by Tom Gaylord

Writing as B.B. Pelletier

An assortment of o-rings.

This report covers:

- History

- Flexibility is key

- O-ring failure

- O-rings as a face seal

- O-ring-assortments

- Hardness

- Some o-ring facts

- The seats or channels they sit in help o-rings work!

- O-rings used other ways

- Summary

An o-ring is a donut-shaped elastomer (pliable) seal that performs sealing functions for hydraulics and gasses. Airguns use o-rings a lot, and for different purposes. They help us enjoy our hobby with a minimum of fuss. But what do we know about them?

History

The first patent for an o-ring was by the Swedish inventor, J.O. Lundberg. It was granted in 1896. Not much is known about him, but Danish machinist, Neils Christensen who came to the U.S. in 1891, patented the o-ring in this country in 1937. No doubt his work originated from his development of a superior air brake that Westinghouse, a leader in air brake technology since George Westinghouse invented the first fail-safe railroad air brake in 1869, gained control of. In World War II the U.S. government declared the o-ring a critical mechanical seal technology and gave it to numerous manufacturers, paying Christensen a stipend of $75,000 for his rights. Long after the war was over and he had passed away his family received another $100,000

Flexibility is key

For an o-ring to work it usually needs to be flexible. One of the most noteworthy failures of an o-ring that was not flexible was the space shuttle Challenger disaster in January, 1986. Caltech physicist and Nobel laureate, Richard Feynman demonstrated that the cold experienced during launch as the rocket rose had hardened the large o-ring that sealed the right solid rocket booster to the point that it crumbled in failure. Let’s see why flexibility is so important.

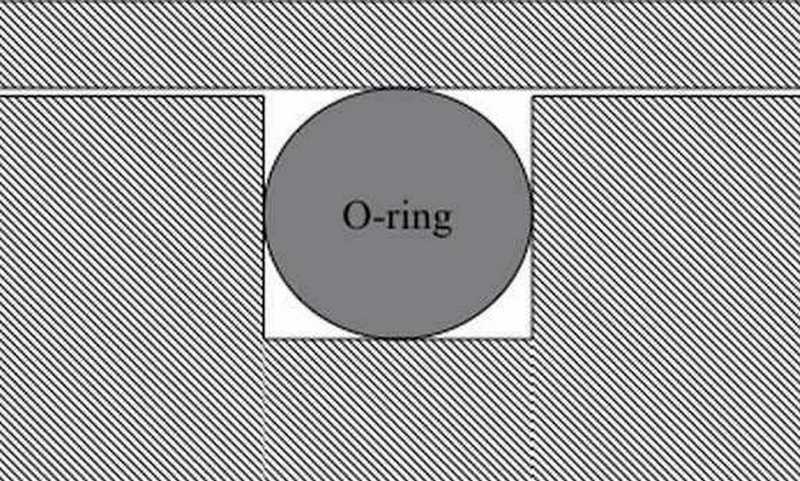

An o-ring sealed two adjoining parts (top and bottom)

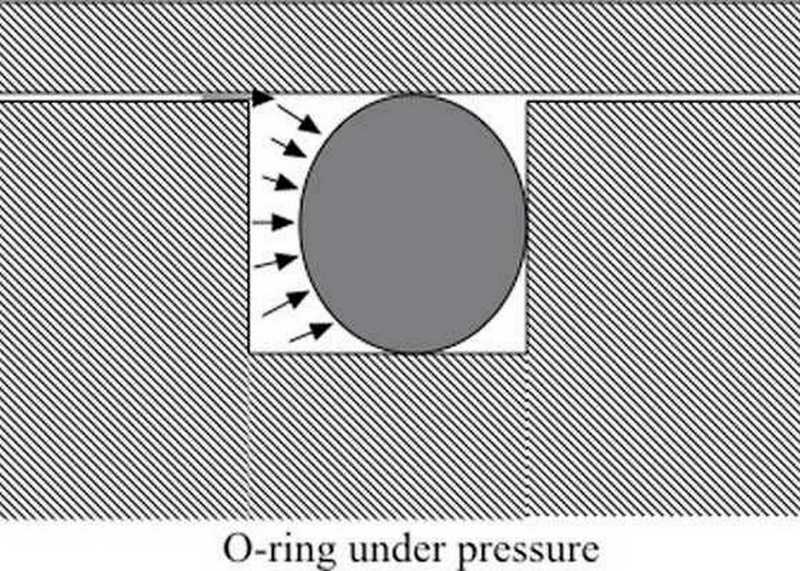

When under pressure (gas is coming from the left in this drawing), the o-ring deforms and presses against the tiny opening at the upper right, sealing it tight.

In both drawings I have made the clearances between the parts larger than it should be, to make it easier to see.

O-ring failure

O-rings don’t just fail in aerospace applications. We have seen them fail from rigidity in airguns, too. Read the report titled Crosman Mark I and II reseal to learn a lot more about them. In those two reports we saw how a hardened o-ring crumbles when it’s removed, and how a fresh one reseals the airgun instantly.

Another way an o-ring can fail is if it extrudes (gets squeezed through) the opening it is trying to seal. That happens when the ring material is too soft for the application or the tolerances between parts are too great or the o-ring channel is cut improperly.

O-rings as a face seal

We also see o-rings used as face seals in some airguns. One common use is as the breech seal of a breakbarrel airgun. I have shown you this many times as I rebuilt Diana air rifles over the years. The most recent was the Diana 27S, whose breech seal had hardened from the passage of time. When I replaced it with a fresh o-ring the rifle gained some velocity, though not the 300+ f.p.s. I initially thought.

Diana breech seal.

Not all breakbarrel breech seals are o-rings, even though they may look like they are. Weihrauch has used specially designed breech seals that appear to be o-rings when they are installed, but when you examine one outside the airgun you see a big difference.

Weihrauch breech seals look like o-rings when they are in the gun, but they are not.

O-ring-assortments

Beware, because here comes The Great Enabler! Several months ago I realized I was buying o-rings one at a time for projects as I needed them. That’s not the wisest thing for a dedicated airgunner to do. So I went online and searched for assortments of o-rings. I found many and it came down to two things — what did I need and how much did I want to spend? For me this is a business expense, so yes it comes out of my pocket — sort of. But when I buy something like this I get to spend it before Uncle Sam can.

When you need an o-ring they are specified by their internal diameter (ID) and the diameter of the ring material. The outside diameter (OD) of the o-ring is just given for informational purposes, because when you think about it, the ID and ring material size determine the OD automatically.

I bought an SAE assortment and a metric assortment, but because they are pliable , they will interchange if they are close. If you want to get really picky, o-rings come in aerospace standard 568 (AS568) and ISO 3601 sizes. They also come in a wide variety of materials with Buna (Nitrile), Neoprene, Urethane, Viton, Teflon (PTFE) and Silicone being some of the most common. Airgunners tend to use Buna, Teflon and Urethane. Buna is more pliable and Urethane is more resistant to tearing and abrasion.

Hardness

A lot of people use the term durometer when referring to o-rings without understanding it. A durometer is a test instrument that measures a nonmetallic material’s resistance to puncture and abrasion. The Shore scale is used. When we talk about o-rings I see the term 90 durometer tossed around a lot. A 90-durometer rating only has real meaning when matched to the Shore hardness scale to which it applies. On the Shore 00 scale a 90 rating is medium hard, while on the Shore D scale a 90 rating is extra hard — almost as hard as it gets! Your car’s tires are a zero to 10 on the Shore D scale and a 90 on the Shore 00 scale.

Some o-ring facts

1. To perform correctly, a hard o-ring needs tighter tolerances than a softer o-ring.

2. An o-ring usually needs lubrication to do its job – but not always.

3. When an o-ring seals something, it only needs to be finger-tight.

4. An o-ring can look fine yet hide a tear or a puncture that will leak under pressure.

5. An o-ring can look ratty yet still seal perfectly.

6. The durometer rating of an o-ring can change over time, as it hardens.

The seats or channels they sit in help o-rings work!

If the seats are too wide or too deep, the o-ring will not seal the joint as intended. Also, the shape of the o-ring seat or channel is somewhat important. While there is a lot of room for slop with an o-ring (that is one of their endearing qualities), you can’t get away with murder. A perfectly square channel with no radius in the corners may present sharp edges to the o-ring under pressure. It can cut the o-ring, causing it to fail quickly!

O-rings used other ways

Besides seals we find other uses for o-rings in airguns. Sometimes they are used to hold things together — sort of like precision rubber bands. I find that a lot in silencers. And a number of rotary magazines use o-rings to hold the pellets inside in place. I’m sure they are used in other ways, as well. We owe a lot to the common o-ring

Summary

There is a lot more to know than what I have presented today. These have just been some of the basics about o-rings. We deal with them so much I thought it would be nice if we knew a few things about them.

B.B.,

You left out that the porosity of the material matters also as that the O-ring swells when it absorbs the oils it comes in contact with.

Siraniko

Siraniko,

Oh, boy! How did I not mention that?

B.B.

Siraniko,

O-rings can also absorb gases, although I suppose the CO2 that they sometimes absorb is in liquid form at the moment. If I recall correctly, that might have been an issue with the (early only?) Umarex Fusion.

Michael

Michael,

Physical properties change when under pressure too. The choice of O-ring material is also determined by the environment it is going to be used in.

Siraniko

B.B.

A most unusual and interesting topic. I use o-rings to help prevent some screws from loosening due to vibration.

-Y

Yogi,

You are a man of amazing coincidence! Loaning my neighbor an o-ring for just that purpose the day before was what prompted this report! 🙂

B.B.

BB,

Now I know who I need to contact!

As you have noted, sometimes a little lubrication can help an o ring immensely. With most PCPs I like to put a couple of drops of silicone oil on occasion in the foster fitting when I fill them. This will enter the air reservoir and disperse throughout the air rifle, many times refreshing the sealing capabilities of o rings. If there happens to be a slight leak at a particular o ring, the silicone oil will migrate to there, lubricate the o ring and usually help seal the slight leak.

DANGER! DANGER! DANGER!

DO NOT USE PETROLEUM BASED OILS! USE ONLY SILICONE OILS APPROVED FOR HIGH PRESSURE! IF YOU DO NOT KNOW WHAT YOU ARE DOING, DON’T!

BB,

A little more on lubrication of o rings. With my RAW, the manual says not to lubricate the o rings, so I have not. I guess I have broken The Golden Rule of Guydom. I hope that I can be forgiven.

RR,

That is quite odd. I wonder why? Maybe they think that people are not smart enough to use the correct oil? Personally,… I would, at the least, would want something at the probe/breech area where there is a lot of action going on with loading of each shot.

Chris

Chris,

Or it may be that the o-rings you would lubricate don’t need it. I really don’t know.

B.B.

I’m fortunate to have one of the worlds largest distributors of o rings 15 minutes from my home. Rocket Seals carries AND MAKES all types of o rings:

Viton (FKM)

EPDM (EPR)

Silicone (SiR)

Highly Saturated Nitrile (HSN)

PTFE (a generic compound of Teflon™, a trademark of The Chemours Company)

PTFE Coated (PTFE coated, usually Silicone or Viton)

PTFE Encapsulated (Usually Silicone or Viton covered with a PTFE tube)

Kalrez, Chemraz, Simriz (FFKM)

Aflaz (TFE/P)

and even make Custom compounds and formulations.

They also carry Quad rings, X-rings, and Square Cut O-Rings

Back-up rings

Cord stock

Spliced and Vulcanized O-Rings

They told me long ago that all O-Rings benefit from lubrication. The problem is that most people use the wrong lubrication, apply it incorrectly, use too much, etc. The second biggest problem of O-Ring failure is over tightening.

Here are some of the things regarding lubrication of O-Rings that they told me that I remember:

1-never use petroleum based lubricants

2-silicone grease or silicone oil is preferred in most applications. Silicone grease stays in place and keeps the O-Ring in place better for assembly-reassembly but for lubing large amounts of o-rings silicone oil is ok. NEVER use silicone oil sprays since they typically contain petroleum based products as carriers. Quit using Vaseline.

3-Food grade silicone grease for many applications is paramount when contact with humans is expected, i.e., scuba diving regulators, medical breathing devices, food production, etc.

As to how much lubricant to apply use common sense. Are you reassembling a watch or are you a plumber putting together a 12″ connection? BTW, silicone grease is so common with plumbing it’s often called and labeled Plumbers Grease.

No Vaseline?! Aah man!

Maybe I will feed my HM1000X a couple of drops of silicone oil.

BB

Useful topic. I had a common garden hose connection that seemed to disdain common “rubber” washers. A new one leaked as much as the old one. O ring to the rescue!

I have a Beeman AR2078A, a descendant of the Crosman 160 family, that uses three O rings where the barrel breech connects to receiver. Some torn places are evident. I replaced those but later discovered I scraped the new ones when connecting the barrel. My bad! Yet the rifle seems to not care. Accuracy is quite good even at 25 yards.

Deck

Deck,

Like I said, sometimes ratty rings work well.

B.B.

BB ,

Most important topic when repairing guns is sizing the seals . There are 2 sizes

SAE which are #009 etc.

METRIC which is ID and DIAMETER so a 7 x 2.5mm is 7mm on the ID and has a Diameter of 2.5mm

Keep in mind when repairing a gun with dried out seals sometimes they will look square ! Measure the seats and OD to help match up . I would say on average a reseal will last about 5 years with Buna . The longevity of the seals is dependent upon the manufacturers keeping the tolerance tight so the seals will not extrude.

Gene

My Benjamin Marauder was not holding pressure. I traced the leak to the pressure guage bolt hole but after further attempts to seal that, I realized the leak was coming along a path from one of two interior o rings that were on the aluminum(?) block that the pressure guage screwed into. Two new o rings from my assortment and all was right with the world again.

Fred formerly of DPRoNJ now Happily in GA

BB ,

Did that o-ring kit come from NAPA ? I have a Metric and SAE set at home also for tinkering, problem is the assortments miss allot of the needed sizes . They go off of AC and Air Tool sizes that are commonly encountered in Automotive work . Not a bad kit for the money , my kit is older and seals are of US mfg. , my friend bought the same kit recently to redo some air tools and they are Chinese seals ! Watch out for the Harbor Freight kits , I have redone allot of customers guns from those soft seals ! Source them from Grainger or McMaster save yourself some frustration and time. My 2 cents for now .

Gene

Gene,

There came from Grainger and were made in China.

B.B.

Fred ,

In Marauders You need (4) #118 in the tank unit and (1) #009 for the gauge block seat . Hopefully this will help out the Marauder owners . First and Second Generations use the same seals .

Gene

B.B.,

Ok now I’m confused. I always use Crosman Pelgun oil on my C02 and Pump pellet/bb guns. They don’t have the high pressure that a PCP has (I think C02 is around 900 psi?) so I was told it was ok. But I never though about Pelgun oil being from Petroleum. So in time, does this hurt the O rings/seals? Would Silicone (like RWS Brand) be a better choice for longevity.

Doc

Doc,

Pellgunoil is fine for all pneumatics except PCPs. It’s also good for all CO2 guns. Keep using it.

B.B.

B.B.,

Ever since this craziness started worldwide I’ve managed to pick up a new hobby of shooting with my air rifle. I picked up a crosman nitro piston .177 break barrel and I love it. I’ve done research on a lot of your videos and such and have seen that to properly lubricate my piston seal i should be using silicone chamber oil only and a very minimal amount (1 drop) through compression chamber. I’m struggling to find reliable info on the correct oil that should be used to lubricate the remaining portion of the gun (if anything else should even be lubricated? ie. outside the piston, hinges, and other places I maybe unaware of?). I’ve read online that pellgun oil should not be used in break barrels air rifles. Manual says no petroleum based oils and only specifies to lubricate the piston seal via the compression chamber. (Also wondering if it is better to lubricate through compression chamber or to manually apply oil on piston seal with a brush after disassembly of air rifle?)

I apologize for the length of this and number of questions in advance. Any help on this would be greatly appreciated. 🙂

Joe S

FirstTimeShooter/Joe S,

Here are some links:

/blog/2016/10/some-talk-about-airgun-lubrication-part-1/

/blog/2014/04/airgun-lubrication-spring-guns-part-2/

Hope this clears up some of the questions you posted. Welcome to the blog.

Siraniko

FTS,

Did Siraniko’s answer work for you, or had you read those reports already?

B.B.

B.B.,

I have just read them and gotten more useful information, but my beginner knowledge is preventing me from being confident on understanding the smaller parts that need to be lubricated. I would again like to apologize in advance for the length of this comment just want to get everything in this. Going to use quotes from those articles to help:

1. “Synthetic seals come in all modern airguns, but since most of them shoot faster than 600 f.p.s., I advise everyone to use silicone chamber oil for their seals.”

I understand silicone chamber oil for piston seal.

2. for the bearings/buttons on the piston that suspend the piston in the gun:

“many of them have synthetic bearings on the outside that suspend the moving parts, isolating them from the rest on the inside of the airgun. Moly should be used for the bearing areas of a gas spring and use it very sparingly.”

Attached is the picture you posted in the article – am i applying moly to the little synthetic bearings/buttons (circled in red in 1st pic)? or is it elsewhere (also have to check if i even have those synthetic bearings/buttons on my piston next time i disassemble)

3. “moly on high-stress parts like the baseblock spacers on a breakbarrel and oil on the common linkage parts.”

I believe i understand the base block spacer and pivot bolt need moly (circled in red in 2nd pic), but the ‘common linkages’ or any remaining spots that i have not circled in red i am feeling unsure of. you also say “oil on common linkage parts” but i am unsure of what type of oil – do i use the silicone chamber oil or what do you suggest for the common linkage parts?

Also still curious about best application of lubrication onto piston seal (drop in via compression chamber or to apply with a brush after disassembly).

Thank you again in advance and the Canadian in me is screaming to continuously apologize for the length of this!

wouldn’t let me post 2 pics so here’s he 2nd pic of pivot bolt and base block spacers (at least i think!)

FTS,

You are doing a great job. From what I can see, you understand almost everything.

Here is one tip. Silicone chamber oil does not lubricate metal parts very well. It’s too thin and breaks down. Use petroleum-based oils for that. 3-in-One oil is a good one for metal parts that are not under high stress. Or a good gun oil like Rem Oil is also fine.

The drop of piston seal oil goes in through the air transfer port, which is the hole behind the breech. If you are unsure, stand the gun (rifle and pistol) up so the muzzle points to the ceiling and drop the oil =into the muzzle. Allow several hours for it to work its way down and into the compression chamber.

B.B.

B.B.,

Thank you so much for your help. Just to get a quick final recap:

-silicone chamber oil for piston seal and breech seal

-moly for pivot bolt and base block spacers

-petroleum based/3 in 1/Rem Oil for common linkage parts and for outside of piston (? this one i am not sure on still maybe you could elaborate a little bit more)

Thanks again and hopefully this will be the last of my questions on this topic for now 🙂

FTS,

That’s right. On the last one that you are not quite sure of, you are using plain old lubricating oil on everything that needs to be lubricated and doesn’t need something special.

B.B.

Off topic,

The neighbor went out today to get some .177 pellets for his Swiss Arms something or other whammy blaster (other stuff too) and stopped at Rural King and Walmart and “said” that both stores were out of (all) pellets and bb’s.

Anyone else seeing this? I will be at (probably) both on Fri.,…. so I will see for myself.

Chris

Chris

Was at Walmart the other day and they had pellets and such.

And just to say I got my order today of some pellets I ordered from PA Saturday after 3:00 pm. Got my tracking order Monday morning. So normal dilevery time for me which I was surprised. And I ordered JSB .25 caliber AirArms .177 and .22 caliber and Winchester round nose pellets. So they was all still in stock at PA.

Gunfun1

I too had a quicker delivery than expected from PA. The Sig ASP20 arrived. So far it lives up to expectations. I chose not to clean the barrel which did not appear to have much machining debris in the bore. I decided to shoot it out with Basics pellets while sighting in a scope. First try at 25 yards using JSB Heavy .177 yielded a 10 shot .80″ followed by a .55″ group, good enough to think breaking in, pellets and hold testing would be promising. This robust rifle exudes quality and looks like it will last many years. Oh, the trigger really does adjust as advertised and as BB said.

Stay safe.

Deck

Deck,

Well done! That is a pretty darn good endorsement right there! Was it scoped for the groups?

Chris

Edit,…. looking again,… I see it has no open sights,… so of course scoped. Still,…. very nice!

Deck

Thanks for the update about PA and the Sig ASP20. Sounds like it is a nice gun.

And cool you was able to just shoot it to break it in. I don’t like having to do extra work just to try to get a gun to shoot good.

I thought we would hear more from people who got these guns. Glad you gave a update.

Gunfun 1 & Chris

Yep, scoped. Not with a Whiskey which would be nice. My opinion only is that being limited to 25 yards distance, the cost/benefit does not make sense. I shoot firearms at a rifle range and that is a different story. For the Sig I mounted a CP 6-20×50 which requires eye position and relief to be in one place. This is bad for anything except target shooting with no time constraints. It takes away parallax problems (learned this from BB).

I am pleased with this rifle. I should repeat what has been said by others; it is heavy but I love my FWB300S which is also heavy. Deck shooting or a sitting position is perfect for a heavy and steady gun.

Deck

Deck

Sounds like its possibly a nice bench rest gun.

And forgot what JSB heavy .177 pellet are you using? The 10.34 grain pellets?

Gunfun1

JSB Exact Diabolo 10.34 grains. It is only the first pellet I’ve tried. Weather yesterday limited my fun.

Deck

Deck

Yep I like those pellets. The AirArms 10.3’s are the same and work just as well from what I have seen.

And the weather hasn’t been cooperating for the last 3 days or so here. Rainy and cold and extremely windy. Suppose to be sunny and in the mid 70’s but windy again. The wind is suppose to stop tomorrow. I hope.

But keep us updated on the ASP.

Gunfun1

I have 2 favorite AA pellet types but have not tried the 10.3 gr. Will try them.

Winds persist here also but got two 25 yard 10 shot groups with Sig ASP20 & JSB Heavy 10.34 gr. First was another .80″. I changed to a curled palm artillery hold under the mid forearm. Trigger sqeezed by index finger and thumb on top of stock grip. This second group was .43″ which I think is surprising in swirly 6-10 mph wind. I shot one 10 shot group which measured .63″ with my HW50s in .22 using Its favorite pellet, H&N Field Target Trophy 5.55 mm head diameter or larger for comparison. This Weihrauch is one of my best wind airguns. I will do further layman testing on the Sig and give you summary.

Deck

Deck

It actually turned out to be a good day here after noon time. My guns seemed to be grouping good effortlessly today when the wind calmed down. I was most happy.

And that is nice groups with your guns. I see you are happy with the ASP. And to show up your favorite wind gun says something.

And yes try the AirArms 10.3 grain pellets. I think you will be happy. And to top it off they are cheaper than the JSB 10.34’s.

Sounds like you are having a good time shooting your air guns. You know that’s what matters the most. Especially right now with this covid stuff.

Enjoy yourself is the best I can say. Looking to hear more from you. 🙂

Gunfun1

Update on my Sig ASP20.

I said I opted for a popular priced CP 6-20×50 scope considering my 25 yard maximum target range. My mistake, POI began wandering every whichaway. Frustrated about the poor accuracy I switched to another scope and got a 10 shot 1/2″ group at 25 yards. I confirmed it with a quickly shot 3/4″ group. The upshot of this is I learned the hard way what most responders on this blog already know. A powerful springer needs a scope that can stand the shock.

Deck

Deck

Yep amazing what can come up with this air gun stuff.

Glad that different scope did the trick.

Deck,

Thanks for this comment. Is the first scope perhaps adjusted past thge halfway mark foir elevation?

B.B.

B.B.,

This is a great report that brought back memories. As a radar guy, I work a lot with waveguides, which are basically a single conductor with a rectangular cross section. To prevent moisture in the waveguides, many systems that use them have them pressurized. I recall one antenna I worked on years ago that was supposed to work down to minus 40 degrees F. Indicators from flight test equipment showed that the waveguides were leaking somewhere along the line. We were suspicious of the antenna, the back of which was covered with small sections of waveguide and dozens of O-rings. So we stuck the pressurized antenna (with hoses running to it) in a bath of Isopropyl alcohol, and started adding dry ice, while we monitored the temperature (note: this set up can get down to minus 77 degrees C). Sadly, long before we hit minus 40 F, the antenna leaked like a sieve, because the O-rings shrank too much and failed to produce a good seal. On the bright side, it was a cool test, and we got some great pics of it bubbling in the alcohol (next to a thermometer)…our boss was impressed…fun stuff! =>

Thanking you for the memories,

dave

Dave

Would of liked to seen that experiment.

Gunfun1, it was crazy fun! Our Quality guy actually pushed for us to be allowed to do it…

…just as long as he got to be there, and he was. =)~

Dave

Well of course he had to be there. 🙂

A rule of thumb that is often useful for sizing O-ring groves in heavy machinery goes something like this: The O-ring is somewhat larger than its nominal cross sectional size — for example, a 1/8″ O-ring is actually 0.139″ cross section. Make the groove depth the same as the nominal cross section size, so 1/8″ deep for a 1/8″ O-ring. Then make the groove half again as wide, so 3/16″ wide for a 1/8″ O-ring. This rule of thumb is not the same as given in the O-ring charts but is representative. I suspect this method is not used for O-rings in airguns.

Gordonsbuck, that’s pretty interesting; thank you for sharing it. =>

After long years, I pulled out my Walther LGR and found one of its breech seals turned into brown crumbs. Makes me wonder if the LGR had a leather seal in the breech. Thanks for the blog today, it comes just vin the right time 🙂

Mel,

No, the LGR had a synthetic seal and it did what you described.

B.B.

Hi BB,

On the .177 Benjamin Marauder Gen 1 (BP1763), when replacing the four big o-rings (1763-026) on the Valve Assy, Fill Adapter Assy and Gauge Port Assy, what material should they be made from?

Thanks,

Doug

Doug,

That is a question for someone who knows the answer. I suggest you talk to Gene Salvino at Pyramyd AIR Tech Support, or to Crosman.

BB