait for that, I will buy it the second its available.

That is pretty cool. I remember calling for such a thing a long time ago. Sign me up for the pre-order.

Matt61

BB,thanks for the info.I to I’m another one that wondered what is a top hat because I read guys replacing them.Sometimes one is reluctant to ask questions for fear of sounding not as up to date about something as he should because seems like everyone else knows about the subject but him. Good to know what makes my old R-1 tick.I need to get out and jump start it cause every since I have entered the world of PCP its collecting dust.Sorry R-1 owners,I promise to be a better dad and give it some TLC.

Question are always welcome Steve. That’s how we all learn. Chances are that many other readers have the same question!

BTW, I have a Beeman R1 laser from the 90’s in.20 cal. I remember being so excited when I first got it but then I was so disgusted because I couldn’t shoot it accurately! When I got interested in airgunning again in 2011, I discovered this blog and began reading the archives voraciously. I learned all about the artillery hold and what I was doing wrong. I eventually learned enough to build a spring compressor and rebuild my own guns. I bought a maccari run kit for the R1 which included a new spring and top hat. I didn’t know it was called a top hat at the time, though.

B.B. Great Blog ! Wish you would add “Email” at the end to forward. I do not use FaceBook or any other system.

Thank you !

Pete

B.B. I notice in my latest Shotgun News (3/20/14 ), a mention of Crosman Nitro Piston 2. When will that be reviewed ?

Thanks !

Pete

Pet6e,

The NP2 will be reviewed just as soon as it comes out. At the SHOT Show Crosman told me April. Now they are saying June. They know I want one to test, so I will get priority on it when it comes out.

I told them I will buy the one they send me.

B.B.

Howdy Mr. BB, sir, awesome as usual, thanx. Not suggesting that yesterday was way beyond silly, but next week can we “discuss” which color of crayon is best & are the new ones really better!?! Have a great weekend ya’ll, shoot/ride safe.

Beaz

Beazer I thought we were going to discuss new verses old erasers. How they work and if the new material was better than the old. See what happens when I skip school for a day. 🙂

Regarding Yesterday. Bradly asked about the 901. I could swear this gun had a metal receiver. I was apparently wrong because Daisy lists the receiver as Advanced Composite. I could’ve been wrong about the model but the gun I handled in the store that day was a new Daisy multi pump and it felt very solid.

My question is, Does Daisy have a current production gun that has a metal receiver or could this have been a limited edition gun?

Reb

no, daisy does not make anything w/ metal receiver, however this is just the outside, the inside is steel.

the 901 is very solid feeling.

Awesome! Thanks Rob.

There you go Bradly! Metal on the inside, I’ve read that the stock material is dense enough to be comparable to shotgun stock. Let me know how it shoots. I’d really be interested in one in .22.

Yes every now and then Daisy does make metal receivers on some off their offerings 880 lookalike models and not to be funny but their bb guns are mostly metal Red Ryder/Buck/499 Champion. Check out the Daisy Museum Store on line they all way have some sort of special edition or commemorative item.

Dumb question, but how is the spring fitted to the guide during fine tuning? Is it a matter of finding a larger guide or a smaller spring?

dd,

The guide is typically sized to the spring.

kevin

DD,

Many of the better tuners actually turn out their own guides, fitting them exactly to specific springs.

B.NB.

DD,

Another option is to use a sleeve of some sort to take up the excess clearance between the guide and spring. I used part of a soda can to sleeve the guide in a Diana 16 and a Haenel 303 – both were quite buzzy to start with. Some people also use heat-shrink tubing. One advantage of using sheet metal is you can fold out tabs on one end so the sleeve is locked in place by the spring.

Paul in Liberty County

Good ideas, Paul! I made a sleeve/liner using the plastic from a 2 liter soda bottle to go inside the piston of my old weirauch hw50 to help keep the spring from rattling against the piston interior. I hadn’t thought of making sleeves for the rear spring guide.

I have a stock tx200 that still has some buzz even after a lube tune with maccari tar on the spring. The next time I take it apart I’ll take a closer look at the fit of the spring guide and see if I think a thin sleeve from a soda can will help.

I’ve glossed this blog, hoping the “Top Hat” discussion would include the workings of the AirForce airguns. It would be nice if you would consider that subject in a near future article.

Rich,

I intentionally left out the AirForce top hat, which is an air valve part. I wanted to avoid confusion.

I’m going to be out of the office next week, but if you will remind me in a week, I will be glad to address that top hat in a special report for you.

B.B.

I almost made that reply about the AirForce top hat and figured you did not include it for some reason.

But I think that would be a great topic.

Oh and I did try that laser and scope shooting yesterday that we talked about on the topic about Why does the point of impact shift. Kind of worked out ok.

BTW I was checking out the air hawk elite review, (blackhawk elite is the same in a different stock) and it was from June 2008, and Matt61-16? Sorry, was there! Talk about veteran poster, anybody else been posting that long, besides BB, You guys should get some kinda discount. Good job everybody new and old,(posting wise) that makes this a great blog.

B.B.,

Thank you for your great article; it does clear things up. But why the heavy top hat, I mean if a steel spring piston bounces back a few 100th inch because of the heavy pellet, so what?

The pellet will shoot out of the barrel.

Joe,

When the piston rebounds, it lowers the air pressure behind the pellet, and that lowers the velocity of the pellet. That heavy top hat gives you the most power you can get with a heavy pellet in a spring gun.

We are probably talking about a velocity difference of around 100 f.p.s., which could be half a foot-pound for some heavyweight pellets.

B.B.

B.B.,

But doesn’t a heavy Top Hat also increases the recoil of the gun?

Joe,

No. In fact, if the powerplant is better balanced because of the heavier top hat the recoil will decrease.

B.B.

Everybody,

I need to find an artist who is able to illustrate a short story I’ve written about an airgun. This story will be part of a small book I hope to publish soon, and the central theme is airguns.

The artist has to be able to draw line drawings that appear to be old-fasshioned woodcuts.

Artists interested in finding out more about this project may contact me at

blogger@pyramydair.com

B.B.

B.B.,

If it’s paint by number I can help.

kevin

Lol!

I had a thought along the same lines…

The only thing I can draw are the drapes!

Hi BB.

I am a professional artist and I would love to assist you on your book. I’ve sent you two invitations to view separate sets of work of mine on Flickr. The first is of line drawings and portraits. The second is of murals and other paintings. I should have told you that I am also fluent in creating digital work. Working digitally makes everything easier when it comes to print (as I recently found out when completing some medical illustrations). Please let me know that you do…or especially if you don’t…receive them.

Rob

I expected no less from the blog. I was going to say that I just completed a book called How to Draw in 30 Days, and I’ve shown something of a flair for tracing things on my new tracing paper.

As a related point, I used to wonder about the artwork that was done on the WWII airplanes of such volume and quality. I’m talking mostly about the nose art, and the symbols for downed planes next to the cockpit, and to an extent the camouflage patterns. It seems that this was done by having a real artist cut out some kind of negative template in cloth or paper. And then the unskilled would move in an spray point onto the template(s) in the right sequence. Perhaps this is the paint by the numbers that Kevin mentioned. That I could do too.

Matt61

Hi BB.

I just wrote this but it didn’t show up. I’ll try again.

I am a professional artist. I would love to assist you with your book. I sent you 2 ‘shares’ from my Flickr site. The first is a few of my line drawings and portraits. The second contains several of my murals and other paintings. I should have also mentioned that I can work in digital media. This is very helpful when it comes to print because the work doesn’t have to be digitized, it already is. Much cleaner that way. Anyway, please let me know that you received my Flickr invitations or if you had difficulties (computers are imperfect).

Thanks much.

Rob

Rob,

Thanks, I got your submission and emailed you back.

B.B.

Imperfect?…

“I am not perfect. Merely impenetrable. I maintain my pride in the face of man, but abandon it before God, who brought me out of nothingness and made me what I am.” –The Count of Monte Cristo.

Matt61

Just a test to see if this is posted. Having problems.

BB I have replied to your call for artists and have sent some examples of my artwork. Be glad to help with your project.

BB,first give R.DNA first choice on this.I am a artist.Background is full page newspaper adds,goldsmith,woodcarver,custom gun stocks,landscape painter and portrait painter and furniture builder,and house construction with rock and logs.here is my only catch,I am all tied up until about this November. The winter months would be better for me only if your project is going on then.Plus I would be interested in the photo’s that I would be looking at to draw and hopefully good crisp pictures.Again let R.DNA have at it first because if you want it fast he could probably serve you faster. I can send you pictures of my art and carvings if you like.Thanks you,Steve

Steve,

Are you sure?

B.B.

I have drawn baths,, and guns,, only occasionally have I drawn shades,, tho very well, in my opinion,, Mostly I draw mugs and pitchers of beer and a lot of unwanted attention. If you think any of that will be of help to you,, well,, I’ll let you draw your own conclusions.

Ed

Has it been 10 years for the blog? We should have an anniversary day to mark the beginning. It’s sort of like the way that when MTV started back in the 80s, it’s very first song was “Video Killed the Radio Star” to usher in a new era.

Anyway, I’ve been around for most of the blog, and I still didn’t know what a top hat is. Actually, my only recollection of it was in reference to a pcp, but I guess I got that all wrong. I was more interested in seeing the piston seal. All this time, I’d been picturing it as a sort of thin membrane. It makes a lot more sense in the form that’s shown. But that does raise the question of what happened to my IZH 61 in which, Derrick tells me, the piston seal got blown. How could something as stout as what is shown get blown? Could air pressure be so great as to rupture it somehow? Anyway, Derrick got it fixed, and the old rifle is shooting as well as ever.

Matt61

Matt,

It’s been 9 year and this is the start of year 10.

B.B.

YesBBI’ m sure.I’d like to contribute something to the world of airguns in some way. There is only one risk with me and that would be the Fred Sandford big one cause two years ago I had the big one known as massive coded seven times so that’s all to be up front with you and there is a risk dealing with me in that respect so for whats its worth there ya go.And I would like to see some of what your wanting me to draw at first.You have my E-mail Address I believe fell free to show a few things you would like.Plus any thing I would have to e-mail you My wife would have to do at work because here at home all we can get is dial up and you know how slooooooooow that can take! She won’t mind doing for me because I can’t do it here.Thanks,Steve

Steve,

Thanks for responding, but I already have two guys in negotiations.

Thanks,

B.B.

B.B., I had asked about the copper coating on bbs and their affect on rifled bores, but what Di you think about copper plated pellets? The kodiaks have a thick jacket of copper and only copper is contacting the rifling. Maybe you’ve already investigated thus, if so disregard, but do you think there’s any significant long term affects on the bore, positive or negative? I have kodiaks that were not going so good and are now second in accuracy and shooting smoothly. I will be using them a fair amount and would like ti know if Im doing harm or doing favors. Thank you if you can help me understand more about this.

And what about using cooper coated pellets in brass barrels (old 397/392/Sheridan’s). I guess its safer to use lead only.

RDNA,

Again, that coating is very thin. Push a pellet through the bore and you should see lead breaking through at the rifling.

I have no opinion about these pellets, except I don’t use them much. Lead is the best material I have found for all rifled bores in airguns.

B.B.

Thats good to know, copper seems to be soft enough for good steel barrels but Chris in CT I think your right that brass is not hard enough. I was looking at hardness scales and they say aluminum is softer than copper, a little harder than lead. Is that the alloy in alloy pellets? An aluminum alloy? That would explain the lightweight and smooth silver appearance.. Does anybody know if that’s correct or what the alloys are?

Tin and/or antimony.

Was anyone aware B.B. will be shooting an episode of American Airgunner next week? That is so cool, Is this show in any cable outlets or strictly a web based program? I’ve refused to pay for cable for almost 4 years now, only ever wanted to watch movies and couldn’t stand the snookis and hiltons and kardashians of the world invading my brain any longer. Just about anything on cable can be found on the web so why get robbed for nothing but junk on a thousand channels. Oh and if anyone hunts and hasn’t seen Full Service Hunt its kinda graphic but really is a learning experience of shot placement! Sorry if that’s spamming, I love the site as I think food tastes better when you bring it down, bring it home and bring it to a boil.

R-dna,I haven’t had a TV signal sense the big switch and I live at the base of 350′ foot hills and no way to get a dish signal or anything over the air except radio.Folks are saying to them self’s about now, how does he stand it?.Easy I’m kinda like you.Holly wood has nothing for me these days but garbage! I am by no means apart of there world and nothing they can ever offer me or my wife these days.Hollywood has ruined this country with there TV trash and come to think of it the world also.I find it sort of funny when I’m standing at the check out lines in Kroger or were ever and before me is all those Hollywood magazines and I don’t have a clue who all those people are that made all there cover stories.So and so is having so and so’s baby but being sued by his ex”s so and so.Just what a healthy brain needs to be feed,that what mall zombies are interested in.One last thing, did ya her last week that a survey was made with the younger folks teens tru 20’s.About 1/3rd of them thought the sun re voled around the earth! these people have driver licences and some probably have concealed caring permits! OK that was fun because it is the truth.Good night all,hope the Sun rises in the east in the morning ‘or was that the west?’ O well who cares anyway if your a Mall zombie walking into walls poking at that little device.

Hey RDNA,

Amen on cutting out the cable. The Hiltdashions actually suck the brain cells out of your ears and laser idiocy in through your eyeballs. I’ve been without cable for years–happily. Replaced it with Netflix because I–like you–enjoy the movies. Found out that Netflix not only has the movies…but seasons and seasons of my favorite shows without commercials! What I haven’t found is American Airgunner. I’ve only found it online.

Yeah, the movies would rack up huge bills for on demand with cable, I said why pay for cable when the only thing good it can do is sell me movies? I can get used DVDs for a dollar and watch anything you can think of fir free online. We started collecting dvds and now can watch a movie we haven’t seen in literal years there’s so many, or grab a new movie to watch with the leftover change in your pocket. If I Di the math it would be at least 5000$we’ve saved. Plus my kids don’t think 24 hour stupidity is normal. That was another huge reason, I don’t want them thinking the crap on cable is acceptable.

For six years now I to the library and have still not watch all the stuff I enjoy like Nature,National Geo.History, etc.Not much on movies but you get about anything you want for ten days for FREE.Thousands of DVD’s of course not as up to date as a rentel but everything becomes old after awhile if your patient and don’t have to get the new release’s.May want to take advanage of it cause your taxes pay for it and the Library take my word will become just like Movie Warehouse did, extinct.Kendals,Nooks E-book will some close um up or shrink um to a downloading operation only.Hope not I enjoy the DVDs etc.

RDNA-i just got the meaning of your name. Quite the image. Thanks.

BB,

I am sure I will buy your book! Paper or kindle. Great blog!