This is a guest report on 3D printing by reader 45Bravo whose name is Ian McKee. Just the title seems attractive to me!

If you’d like to write a guest post for this blog, please email me at blogger@pyramydair.com.

Take it away, 45Bravo.

3D Printing obsolete airgun parts and airgun stuff

by Ian McKee

This report covers:

- Parts

- 3D printer

- If you can think it, it can be made

- The colors and possibilities are endless

In June 2016, BB wrote a blog titled. “How hard can it be?” about what it entails for a person or company to make or mass produce old or obsolete airgun parts for resale. It’s a good read, but with the proliferation of low cost, high quality 3D printers for personal use, and the hobbyist who has time on his hands and likes to tinker, that manufacturing model has taken a new direction.

Back in 2011, B.B. wrote a 3 part blog about the Cybergun 4.5mm Mini Uzi CO2 airgun. By the comments, it was a pretty popular and reasonably accurate gun.

Mini Uzi.

A few years ago, I picked up an early model Umarex 4.5mm Mini Uzi CO2-powered selective fire submachine gun that was not functioning. The Umarex Mini Uzi was actually made by KWA in Taiwan, but is marked IMI and was sold under license from IMI (Israeli Military Industries), the maker of the firearm Uzi.

Since the gun wasn’t working, and it is an iconic firearm in history, and it is relatively small, I hung the Umarex model on the wall over my desk/workbench as a decoration.

I had intentions of getting the parts to fix it, but just never got around to it.

Parts

Fast forward to the present day, with the high prices of firearm ammunition, and my recent experience with the Crosman DPMS SBR BB gun, my interest in the Uzi was rekindled.

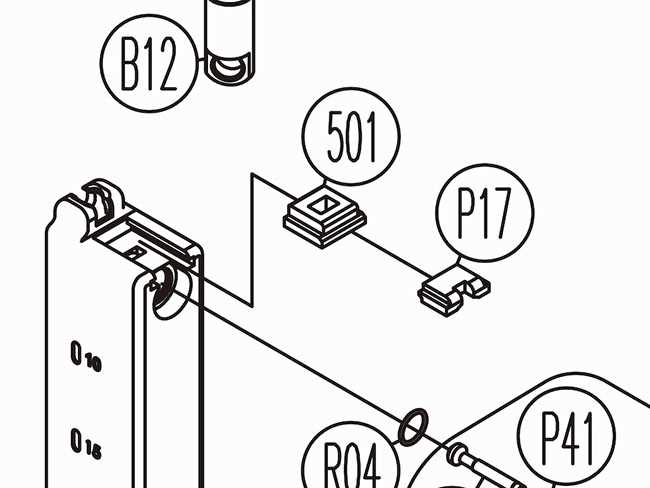

Umarex no longer supports the gun, and KWA is not shipping replacement parts until further notice due to Covid. Some places still sell new old stock magazines for about $50, but all I need is a $4 part. It’s part number 501, called the Gas Route Packing, is basically a rubber seal that routes the CO2 gas from the magazine to the bolt at the moment of firing.

Do I really have to spend $50 to get a $4 rubber part, and still have only 1 working magazine?

3D printer

Enter personal 3D printers to the rescue. I had the chance to buy a gently used 3D printer called an Ender 3 Pro, for $100 used. It sells online for about $240.

Ender 3 Pro

My new toy!

It looks a little like a science project, and needs some assembly, but that prepares you to perform any needed maintenance it may need in the future, like tightening belts or replacing worn parts, or even adding new upgrades to the printer as they evolve.

If you are not familiar with 3D printers, basically you would use a Computer Aided Design program (called a CAD program obviously) to “build” a 3 dimensional drawing of something you have dreamed up, or a part of something you need but can no longer get. Many free-to-use CAD programs are available online.

If you have the original part, you can take measurements and draw the replacement part. Once the drawing is “built” digitally, you can save and share the file with anyone in the world and they can replicate your part for themselves.

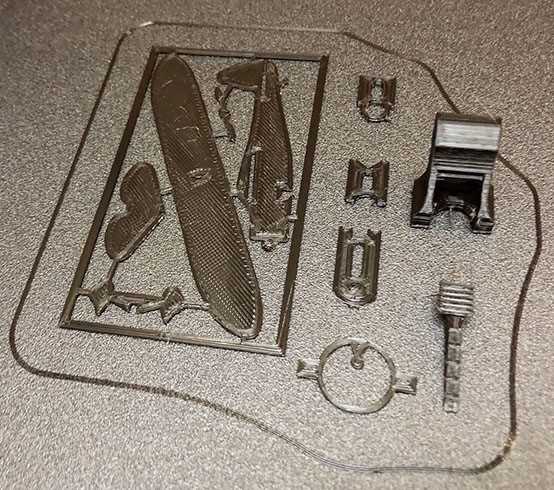

Pellet tin dividers.

The printer is basically a computer controlled hot glue gun that applies a series of very thin layers of about .16mm thick of a material called filament, (it looks like weedeater string) in precise X, Y and Z coordinates to build a 3 dimensional object, layer by layer.

There are several sites on the internet where people share 3D printer files of many different things, including many parts and accessories for airguns so you don’t have to be versed in a CAD program to start printing things, just download and go!

I found the file for the part I needed on thingiverse.com, this file is free to use, but it is covered under a non-commercial license by the designer, so anyone using this particular file cannot sell it commercially but they are free to download and use it for their personal enjoyment.

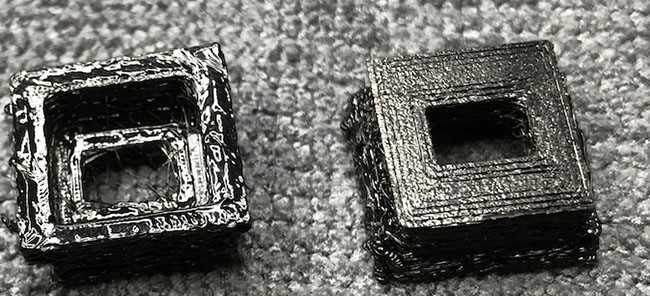

But many files on the sites are free to use in any way you wish, including the right to sell the parts if you want. Since I am new to 3D printing and am still in the steep learning curve stage, I put out a feeler on one of the airgun forums, and got a response. One of the members already had his printer setup to print in rubber, and printed me 10 of the parts for the cost of the printing filament, and shipping. Thank you Roger. The parts may not be the prettiest things, but they work, and now I have a lifetime supply of them.

These parts were printed with a material called Priline TPU. It is soft like rubber, but also durable.

If you can think it, it can be made

Do you need a multi-shot adapter for an Air Arms S200? The 3D printer files are available online for FREE.

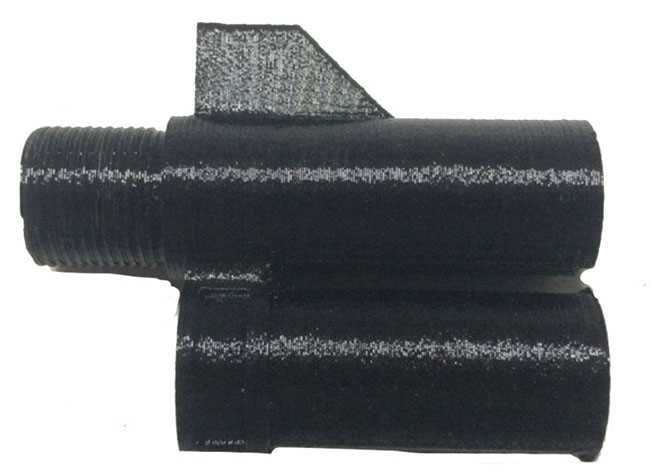

Do you need a front sight insert for your vintage airgun? Yep, you can print one. Rear sights for your Crosman 1377? Toys for the kids and grandkids? How about a 1/2×20 adapter to put a moderator on your Crosman 13XX custom build you have been working on?

13XX front sight and adaptor.

Barrel band.

All of these items were printed at the same time. They are a little rough as I did not have my printer calibrated correctly at the time I printed them.

Scope mounts for a Crosman Mark I? Yep, I have files for those too.

An inexpensive no-gunsmithing mount for the Crosman Mark I&II guns.

3D Printers are capable of printing in many types of filament, the filament most commonly used is called PLA (Poly Lactic Acid) and is available in many colors but you can use ABS plastic filament and some 3D printers can even print in metal.

The colors and possibilities are endless

So, sound off in the comments, post some ideas, what parts for an airgun would you like to see printed?

Shoot safe, have fun.

Ian

Funny, just yesterday I was looking at the M3 Grease gun on the PA site and noticed the distinct 3D pattern trail on the front sight.

I got an M11 Bullpup stock conversion from a company that specializes in 3D printed bullpup and custom stock conversions for airsoft and paintball enthusiasts, and ?

There always seems to be an obvious tell tail printing pattern exposed but to be honest it looks like a high tech design and not detrimental at all when high precision equipment is used.

This company, SRU-Precision.com has some really nice 3D conversion stocks they print out and now they are into protection gear. Worth checking them out. Some may even work for or be modified for air guns.

Bob M

Bob M,

The detail on the M3 is incredible! They even have the weld beads and the front spring barrel lock! I would not be surprised if you could take the barrel off like the original.

RR

You may be right. Don’t see another way to get inside it.

They are getting good at making these plastics look and feel like metal. The Crosman AK1 is the same. They even replicate spot welds.

Bob M,

I have seriously considered one of those TCFKAC or Umarex rockolas, but I have a real serious hang-up about replica airguns.

But now TCFKAC has come to the rescue! This year they will be introducing the ST1, which looks like something an Imperial Storm Trooper would carry.

I have long thought someone should be introducing syfy and steampunk designs into the airgun world, most especially with all of these “replica” airguns out there.

The airgun platform offers up a whole new designer’s dream world, limited only by imagination. This has been touched on before, but not really explored very much. The manufacturers are starting to experiment with such.

RR

Have not seen that one yet. Mechanical looking things get my attention.

For example, early motorcycles are works of art to me with all the working parts .exposed.

Bob M,

You would really like some of my antique air rifles. They are awesome, cool looking.

/blog/2019/01/webley-service-mark-ii-part-7/

Yes, I like the old bikes also.

RR

Yes I like that one. A good mix of metal and wood.

They are cool. I been thinking about getting 3 or so of them and make some things and also get some printing contracts.

My boss at the machine shop I work at his wife has 4 of them right now. She gets contracts on line of like 100 piece runs of parts. He says she averages a little over a $1000 a month. But will make $2000 a month occasionally.

To me it sounds like a nice layed back job/hobby when I retire.

Y’all are giving me mental whiplash. You went from yesterday’s “they don’t make ‘em like they used to” crotchety old men to this stuff in one day!!!

Motorman

St. Louis, MO

Motorman,

That was intentional! Today’s report inspired yesterday’s. 😉

BB

That’s our enabler at work there!

Ian

The only limit is your imagination and the material strength that you print the part with.

Siraniko

Ian,

Thanks for the cool report!

Do you know the shore hardness factor(I think that is what it is called) for the various plastics and rubber that you had made?

Thanks,

-Yogi

I do not, I have been printing my own stuff for about a week, I am still a kid with a new toy!

Will have to dig in deeper when I get over the newness factor..

Yogi,

From searching on the web Priline (brand) TPU (Thermoplastic Polyurethanes) has a Shore A hardness 98. While PLA has a Shore D hardness of 83 against ABS which has a Shore D hardness of 76.

Siraniko

Siraniko,

I like my girls in a Shore 00 80; slightly firmer than a baby bottle nipple.

shootski

Ian,

Most interesting. I have thought of getting one of these “toys” myself. I can think of a few airgun projects that would work well.

Greetings all!

I certainly agree with this post. A couple of years ago I got into the 3d craze, and wound up making some really useful things for my old Sumatra. My personal favorite was a carrier for loaded magazines. The mag design didn’t have any pellet retention built in, so if you tried carrying them in the field, they’d just dump the pellets out in your pocket. And, I made a couple of ways to carry said magazines. One was even a sidecar mount. Fun stuff!

Here’s the carrier..

Very cool!

B.B.,

All I can say is “Wow!” I missed yesterday’s report (was offline) till this morning; hence, I concur with Motorman, “Y’all are giving me mental whiplash,” but I mean that in a good way, of course. 🙂

Thanking you for all you do,

dave

Fascinating stuff; this is great, empowering technology which is actually useful, as opposed to a lot of the life-wasting “tech” out there in Etherland. Not just for the airgunners, but also for others, like vintage vehicle types seeking parts made of Unobtainium. FM can see the benefit and potential for replicating parts made from early plastics, such as Bakelite, and at reasonable cost.

Ian,

Thiank you for this blog. You have given me a lot to think about. I like to take care of things and keep them forever. While I am aware of the potential of 3d printing, I had not considered how it could be a way to “source” obsolete parts. This opens a whole new world for long term ownership….

And the pellet dividers! Clever.

If you look, one of the dividers is taller than the other two.

the shorter dividers stack on top of each other and are sized perfectly to fit inside of a Crosman pellet tin.

Ian

Sometimes the part just needs to be cast, and a small mold made, TAP plastics has all the things for that. My GSD’s hearing is so good, if I even put my hand on the frame of my Emperror Scorpion 1911, she will come trotting in from a nap in the bed room because its BB time! Its still holding up. Nice report too, waiting for the metal powder ones.

Rob

I have a question for those of you with legal minds: could there be copyright or patent

issue by making parts in this manner? I suppose that with obsolete parts there wouldn’t be a problem, but what if someone started “printing” brand new Umarex airguns and selling them online under the “Knockoffs” brand? Just my devious side oozing to the surface here. It’s ok, my attorney at law friends, it’s just a thought. No lawsuits here, please. Orv.

Hoppalong Doc,

If I reckon correctly it is more expensive and time consuming to print a commercial item than it would be to simply buy it off the shelf. 3D printing’s advantage is that you can make a prototype and make changes as needed. We are still a long ways from Star Trek replicators that will produce what we ask for.

Siraniko

Be this as it may, it seems as if we’re entering a Brave New World, not of my ken. Orv.

Thanks Ian!

Thingiverse.com is an interesting place to browse isn’t it! All kinds of neat stuff!

Been (casually) looking at 3d printers ever since I saw a $100,000 one demonstrated at a trade show a couple of decades ago. That unit could scan and replicate a complex 3d object just by putting the original on the turntable and pressing the start button or create the object from computer files.

Prices have come way down and reliability/functionality has improved to the point I’m considering one for all the reasons you list in your report. I’m holding off because the hot plastic fumes will make this an “out in the garage tool” and we still have a couple of months of winter to endure yet. We’ll see what new technology and models are available in the spring.

Another technology that is of interest is inexpensive CNC routers for the home use. They are designed mostly for 3d carving wood but can also handle plastics and soft metals. I’m researching them to see if they are accurate/consistent enough to machine parts for airguns. Seems that there is quite a cottage-industry of people buying several of the CNC routers and making signs and stuff.

Yeah, you said it right: TOYS What a time to be in your second childhood eh?

Hank

I have been casually following them as well.

But when this one dropped in my lap with 2 spools Of filament, I had to jump on it.

The filament runs about $20 a spool (1 kilo) and has about 330 yards on a spool.

Don’t blame you – I would jump on a deal like that as well! Great that you got one!

I should keep an eye out for a used 3d printer, guess that people will buy them as a novelty and sell them when they realize there’s quite a learning curve and printing things is slow.

That’s exactly what happened here, the owner was into drones and drone racing.

His friends suggested he get a 3D printer so he could make his own parts when he needed to replace broken ones.

He thought it was just set it up once, and turn out parts as needed.

But to get accurate parts, you need to be more into it than just throw the file at the printer.

To get my best prints I adjust the bed level before I start printing, then make sure the first layer is laying down correctly (if it isn’t, the part could shift and ruin the print).

Ian

Good morning brother-in-law. FYI, I regularly use the bike you “gifted me“. This was a fascinating off-topic blog since I regularly work with seismic data on a workstation and enjoy using a computer. While I look forward to your daily airgun blogs , I also enjoy the off-topic ones like firearms and your long adventure with using a straight razor to shave. So let me make a suggestion. Since many of us want to learn to use this newer technology, why don’t you look into purchasing a new or used 3-D printing machine and walk us newbies through what we need to know about these pieces of hardware. What brands to look for or avoid? What accessories should we be looking for with the 3-D printer? What size printer versus cost should we be looking at? The other piece of the puzzle is what software to use and which one gives you the most bang for the buck? Does it matter if you use Apple or Microsoft operating system?

Once you are set up and running, why not have a contest of your subscribers and have them send in the part that they would like you to “build“ on your new 3-D printer for their airgun? After you select a winner, then you can write several blogs on your first experience using the hardware and software to manufacture this item. It would be a learning experience not only for your subscribers but also for you and we would all learn together what is involved in 3-D printing process. Just a suggestion for a future blog. Stay safe.

Bob,

Thank you very much but I just spent the whole enchilada on a new computer this morning. Got to work hard and make some more money.

BB

BB

I seen that your computer failed the other day.

What happened?

GF1,

Battery died.

BB

BB

I’m guessing a laptop. Couldn’t you just replace the battery? I did one many years back in a laptop I owned.

If You don’t mind I will throw in a couple of things you mentioned that I neglected to include in the blog.

You can run windows or Mac, but there is more software out there for the pc.

I run Mac myself, but all of my certifications are in Windows environment.

I am running my software on 2 different machines, one is a newer MacBook Pro with the latest OS.

And the other one is a 2011 MacBookpro running High Sierra.

I like the keyboard on the 2011 machine so I use it to type my articles, the newer one is half the weight of the older machine, and has a newer style keyboard I don’t like the feel of so I use it when I am traveling.

I convert the files on the laptop, and save them to an Micro SD memory card.

And insert that card into the printer and print from the printer menu.

You can physically connect the printer to the computer, but you don’t have to.

Ian

Ian

We use ethernet at work. We have 50 machines or more that we send programs we write with cad cam and such to the machines. Then they get set up to run the part/parts.

I’m guessing that’s what your using your SD card for. Kind of a flash drive I suppose.

The engineer at work that was doing tool holder development with proto type 3D printed mock up parts got into it with somebody at work and guit. All that stopped at work. So now nobody even talks about it. I think it was in a way to advanced for work in some people’s minds but other people wanted more of it to happen. Me I think it was wrong timing at work for the 3D printing (experiments. Anyway that’s done at work. I myself think he presented it to them wrong at work. Upper management thought it would be different is what I believe.

Hard to know what the higher ups think, sometimes they treat us like mushrooms. (If you know what I mean.)

I worked for a company in the 90’s designing monthly sales flyers for Ace hardware stores.

we were farming all of our SyQuest 88 mb data drives backups to an outside company to burn them to CD, costing like 3 grand a month I showed my supervisor a CD burner (they were not common for everyone to have one back then) and priced what it would take to set up a computer to do our own backups.

He got the ok, we set it up and paid for the system in the first month.

He got the pat on the back.

I got to do the backups….

Ian.

Here is some obsolete info for your reading pleasure.

https://obsoletemedia.org/syquest-ezflyer/

This sound brings back memories.

https://m.youtube.com/watch?v=Z7eBkXLzTH4

Ian

Yep know what you mean about the other guy getting the pat on the back and then I got to do the work. And you know ole Gunfun1 wasn’t to shy about letting both of them know what I thought. It didn’t really make much difference but at least Gunfun1 felt better. 🙂

My first Elaborate self design project will probably be a set of ambidextrous grips for the Crosman Mk1 series, they do make filaments that are infused with real wood particles, and it prints really neat.

Then I will try a set of grips for the Crosman 38t guns since the left grips seem to break or get lost over time.

Right now I am learning how fine of a resolution I can print.

The wheels on the car actually roll.

The car and egg are printed in place, so no assembly required.

The car was one print file, the egg was another.

And yes that is a penny under the car.

Ian.

Nice and can see you’re having fun with it. Good idea on replicating the 38T grips – when I shipped my revolver to Precision Pellet for repair and overhaul, Rick Willnecker said to keep the grips home “because you can’t find replacements.”

Exactly, I have had to repair the indexing post on the left side of several.

They are unobtanium unfortunately..

The hard part would be the retention clip that connects to the co2 cartridge.

But I think a couple of neodymium magnets would solve that problem.

Ian

Non-genius FM has managed to solve a problem or two with those neodymium magnets – they make pretty handy hack solutions sometimes.

45Bravo,

Ian i want to start out saying how much I always enjoy your Repair Blogs.

I did a reply on yesterday’s Blog about Right To Repair but posted it late in the day because i have been paddling most mornings since we have no good snow nearby.

I hope you agree that a repost is okay.

From yesterday a reply to Faulty Manual:

” iFixit.com and other sights are a big help getting accurate diagrams, removal of intentional booby traps, Manuals, Diagnostic Tools, Parts Lists, Specialty Tools, Independent Repair Shop Support, and how to information to consumers.

Part of the Right to Repair Movement is about the attempts by some to change the basics of Ownership. We aren’t talking about Warranty rules but what you actually Own when you paid your money to buy something.

The Tech World started this shift but the Business Model is spreading fast.”

shootski

Even John Deere is against right to repair.

Gone are the days a farmer kept his tractor going with bailing wire and pliers.

You need a laptop and the right software to keep a diesel tractor going now.

Ian..

45Bravo,

There are airguns and other shooting tools, E.g,, (exempli gratia) Chronographs that require on line Firmware and App updates.

We need a Guest Blog from PA about their experience with Right to Repair issues from a merchant’s perspective. PA provides some parts, Manuals, Perhaps how the various Manufacturers help or hinder the process of being an independent Repair provider as well as a Warranty Repair Station.

I also wonder how many PA customers have viewed this linked page:

/faq#Service

And, NO they don’t repair John Deere Tractors or Combines!

shootski

Ian

True but not completely. Other things mess up besides the computors.

That’s why FM likes the “legacy machines,” with no digital anything on board. Love the smell of a carburetor in the morning!

Kids these days have no idea what “points plugs and condensers” are used for……

Or lug wrenches, grease guns, spark-plug gappers…

Way off topic but still into repair and replace. They are replacing all the wood powerline poles with pre-rusted metal ones outside my home (CA) while I’m trying to read the blog.

Even the cables are new and ‘insulated’. A solution to downed power line fires here and perhaps an end to the precautionary high wind advisory shutdowns.

A helicopter with a heavy weight hanging from a cable drags the new lines for miles from a huge spool across rollers installed on the poles. Then the linemen transfer it to the insulators. Amazing thing to watch.

Bob M,

Pre rusted…same color as Boxcars?

I sure hope those Insulator are very robust or…

Let the Electrocutions Begin!

shootski

When we lived in Colorado, they started installing cell phone towers on the mountain tops.

People complained about the unsightly towers.

Then they came up with the “Franken Pine” it was a cell tower, but made to look something like a tree on top of the mountains.

Ian

45Brovo,

I think I ran into at least one of those! In Miami and the Keys they have ones that look like Palm trees; here in Washington DC they make them look like Shot Spotters or some legislators hung in Effigy closer to The Hill… Lol!

shootski

Shootski

Here in San Diego we have a very big elevated water tank on I believe a college campus and it is completely rust covered. They did however attach a big silver metal cloud to it, art ?

Anyway a local free paper called the READER did an article on it in response to questions as to why it was left so ugly.

Evidently the rust coating actually acts as a rust inhibitor and requires no repainting. Kind of like gun bluing but much uglier. Perhaps the word spread to SDGE that this would be great for the new metal power poles.

The part that enters the ground and a little above is covered in a light colored epoxy paint. May be powder coat?

I’m sure it’s a chemically induced rust. It looks just like a wood pole from a distance.

We have one of those pine tree transmitters here also. Looks like a big fake pine Christmas tree, too perfect.

The rusted finish is possibly CorTen steel. It is a common finish on road structures, light poles, etc. Protects like bluing but does not require oiling.

jumpin,

I bet it is COR-TEN® or a clone of it!

https://www.ssab.com/brands-and-products/cor-ten

US Steel was the originator of the real stuff. One of the most interesting misuses of the stuff was by Chicago; they have a sculpture called “Chicago’s Picasso” (actually unnamed) that is fabricated of COR-TEN® that was nice and shiney when it was installed. Well not long after it quickly turned rust brown…Oh My! So the city paid to have it POLISHED! I wonder if they still are polishing the thing AWAY to this day?

Maybe Bob M can start a “polish the poles and the water tank” movement! After all they are rusting away with “Chicago’s Picasso” aren’t they

STUPID Government at work spending our taxes!

shootski

jumpin

Checked it out, that must be it, thanks. Probably the same material used on the border wall.

Bob

I would like to see that cable install.

GF1

You know I actually took a few pictures and then decided nobody really cares about this and deleted them 🙁 They already ran the 4 white cables.

Strange, they cut off the top of the old wood pole and left the telephone cables in tact on it. They were much lower.

Bob

Crazy amazing stuff. I love flying stuff.

I would of been watching and shaking my head in amazement. Glad you posted about it.

GF1

Found one

Bob

Thanks for the picture. I bet that was cool watching the helicopter maneuvering.

GF1

Hell of a pilot. He had to lay that cable on a small roller while keeping enough tension on it to avoid it drooping too much between the poles or lifting it off one as he went down the line. He kept those rollers humming on all the poles till he reached the end beyond my line of sight. Almost a Circus act. And those lift trucks were hopscotching down the line behind him. They may have been adjusting and locking down the tension between poles? A lot of noise and dust blowing.

I had no less than three warning signs ‘in my dead end driveway’ warning about men at work and being prepared to stop with a road guard director who spent all his time retrieving the blown over signs.

Bob

It posted in the wrong place. It was suppose to be after your comment about a hell of a pilot. And I agree.

GF1

You just described the reaction my neighbor and I had. The dogs had to be contained they went crazy.

A once in a lifetime event for sure. We made sure we did not distract the traffic director in our driveway too. Who knows how many lives we saved from a head on in a one lane detour. Come to think of it … it is only a one lane road all the time anyway?

Bob M,

Looks like a Bell 206; could you tell if it was a single or double engine?

shootski

Shootski

No, too high. Zoomed in on my phone, no help but the exhaust does look a bit off center in the pic. Lineman said they sometimes use the helicopter to drop the poles in when the place is not accessible by the crane truck.

Hate working on helicopters.

Too much time on H2 Kamen and H3 Sikorsky

B.B.,

“Battery died.”

Which battery? The one on the Motherboard or the one that powers your laptop when not plugged in to line power? If Motherboard battery (typically a Coin Style) it should be replaceable and your laptop will be able to function normally. The main Off Line Power battery can also be replaced but most manufacturers don’t make it simple; either the actual remove an replace or sourcing the actual replacement are intentionally made difficult.

Hopefully whatever the case you didn’t lose any files in te evolution.

shootski

Shootski

Evidently we ran out of reply space so I dropped down to here.

Now I can’t have people going around saying “All he does all day is polish his pole” They may get the wrong impression. Besides there are too many attachments on it to keep a steady ‘Wax on, wax off ” stroke.

However … there are many plastic plugs in all the predrilled holes in it and when they dry out and rot away these poles may start whistling Dixie in the wind.

May need a 3D printer to recreate them. Or fine tune the pole to play a nice entertaining song. People could be employed as professional power pole tuners. New jobs for all the unemployed !

Crap … perfect for bee hives 🙁

Bob M,

Yellow Jackets! Need to issue Bug-a-Salts to the Linemen.

They need to 303 the plastic plugs! That is the same stuff we used on our cockpit canopies back in the ’70s to keep them from going opaque in the tropical sun.

shootski

Shootski

Never used it but it looks like something I could use now. Spent a lot of time using canopy polish and Never Dull.

Ian, to answer your original question at the end of your excellent article, I would like to 3D print a copy of me and set it up at work so I can go fishing.

Seriously, there are many vintage guns that are very hard to source parts for, let’s say there was a rubber part that dried up and started to crumble or a plastic part that got fatigued and broke. That’s where I would start.

I believe there are also 3D scanners now, too. Imagine: scan a 3D part and then the machine makes its own CAD file and makes 3D copies in any color.

My understanding is that 3D printers were initially used in industry for limited runs of making parts for testing to lower the cost of tooling before ramping up production. Now they have gotten cheap enough and use so many different kinds of polymers, rubbers, and even metals, that they can be used just for fun! They also can be built huge and can make parts of houses, and even bridges. Amazing technology.

RG

You are dead on about companies that are using 3D printers. They are the smart companies.

All,

What I want to work on is a extended mag for the Semi Auto Marauder (SAM) that will hold 20 or more shots.

It will hang out the right side of the gun and 2 springs will feed the gun. The normal spring in the Marauder mag and a pusher spring to move the pellets like the Co2 bb mags.

Of course there will be things that need revised as they come up.

The way I see it is the 3D printer gives me the option to try to make it. Before the 3D printer tell me how it would of been able for a individual to do. Probably very unlikely unless you was a very good machinist or even die maker to injection mold it. Either way it would of been difficult to accomplish.

And just to say. One of my next projects that I have been thinking about doing is turning a Semi Auto Marauder (SAM) into a .25 caliber instead of a .22 caliber. I think it’s really not going to be hard at all.

BB, 45Bravo, P/A

Sorry for kind of hijacking the blog with this power pole stuff. Did not know it would be such an interesting topic.

OMG. Just had an epiphany !

I could use one of these printers to make up lots of ‘Round Tuits’ and catch up on all my deferred air gun projects. Not to mention the rest.

Nothing wrong with discussing technology and innovations that REALLY innovate. That’s why FM loves to watch “Dirty Jobs” with Mike Rowe. Speaking of water tanks, there was a really interesting episode recently about cleaning out the insides of a water tank in Mississippi. He oughta do a show about working in an airgun factory. 😉

FM,

You nee to visit a Wastewater Treatment Facility!

One I have visited repeatedly over the years is: https://www.dcwater.com/blue-plains

Interesting what comes into that plant! But more interesting is how clean the water is exiting the facility to the Potomac.

Since I paddle the tidal Potomac River often i keep tabs on the biggest source of clean water and potential pollution of the water i practice my self rescue techniques and rolls in.

shootski