by Tom Gaylord

Writing as B.B. Pelletier

The IZH 61 sidelever repeating air rifle.

This report covers:

But first

Velocity

Where to oil

Manual wrong?

The rifle is oiled!

How fast

RWS Basic

Discussion

Loading the clip

Falcons

But wait

Why not do both?

Where does that leave us?

A different clip

Discussion 2

Trigger pull

Cocking effort

Summary

Today I’m going to shoot the IZH-61 rifle and see what velocity it produces. A healthy 61 should make close to 500 f.p.s. with lighter (7-grain) pellets. Since I have two rifles, I’m just going to shoot one from this point on. That will be the one that I showed you in Part 1 — the one that was accepted on November 26, 2005.

But first

Before I start the test I have something to tell you. I have told you several times how my rememberer isn’t what it used to be. Apparently its function is being replaced my my forgetter that is very active and only too willing to wipe my hard disc.

In Part One I made the following statement.

“Unfortunately after the final shot the bolt is still stuck through the last pellet chamber, so the rifle has to be cocked again to remove the clip. Or, you can just leave the empty clip in the receiver until you want to shoot again and no dry-firing is required.”

Reader Vassili Z. from Buenos Aries commented with the following.

“Though I read the blog every day, I seldom comment. I want to point that, at least in my 61 (bought here in Buenos Aires about a decade ago; they are no more imported), there is a spring loaded silver lever at the right side, sort of a silver triangle, which allows the bolt to retract without cocking the action. In fact, when you press this lever, the bolt pops back, as it is spring-loaded to do so. Thus you can then press the upper lever and take out the clip without operating the side lever.”

Well — of course he’s right! That’s how the rifle works and that’s how the empty clip is removed. Let me show you,

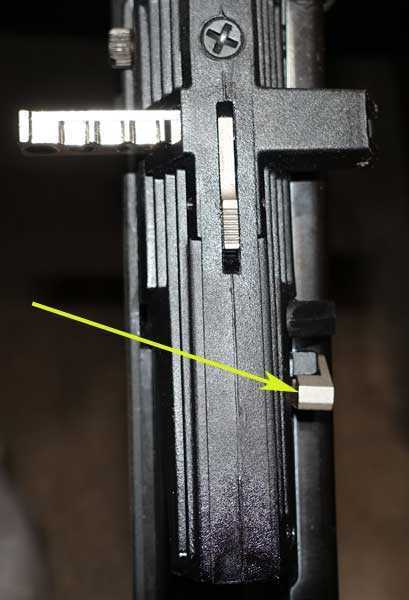

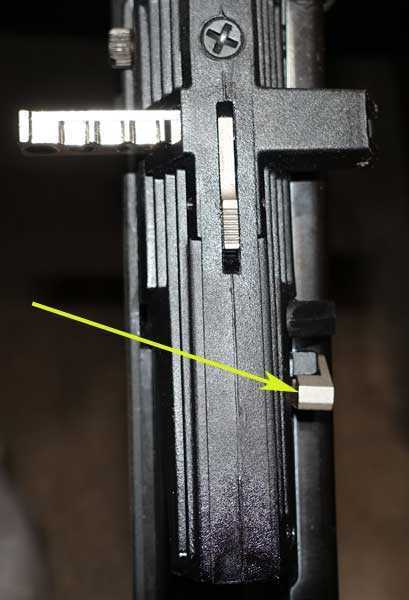

The lever or button that releases the bolt carrier (arrow) is forward, holding the clip in the action.

Pushing the top of the silver button forward releases the bolt carrier, pulling the bolt back and out of the clip. The clip can now be released from the receiver.

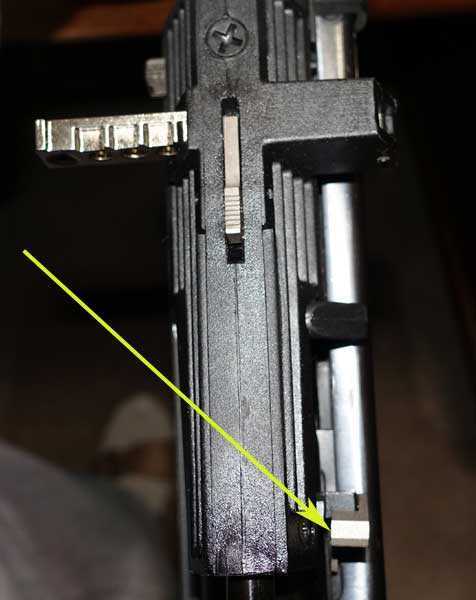

View from the right side showing the same thing. Carrier forward.

Carrier back.

Thank you Vassili. You put the train back on the track!

Velocity

To test the velocity in a spring-piston airgun you first need to determine that the piston seal is lubricated. If the seal is synthetic it only needs a drop or two but if it is leather it needs to be saturated to soften and preserve the leather.

I didn’t know which type of seal the 61 has, so I went to that in-depth resource for airguns — Ebay! Don’t laugh! If you search for IZH-61 piston seals there you will discover that the same ones that fit both the 60 and 61 also fit the IZH MP512, MP514K, IZH 53 and the 53M. And the seals they call “original” are synthetic. In fact, I believe the Baikal company is selling both seals and entire steel pistons with seals directly on Ebay!

There is also a leather IZH-61 piston seal available. It’s sold as a custom piston gasket cup seal. It’s being sold by a Russian dealer located in Izhevsk who calls himself izzygear, which tells me he is well-connected to the worldwide airgun community and also speaks and understands English quite well. I wouldn’t be surprised to learn that he reads this blog! It’s probably someone at the IZH factory.

The bottom line is — my two new old stock 61s both have synthetic piston seals and therefore only need a drop or two of oil. But where to put it?

Where to oil

Okay, the last tip was to press forward on the top of that silver bolt release button on the right side of the action. Here is what happens to the air transfer port when you do that.

With the clip removed you can see how the bolt passes through it when it is forward.

If you look at the rifle from the side you will see that the piston does not line up with the barrel. It’s lower. The compressed air generated by the piston has to flow up to the breech, entering around the narrow tip of the bolt inside the rear end of the barrel. And I would now like to point out that I am the only one calling that part that slides back and forth and pushes the pellet from the clip into the breech the bolt. It’s called many things around the world, but bolt doesn’t seem to be one of them.

So, move the “bolt” back and drop the oil into the rear of the barrel with the muzzle pointed slightly down and the front sight sticking up. You are trying to get oil to flow into the tiny air hole at the bottom rear of the breech. In fact, that is exactly what the American-written manual says to do — not that I ever read manuals or tell anyone to follow them!

Manual wrong?

But I will point out something that I think the American-written manual (from EAA) got wrong. They say to use a high-flashpoint oil for the piston seal. That would be correct for a powerful spring-piston airgun. However, you don’t need to do that with a 500 f.p.s. spring-piston gun! Use regular household oil, because it works just as well and there is no danger of a detonation in a spring gun as weak as this. Silicone oil won’t harm the rifle, but neither will 3-in-One.

The rifle is oiled!

In Part One I told you that the magazine feed mechanism was iffy when I got the rifle. Lubricating it as I wrote about in Part One got it up to 90 percent reliability. As I have been writing this report I have been lubricating the rifle all over and it is now functioning and feeding reliably all the time. It’s 100 percent — or nearly so, as you will learn! Remember — it was made back in 2005 and has been sitting around for about 15 years. The oils that were applied back then have thickened and gummed up a bit, which caused the problems I mentioned, but all it took was fresh oil and the parts sprang back to instant life!

How fast

Now let’s look at velocity. I have waited until now for this very moment. I know the rifle shoots okay, but I have no idea how fast it is shooting. We will discover that together!

RWS Basic

The RWS Basic wadcutter pellet weighs 7 grains. That should give us a good idea of the velocity potential. I shot 10 of them using the same magazine for all 10. That would be five, followed by a second five. Let me show you the string.

Shot….Vel

1……..399

2……..399

3……..394

4……..402

5……..421

6……..395

7……..366

8……..387

9……..413

10……414

The average for this string is 399 f.p.s. But look at shots 4 and 5 and 9 and 10. Those four shots are from the last two chambers in the clip and they all went faster than 400 f.p.s. They were the only shots to do so in this string.

The extreme spread went from a low of 366 to a high of 421 f.p.s. That’s a difference of 55 f.p.s. At the average velocity the Basic pellet generated 2.48 foot-pounds at the muzzle. Lets do that again!

Shot….Vel

1……..375

2……..392

3……..418

4……..391

5……..426

6……..381

7……..398

8……..383

9……..415

10……408

This time the velocity varied more from chamber to chamber, but the average was the same 399 f.p.s. The spread this time went from 375 to 426 — a difference of 51 f.p.s.

Discussion

I think several things are happening. First I think the piston has too much oil. I could see a light spray around the breech when the gun fired the first few times. Next, I think the rifle is breaking in. Until now it hasn’t had a chance to. And finally I think the chambers in the clip are ever-so-slightly different and are giving different velocities. I will say that when I pressed the pellets into the clip with my seating tool they all went in with a sharp pop.

Loading the clip

I pushed the pellets flush into the clip chambers with my finger, then seated them with a precision seating tool — a fat ballpoint pen with the point retracted. It was just fat enough to push each pellet a small fraction of an inch into the clip.

I used a fat pen with the point retracted to seat the pellets in the clip.

Falcons

Next we will try the Air Arms Falcon dome that’s made by JSB. Falcons weigh 7.33-grains so by weight alone they should shoot slower than Basics.

Shot….Vel

1……..425

2……..424

3……..421

4……..423

5……..412

6……..415

7……..423

8……..436

9……..433

10……414

Okay — does that surprise you? First, Falcons averaged 422 f.p.s. in this rifle. Second, at that velocity they generate 2.9 foot-pounds. Third the spread went from a low of 412 to a high of 436 — a difference of 24 f.p.s. Don’t gotta be a rocket scientist (no offense, Jane) to realize this rifle “likes” this pellet a lot more than Basics.

But wait

Yes, there is more to ponder. The next and last pellet was the H&N Finale Match Light that weighs 7.87 grains — despite the name. I wonder what we are going to see?

Shot….Vel

1……..365

2……..357

3……..did not register

4…….. a blank — the mechanism failed to advance the clip

5……..420 — WHAT?

6……..415

7……..341

8……..370

9……..383

10……416

11……412

That is a total of 9 shots recorded so far in this string. Shot number 5 made me think a different pellet had found its way into the tin, but shot 6 put an end to that. Shots 10 and 11 are also much faster. Is that the effect of those two larger chambers again? Because it does seem to line up.

BUT — and this is a big one! I still had one more pellet to fire to complete my string of 10. Should I shoot it from the chamber at one end of the clip where I believed it would shoot slowly? Or should I use the chamber at the other end where it would shoot faster?

Why not do both?

I loaded the chambers at both ends of the clip. The first pellet was fired from the slow end and registered 359 f.p.s. Using that as shot 10, the string averaged 384 f.p.s. and generated 2.58 foot-pounds. The low was 357 and the high was 420 f.p.s. — a difference of 63 f.p.s.

The last chamber registered 392 f.p.s., which made the average for the string 387 f.p.s. So, although the difference in the last two shots was 33 f.p.s., the difference in the average velocity for the string only rose by 3 f.p.s., which is what averages tend to do. The spread for this string is the same as before. The energy registered for the new average is 2.62 foot pounds.

Where does that leave us?

Don’t start inventing a universe for this IZH-61 to inhabit just yet. I think you can see that it is too soon after the Big Bang and things have not sorted themselves out. This rifle still needs to break in. But I am still curious. I want to do two more things. First, now that I have shot a total of 42 shots on the rifle, I wonder how another string of pellets will look. I don’t think the rifle likes Basics too much, so let’s shoot Falcons.

Shot….Vel

1……..423

2……..437

3……..423

4……..433

5……..438

6……..421

7……..423

8……..424

9……..420

10……435

The average for this string is 428 f.p.s. and the spread goes from 420 to 438 — a range of 18 f.p.s. The previous average with this clip and pellet was 422 f.p.s. with a spread of 24 f.p.s. So this string is both faster and more consistent. Is the gun settling down as it breaks in? Probably, but it’s too soon to tell.

A different clip

The other thing I wanted to try was this Falcon pellet in a different clip. For the next string the same clip was used for all 10 shots, but it was different from the clip I had used before.

This clip has one loose chamber that the pellet kept falling out after it was seated. I had to take special pains to load that clip into the rifle without the pellet falling out.

Following seating with the pen the pellet in the fourth chamber kept falling out.

Shot….Vel

1……..414

2……..407

3……..430

4……..412

5……..420

6……..433

7……..417

8……..413

9……..418

10……428

The average for this string was 419 f.p.s. The spread went from 407 to 433 f.p.s. — a difference of 26 f.p.s.

Discussion 2

I think the rifle is breaking in. Of all 62 shots fired today there was just one failure of the clip to advance, resulting in a blank shot. Other than that the clip advanced smartly every time.

Will this rifle ever get up to 500 f.p.s.? It’s possible but I think unlikely. Falcons will probably settle out in the 440s and there might be another pellet that averages 10-15 f.p.s. faster, but I think that’s about as far as this rifle will go.

Trigger pull

The trigger is very light at 1 lb. 8 oz. The pull is single stage and mushy. I can’t tell when the rifle will fire. I’ll need to concentrate when shooting this light rifle at targets, because that unpredictable trigger will keep me guessing.

Cocking effort

The rifle cocks with 11 lbs. of effort. At the end of the cocking stroke a little extra pull is needed to set the trigger, so call it 14 lbs. It is extremely light for a spring-piston air rifle. Does that indicate that the mainspring is weak? I don’t think so. At any rate I’m happy with the velocity we have now, so it doesn’t matter.

Summary

This IZH-46 is an air rifle that needs to be loved and used a lot. It practically begs to be shot. Unfortunately, with all the testing I do I won’t be able to do that. It’s a great little plinker for someone who has the time!

I am excited about testing the accuracy.

And now its time to start the line.

After the accuracy portion, who will be the lucky airgunner that talks B.B. into putting the 61 up for adoption.

Very interesting blog today, breaking in after 15 years in a box.

Who else has an airgun that is in working order, that they haven’t shot in that long, or longer..

Ian

Ian,

Some of mine may have sat around that long or longer and not been shot, but since these old gals moved here to RRHFWA, they get out quite often for a little fresh air and some exercise. Of course these ladies were meant to be around for many years and are made to be.

My Diana 6G sat for 25 years in my Mom’s basement. First time shooting it in that long, phst. The seals were all gone…

-Y

Yogi,

Oooh. Those old Diana seals were “infamous” for that. I do hope that you have since had that lady brought back up to snuff.

Sent to David Slade and all is well now. Shoots like a dream…

-Y

Oh yeah.

BB,

There may be a room available at RidgeRunner’s Home For Wayward Airguns. 😉

BB,

Wow, very extensive testing. Glad to see it is up and running (with only a minor glitch or two). Looking forwards to the accuracy phase of testing.

Good Day to you and to all,………… Chris

Chris,

Is my rememberer working? You have a Maximus Hunter, do you not? Is the muzzle adapter screwed on or is it just glued on? I can buy the adapter separately to mount to a regular Maximus.

RR,

Yes, I have the Maximus Hunter. I was playing with the barrel band and wanted to take it off. I tried an industrial heat gun and it did not budge. So,… I just played with the position, fore and aft. Therefore, I can not answer your question. Once the cap is off, anything 1/2-20 will screw right on.

Can you see from a picture if it has ID threads?

Chris

Chris,

Not really. I am looking at the exploded view that TCFKAC has. It likely just glues on.

Thanks.

B.B.

Do you know why there are import restrictions on IZH guns and not other Russian guns, several PCP’s come to mind?

-Y

Yogi,

The company that makes these IZH airguns also makes Russian weaponry, hence the import restrictions.

Are any of the Chinese airguns made by their Red Army’s weapons suppliers?

-Y

Yogi,

That I do not know as I have not as of yet bought a Chinese airgun, nor researched such. It would not surprise me. Also, the Chinese would likely lie and show a picture of it.

We USED to be able to import Norinco powder burners to the USA, (my wife gave me a Norinco 9mm Uzi as a wedding gift.)

You don’t see wedding gifts like that any more…

I always wanted a Norinco M1a (norinco 305) but never got one, Canada has them, but we are left in the cold.

Yes I know they have had some issues over the years, but it is still in production over 20 years later.

If you turned out a really poor rifle, you would not still be selling them after that long.

Hmmm, I wonder how hard the US guards search your car coming back in after a weekend trip?

Ian,

How ’bout you give it a go and tell me how it is?

I have been through Canada once driving to and from Alaska.

but we didn’t get searched going through either time

a friend of mine did tell me of a horror story going into Canada.

He has passed away now so I can talk about him. let’s just say the Lord watched out over a fool that day, and everything worked out for him and they didn’t find 2 weapons in the RV, and towed minivan. but it could’ve been real ugly.

His first mistake was wearing a T-shirt that had our Shooting club logo on it. ”Cajun Combat Shooters.”

With silhouettes of an ar-15, a Remington 870, and a browning P35

“Search me, please.”

Ian,

Norinco used to make a copy of the Winchester 97 WW1 trench gun. While you are in Canada, how about picking one of those up also.

Did the dry fire of the H&N match pellet cause the next shot to shoot a little hotter?

B.B.,

Just noticed that the home webpage of the blog had severely truncated the topic for today’s blog. I’m used to seeing at least a couple of paragraphs before I have to click Read More. Today I have to click on the title to read the article. It’s a small niggle just don’t know what other changes are lurking waiting to be found.

Siraniko

Siraniko,

The IT guys are at it again! I’m just happy we can still see the blog!

B.B.

BB ,

The 60 and 61 will be allot more consistent if You use a lithium grease . Do not use TIAT, it is too thick and will slow it down . The problem with oil is it will creep into the chamber. All 60 and 61 rifles have come with synthetic seals , in such a weak power plant the spring and seals last a long time. We have only ever had to repair a few of them and Pyramyd has sold thousands of them ! . The biggest problem is with the 61 and people jamming the barrel up with pellets. Stay away from lead free pellets in these , they will get stuck in the barrel . Hopefully this helps everyone out .

Hello Gene,

Have seen you comment here several times so thought that I would ask you this question because you have probably rebuilt some of these old airguns in the past. Maybe you have seen me post here about it, or maybe not.

I rebuilt my old Crosman 147 muti-point this past summer. I installed all new seals, including the cup seal and the updated Teflon check valve and spring. Right after the rebuild I pumped it a few times to make sure everything was working correctly. At that time is seemed to be fine.

Just recently I had a chance to shoot it a lot more and discovered that it was not up to par as I had thought. After about four pump strokes it doesn’t seem to build any more pressure, no matter how many added pump strokes. It seems to hold pressure in the valve okay but is definitely not as powerful as I remember. I have since completely disassembled everything to insure that the seals were okay and assembly correctly. Everything was fine but after reassembling, the rifle performs exactly as before. I can hear the sound of air movement at the end of the pump stroke, as if leaking past the cup seal perhaps. I thoroughly cleaned the reservoir bore with Ballistol before assembly and it looks perfect.

Any thoughts or suggestions would be much appreciated.

Geo

Geo,

I think you answered your question. If you hear leaking as the pump reaches the high compression part of the stroke.

Sounds like a bad piston seal.

Don

Yes, but the piston cup seal is new. It wasn’t nicked or damaged when assembled.

Then it has to be in the valve seal or the exhaust valve.

Well, those are new as well. Even a new quad seal which is difficult to replace.

Try putting 10 drops of crosman pellgun oil in the pump air intake and shoot a few shots. See if that makes any difference.

Don, that’s a very good idea. I was thinking of that myself too. I put a lot of Pellgun Oil on the felt washer but that may not be adequate to lube the tube sufficiently. I will give that a go next. Thanks.

Geo

Geo,

Without knowing what you have exactly,… and if all the o-rings are good,… a valve seal face might be the culprit. ??? you ask.? It could be that the seal faces are not at the same angle. (IF? that is at all the case?) Lapping of some sort being the fix. On the cross-hatching of the cylinder,… it sounds good to me. You would not put new rings on engine pistons without crosshatching the cylinders. The 2 work together to get both items mated to each other.

I will say though,… you seem to be having to go over and above a normal rebuild/reseal. Why for sure,… I do not know.

Chris

Chris,

Maybe you don’t remember that I totally rebuilt my Crosman 147 last summer. I just haven’t shot it much, other than to just test fire it after I reassembled it. I replaced ALL of the seals, even the quad seal, and piston cup seal. Everything is new and the rifle was thoroughly cleaned before reassembly. Don just suggested putting more oil in the tube ahead of the cup seal. I was thinking the same. I oiled the felt washer but that may not be sufficient to properly lube the freshly cleaned tube and make a good seal.

I really should not have to hone the tube. It’s in excellent condition. Yes, honing a cylinder before installing new rings in an engine is not optional…if you want the new rings to seal.

Geo

Geo,

I know, as that is what we were talking about a few days ago, with you posting pictures. Here is the last sentence in a post of yours from a few days ago,…

“…….. One thing, there was an upgraded Teflon check valve and spring with the new seal kit. Maybe that has something to do with the pumping action?”

Without having the internals in front of me,.. I can’t say anything for sure.

My comment was more akin to,…. IF you had a new valve/face/seat and IF that gets installed into an old valve body, maybe the (old) surface and (new) surface are not mating ideally. Hard part to hard part,.. not o-rings.

The same could be true for a complete new drop in valve. Maybe 2 critical, hard mating surfaces, are not well mated?

Just some ideas/thoughts. With you having a technical background, QC and having a critical eye,… I am sure this is quite frustrating to not be able to figure out quickly.

As for cylinder honing,.. I will bet that rarely ever gets done,… even by the pro rebuild guys. I recall that BB did it on a scratched springer cylinder once, but that is a bit different, and, you said it looked fine.

At any rate,… keep us posted,…….. Chris

Chris,

I made a general post at the bottom. No joy 🙁

Gene,

What kind of lithium grease do you recommend? I lubed my IZHs with Honda moly and it seems to be okay. I’m getting 460+ fps with my 60 and around 420 fps with my 61. Both are plastic frames.

B.B. and Readership,

The BLOG is REALLY unstable as of this writing!!!!

Copy to your CLIPBOARD anything you don’t want to lose when you click REPLY/Post Comment!

shootski

shootski,

IT is working on the truncation problem and one other that I’m aware of. So stuff is going to happen.

B.B.

Hi B.B.,

After you began this report, I have been working with my IZH-61 with the plastic clips and found the best pellet so far and the groups shrank to down from roughly 2″ to 1/2 to 3/4″ at ten yards. Not great, but better! I also went inside and inspected the piston seal for leakage (it was in good shape) and lubed the cylinder with silicone oil. I did use TIAT on the spring, which Gene Salvino said will slow the pellet down too much. So with the confidence that the piston seal is OK and using Crosman Premier lights from the cardboard box, my funny little Baikal that grouped so poorly has become a fun shooter! I haven’t chronied it yet, but the time delay over the ten yards from shot to impact is very noticeable. I’ll chrony it, clean the TIAT off the spring, lube it with spring oil and see how the velocity changes.

The barrel crown is a deep, cone-shaped recess, a type I’d never seen before, what do you think about that design?

I did the experiment of shooting at the 5 targets, one target per clip position and found differences. The problem is that I’m not sure the differences are not my fault. So I’ll do it again and see if the patterns remain consistent. What fun!

Will S.,

How deep is DEEP? GOOGLE is your friend with pictures, lots of pictures. Just enter: target rifle barrel crown. You will find some great variability and even a bunch of deep cone crowns!

How many shots on each targets with each clip position are you doing? The more over five per target that you do the better the odds are that it is the rifle/clip port and not you that you are seeing on each target.

Good testing!

shootski

A deep crown always makes me wonder about intermediate/transitional ballistics. If the projectile is past the rifling but still in the path of confined gas a lot can happen. I try to keep my crown short and symmetrical to the end of the barrel.

Though look at all the attachments that we put on the end of the barrel?

It would be interesting to do some testing with different crown configurations to see the effect. What happens if the end of the barrel is not square to the bore etc.

Don

Benji-Don,

I’m with you on being doubtful one a deep cone. Of course the intermediate/Transitional Balistics is an area of only recent research and not a great deal of it has been successful replicated and even less reliable data exists for modeling what angular and depth changes cause in terms of accuracy and repeatability. Folks put stuff on the end of their barrels and if for some reason they get real or imagined improvement they are usually loath to change and of course immediately post about the breakthrough or hide it from other competitors.

I personally keep it simple and stick to the basics fundamentals of shooting as having the biggest impact on my shooting.

I have a gut feeling that a barrel muzzle that isn’t square to the Bore Axis is something to avoid. I have a little anecdotally obtained opinion on that. I had a shooting/skiing friend who obtained virtually every new thing for his competition rifle, he even had it fluted, then stress relieved and then when he head about cryogenic treatment he got that done. He DIY’ed his muzzle crown. The job was done using the outside dimensions of the barrel instead of the Bore Axis his results unfortunately didn’t improve…they actually got significantly worse causing the coach to ask WHAT DID YOU DO TO YOUR RIFLE this time! Even with the shorter, but properly recrowned barrel by a Gunsmith, his scores returned to the same as before. Unless I was an accomplished Gunsmith I would never DIY something so critical to accuracy.

I’ll shut up now since my gut tells me you know all about the subject. I have mostly flush crowns, a few stepped and one or two with 11° chamfers but I wouldn’t call them deep cones. Some day soon I hope we get some real data and reliable models on the Transitional Ballistics.

shootski

shootski

Here’s a photo of the end of the muzzle of my MP-61. Pretty interesting conical crown. With the cap on, there is a tiny chamber for air to have some sort of behavior during the shot. This arrangement might act to even out the air pressure behind the pellet exiting the muzzle and possibly shape the airflow so it doesn’t upset the pellet’s initial flight. It would be neat to put an air stripper on the end and see what happens.

Regarding pellet choice, the ones whose skirt fit the clip the tightest gave me the smallest groups.

Will S.,

I have never owned a 60 or 61 so i have no idea if that is the typical crown. I have never seen one like your rifles before. It made me think of the Megaphone on the end of an AK!

When I first started shooting, sixtyfive years ago muzzle crowns were explained as simply something done to protect the rifling. I wonder how we have gotten to believe all the other things that are attributed to them without a whole lot of hard data or even replicable experiments?

The pellet skirt fit makes sense. Maybe B.B. can get out a Micrometer like these (https://www.mitutoyo.co.jp/eng/products/naikei/naikei.html) to measure the Bores in the clips for dimensional consistency as well as a standard Micrometer for the outside clip dimensions for the same consistency.

shootski

Shootski,

“I wonder how we have gotten to believe all the other things that are attributed to them without a whole lot of hard data or even replicable experiments?”

Amen! I try to make that my golden rule when testing myself or from others that have something that I want to buy. Amen!

Chris

Will,

Thank you for that. I never would have thought of Premiers for this rifle! But I will now try them.

As for the 5 target test, it’s a good way to test clips. I may try it myself! 🙂

B.B.

Geo ,

I would try a new pump seal first , if this is not the culprit You will have to go into the valve assembly . The valve could have a slow leak . We quit doing most old Crosman and Benjamin guns once the PCP repairs started .

Patrick ,

Any good lithium grease is fine as long as it isn’t too thick and tacky . The Honda Moly is fine, it is still lubing the action well , the problem with Moly greases is in the more powerful guns they lubricate too well and cause the gun to buzz . Moly is complete overkill for any springer made . You want a grease that is more fluid than dryer. There is no need to clean and re lube Your gun . In any springer shooting less than 800 fps I generally use Lithium grease . In guns that are considered Magnums I use the Tune In A Tube from AirVenturi due to its excellent barrier lubes and tackifiers. In a R9 or 97k ,34 and 350 Magnum Dianas Tune In a Tube is the best lube going . Hope this helped You out ,

Gene

Dear BB

I appreciate very much your mentioning of my little observation. It was the least I could do given all what I have learned from the blog.

Best regards!

Vassili,

You cleared up that oversight and I am grateful to you for it.

I am curious about something. Did you you ever serve in The North Caucasian Command of the Soviet Army? Under General Alexi Bimbush? I think I remember a soldier by your name in that unit. Just curious.

B.B.

For those of you who like the ability to swap out calibers easily, and for a very reasonable cost. Check out this video by Tyler of the Hatsan Hydra QE PCP Air Rifle. https://www.youtube.com/watch?v=e4h_O1Q3YQc&feature=em-lsp

Geo

My two Marauder trigger blades are on their way to me. The tracking system informs me they should arrive on Wednesday, the 19th. I hope that with the video and other information I now have, I can replace the trigger easily if I am patient and cautious.

I have found once source that offers both the trigger blade and the sear, reported to be made of durable metal and high grade metal, but nothing more specific.

Both the trigger and sear appear to be something any machinist could fabricate, and I know at least one who has done so for himself. I don’t know him well enough to approach him about doing a job for me, however. I suppose I can casually ask him about it since he did post the fact on a forum.

I even believe the trigger and sear can be hand crafted with a few hand tools.

I suppose Crosman is leaving it to individuals and third parties since they appear to be offering the same product without improvement of material.

The .25 will be getting a bit of exercise over the next few days. Hopefully, all will be well.

~ken

Hey everyone,

Could this gun be a candidate for the gun that moderns to take with them to the parlor when they retire for Brandy and cigars and shooting after the dinner party.It’s certainly not the TR-5 🙂

Brent

Brent,

Are you so sure that we here are all that “refined” here at the blog? Now,… if you are talking having your fill at a good backyard BBQ (dinner party) and heading for the garage/backyard/basement (parlor) and taking the cooler full of brews with you (brandy),… well then,..”we” might? fit that description. 😉

That said,… back in the day,… that would have been a good time (air gun/parlor/brandy/cigars). Even thinking about it has my nose rising to the sky and I seem to have picked up a bit of an English accent. (Refined) accent mind you,…. not one of a commoner. 😉

🙂 Chris

ChrisUSA,

Speak for yourself Sir; but please pass the Port!

The Smoking Lamp is lighted!

I learned how to do this correctly from the Drill and Ceremonies Manual:

“10. Table Setting. A formal table setting using a unit’s silver, crystal, and

china can make a handsome picture. A lay plate is in the center, partially covered

by a neatly folded napkin on top of which lies the place card. To its left,

working from the outside toward the plate, will be the forks in the order of use–

fish, meat, and salad, the latter properly being eaten after the main entree. To

its right, working from the outside toward the plate, will be the fruit and soup

spoons, then the knives in order of use–fish, meat, and salad. However, the

oyster fork is always outboard on the right side. Above the knives will be the

crystal. Again working from the outside toward the center, in order of use–a

sherry glass for white wine, one for red wine, a Claret glass for port (found only

at stag dinners), and a goblet for water. Thus, by merely proceeding in order, the

wrong equipment cannot be used. After each course, a well-trained steward will

remove all extra silver and glass, again aiding the choice of the proper utensil at

the proper time. The dessert implements are normally found on the dessert plate.

If not, they will be innermost utensils of their kind. Butter plates are not used

on formal setting. The center of the table is decorated with flowers or unit

silver. Candelabra will furnish all light. Nuts, celery, etc. are placed in

appropriate dishes and removed at the proper time. Ashtrays and cigarette

containers will be conspicuously absent.

Shootski,

You never fail to amaze,… and it should be no surprise,… as I suspected as much! 🙂

Well done!

While I will forever remain,.. “a legend in my own mind”,… sorry to say that I shall never reach such proper dinner etiquette protocol,… nor sure I would want to. (I recall the movie Pretty Woman,.. and the line which states “I can’t ever remember which fork to use,… for what”) 😉 LOL! Not even if I hit the lottery for a mere 1 Million. I honestly think that I would stay right where I am at, invest it, grow it and see where it could be put to best use.

Simple ol’ me don’t need much. Long term financial security would be a blessing,… but covered good for now.

I am thankful.

Chris

ChrisUSA,

A happy man or woman is the one who has balanced their income and outgo either equally or better still with a small surplus. That is all I have ever needed or wanted. That approach has made for a large measure of contentment; a state of being, far more desirable than the “all the time” happiness so many long for but never have!

Pretty Woman one of our favorite films! Have you seen Richard Gere in An Officer and a Gentleman? I identified with Mayo!

Security of any kind is a Chimera as my parents taught us by relating their experiences losing everything twice in their lifetimes to war(s.). The only hope we have is in our skills, knowledge and the circle of loyal family and friends we cultivate with good deeds.

shootski

Shootski,

Well said. I always aspire to do the same. 🙂 Yes, I have seen An Officer and a Gentleman. Another fine movie. Richard Gere is good. I can relate to him,… with the small exception of everything that I can’t relate to. If it is ok with you,… I will skip the part of loosing everything,… twice. 😉 Understand,… it ain’t the money mind you,… but it sure as heck don’t hurt either. Just sayin’,….. 🙂

Have a pleasant evening,……. Chris

Continued Crosman 147 multi-pump saga:

Today I pulled the pump rod back and put several drops of Pellgun Oil behind the cup seal. That made no difference and the pressure still does not increase beyond 3-4 pump strokes. I can definitely hear air escaping from the tube as the piston nears the valve body. I am 99% sure that air is bypassing the new cup seal as pressure builds. So, not sure what else to do at this point.

Geo

Geo,

I did see. Perhaps, if it is worth it to you,… send it off to an expert.

So,.. the air is leaking past the piston head and back down the compression tube,.. as best you can ascertain?

It is not leaking past the valve (through or around?) which I would think would show a leak at the breech end.

I do not know. With BB and the posters here,.. we have a powerful crew. I am sure that someone here will head you in the right direction.

🙁 Chris

Chris,

Yes, it definitely sounds like air escaping from the compression tube. The valve holds air and the rifle will shoot at about half power, I would estimate. I know it won’t shoot through even one side of a pellet tin.

I already have almost $50 invested in parts. I would like to get it shooting full power, but I am not going to spend a ton of money shipping it off to be repaired. If I can’t do it…it won’t get done. I am running out of ideas though. I can’t buy another cup seal without buy a complete seal kit again. 🙁

Geo

Geo,

Well,… I am hoping BB or someone here can put you in touch with someone that might have an idea of what,.. is up. Beyond that,.. I do not know.

Have you tried asking for another seal from where you got the kit from?,… if an option?

Chris

Chris,

Yes, I have contacted the company I purchased the seal kit from and asked them for recommendations. They were quick to reply, but offered most of the same suggestions as was discussed here in the blog already. I have also sent an email to Rick Willnecker. I purchased the rivet pin and bushing from his company. He does Crosman repairs so I thought he might have some different ideas. He has not replied to me yet.

Geo

Geo

I guess you didn’t try honing the cylinder with a brake hone like I suggested the other day.

If you got length wise scratches in the cylinder the pump seal will bleed air past.

I say do a light cross hatch with a little transmission fluid. And you might as well replace the seal too. If the cylinder has a scratch it will probably mess up the pump seal too.

GF1,

No, I have not tried honing the tube yet. Actually, it looks to be in excellent condition after a thorough cleaning. I see no scratches or pits. I am going to try pressing the brass collar down a little tighter against the base of the seal. Bfrey suggested that air could be leaking past the bottom of the seal if the collar is not down tight against the bottom.

Geo

Geo

Yep if it looks smooth in the tube its probably ok. And yep it sounds like it could be that brass collar.

Let us know what happens.

Dear BB

I regret having to disappoint you! I was born here in Buenos Aires, and my nickname comes from a famous sniper from which I knew in the books by William Craig and Anthony Beevor about the battle of Volgograd/Stalingrad (I also know that there is a film loosely reflecting his story). Had I been reading a book about an American war hero when I first commented in the blog, and I could certainly be signing with a corresponding nickname. I have the greatest respect for any soldier who has fought honorably for his motherland. Though while I was very young I wanted to enter the navy, my father dissuaded me, given the very poor resources devoted here to the national defense, and a certain local bad habit of military messing more with politics than with their specific missions. Time proved his advise was right.

Regards!

Vassili,

Good to hear from folks in other parts of the World. We do not get enough of that around here. I always enjoy a perspective from another world away.

Keep in touch,… Chris

Sorry,… but I must ask,… do toilets really flush the opposite rotational direction in the southern hemisphere? I would weigh on on mine,… but it seems to be one of those modern straight down flushers. The kitchen sink however does seem to indicate a clockwise directional down flow. (just checked) While on the topic of directional flow, do your air guns require a left hand twist VS the the traditional right hand twist? Or,.. is that a bunch of BS?

🙂 Chris

Vassili,

Well thank you for clearing that up for me. And good for you for listening to your father.

B.B.

Geo,

Just wondering, when you put the new cup seal on are you sure that you properly bottomed out the brass cup that holds it in place? If it’s not down tight enough on the seal, air will leak back up between the brass and inside seal wall. Gently grab the seal at its base and try to turn it. If it moves the brass keeper isn’t tight enough to make a seal on its base. On the other hand, you can’t just smack it down too hard or the seal base will distort and flare out going in the opposite direction. Go ahead, ask me how I found this out.

One other tidbit: The new cup seal for my 101 had a thicker base than the original. When installing the brass cup it actually protruded out past the end of the aluminum shaft. When it was driven flush as on the original install from the factory it distorted the base of the seal. After a little measuring, and about 45 sec. on the lathe it now fits as it should!

Geo, keep plugging away! “Good things will eventually happen”

BobF

Bfrey56,

Hey! That is something I had not thought of…great, something new. I was working on the rifle this afternoon. I pulled the pump assembly out and put several drops of pellgun oil behind the cup seal. While I had the piston out I checked the cup seal over. I was able to rotate the seal, though it is not loose as if the brass collar is not pressed down far enough. Maybe if the seal can be rotated at all, it’s too loose? That’s a very good suggestion. The brass collar is flush with the end of the rod. I did wonder about pressing the collar down a little to see if it helped. I can see how it would not be good to over squeeze the base of the seal.

What you say makes perfect sense. Tomorrow if I get a chance I will work on pressing that collar down just a little and see what happens. Thanks so much for weighing in on my issue.

Geo

B.B. and Readership,

My darling wife is free of the Acute Rehabilitation Facility! Our thanks to all of you for your prayers and well wishes. She has more work to do to get over the surgeries getting the nerves and muscles back as much as is possible. She is shooting fora 100% recovery and I don’t doubt that she will if anyone can.

So thank you again and we both pray and wish all of you and yours good health and fortune.

Mrs. & Mr. shootski

Shootski,

Very glad to hear that your wife is progressing well with her recovery.

Geo

Geo,

Thank you,

shootski

Great news Shootski,

Hoping for the best.

Mike

shootski,

Praise the Lord! A good report!

B.B.

Mike,

Thank you for your wishes,

shootski

B.B.,

Our Lord is all! Amen.

shootski

Shootski,

I’m glad that she has gotten home and is very well on her way to recovery. Having people praying for her recovery and having a loving and supportive husband really makes a difference in the recovery of patients.

Siraniko

Siraniko,

Amen!

shootski

Shootski,

Very good. Best wishes for a speedy and full recovery.

Chris

Chris,

We both thank you!

shootski

Shootski

Good to hear you wife is home.

My wife is out of work now since last Thursday. She did something to her rotater cuff in her left arm at work lifting some heavy trash bags out in the dumpster above her head. Suppose to go to the doctor Monday to see what is up.

Always something it seems.

GF1,

Best wishes on the wife getting fixed up soon. The older we get, the more proper lifting and movement are important. Really, it should always be,.. but many ignore until they get past 50 (or so). At least the medical end should be covered by it occurring at work. As I am sure Shootski would say,… being properly fit goes a long way too.

Chris

Chris

Thanks about my wife. And she watches her weight and cooks right. She doesn’t lift weights like I do. But pretty fit for her age.

Things just start happening the older you get..

And we’ll see what happens with her work. They have rubbed me wrong in the past. But had to straighten them out. And have no problem doing it again. Tou know old Gunfun1. 🙂

Gunfun1,

“Always something it seems.” Isn’t that the truth!

We will pray for and wish your wife the best care and a speedy recovery. Gunfun1 you take her company to the mat and pin them DOWN hard! I know you can!

Take good care of her; I know you will!

shootski

Shootski

Thanks. And yep with what you said.

Geo791,

If you could rotate the seal at all the brass cup is not tight enough! It will probably hold one or two pumps okay but once you get past that the higher pressure will force air back up the aluminum shaft portion, out under the brass plug, and finally up the inner seal wall. You have now bypassed the seal assembly at that point. Thats my story and I’m sticking to it!

Don’t know if the 147 is the same as the 101, but the brass retainer plug on my 101 was actually machined with a chamfer on the bottom side where it fits around the aluminum shaft. The chamfer goes down towards the seal when reinstalling. No special installation tool required. Just find a 1/4″ or 3/8″ drive socket that fits the plug, making sure the splines inside won’t contact the aluminum shaft, add small ball peen hammer and have at her. Also put a small amount of rosin on the aluminum to make sure nothing was going to move but that is more because of my OCD than anything else.

Good luck, hope this works for you!

BobF

BobF,

I did as you suggested. I used a 3/8″ ID drill bushing and tapped the brass collar down. I would estimate that I moved it about .030″ to .050″ at the most. I reassembled the pump lever and no more air leaking. It’s now pumping and builds pressure with each stroke. Problem solved. Thanks so much for the great suggestion. I was about to order a new seal kit.

Geo

Geo,

Well done!!!! 🙂 It all sounds a bit odd and something that could easily not get done right. Not very straight forwards,.. in other words.

Chris