by Tom Gaylord

Writing as B.B. Pelletier

Today’s report is a translation that describes how to disassemble a Feinwerkbau 300 air rifle. It was written for us by reader Stephan Szlosze, who we know as CptKlotz, our intrepid German airgunner. We are breaking this into 3 parts because of the large number of photos.

If you’d like to write a guest post for this blog, please email me.

Before I turn this over, I want to emphasize that disassembly of an airgun is both dangerous to the person doing the work as well as to the rifle. Do not undertake this project unless you have read and understood all the instructions.

Over to you, CptKlotz.

This report covers:

- Introduction

- Our thanks

- Tools needed for the job

- Step 1

- Step 2.

- Step 3.

- Step 4.

- Step 5.

- Step 6

Introduction

The following guide will explain how to disassemble the FWB 300 series rifles for repairs. Much of it applies to the older 150 series rifles as well, but there are some differences.

Many of the spare parts are still available from Feinwerkbau, including springs and seals.

Our thanks

This article was originally published on the German co2air forums (www.co2air.de). It was created by the users Pellet (original text guide), Paramags (additional information and FWB150 details ) and boerni (photos and forum post). They kindly gave me permission to translate their guide so people who can’t read German can use it as well. The original forum post can be found here.

Translation by Stephan Szlosze (CptKlotz). Any text in italics is a comment from the translator.

Disclaimer: If you decide to work on your gun, you do so at your own risk. Neither Pyramyd AIR, co2air.de, the authors or I will accept any responsibility for injury or damage to you, your rifle or your equipment. Please read the guide carefully and proceed with caution.

Tools needed for the job

1. Large flat blade screwdriver (5 mm blade)

2. Small flat blade screwdriver (3 – 4mm blade)

3. Needle nose pliers

4. 17mm wrench

Step 1.

After removing the diopter sight or scope, the action must be taken out of the stock. To do so, you will need to remove two screws.

To remove the stock, first remove these two screws (red arrows).

Now, the action can be lifted out of the stock. The screws that were removed can now be removed from the bottom of the stock

Stock removed.

Step 2. (optional)

Now you can start disassembling the action. The first step is to remove the trigger blade. Remove the screw shown in the picture. The blade can then be pushed forward and removed.

Remove the screw and slide the trigger blade forward and off its bar.

Step 3.

Use the pliers to unhook the spring.

Step 4.

Now the two guiding bolts at the front have to be removed.

You first need to remove the E-clip locking washer that secures each bolt. The picture isn’t very clear but you will get the idea when you see the bolts removed.

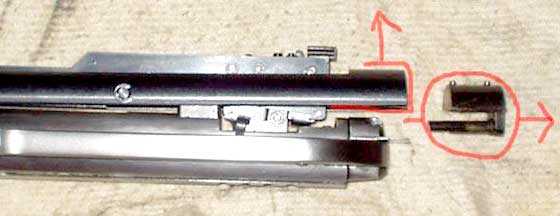

This is what the bolts and e-clip (circlip) locking washers look like after removal:

After removing the locking washers, the bolts can be pulled out towards the front.

Step 5.

Now the base (the part that is now loose) can be lifted up at the rear end of the action. This makes it possible to pull out the rear guiding bolt.

Step 6.

The base now has to be removed entirely. You need to remove another E-clip locking washer and then pull out the bolt to the side.

The base holding bolt (arrow) can be pulled out.

The base can now be lifted off.

We’ll stop there today, and tomorrow we will finish the disassembly of the FWB 300. Remember to thank CptKlotz for this information.

THANK YOU! CptKlotz! Semper fi!

Thank the guys who wrote this in the first place, I just translated it with some help from BB 🙂

I profitted from that article and now I can give something back to the community…

CK

Nice job. Looks real familiar for some reason. Oh yea I got one from RidgeRunner that looks identical to yours.

You know PilkGuns has parts also. New and used. That’s who I went through for parts for mine.

And again nice blog.

Well B.B.,

This is and is not a timely article for me, If you remember several weeks back you and some others highly suggested that I should get my hands on a FWB 300S. I have been attempting to ever since with really no luck at all. My biggest issue seems to be that I need either an ambidextrous or lefty set up. This is turning into a big hurdle.

So, I reissue a cry to you all that if you spot a FWB 300S available in either a lefty or ambidextrous configuration please let me know asap. I truly appreciate any help you can give.

In the meantime though, I am attempting a project I basically swore I would never do. I am modifying a Crosman 2240. In addtion to increasing the power via a 12″ 22 cal. barrel, increased transfer port size and stronger hammer spring with fluted polished s.s. hammer Aesthetically I am giving the gun a stainless steel look. I am trying to get the breach made of stainless or at least highly polished steel. Same thing for the CO2 tube. I have all of the remaining parts in stainless in hand. I already have the wood grips I want. Basically the only things remaining black (blued) are the barrel, grip frame and rear site. I am having trouble locating the stainless steel breech and CO2 tube. Again, if anyone has a solid lead on these two items please let me know.

I am having great fun doing this except for the frustrating efforts to locate the S.S. breech and air tube. Please excuse me for going off topic but I thought these were exciting, to me at least, times.

God Bless

G&G

G&G,

If you can find someone who is familiar with repairing FWB300 stocks, I might be able to help you with a left hand stock. I happen to have one that is broken at the wrist. The dowel is still holding it together. There are some guys who are real good at restoring these stocks.

RR,

The guy who repaired my Falke 90 stock, Doug Phillips, does target rifle stocks. They all break at the wrist in the same way.

/blog/2012/12/falke-90-test-part-2/

B.B.

I do indeed remember Doug Phillips working on your stock and he did a superb job of it.

I actually have two busted FWB300S stocks, one leftie and one rightie. I have them boxed up thinking I might send them out to be fixed some time although I myself do not need them, but someone else might.

RidgeRunner,

Unfortunately I don’t know anyone who could do that work. Thanks anyway.

G&G

G&G

Search

“aftermarket parts for Crosman 2240”

You won’t believe all the sites that come up with parts available.

I figured that was the safest way to say without maybe listing PA competitors.

And have you tryed Pilkguns for a 300s. I know a while back he had several used guns on the shelf that he was useing as donar guns.

Just maybe he would know where a left hand stock model is at.

Maybe you could buy a right hand gun and change stocks if you came up with a left hand stock. Somebody out there could of got a left hand gun for whatever reason and changed to right hand stock.

Or maybe have somebody do some custom stock work to a right hand model. Just throwing some ideas out there.

Gunfun1,

I think I have found most of the companies (people) who make those parts. I am currently talking to Cothran Machine Works and Alliance Hobby. Unfortunately neither one alone makes all of the parts required in polished stainless steel. I am looking at another option right now which would be matte finish stainless.

Thanks,

G&G

Tandwweir,

Let me make a few suggestions concerning your project.

1 Leave your sights black, much easier to see and nice contrast.

2 Use a satin finish instead of a polished one, glare is not good.

3 You can have all of the steel/SS parts blasted with glass beads to give you a uniform, non glare finish, if aluminum is involved, it will be more dull. There are two types of plating available for ferrous metals, which are very durable, industrial chrome and Armoloy. The latter is impervious to just about everything and I believe even harder than the former.

Bugbuster

Bugbuster,

Thanks for the tips. I intended to leave the sights black. I have a Williams and a LPA sight I’ll probably use.

I had not thought about the glare issue although I was aware of it. Thanks.

Again, it did not occur to me to buy the parts in a blued finish and then find someone to refinish them. It’s worth a look.

Thanks again,

G&G

Tandwweir,

You are welcome, just speaking from experience. When i used to shoot in competition, we used to blacken our sights with a carbide lamp, nice dark flat black finish, sharp sight picture, no can do on these modern plastic ones usually found on airguns! The fiber optic ones are OK, if you are hunting large animals, just not so much for real precision work.

Bugbuster

G&G

Have you thought about converting it to pcp. I know you got pcp guns. Maybe you could find something you would like in pcp for the 2240.

Gunfun1,

I’ve only got three PCP handguns and I turned two of those into carbines. However, I really want to keep this as a CO2 pistol. I actually like CO2 which I can shoot year round here. I do not like it as much as a PCP but I really just want to keep this one as a CO2.

If I weren’t looking for more power and a color change I wouldn’t even change the barrel. This one is amazingly accurate. Boy was I surprised. I wonder if this is normal?

G&G

G&G

The 2240’s I have had throughout time immediately got a steel breech and a .177 or .22 caliber Discovery barrel.

I had redot dot sights or scopes on mine. Then I did the pcp conversion. I never really shot the short .22 barrel that comes on the gun. So I don’t know how accurate that barrel is.

What kind of groups did you get out of the factory barrel? And is that as it comes out of the box and how was you shooting and what distance?

Gunfun1,

Currently I am shooting it as it came out of the box. It’s averaging 408 fps with JSB 15.89 gr. pellets. I am hoping that between the longer barrel, transfer port size increase(25%) and more powerful hammer spring I can get it close to 500 fps. I had hoped it would shoot closer to 450 fps out of the box. Haven’t tried lighter pellets yet due to accuracy I’m getting.

I have been shooting it a 10 meters and averaging 1″ groups or slightly less in a rested position. 1.25″ to 1.5″ standing unsupported. At 50′ I can usually keep it under 2″ to 2.5″ for the first 20 shots. Obviously it’s not match grade but much better than I expected. It’s as good as either my 586 or 686 and I use the factory sights with both of those. I would expect to get better as I get more comfortable with it. Still getting used to the push(slight recoil) it gives when fired. That is with the plastic grips which are too narrow for my taste.

I will try it with a red dot after the conversion.

G&G

G&G

Much better groups than I could ever think about shooting with a pistol.

The thing that I would like to know is after the conversion what results you get shooting the gun as you just described.

So keep updating as you figure out what parts you put on your 2240. And of course the results.

Gunfun1,

Well truth be told I enjoy shooting handguns every bit as much as rifles. Still better with rifles though. My son is uncannily good with handguns despite not having shot as much as I. I guess I have an inherent ability with them also.

Too bad I’m not much younger. I can only shoot pistol with two hands. I’m just too shaky one handed and not nearly as accurate. Unless someone starts shooting IPSC(is that right?) style competitions around here with air guns I’ll never be able to compete which I can do very well with rifles.

For that reason I shoot rifles much more than hand guns despite my enjoyment of handguns. I can do notably better with my Crosman Silhouette pistol than with my CO2 guns. I really like shooting that one.

G&G

G&G

I just can’t get comfortable with a hand gun. It’s like I’m always figitting around to get the right hold and I’m never steady unless I rest it.

Then there’s the sight issue.

Do you use dot sights on your pistols or maybe pistol scopes? Or other type of sights like peep sights.

Gunfun1,

There was no Reply button under your last post so I’m replying here. I use dot sights on every pistol that is a “target” gun. Those include my Silhouette, 2300S, 2300KT, P1 and P3. Those pistols I turned into carbines, 1720T and P-Rod, all have scopes of course. Jury is out on the 2240 until after the conversion. It’s not a target pistol right now.

G&G

G & G,

As has been mentioned, call or email pilkguns and ask if they have a left handed fwb 300. Here’s a very nice tyrolean, left handed for sale:

http://www.network54.com/Forum/79574/thread/1436228557

You should also call or email Jim Edmondson and let him know you’re a buyer for a left handed fwb 300. Here’s his contact info:

x.troutdr@gmail.com

Phone: 818-451-8864 PST

Date: 2015-08-05 17:27:43

I would also call or email Carel and let him know the same thing. Here’s his contact info:

Email: i.cube.i@gmail.com

Phone: 0508539193

Date: 2015-08-05 12:53:11

kevin

Kevin,

Thank you very much! I did get the lead on Jim Edmonson from another source. But, with all three I should be able to find one. Thanks!

I can not find the Tyrolean on the Yellow now, anywhere. I’ve checked July 6th and it’s not there. But I sent an e-mail to your link. We’ll see what happens. Funny thing, the Bluebook says to deduct money for left handed yet this one’s very expensive. Probably due to the stock and condition. It looks brand new. When did FWB stop making these?

G&G

Kevin,

When I send a reply to your link the post for the FWB disappears. We’ll see what happens.

G&G

G & G,

Don’t reply to the post about the left handed tyro lean stocked FWB 300, send the owner an email to find out if it’s still for sale. His email address is,

lgrable02@gmail.com

I think Feinwerkbau quit producing the 300 in the late 80’s. Here’s a link to determine the age of a gun based on its serial number,

http://www.network54.com/Forum/405945/thread/1389519214

kevin

G&G,

Do you have a copy of the Bluebook for airguns ? For the 300, the left option does seem to have been offered. It says subtract 10% for that. Odd, as I thought that left’s were more valuable. At anyrate, it has been mentioned that a used guns worth is really based on sale history, past and present, and condition of course. I can copy the BlueBook info. in a reply if interested.

Being a lefty (rifle) myself, I can relate to the lack of left and ambi. options. Best of luck in your search.

Chris,

The reason they are worth less is they are harder to sell. I am a lefty myself, however I was taught to shoot right handed. It is very awkward for me to shoot left handed.

RR,

For the TX200, it say’s to add 150$ for left/walnut. Believe me, you pay that and then some for a new left/only offered in Walnut. You are right though,…I bet they would be harder to sell. Then again, there would be fewer made. Supply and demand as well as past and current sales $,…I suppose are the “rule”.

Thanks, Chris

Chris USA,

That’s good to know about the Left Walnut TX200. I have one.

G&G

Chris,

I am semi-ambidextrous doing some things left handed, some right handed and some both ways. I shoot handguns right handed and rifles left handed. I just do whatever feels natural.

G&G

Thanks Stephan!

Great stuff!

I’d like to ‘do’ the action of my 1976 300s. Theres some rust and pitting on the barrel and action. Im planning to use scotsch brite to take off all the imperfections.

Does anyone know with what I can ‘do’ the action with?

Is there some sort of paint or coating witch will last for ever?

You could go with an epoxycote or ceramic or ionized finish, they stick pretty well but most require baking for best results

just a few options.

Thanks!

That looks like some pretty user-friendly stuff that Vana2 shared there.

The last product I tried didn’t cure completely and left traces on my hands while reinstalling my exhaust manifolds so I really like the low baking temp.

Hi Dutchjozef,

I have been thinking about refinishing my Crosman 101 with a product called Duracoat. Its a two-part epoxy that is sprayed on with an aerosol can.

Here is a link:

http://www.duracoat-finishes.com/

Yep, that seems to do the job. But I cant find dutch shops selling the coat. Maybe I should order it from the us

I’d have to order it myself.

Nice!

CK,

Great blog. Love the pics. Looking forward to part 2.

Pete

I’m amazed at this knowledge and ability. But PA has no need to worry about liability from me as I would never think of disassembling an airgun. I was amazed at the stiffness of the IZH 61 spring which felt like a solid piece of metal with no give. The force it could generate when compressed would be considerable, and one can only imagine scaling that up to a high powered spring gun. I recall that when B.B. was disassembling a spring gun of no great power, a piece flew off that could have broken his arm if it had made contact. And then there is Duskwight who told me that the giant spring on my B30 is restrained by some small part from flying backwards into my face. 🙂 So, I will admire from a distance.

Vana2, your friend is lucky to have such a teacher. I myself have never seen directly the near and far zeros of airguns. Do they fall within 100 yards? I would think the far zero is beyond that for the more powerful guns. That business of tracing the trajectory through targets at various distances is something done in Frank Mann’s comprehensive tome, the Bullet’s Flight from Powder to Target. Even without that set-up, I was astounded that I could see the trajectory of pellets from my Walther Nighthawk and Crosman 1077.

Ridgerunner, going from a tiny hole at 25 yards to 4 inches at 50 yards sounds like more than range probable error. Apart from something external like wind, I wonder if some guns just lose power faster over distance. You here about “self-compensating” guns that get more accurate with distance although I don’t know how that can be physically possible. But at least for firearms, I suspect variations in range performance are more the result of different twist rates and cartridge loadings. I don’t know why your Gamo would vary so much.

Dutchjozef, I believe you were telling me about Sean Connery’s airgun used for the James Bond promotion. Is that right? Here is another question for you. I just saw a YouTube video where Connery is forced by M to give up his old Beretta in favor of the Walther. Any idea what model Beretta that would be? 🙂 It certainly wouldn’t be the model 92. However, the whole thing may be made up. Q, in praise of the Walther, said that its 7.65mm cartridge hit like a “brick through a window.” (!?) Wouldn’t this be the .32 caliber, among the most anemic of firearms?

Matt61

Matt61

I worked with an ex cop when at Harley that had been shot several different time by criminal with either 25 or 32 caliber round while wearing his very heavy leather Harley made jacket ( a 35 to 40 pound leather jacket ) and stated this was before bullet proof vest for law enforcement back in the 70s and while he was bruised and sore the bullets just bounced off the jacket without the slightest indication of any penetration even having occurred to the leather.

So yes if you plan on using a 25 or 32 for anything other than just plinking as that’s about all they are good for just make sure if you shoot at someone with them they do not have on a leather jacket because if they do you may just have a much angrier individual to deal with than they were originally.

Disassembling and repairing a high powered spring gun is not that difficult or daunting of a task if you just use common sense and the proper tool to do so. I will say my 50 years as a auto and motorcycle technician gave me a head start as to the knowledge required to work on air guns safely as I have changed out more MacPherson strut springs and plain old coil springs on cars that are under far more tension and capable of far more serious injury potentials than any air gun could ever be without any injury to my self or others but again it was with proper tools which makes all the difference. I made my own homemade spring compressor out of a 2 x 8 and an 10 inch c clamp with the fixed end cut off and bolted to the 2 x 8 to compress the springs and then just make whatever adapter required out of wood or delrin to secure the guns action and push on the rear spring guide to compress the spring and remove the retention pin or screw to take it apart. So with common sense and some home grown ingenuity it can be done safely and easily without harm to yourself or others.

The first spring gun I rebuilt was a RWS 54 and I did it without the aid of a compressor, but then my fairly heavy body weight ( 205 pounds at the time ) and a leather glove to allow me to get all of my body weight over the end cap allowed me to compress the spring and push to retaining pins out with a screw driver and release the springs tension safely although my compressor makes it much easier now for sure but I still would not hesitate to do it by hand if that was all I had on hand and in 50 years of being a technician I still have all my fingers and toes and never filed a worker compensation claim as I have never been hurt at work .

If you are not comfortable doing the work though by all means do not attempt it as magnum spring guns can hurt you easily and badly if not worked on safely.

BD

Matt61,

It is a useful and fun exercise to plot trajectories – I have done it for arrows, pellets and bullets.

The near-zero, mid-range and far-zero are determined by a number of factors… velocity, BC, weight and the distance the line of sight is over the line of the bore. Yes, under 100 yards for airguns, typically between 20 yards for near-zero and 45 yards for far-zero – give or take a bit.

I don’t have numbers for an air rifle with me but as an example, I use a plus/minus 2” kill-zone for my 30-06 (150 grain, 3070 fps, 1.5” scope height). That makes my NZ 40 yards, the MR 130 yards and my FZ at 215 yards so my point-blank range (the theoretical “no compensation range” to keep the POI within 2” of the POA) is 250 yards. This means that if I aim dead center on a groundhog at 250 yards I will hit it without needing to compensate. At that range I put the crosshairs on the top of the groundhogs nose and get center chest hits.

For my air rifles I use a plus/minus 1 centimetre (3/8”) kill-zone and work backwards from there to determine my NZ,MR and FZ ranges.

The Chairgun software ( freeware from Hawke http://www.hawkeoptics.com/chairgun.html ) is great because it shows you the curves for the parameters you enter.

Matt,

James Bond’s was Beretta M1934 in .25 ACP.

A couple of funny things:

Maj. Boothroyd, who gave JB his PPK in 7.65 (played by longbarrel PP in .380 in the movie) was a real person. He wrote to Ian Fleming that his choice of weapon was not very good and proposed PPK – same size, less weight. more stopping power. So he was put into the novel and movie. In fact Beretta failed Bond in “From Russia With Love” which precedes “Dr. No”.

In Soviet cult classic comedy “The Diamond Arm” it’s given to a completely pacifist main character for self-defence. An obvious nod to 007 movies.

duskwight

The old James Bond pistol would have been a Beretta Model 950. The writer Ian Fleming was no gun guy so it’s no surprise that he wrote that the .32 ACP was a powerhouse. That said, either the .25 or .32 will kill you very dead if you are shot in the head with either at close range. Those that say they won’t haven’t seen the elephant.

Mike

Correction, the Bond gun was a Beretta Model 418.

Mike

BB,

thanks for looking over my translation. Now I know the term “e-clip washer” 🙂

You removed the “(optional)” for step 2. Was that an oversight or did you feel it was better to just remove the trigger blade so it doesn’t get damaged?

Stephan

Stephan,

That was an oversight. I will put it back in.

Thanks,

B.B.

Ok, thanks…

There’s one more thing that got me wondering…

Is a 17mm wrench a common item for Americans (or people in other countries)? We are totally used to these metric sizes but what about you folks?

Is there a suitable wrench in a typical set or is there a danger of ruining the screw with a tool that “almost” fits?

Stephan,

Metric wrenches are fairly common over here. I bought mine in the 1960s. 14mm is the most common size and is nearly the same as 9/16″.

B.B.

CptKlotz,

Critical to use the proper size wrench.

Very common for us on this side of the pond to have metric and standard (SAE) sizes of tools.

Thanks for translating this disassembly.

Kevin

Stephan,

Thanks for the guide. I checked it against my experience with 300S and it seems to be exactly the way you describe it.

However I’d add something to your toolkit from my own experience:

A wide flat blade screwdriver for big screws in the stock (it hepls not to ruin the slot) 8 mm wide

Some plastic/brass punches/rods for working with pins.

Small plastic or wooden mallet.

An awl or special tool for e-clips, removing them with small screwdriver may end in e-clips jumping off 🙂

A bottle of blue Loctite for lever screw/pin when it comes to reassembly.

A degreaser spray or acetone for cleaning trigger mechanism and guiding bolts

3 drops of full synthetic motor oil – for lubing guiding bolts and almost half a drop for servicing complression ring.

duskwight