by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- It begins with lead

- Lead becomes wire

- Wire becomes balls

- Clean and lubricate

- Swaging

- Hot off the press

- Production begins

- Pack and ship

Airgunners are naturally curious, and when it comes to their ammunition, their curiosity piques. Today we will take a look at how JSB, the Czech Republic pellet manufacturer, makes pellets. This report was made possible by information and photos supplied by JSB.

It begins with lead

The process naturally begins with lead — a lot of lead. JSB buys lead in ingots that are at least 99.97 percent pure. They melt this lead and add a small amount of antimony for optimal hardness and to prevent rapid oxidation. This process is entirely controlled by them so they know the quality of the end result.

It takes a lot of pure lead ingots to feed the pellet manufacturing process.

JSB alloys the lead to their own specifications in-house.

Lead becomes wire

The melted alloy is cast into lead wire, which is the most common form for lead that’s going to be swaged into diabolo pellets. The wire comes out in different diameters, depending on the weight of the pellets they want to make. But JSB adds another step in the process at this point.

Wire becomes balls

They chop the wire into small pieces with very precise weights. Most pellet makers would then swage these pieces, called preforms, but JSB adds one additional step. The wire pieces are turned into balls before being fed into the swaging machine.

JSB calls the balls semi-finished products and they make them in weights that range from 0.475 grams (7.33 grains) up to 5 grams (77.16 grains). These correspond to the pellets that will be made.

Lead balls are swaged into pellets.

Clean and lubricate

The semi-finished products (balls) are then cleaned and lubricated prior to swaging. Some are sent to an extremely precise scale and weighed to a sensitivity of 0.0001 grams (0.015432 grains) for further sorting. This scale is extremely expensive and has a limited capacity, so only the JSB Exact and Premium Match pellets are processed on it.

Swaging

Now the lead balls are fed into the swaging machines. Each machine die has as many as 10 holes for pellets and only one lot of pellets is run on one machine at one time. There are 54 swaging lines in the factory. If any of the tooling has to be changed, the resulting pellets fall into a new and different die lot.

You must also understand that each die is unique. Even if it makes a pellet they have other dies for, each die produces slightly different pellets and it is the lot number that controls this. Pellets are kept in the lots in which they were made because serious competitors demand such regulation.

I would love to show you what this swaging machinery looks like, but JSB considers all of it highly proprietary and secret. They build all of it in-house and will not show it outside the company. This is not unusual. I encountered the same secrecy on Crosman’s pellet line years ago.

Hot off the press

Before the company commits to a production run, freshly made pellets are taken to their test range and tested for group size. If the pellets pass the test, the production run starts.

Each batch of pellets gets tested for grouping before the production run begins.

The test range is automated to speed things along. Undoubtedly, JSB uses this facility a lot!

A push of the button and the target frame returns for evaluation. Each batch is checked this way.

Production begins

Once quality control announces success, the production run begins. From there the output is 100 percent inspected by one of 22 female inspectors. Nothing passes unless they say so. Production moves rapidly, producing great quantities of pellets to be inspected.

once production starts, the pellets begin to pile up.

Now is where those 22 inspectors come into play. They look at each pellet for imperfections and only the best make it into the tins.

Hand inspection of each pellet ensures high quality.

We don’t think about the rejects a company like JSB might see, but that’s because the inspectors remove them from the batch before they are packaged. JSB has a reject rate of 2 percent. Those pellets are remelted to go into a future batch, and what we see is what passed their test.

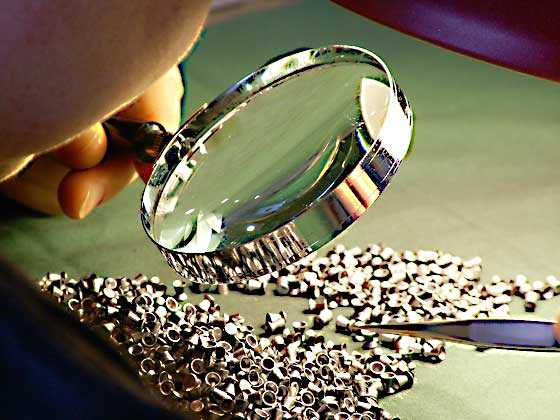

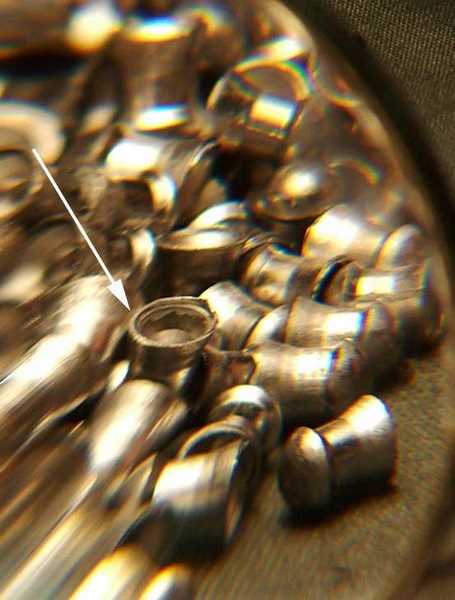

This look through an inspector’s magnifying glass shows what they are looking for (arrow).

Pack and ship

Once the pellets have passed the inspectors’ gauntlet they are packed and readied for shipment to more than 50 countries around the world. Pyramyd AIR receives JSB pellets on wooden skids on hundreds of tins per skid. One can only imagine the number of labor hours that go into such a shipment.

After inspection the pellets are loaded into tins, weighed and sealed. Then they’re ready to go to over 50 countries around the world.

BB

Very cool. I read it and it was over before I knew it. It felt like I wanted to read more about it.

And I don’t know how them inspector ladies can do that day after day. I would be seeing cross eyed before half of the day was over.

Interesting, B.B. – after all my study of pellets, JSB are still my favorite. Interesting to note, the final stage involves a manual inspection. It is likely that they are like most inspectors, not perfect. But good to see that they do have some automated weighing in the process.

Thank you for this report! I have been in the precious s metal business in passed! Recovered a lot of lead, silver etc. And might mention I sold tons of lead! Have made shot for shotguns etc. and so on! I’m still retaining several tons of lead! I know of a few shooting clubs that prefer the lino-type lead because it is stronger harder lead! They make their own pellets! Semper fi!

Thank you again BB for explaining another branch of our wonderful airgun hobby.

I did find one they missed in my first tin of Monsters, it musta been heading for one of their lighter dies because it’s only about1/2 the size of the rest

I’ve got a Golden ticket!

To the Wonkavator. 🙂

Hahahaa, nice one Reb!

I still like that movie!

One of my favorites as well and an all time classic.

Reb,

A mini-monster ? Maybe a new type of sampler pack ? 😉

It looks like they roll those balls into the half of the die that forms the head and then press a skirt into it, that explains the “perfect ” hemispherical domes.

Hello BB and Fellow Airgunners

What a nice surprise to see my favourite pellet manufacturer highlighted in todays blog. I also use pellets from most of the major manufacturers, however I usually reach for the JSB’s when I need to make a head shot on a starling at 30 meters. I have come to rely on them for their superior accuracy. As your article states, they are extremely uniform from pellet to pellet. It’s good to see they still rely on humans to weed out the pellets that are flawed in some way.

You begin the blog by stating JSB’s are made in Hungary. I looked at a half dozen tins, and they all say “Made in the Czech Republic”. A seemingly insignificant error, but because I have relatives in the Czech Republic, I’m sure they would want me to point this out.

Ciao

Titus

Titus,

That’s what happens when I don’t have Edith editing me!

Thanks for the catch. Czech Republic.

B.B.

B.B.

Thank you for this very interesting one. I now use only JSB Exact Diabolo pellets for all my shooting. I also have a few tins of Predators for big kills. I favor the Exact cos of the consistent accuracy. It also has very good knock down punch in a magnum springer. I often wonder how the heck JSB does it. Well, now I know!

Sir, if you feel up to it, would you please do an article on the life & times of Ms. Edith. With your eloquence it would be so good. It would be a great way to honor her memory & the immense contribution she made for us all.

Errol

Errol,

I will do that — I promise. Give me some time.

B.B.

B.B.

Thank you so much Sir. Take all the time you need. God Bless you.

Errol

That’s a great idea if B.B. is up for it. The few tidbits that Edith passed on were quite tantalizing like her dates to shoot in junkyard, and her fascination with tennis.

Matt61

It was very interesting to learn about the manufacturing process. I can only speak for myself – I would very much enjoy more blogs based along how items are manufactured/repaired/serviced. Thank you so much for the blog subject. Great stuff.

Nice report. Nice look at the factory and test range as well. I would think that all of us would like to think that all pellets are done this way, no matter the brand, no matter what your guns “likes”. But alas,…

Really, it is amazing that pellets could be shipped that far and arrive in the pristine condition that they do. It really is. Of coarse PA does their part with their fine foam block packaging. I have yet to see a bad tin from them.

As it turns out, I have 2 types of Exacts. Mmmmmm,…..I guess it’s me after all. 😉

B.B.,

I enjoyed reading this report very much.

Thanks

Thanks B.B.! Very interesting read!

I would like to see pictures of the swaging die if they are available. Curious if it is single or multi-cavity.

Vana2,

The swaging process is a secret in this and in all pellet making companies.

I mentioned in the report that there are up to 10 dies holes (depending on caliber) in a die.

B.B.

Sorry, I missed those details when I was skimming before starting work this morning. I re-read at lunch time when there are more comments to view.

I was thinking… have a 6-ton log-splitter, could use that for swaging and around 50 pounds of wheel weights that would make a lot of pellets… naw, will stick with the JSBs – my rifles have a strong preference for them. 🙂

BB,

cool report. I always liked the childrens’ TV shows where they showed how machines work or things are produced.

I wish there had been more pics of the tools and machines but I can understand that JSB need to protect their “know how”.

I wonder why the raw lead is such a peculiar shape. Why not a simple block?

Another thing: You still have the “FWB 150 vs 300” addition for the disassembly guide. I guess that will fill one blog nicely.

I *could* write down some of my experiences with my 300S, but I fear I’ll repeat things that have already been said a thousand times and bore the readers.

I won’t do a reassembly guide because I don’t want to mess with my rifle again. I also don’t have any material I could translate. Besides, I think doing all the steps “backwards” should work fine. It did for me and I’m not a master mechanic 🙂

So, unless folks really want to know something specific (that I could answer), there’s not much point in doing a part 4.

Stephan

Stephan,

The 150 is planned for later this week.

B.B.

Yeah, the question is just whether there is any additional info I should provide. The more I think about it, the less I can think of anything interesting to write that hasn’t been written before by you or other people 🙂

I guess we can post the 150 report and be done with it. Everything else is available already.

Stephan,

Okay.

B.B.

Stephan,

There’s a couple of tricky things about reassembly and some people can get it wrong. First the safety ratchet must be set in place in piston chamber correctly or else you risk damaging your airgun. It cannot be done simply inserting your chamber. Second – leaf spring that blocks trigger must be put inside the right way or it can be bent if placed incorrectly.

Shape of lead blocks is due to the requirement that is should easily leave the mould and properly set down when it cools. That’s why it’s “conical”.

duskwight

The part about the leaf spring is covered in the guide that I translated.

I don’t remember whether I had trouble with the ratchet. I don’t think so and I certainly can’t explain it.

If you can explain it in detail, maybe BB can add a note in the report.

Well, on assembly people tend to overlook what was written in disassembly section 🙂

I met several jammed FWB 300 with a long scratch on the belly of a sliding chamber. People assembled their rifle without checking that the sliding chamber is connected to the ratchet the right way – construction allows it – and tried to cock the airgun. Consequences were quite predictable. So there must be a note for reassembly – to check that ratchet and chamber are connected, ratchet’s tooth must be inside chamber’s square hole.

Duskwight

That rachet placement in the cylinder notch is one of the reasons I asked for a assembly instructions.

And while we’re talking about the 300 what kind of lube do you use on the front pins for the sliding action.

Can anyone help with the placement of the ratchet on the FWB 300 when assembling?

B.B.

Well… I suppose if there’s so much interest in this and nobody is planning to work on his 300 anyway, I *might* be bothered to look into the ratchet thing.

I won’t open up the power plant again, though 🙂

Maybe we can pool our knowledge for a kind of “everything you need to know about servicing and assembling a FWB 300” report.

B.B.

I’ll try, this week I might have one on my hands that needs service anyway. Or I’ll just field-strip my own gun.

Meanwhile I’ll use links to pics from another site to explain, I hope B.B. will forgive me for doing that, as I use them for public good and with no intent of owning them or making any kind of profit from them. All rights to the pics belong to their respected authors.

http://popgun.ru/files/g/96/thumbs/2401396.jpg Here the said notch is a rectangular depression in the left side of a silver detail that’s visible in the slot.

On this photo the tooth is right below “p” in word beartrap: http://www.pilkguns.com/tenp/fwb300step7.jpg and notch is directly above it, not well pictured.

Same stuff on this pic: http://www.pilkguns.com/tenp/FWB300S_10.jpg but in another order – tooth pops out in the middle of the upper side of a black rail at the very top and notch can be seen to the right inside the slot on the cylinder below.

So when you reassemble your FWB 300, pay attention and before you screw on the rail, make tooth to fit inside the notch to avoid aforementioned trouble and damage.

duskwight

Duskwight: Thanks for the link.

Now I remember. The piston and ratchet being what they are, I think it was immediately obvious to me that they need to be in contact like that.

That site seems to be pretty useful anyway. I found some interesting pistol shooting tips that I mentioned a few days ago.

Maybe if we ask nicely, we can get permission to use the pictures 🙂

Maybe you can try to get permission to use those pictures and I could ask Feinwerkbau about the lubrication… Perhaps we can gather enough material for a part 4 afterall…

Is there anything else anybody would like to know from FWB?

Stephan, we’d like to know ‘ factory inside information’ ….. being info that’s not regularly posted on the web. You know…. designers info….the proces… und so weiter:)

CptKlotz,

2 armed men are the embodiment of politeness when they ask for permission from God knows how many other armed men 😉

In my main line of work there’s a sort of a rule: obvious things need the most explanation. In 90% of cases obvious is obscure for everyone except for the speaker. I’m trying hard to follow it sometimes three or four times a day myself.

duskwight

duskwight,

That picture clears everything up for me. Assembly is a parts alignment issue.

B.B.

Gunfun,

In my experience, you can use some synthetic motor oil – it sticks good to polished surfaces and all you need is almost half a drop per pin, 2 front and 1 rear. The same oil (but even less amount) can be used to lube the compression ring. Less is better in that case.

duskwight

Duskwight

Thanks for that tip. And I use a few drops of transmission fluid down in the transfer port hole. It will keep the ring seated to the cylinder a little better than motor oil.

Let me know what you think.

Gunfun,

I have no experience with that, so I cannot recommend and would rather avoid unknown solutions. Primarily due to the the fact that it contains a lot more chems – that can affect plastic seals – and I doubt that it’s made to retain its lubricating qualities in high pressure/high temperature conditions that are present in engine or springer piston-cylinder pair.

Anyway, less is better. Get some on your finger and rub around the ring, that’ll be more than enough.

duskwight

Duskwight

That’s true how could you recommend if you never tryed it.

That is what we done with engines before start up. Helps seat the rings quicker and it doesn’t take much at all.

I do it about every 2 tins of 500 and only a couple drops. And that is on the FWB 300 only since it uses a cast iron ring. Now chrome moly rings that’s another story.

And remember there is no seals on the 300 piston. There is a plastic round bumb stop on the front of the piston. More than likely 2-3 drops would not harm it. But that’s something that would need to be checked after time.

And thinking about that now maybe if there was a assembly instructions blog done maybe lubricants should state to use only factory recommended lubes. Since so many people have their own idea of what they like to use.

Gunfun1,

And what about synthetic piston seals ? What do you recommend there ?

That’s the kind of stuff I try to find before committing!

So that’s what flies towards my targets 🙂

I always bring a sausage back with me when I’m visiting Czech Republic. To me they are a universal standard – there’s practically no airgun that “doesn’t like” them. They give at least good performance in any properly-working airgun. So if a system performs badly, that means something is wrong with the system.

duskwight

For airgunners obsessed with accuracy JSB pellets are among if not the favorite.

I’ve always been curious as to why JSB occasionally changes the graphics and colors on the tins/containers of their pellets. When they do this airgunners go berserk wondering if their favorite pellet has been changed along with the tin.

I find it interesting that, “Before the company commits to a production run, freshly made pellets are taken to their test range and tested for group size. If the pellets pass the test, the production run starts.” Looks like a Steyr in the 4th picture that they use for testing pellets for group size. Even a Steyr is pellet fussy. They must have lots of guns they use since they produce multiple weights within every caliber and they produce multiple calibers of pellets.

kevin

I had to smile at all of the dents in the target frame.

100% manual inspection – that must make for a heavy (pun intended) days work!

I’ve done inspection of wired assemblies, mechanical parts and printed circuit boards (bare and assembled) – it is amazing how quickly the mind will filter what the eye sees and draw your attention to something that is different that the rest.

Would still be tedious to look at so many shinny objects for so long.

Like when hunting… bush, bush, bush, ear, bush – hey! There is a deer attached to that ear!! 🙂

And now for something completely different…

I’ve mounted a red dot sight on my HW45 just to see what it’s like.

It actually seems to help a lot. Not having to align the sights seems to free up brain capacity for proper holding and trigger control.

It seems I finally got the “Col. Bonsall” method to work (maybe the added mass of the sight on top of the barrel helps, too). I finally got my shots to form something resembling a group. Pretty cool 🙂

So, the Czech Republic strikes again. They are the ones who make the CZ pistol that I have my eyes on, so they are doing something right.

This description of pellets raises a long-standing question of mine of just how modern manufacturing produces things of such great variety in such great quantity. Looking at the interior of a car with all of its unusual shapes and sizes down to the tiniest detail, you wonder what process could produce it. The same thought occurred to a Roman gladiator in a novel who was preserved through freezing and reanimated in modern times. He is amazed at how the barbarians are awash in iron and how they can produce so much of such uniformity.

I can see the lead ingots being cast into a wire then chopped up with the pieces shaped into balls. Those are simple shapes. But how does the ball get turned into a pellet with the flared skirt? Presumably that is part of the mysterious swaging process and something that JSB wants to keep secret. What is with the all-female inspection team? Sexism! 🙂 I would say that this is a punishing job. It sounds like the job of a relative of mine who spent her career on an assembly line inspecting the taillights for cars. She said it was hard work. The pace was fast, and the company would come down on you for errors. In the pictures it looks like the inspectors have all the pellets in view but don’t separate them to look at every last one individually. One also wonders how the inspectors are checked to see if they are goofing off. The accuracy test sounds like much more fun, but it appears to be completely automated. Anyone recognize that test gun? It looks pretty impressive.

ChrisUSA, you are off the hook with your group size. If you are just excluding called flyers, then you are fine. The statistics only apply where there is no systematic intervention like a blown shot. The only problem would be in going back to a group without called flyers and selecting sub-groups.

Matt61

Matt,

Test gun is Steyr LG100 I believe.

And there’s no sexism. Women surpass men when it comes to seeing difference between many similar objects – a part they are better as spotters and snipers. They have softer hands and they are much more patient than us when it comes to tasks like that. Ask Mother Nature why 🙂

I had a diamond facility near my school – actually a federal diamond facility and they had a constant demand of girls aged 18-25. Keen eyes and soft hands with slim fingers, feeling slightest mistakes in form and able to manipulate and sort palms of diamonds as well as single tiny ones.

duskwight

That’s quite an advertisement for a gun to be the test gun for JSB pellets.

So, the selection of women is part of the idea that women are more perceptive than men. Don’t say that around academic feminists. 🙂 Nevertheless, I expect that you are right. It also explains footage I’ve seen of women working in armament factories during WWII in Russia and elsewhere. No doubt that filled a need left by men who were drafted, but maybe they were just better at the work.

Matt61

Matt61,

🙂 Whew,…I was worried there. Thanks for the reprieve !

On “called flyers”, what is that exactly? Do you call it (before) the pellet hits ? or,…is it a choice you make (after) the shot hits ? Follow through and keeping the eye on the target, after the shot,…I find that most of the time that I know (before) the pellet hits that I messed up. It’s an instinct, but one I am still working on.

Do you call a “flyer” after or before the shot hits ? If before,…you better be pretty darn quick about it !

And yea,….I try to keep it on the “up and up”. Actually, it would make a good topic. Speaking from experience, as a new shooter, I beat myself up pretty hard on group size. The more I learned,…and shot,..I learned when a shot was on and when it was not,…(before) it hit. Call it “timing the wiggle” if you will.

Thanks,…Chris

Chris,

I am surprised to see your question about called flyers. Are you not aware that a shooter who watches the sights at the moment of firing can do this very accurately? I am not trying to be snotty about this — I’m really curious that you are asking about it.

Do I need to do a blog?

B.B.

B.B.,

I do not recall “called flyers” ever being explained. As you read, I have been able to pretty regularly “know” when I “blew it” (before) the pellet hits. But, being new, it’s still an “instinct” I am still learning.

I was just curious as to the “proper” use of the term and it’s real life application.

So to your question,…yes. I think it would be a good “learning step” for new shooters. After all, if a new shooter can’t get the 1/2″ groups at 50 yds. that they read about other shooters doing,…then they may get discouraged and quit. I came about this realization on my own, analyzed it, and decided to cut myself some “slack” and do the “make up” shots. Being “a bit” older, I did not give so quick.

If you read the back and forth between Matt61 and me yesterday,.. 😉 it will give you a pretty good idea at how I arrived at my current mindset.

Thanks,…..Chris

Chris USA

Above you asked about what I would use on synthetic seals.

I like the RWS silicone oil. That way I can use it in my springers and pcp guns.

And you know how it goes thats just what I like. I’m sure people have their own favorite lubes to use.

GF1,

I got a bottle awhile back on one my orders,…Factoring in 3,000+ shots, 2 tunes, when do you think the TX might need a drop or two ? I did use a light coat of white lithium on the tunes. The LGU ?

Can’t for the life of me remember who told me to do that…… 😉

By the way, no smoke or “cracks” with the 12fpe- tune,….the HO had a “few” and smoked for a “few”, despite the same light application. Mmmmm.

Chris USA

About the only time I will put the RWS silicone oil into the transfer port hole on a springer is if I see the groups change. Basically the group gets bigger or if my poi starts dropping. Pretty well works out like how I talked about a few drops down the barrel. If you oil the transfer port hole it will blow some oil into the barrel. It will clean itself out usually after 10 shots at the most.

And I said this before. I don’t do this everytime I’m shooting bad groups. I will only do that if its been a long time since I done it. Could be up to 3000 shots are more. You just got to watch what the pellets are doing at the target. If you shoot a gun long enough you will know how it acts. And you have to be aware of how the gun groups. If it changes and all other variables are pretty much the same. Then it could be lube time.

Chris USA

Oh and yes the white lithium grease when I do a tune. I use it on the spring and the plastic spring giude. A light amount on the seal and cylinder wall.

It’s worked fore me.

Chris,

Okay — that was what I was hoping you would say. I don’t like to belabor the fundamental things too much, and it’s hard to know when I’m doing it. But if you don’t know than there are hundreds of others who don’t comment who are in the same boat.

I will do a blog on calling your shots.

Just understand that the ability to call shots has little to do with shooting half-inch groups at 50 yards. Though I’m sure there is a connection.

B.B.

B.B.,

I am happy to get 1/2″ at 25 or 30…… 😉

I guess the general sense is there is a “learning curve” that is long and sometimes complicated and that a “newbie” should realize that and not beat themselves up too hard.

That’s hard, real hard,… for someone that has not shot all their life. It is reality though. And it is also a reminder to pay respect to those that have and that are “good”,… or even “great”. They “paid” their “dues”. Best advice of all,…try your best to learn from them.

And yea,…while I did not know the exact application of the term, I am learning when I “messed up”,….most of the time anyways.

Thanks,…Chris

Not to worry. I wasn’t going to tell on you. 🙂 I didn’t realize that you are a new shooter and assumed many shooters here who have shot for their whole lives. I also met one such salty shooter at the range. While casually smoking a cigar on the firing line, he explained how he has been shooting for the last 50 years and that he currently has something like 40,000 rounds of ammunition in storage. When I asked him where he put it all and how he safeguarded it against wildfires, he explained that he had built a shed made out of a material that sounded like pvc something and coated it with 10 layers of fireproof paint and that you needed to go through four locked doors to get to his supplies. I have to admit that he was shooting very accurately with rimfire pistols offhand at 25 yards, almost on a level with Lt. Col. Bonsall.

Anyway, are you new just to airguns or to shooting generally. Being new to the sport has its charms as well as being experienced.

As for calling your shots, I’ll defer to B.B. for a detailed explanation, but I think you grasp the basics. When you release the shot you know whether you used proper technique or if you pulled it. So, the “called” part refers to knowing you screwed up before looking to verify in the scope, but not necessarily before the shot hits the target.

As for how one can know this instantaneously, that’s a mystery that I’m not sure anyone can explain. I expect you are right that it is connected with follow-through which is itself a paradox. How can what you do after the shot affect its accuracy? My Dad still doesn’t believe it is possible. I can’t really explain, but I think you can perceive this in relation to shot technique which is a conscious act. Knowing what you are supposed to do with follow-through and the rest of it means you should know instantly if you failed in your intention. And it’s pretty obvious when you have pulled the shot off target which is a common error.

Matt61

Matt61,

All good points. Yes, I believe follow through matters. If nothing else, it’s doing the SAME thing over and over, the same way……which I think we can all agree,….matters.

As for experience, a .22 semi-rifle,..always jammed,….and a Savage 20ga./.22 over under. Never did much with either. Airguns,….good one’s,…fit me for now. Just wish I started way before now.

As for “knowing”…..shoot 3,000 or so shots,…and you should have a pretty good idea when you “messed up”, before the pellet hits. If not,….maybe time to consider another hobby.

Matt61,

A second thought on follow through I forgot to mention,…a lot has already happened, between trigger pull and when the pellet leaves the barrel. Yes, it all happens so quick,….but I think that it is (then) that follow through makes the difference. I knew that, but had forgot that aspect of folllow through. After the pellet leaves the barrel, it won’t matter. It’s just the after effect of doing your job for that first few micro seconds before it does leave.

Imagine shooting a flintlock musket. 🙂

Absolutely fascinating! Thanks so much for this post. I agree with the sentiment of others: more pieces delving into the making/manufacturing. Would love to see how RWS, FWB, or others make barrels and such things.

A couple of observations. Someone asked why the raw lead comes in that shape. Speaking as one with a bit more than passing knowledge of the copper industry, the shipping shape is similar for all non-noble, non-ferrous metals (well most anyway 🙂 If you look at the “ingots” closely you’ll see that the each contain slots for a forklift (a big un!) to slide in and pick them up. You’ll also note that each batch is exact the same size and will be very close to the same weight. I’ve watched the semis roll out of the AZ copper towns “loaded” with raw ingots of copper. You have to look at the flat beds carefully as the copper pallets are stretched out along the center of the trailer with stacks that aren’t very high. They also run right at the 80,000 lbs weight limit and hard on roads. Lead being heavier would have even fewer “pallets” per truck load. Even stacked on a railroad flat, it still isn’t very tall, nor does it fill up the flatcar.

The actual shaping of the pellet is an extremely specialized stamping or more likely an extruding and undoubtedly their methods aren’t patented as they don’t want to give up even as much info as necessary for a patent. So they are closely held secrets. I’ve run into this in other companies. Think Gore-Tex by WL Gore and Assc. How they actually spin “thread” out of PTFE is a secret and while there are clones, none is quite as good as the original.

I’m still exploring, but I too am finding the JSB line to be top grade.

Oh, and one JSB tip. I note in the reviews at PA everyone dislikes the fact that the lids don’t screw on. Understandable. If you take a 12″ pair of channel locks, set them to be just bigger than the size of the tin and GENTLY squeeze twice on opposite sides, you get a lock that holds even if it’s turned upside down. Figured that one out after I dumped a 500 pellet can on a concrete floor and spent a fair amount of time cleaning them up 🙂

As noted women are the inspectors. Undoubtedly as they gain experience they aren’t actually magnifying each pellet. They have developed an “algorithm” or intuitive sense of rightness for pellet shape. Any anomaly that triggers the “not right shape” will get closer inspection. It is interesting that women tend to do this work world-wide. It seems that among the many things females do better than males is pay close attention to detail. The only exception to this pattern I’m aware of is in the Orthodox Jewish diamond trade where men do the final inspections.

Great post!

B.B.,

I recently ran into a Ballard and an American Boy Scout and thought of you. I was at the Ralph Foster museum at the College of the Ozarks which houses a fairly large collection of firearms. I don’t know anything about these guns that I did not learn from you. And I’ve forgotten most of that LOL.

I also took some pics of airguns and other interesting guns too.

Anyway the guns were all behind glass and the lighting was poor. When you combine that with my lack of skill with a camera the pics are not all that great.

But like I said I thought of you and hope that you can enjoy them. Here’s the link hope it works:

http://s1101.photobucket.com/user/MarkinJHawkland/slideshow/Ralph%20Foster%20Museum

Mark N

Man these pics are horrible. The upload to Photobucket made them even worse. I should eliminate the really fuzzy ones. But I’m afraid to wreck my link.

Mark N

Mark,

I watched the entire slideshow. What guns! The palm rest on the Ballard made me think of a ball flask airgun. And did you notice that the butt hook was adjustable just like they are today?

Thank you for the time and effort to make this presentation.

B.B.

No problem B.B. as I said you are the only guy I know that know anything about the Ballard.

The museum is just a hop, skip and jump from Branson, MO. So if anyone out there is bored in Branson sometime (highly likely IMHO) it’s worth checking out.

Mark N

Gunfun1 and Duskwight

ATF or trans fluid has different properties than RWS silicone oil or synthetic motor oil and will work to seal the steel sealing ring on a 300s piston and in my opinion would be far better than synthetic motor oil as a auto tranny works with 1200 to 1800 psi pressures so the ATF is made to withstand very high hydraulic pressures and does not react to plastics or rubbers as auto trannies have many rubber clutch pack seals and plastic thrust washers inside them so it is far better of a fluid than synthetic motor oil would be in my opinion plus it has a high detergent ratio so it will prevent varnish and gumming up of the inside of the compression chamber as well.

if I had a 300s it would be lubed with ATF rather than synthetic motor oil as motor oil does and will create a sludge/ varnish just like you find indie the oil pans and rocker covers that turn them a brown tint and permanently stain the metal which when have you seen the inside of an auto trannies metal part be stained any color unless it was abused and the clutches were allowed to be burned up due to low fluid level or overheating issues of the engine.

BD

Buldawg

I was wondering if you were ever going to post again.

Are you finally staying cool now?

And I knew there was a reason I always broke in my race engines with a little tranny fluid in the cylinder’s.

And I do believe when I put that FWB zero end gap ring in and added a light coating of the tranny fluid to the ring and cylinder in the 300 it helped seat and seal the ring good. In other words in air gun language it brought the velocity up on the gun.

Now I don’t know what the tranny fluid would be like on a regular seal in a springer or nitro piston gun. But from the way you explained above I think it could work in them also.

But I know its definitely good for sealing cast iron rings.

The big question for me is would it raise the probability of detonation?

I’ve used tranny fluid on my pump guns and trust it with rubber and synthetic materials. The FWB300 isn’t making a lot of power but what about when you get to the higher powered, synthetic sealed guns?

Reb

The thing to do is find out if tranny fluid is petroleum based. And it could cause detonation I suppose in a higher powered springer or nitro piston gun. I wouldn’t use it in a pcp gun either if its petroleum based.

But remember some new springers do detonate till you break them in. So we need to find that out.

I’m sure there are synthetic forms of ATF available but I never was a tranny guy so I’d have to check on that.

Reb

True but I still don’t know how it would work on a springer or nitro piston gun.

The thing would be to see if a couple drops in the transfer port would make the gun detonate.

Again were not talking put a massive amount in the gun. Just enough to keep the seal from being dry.

Gunfun1 atf is highly flammable, that’s why it is dangerous to have a transmission overheat and almost all transmissions now adays incorporate a transmission cooler at the front of the vehicle, some even have scoops and finned pans for extra cooling as well.

Ricka

I know about the tranny coolers and fans and the pans from my race cars.

I would say tranny fluid would be not a good idea for a PCP gun.

A springer or nitro piston gun with a plastic seal or synthetic seal could be ok for a very light oiling of the seal and cylinder wall through the transfer port hole with tranny fluid.

If I remember right the Crosman pellets gun oil is petroleum based and they say not to use it in pcp guns. But I have heard people say they use it in springers and nitro piston guns and pump guns. So possibly tranny fluid could be used for the guns I just now mentioned.

But as far as it goes the few drops of tranny fluid in the 300 has never caused detonation or the frying bacon smell either and no smoke. So maybe with the cast iron ring and the lower power of the 300 it doesn’t show them signs of burning.

So as far as tranny fluid goes on seals and detonation from a higher powered springer I just don’t know. I have never tryed.

I was just looking up silicone based brake fluid and found a new designation: DOT5.1,featuring more consistent compressability resulting in more consistent pedal height.

Reb

DOT 5 brake fluid is all silicone fluid and the difference between it and DOT 3 or DOT 4 is that DOT 5 silicone fluid has a higher boiling temp and does not absorb water or destroy paint but it does absorb air very readily whereas DOT 3 absorbs water and eats paint but does not absorb air and DOT 4 is the same as 3 but just has a higher boiling point similar to DOT 5.

So if someone picks up a bottle of DOT 5 fluid and shakes it up before handing it to you to use or you as most people do automatically pick it up and shake the bottle up DO NOT UES IT FOR 24 HOURS as you just infused so much air into the fluid you will never get a good pedal or lever and will bleed to you are blue in the face and it will be spongy until it has set for 24 plus hours.

We had an engineer at Harley when they switched to DOT% in 2006 come down and show us an experiment with DOT5 fluid using a chemistry beaker and rubber stopper with a tube sticking out of the stopper. He filled the beaker half full of DOT5 fluid from an unshaken bottle and put the stopper on it and proceeded to pull a vacuum on the fluid in the beaker and for 15 minutes the fluid appeared to boil in the beaker until finally it stopped bubbling and being agitated and after 15 minutes of a vacuum there was only half the level of fluid in the beaker that he had started with as that’s how much air was trapped suspended in the fluid that was not visible to the naked eye. So if you shake the bottle you just tripled that amount of air infused into the fluid and is why you have to let it set 24 hours to allow the air to be released out of the fluid.

The bikes we tested at Harley all had the brake fluid vacuumed to remove all possible air before using to bleed the brakes in the bikes and the riders could still get the brake fluid hot enough to boil it on some of the duty cycles the bike were running on and would end up with zero brakes until the bike set 24 hours to allow the air that was infused by boiling the fluid to escape back out of the fluid.

BD

I’ll have to remember not to shake DOT5 fluid but did you catch the newest version, 5.1? What can you tell us about it? Hopefully they’ve addressed the foaming issue.

Reb

Never heard of DOT 5.1 so do not have a clue as to what the difference between it and 5 is and it may be that they have increased its resistance to absorption of air but more likely it is to increase its boiling point as it boils at a lower temp than DOT3/4 but most manufactures have gone to it since it does not eat paint as that was the main reason that Harley switched as they were having to many bikes with paint damage on the assy line from spilled brake fluid even though they used a vacuum fill system.

BD

Gunfun1

Tranny fluid is most definitely petroleum based so its a no go in magnums but Marvel Mystery oil is non flammable up to temperatures of 2500 degrees so it does not burn at normal engine combustion temps but leaves an oil coating that soaks into the metal and stays for ever.

BD

Reb

Yes in a magnum springer it will detonate as tranny fluid is flammable so its a no go in magnums but I think Marvel Mystery oil would be ok as it does not burn at combustion temperatures so it would not ignite at all and leaves an oil film that actually soaks into the metals pores and stays there for ever.

BD

Thanks I may give it a shot!

Buldawg

Tranny fluid definitely be a no go in pcp guns if its flammable.

And maybe the Marvel Mystery oil could just be the new mystery oil for springers for piston seal lubricant.

Maybe we should start testing on one of springers.

Gunfun1 and Reb

Yea I would try Marvel Mystery oil in a magnum before ATF for sure as I know ATF will detonate even worse than pure silicone oil does and it is not petroleum so I would be afraid of ATF in a magnum. The 300s does not have the heat of compression to igniter the ATF so that why its ok in it but the Marvel mystery oil would likely be even better as it soaks into the metal pores and remains there.

Please no ATF in a magnum as I am not willing to test it in one of mine four safety reasons.

BD

Buldawg

And no tranny fluid in a pcp either. Also could be very dangerous.

I was concerned about the fact that I couldn’t find my Pellgun oil when I got my 2400 so I used the tranny sealer on my first Co2 cartridge and could smell it for a while but I have no problems with using 2000psi,so far anyways 🙂

Reb

I have spilled tranny fluid on hot headers and all it did was smoke for a few seconds then was done. I used the Dextron ll and Type F and the Royal Purple and all the same.

But I don’t think I would trust it in a pcp.

Gunfun1

You got it as mine only get fed a little silicone in the fill line every 5 or so fills just to keep o rings and the valves sealed and lubed and to keep corrosion down .

BD

Buldawg

And I would try tranny fluid in a magnum springer.

A couple drops in the transfer port will tell you with only a couple shots taken. I don’t think it’s going to melt the synthetic seal.

But I would not use tranny fluid in a pcp. HPA is alot different than a magnum springer.

Guynfun1

You can try ATF in a magnum springer if you choose to do so but I will not as my springer’s detonate on silicone oil quite violently and sound just like a high velocity 22lr being fired.

I am not worried about melting of the piston seal but rather exploding or grenading of the gun action in my face as ATF is far more volatile than silicone is and it scares me when it detonates so I will not use ATF in my springer’s and crosman makes two oils with one being pellgun oil for pump guns and the other is RM oil for spring guns which is a silicone oil and not the ATF blend of the pellgun oil.

Yep only silicone oil for PCPs for sure.

BD

Buldawg

For safety’s sake it probably wouldn’t be a good idea to try.

But conversation wise there’s a couple things to think about.

First on the magnum springer I believe the pellet and barrel would act as a relief valve in a sense. It could be a violent shot for sure but I think that it would be vented.

Then the second is the PCP. The air resivoir is a enclosed sealed HPA contained area there is no relif valve so to say but the weekest spot in the system. Like the o-rings at the air gauge on a Marauder and the check valve in the Foster fitting or the valve in the tube. And of course the threads. So for a PCP it would be a much more violent explosion than the magnum gun could have because there is nothing venting the air to the atmosphere like the barrel on a magnum gun.

The pcp would not be good. The magnum could have a chance.

But best thing for a person to do is not take a chance if you don’t know about the things that could happen.

That’s why I say for conversation purposes.

Gunfun1

You are right about the springer having a relief valve in the barrel opening versus a PCP and its closed air cylinders but it is also a real possibility that the combustion in a spring gun can occur and progress at a faster rate than the pellet leaves the barrel and create enough pressure to explode the action even as the pellet is leaving the barrel so I am crazy for sure but not stupid.

I like living on the edge and taking chances that I have some margin of control over but testing the speed at which detonation would occur in a spring gun with ATF in the compression chamber is not something I feel I have any control over so not that crazy at least not yet as my mind does come and go as it pleases but it does not stay gone long enough for me to forget about the risks . LOL

Most definitely good for conversation and theory but not to practice with or experiment in my opinion.

BD

Buldawg

You know what. I don’t have any magnum powered springers right now.

What kind of velocity in .177, .22 or .25 caliber do you call magnum.

And if I ever get one I will try a few drops of the tranny fluid just to see. I may be surprised but I don’t think it’s going to blow the gun up.

But I will put the gun under a pillow and some other things over it just to be safe. Oh and I will have to tie a string to the trigger.

All in the name of air gunning. I will risk it for everyone to know. If I ever get one that is.

🙂

Gunfun1

I guess it would be in 177 cal 900 plus fps and 22 cal 800 plus and 25 cal maybe 700 plus as the only 25 spring gun I have is the Hatsan I got from you and 500 fps is by no means a magnum in 25 caliber.

I base that on the fact that my 177 crosman venom will detonate with silicone oil and it shoots 7.9s at just below 900 fps and 10.5s at 850 fps and both my titans in 22 will shoot CP 14,3s at 780 fps and 760 fps and also detonate with silicone oil so that is what I go by in 177 and 22 but have no idea in 25 as the Hatsan smoked during break in but never cracked with the report of detonation when firing it but as I said 500 fps is hardly magnum velocities in 25 cal.

I do not think that ATF will actually explode as well but just not willing to chance it destroying one of my guns just to see if it does or not so if you are willing to perform the test I will support you 100% but will not supply the gun but will supply all the ATF you want as I have gallons left from my GM technician days even 17 years later. LOL

Better make it a Kevlar pillow with some lead bags for good measure just to be safe and light cloth string on the trigger.

BD

Buldawg

Well we may have to wait a long time for me to try the tranny fluid in a magnum springer.

There going to have to figure out how to make one with a better shot cycle before I by another one.

Although I have thought about getting another 54 air king in .177 caliber. I guess that would count as a magnum springer.

But if I do try it one I will let everyone know the results.

Gunfun1

I got my AC fixed today and thankfully the 500 dollar blower motor module was still under warranty so it only cost 138 to replace the module and service the unit while they were out fixing it and its working very good now as I had to turn the thermostat up a degree since its colder than it used to get now. I could not post online since it was so hot in my house the fan in my PC was running full bore just to keep it from overheating and I was not going to burn my PC up by using it in 90 degree temps in the house.

I know tranny fluid will most definitely work in the steel ringed 300s since auto trannies use the exact same sealing steel rings on the pump output hub to direct high pressure fluid to the different valves and clutch packs for shifting operations. I would also go on to say that todays newer electronic shifted trannies have likely the same synthetic material used in air gun piston seals sealing the clutch packs and accumulator pistons as well so I don’t believe it would hurt the seals but it is flammable so I would not use it in a magnum springer as it will detonate as readily as motor oil or any petroleum oil will.

I would be willing to say a very good and cheap lube for all spring gun pistons and compression chambers would be Marvel Mystery oil as it does not burn at engine combustion temperatures so it leaves a film of oil on all the internal cylinder walls, piston crowns, ring lands and grooves and valve seats and stems and will not allow the buildup or formation of carbon deposits inside the engines cylinders or any component in the cylinder. If you take a new car and use as directed from brand new by mixing it in the fuel there will never be any carbon build up on any internal combustion component and the engine will run like new forever and it is catalytic converter safe.

I use it in my bikes at every tank full and can look into the intake ports of my Kawi with the carb slides open and see the valves and there is zero carbon coating the valves at all as all you see is a lightly oil coated valve stem and valve face.

BD

Buldawg

I have used Marvel Mystery oil before. But never in a air gun. I wonder what it would do.

That’s exactly what I used on and in the Feltmans I used to work with! Of course that was only 150 psi tops.

BB,

Thanks for the fascinating blog about manufacturing JSB pellets!

CaptK.,

I’d love to see a reassembly write up for the 300s. Or at least a good description of the trickier parts. I have to admit that my disassembly could have gone more smoothly. This was my first time taking apart and reassembling any air gun.

Things were a little bound up after removing the retaining bolt, and when I tapped the end to give it a little help: sproing! parts all over the shop. So I never got to “see” : how the two springs were oriented, how the two metal “cheese wedges” (part of the safety mechanism?) were positioned, the orientation of the piston with respect to the cocking slot etc. so “reassembly is the reverse of disassembly” doesn’t help everyone!

I had to find a bunch of different guides on the web (all different places) to try to solve this puzzle. Never did find a good answer to place and retain the “cheese wedges” during reassembly.

I built a DIY spring compressor (BB, thanks for the blog describing it!) for the reassembly, and I finally got it done but those “cheese wedges” must have fallen out of place a half dozen times before I finally got them to cooperate. Vertical reassembly would have solved that vexing problem but my spring compressor used the end vice on my wood working bench ( and there’s no way to put my bench vertical!)

I could have rotated the action 180 degrees but then I couldn’t figure out how to make sure the piston was in the correct orientation to allow the square hole to accept the end of the cocking lever. I’m sure there must be a simpler way but without more experience, I just couldn’t see it.

Oh, and is it common knowledge to use a corkscrew to remove the old piston bumper and breech seal? Took me forever to find a site that recommended that! A lot of head scratching during this process!

Thanks again for your translation, made many things much clearer for me, and thanks to all the others for lubrication suggestions.

Jim in Chapel Hill, NC

Jim

All good points about the assembly of a 300s.

Pretty dang cool B.B., I find manufacturing so interesting, like others have stated I have watched many shows throughout life about “how they build…”. I also agree with others that I could read about this all day, very interesting to see what goes into the process even if we don’t get to see behind the curtain…

I will say JSB and H&N are my two manufacturers, I just wish I could find more head size options available for the JSB pellets, I buy H&N in various head sizes for different guns. Thanks, Ricka.

B.B.

My thoughts and prayers are with you!

When it comes to the pellet sorting for malformed pellets, the coffee bean roasters use optical scanners to search for bad beans. After the optical scanner finds a bad bean, a puff of air removes it from the other beans. These machines sort thousands of beans per minute. Couldn’t one of these pellet manufacturers do something similar?

So when we get a tin that is marked at a certain head size, and after pellet sorting we find out that most or all of a different head size, can we blame the ladies???

-Yogi

Yogi,

Could technology replace the inspectors on the line? Probably. But how cool is it that those pellets are hand-sorted? Mistakes and all?

B.B.

Buldawg,

No room for a reply button up there so I hope you see this.

The DOT 5.1 was new to me too and I can’t share a link on this phone but I had it memorized until I couldn’t see what I was typing. I’ll get back with a website that will allow you research it if you’d like

Reb

Yea when you get a chance send me a link as I would like to now what it is and the differences as my bike both use DOT 5.

The average bike rider will never bring DOT 5 to its boiling point like our rider at Harley did as the duty cycle that boiled the fluid was repeated stops from 100 plus mph until the brakes began to fade and give out so it was a duty cycle created to induce brake failure and the brake discs would be all colors of the rainbow at the end of the test and warped all to heck so complete brake rebuilds were the norm on those bikes.

BD

I wish I Could send a link in this phone! I’ll have to give you the website address instead.

TBM brakes, my search was for silicone brake fluid.

Reb

I will look up the TBM fluid when I get a chance and it may be a new formula to enhance the new ABS/ traction control system in today high tech cars since the use ultra high speed valves and servo motors to shut and open fluid passages to apply or release brakes in out of control or panic stop situations encountered by drivers every day on our roads.

It is well known that if a person knows his car and brake system very well that a car will stop in a shorter distances not utilizing the ABS system than if it is activated as it is only designed to allow control of the vehicle in a panic stop situation and not allow for a shorter stopping distance than a car with a person driving it that can bring the tires to the threshold of loss of traction with out actually going past that threshold and causing the tire to slide or skid on the pavement as if they are sliding you have lost traction and therefore stopping power.

I can bring my vehicles ( car and bikes right to the point of skidding with out the tires loosing traction ) in any stopping situation and have never had the ABS system in my cars activate yet in 15 years of ownership. My bikes have no ABS so I have practiced with their brakes to know the exact point that I can apply maximum braking effort with out locking up the tires and it has saved my life more times than I can remember so ABS is for inexperienced drivers and not for a person that knows their vehicles capabilities and braking systems extreme limits and how to utilize them to their fullest possible extent.

BD

I did find some material that said it’s glycol based so it’s not what I was looking for.

Reb

Glycol based brake fluid that’s a new one for sure. I have no clue as to what the benefits of it may be other than keeping temperatures lower or better absorption of the brake temps thru the fluid and into the metal parts but until its been out and real world tested for a few years I will not use it.

BD

BD –

Just joined this blog after reading for the last 2 months. New to airguns but wanted to comment about the brake fluid discussion 2 days ago. Web-searching found epicbleedsolutions.com, it’s a mountain bike site but has a nice table. You said “Glycol based brake fluid that’s a new one for sure.” but DOT 3, 4, and 5.1 are all glycol-based with increasing boiling points, can be safely intermixed. DOT 5 (5.0? but they don’t call it that) is the odd one out, it’s silicone-based and must not be mixed with any of the others.

Didn’t see what the benefits of silicone-base are, but it sure looks like a prescription for disaster when home mechanics go to Auto Depot and get the latest bestest brake fluid – LOL! well, not actually, it won’t be funny at all…

How could “they” devise such a misleading numbering scheme? Oh wait, it’s our government looking out for us…