An assortment of o-rings.

This report covers:

- History

- Flexibility is key

- For all of this to work as it should:

- Correct material

- The seats or channels they sit in help o-rings work!

- Not always round

- Other uses

- Why I wrote this report

Today we look at o-rings. Airgunners use o-rings a lot. Some airguns are noted for how many o-rings they contain. Precharged pneumatics (PCP) use a lot of them, as do CO2 guns. Even spring-piston guns can have a few — with the most notable being the breech seal.

I used to have a couple jars of o-rings until realizing that I was always looking for the right one. That’s when I broke down and ordered two sets from McMaster-Carr — one in metric sizes and one in SAE sizes. Now when I need an o-ring, these boxes are the first place I go.

History

The first patent for an o-ring was by the Swedish inventor, J.O. Lundberg. It was granted in 1896. Not much is known about him, but Danish machinist, Neils Christensen who came to the U.S. in 1891, patented the o-ring in this country in 1937. No doubt his work originated from his development of a superior air brake that Westinghouse, a leader in air brake technology since George Westinghouse invented the first fail-safe railroad air brake in 1869, gained control of.

In World War II the U.S. government declared the o-ring a critical mechanical seal technology and gave it to numerous manufacturers, paying Christensen a stipend of $75,000 for his rights. Long after the war was over and he had passed away his family received another $100,000.

Flexibility is key

For an o-ring to work it usually needs to be flexible. One of the most noteworthy failures of an o-ring that was not flexible was the space shuttle Challenger disaster in January, 1986. Caltech physicist and Nobel laureate, Richard Feynman demonstrated that the cold experienced during launch as the rocket rose had hardened the large o-ring that sealed the right solid rocket booster to the point that it crumbled in failure. Let’s now see why flexibility is so important.

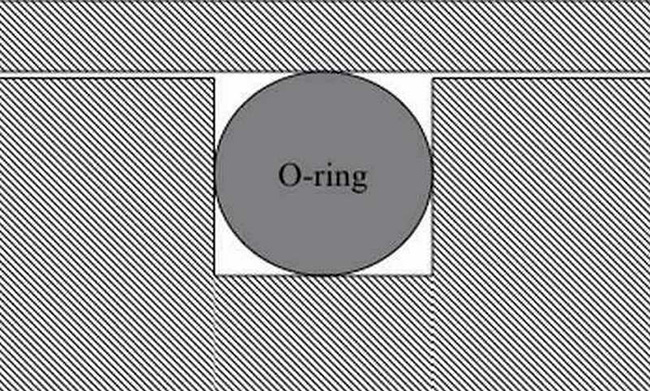

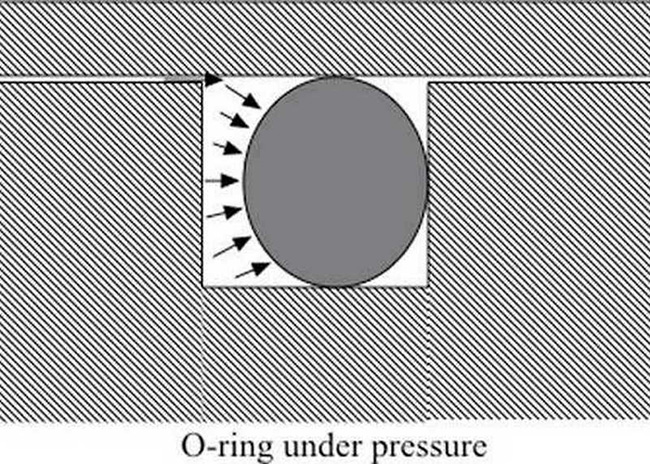

An o-ring seals two adjoining parts, that are located at the top and bottom.

When pressure hits the o-ring, it distorts. As long as the hardness is correct and the groove the o-ring sits in has the right dimensions, the distortion causes the o-ring to flex just enough to seal the parts.

When under pressure (gas is coming from the upper left in this drawing), the o-ring deforms, sealing the tiny opening at the upper right.

For all of this to work as it should:

1. The o-ring channel must be cut right.

2. The o-ring hardness must be correct.

3. The diameter of the o-ring material (not the outer diameter of the entire ring — the diameter of the material the ring is made from) must be correct.

4. The pressure of what is being sealed must fall within acceptable limits for items 1 through 3 above.

5. The o-ring must be made from the correct material.

Correct material

Let’s talk about what the o-ring is sealing for a moment. You see that in the US o-rings only came into use around the start of the second world war. There were airguns made before that time that used leather washers for the same purpose as an o-ring.

When CO2 cartridges were first used in airguns in the late 1940s, the choice of materials o-rings could be made from was very limited. Most early o-rings in guns were made of a material that was porous to CO2 under pressure. After being in a gun and charged for hours or even days, the o-rings were swollen with CO2 gas! They were several times their normal size, which made it all but impossible to open the gas chamber to install another cartridge after the old one ran out.

To fix the issue he gun had to be aside for hours, to allow the gas to slowly leave the O-ring. If you didn’t wait, you would tear the O-ring by unscrewing the cartridge chamber when the ring was still swollen.

The Schimel was notorious for having o-rings that swelled!

The seats or channels they sit in help o-rings work!

You can see in the two drawings above how the size and shape of the o-ring channel is critical for sealing. In fact that (the size and shape of the o-ring channel) is the reason for today’s report. I will explain in a moment.

Here is an o-ring being used as a breech seal for a Diana breakbarrel air rifle.

Not always round

O-rings are always round in their outer shape, but the material they are made from isn’t always round. Two other shapes are square and the quad ring that’s often called X-shape.

Three of the most common shapes of o-ring material.

Other uses

Besides seals we find other uses for o-rings in airguns. Sometimes they are used as elastic bands to hold things together — sort of like precision rubber bands. I find that a lot in silencers. And a number of rotary magazines use o-rings to hold the pellets inside in place. I’m sure they are used in other ways, as well.

Why I wrote this report

I wrote this report because of the upcoming SigAir Super Target air pistol test. In that test we will see whether the height and the shape of an o-ring makes a difference to the velocity of that airgun. I will also show you an alternate way to accomplish similar results. I sure hope it works!

B.B.

About the material o-rings are made of?

Is durometer number the important one for breach seals?

What materials hold up better with petroleum products and high pressure/temperature?

-Yogi

Yogi,

Good questions!

The answers are not as straightforward as you may think. For the petroleum question I don’t know, specifically. What I do when I don’t know things like this is research the material for the application at the time I’m making my choice, because the technology is not static.

For the hardness rating, I know this:

The hardness of rubber o-ring compounds are measured by the Shore A durometer; the higher the durometer, the harder the compound. 70-durometer hardness should be used whenever possible as it offers the best combination of properties for most o-ring applications.

Durometer Shore A scale is a type of measurement for rubber material hardness. The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application. Generally, most rubber materials fall under the rubber durometer scale of Shore A. If you need a rubber or O-ring durometer that feels like a running shoe sole, review our rubber hardness chart below, then pick Shore 70A. A rubber durometer of Shore 70A is the most commonly chosen material hardness for all applications.

Duro 20A = Rubber Band

Duro 40A = Pencil Eraser

Duro 60A = Car Tire Tread

Duro 70A* = Running Shoe Sole

Duro 80A = Leather Belt

Duro 100A = Shopping Cart Wheel

*Most common durometer for O-Rings

And that came from https://www.theoringstore.com/store/index.php?main_page=page&id=7#:~:text=The%20hardness%20of%20rubber%20o,for%20most%20o%2Dring%20applications. They are The o-ring store.

Go to a different retailer and you’ll see a different answer. In other words — it depends.

BB

Ugghhh.. Where was this on Aug 16th 2022 when I ordered a full set like the one that you showed above that are 90d! 🙂 I am guessing they are too hard for any airgun application. Well, at least I know what to get now. Thanks BB!

Bob

Bob,

Not so! I have already used several of these o-rings in the set pictured above as breech seals. They work well for that.

BB

Thanks BB. Thanks for letting me know!

Side note: I went ‘dumpster diving’ in a pawn shop yesterday for a tool that I needed, when I spied a lone airgun in the corner. $49 later and I have a fully operational Webley & Scott Vulcan early Mark III in .177 and imported by Beeman. Overall good condition but missing both sights, shoots at full power, right at 11fpe (818fps w/7.4gr pellet). It has a Beeman lead collector on the barrel end, and a 4×15 scope made by 8 Lenses in Japan. I already have it torn down for cleaning and touch up. Research shows it is supposedly a sister gun to the Beeman C1, the inspirational gun of the artillery hold.

Bob

Honest Bob, $49! Man, you got a sweet deal! 🙂

As I had suspected. Great find. Most pawn shops have no idea what they have. Unfortunately, around here most pawn shops are also gun shops.

BB,

This is a very interesting report; both of the Haenel model 1s I got from Frank (both the .177 and the .22) have modern round o-rings for their breech seals. I don’t know if they came that way from the factory (1938 for the .177 and 1941 for the .22), or if someone upgraded them at a later date. Both seem to work well; I’ve tested both rifles from a rest with a piece of tissue paper on top of the breech and it did not move during the firing of either rifle. So, if someone added them at a later date, they chose the o-rings well, as neither seems to allow any blow-by of air during the firing sequence. 🙂

Blessings to you,

dave

dave,

They probably did have o-rings because they were made in Germany and that country was ahead of the world in this technology.

BB

Cool 🙂

Dave,

All of my old Haenel breakbarrels – both model 1’s and 3’s, came with leather seals. I have used orings as a replacement since it is easier than cutting a new leather seal and they last longer without getting permanently compressed.

Paul in Liberty County

Paul in Liberty County,

Thank you. While I’ve seen BB do it here on this blog, I lack his skills at leather cutting; hence, I also will be using replacement o-rings in these rifles should I ever need them. Yet both have fired thousands of rounds in my hands (and God alone knows how many total!) and are still shooting great; I think these current o-rings will last me the rest of my life. 😉

Blessings to you,

dave

BB,

Another thing you might want to check on is any movement of the barrel that may be creating a gap with the seal. Loosen the attaching screws and see if it pushes in some.

Thanks for this overview. Finding the correct material, size (inner and outer diameter, thickness), material shape, etc. can be mystifying when one is trying to find replacement seals, especially when manufacturers want to sell you the replacements.

You could probably do a deeper dive in one or two more reports.

For my projects I usually find seal kits on EBAY made for the exact model I’m working on. For the Crosman Mark I and II, I have used seal kits of all white urethane o-rings. But for a vintage Beeman R7, I found a breech seal on Pyramyd’s site, size and material, unknown. I will eventually need a few o-ring breech seals for my collection of Winchester-branded Diana springers and my other recent acqisitions.

Errata: under the heading “Correct material”:

“Let’s talk about what the o-ring is sealing for as [a] moment.”

Roamin,

Got it. Thanks — that was a good catch.

BB

I’m looking forward to shootski’s comments. I know he has a deep knowledge on this subject.

I’m kicking myself for missing out on an online auction for a Bronco, although someone had stained the stock a darker color. The winner got a sweet deal.

There’s more information about o rings here than I saw in 4 1/2 years of engineering school. Great write up.

My go to for information on o-rings is the Parker O-ring Handbook. The Parker sales representative would visit our company from time to time and handout copies of the latest handbook. I still have a copy, but life is easier when Parker made it available online in a pdf format. This contains everything you could possible want to know about o-rings: the recommended sizing guide, recommended material for the fluid and operating temperature, and the list goes on… There is 51 pages of fluid recommendations alone, the total amount of information is extensive.

Including recommendations for Yogi’s question, and it depends but generally Buna-N (sometimes called Nitrile NBR) is a low cost option for low temperature <200 F though the maximum operating temperature for Buna-N is 230 F. I find that o-rings tend to fail faster the closer you are to the upper temperature limit.

Typically you can expect a NBR o-rings to last 5 to 10 years but improper installation or removal can lead to premature failure. A higher price option for the same application is Viton, which has a higher temperature limit and with an expected life of greater than 30 years.

https://www.parker.com/content/dam/Parker-com/Literature/O-Ring-Division-Literature/ORD-5700.pdf

bmwsmiley

A word about Viton. As I recall, the hot setup for Amal carburetors on British motorcycles was to replace the fuel bowl inlet needle valve with a Viton tipped unit, in the case that the seat for the needle had worn slightly. I would guess that Viton was soft enough to seal well and resistant to petroleum degradation.

Bill

I would suspect the original problem was the seal taking a set, permanently deformed and no longer sealing completely. Viton takes much longer to take a set than Buna / NBR.

Lots and lots of good info here for folks concerned with resealing their airguns.

Just so you folks know, leather is a superb alternative in some uses. I have several airguns that use leather for their various seals. The major drawback with leather is you must keep it lubricated with an oil of some sort so that it will swell and seal. The oil also will help it remain pliable.

I often use silicon oil, but it does not matter much as these leather seals are often in lower powered sproingers with no problems of dieseling or detonation.

If memory serves correctly, using a hollow punch for those leather seals works well. A set can be had for $10 at Harbor Freight. Just make sure the size of the punch will be large enough to make the leather seal diameter you need.

Fred formerly of the Demokratik Peeples Republik of NJ now happily in GA

B.B. and O-Ringership,

To make Roamin Greco happy: bmwsmiley has a good Resource for Information and the O-ring Store B.B. used for his research and purchase has extensive and accurate technical information as well.

What i can add from experience is that on PCPs your fill fitting Buna-N O-Rings will fail if you fill too fast so if you cannot control the fill rate use Vitton (expensive) polyurethane (a little cheaper) in 80-90 durometer is your go to choice.

You need to also look at the:

Extrusion Gap Pressure Info, section/chart

in the Link that Tom supplied.

Final tips:

Age, Solvents, Oxygen, UV, and heat are your O-Rings enemies (in use as well as in storage) and in that order. Age just means using them, giving them away to cheap airgunners sooner or throwing them out; better than installing them only to watch them promptly fail.

You can use Oxygen absorbers and put them in sealed plastic bags to keep them as fresh for as long as posible if you buy a big kit. Store in a cool place NOT near Arcing Electric things (electric motors) and other sources of OZONE (O³ a type of Oxygen) or the O-Rings will be useless pronto.

USE REAL O-Ring picks/tools.

Better to learn before the first installation to buy at least two (or more) since you WILL damage them while learning where and how to avoid that on the next try.

shootski

Long ago when I was on active duty, we had a significant portion of our high pressure air system go down due to rapid pressurization of the 4500 psi air system. That was several hundred man hours of work and a delayed deployment to replace failed o-rings. All due to being in a hurry. By procedure: raise pressure a a rate not to exceed 100 psi / second. The estimated rate actually used was about 3000 psi / second, 0 to 4500 in less than 2 seconds.

4500 psi air leaks are down right dangerous.

Mike

Mike,

Let me try a guess:

Gas Turbine cold start system.

Certainly beats the shotgun shell Remote Operations J-57engine starts on the Whale (A-3 Skywarrior) aircraft.

shootski

I was on submarines. The 4500 psi air was for the Emergency Blow system and distribution to lower pressure air systems, 3000, 700, 400, 150, 100, and the lowest 20 psi.

My advice as an aircraft hydraulics tech. Don’t mess with O Rings unless you plan on replacing it. You would be pressing your luck trying not to destroy it. Especially if it is old. They can get hard and distorted.