Air Venturi Avenge-X classic wood.

Part 12 where all the earlier links are for the Avenge-X wood stock report series

Part 13

Part 14

This report covers:

- What was part 14 about?

- Research

- Replace gauge seal

- Tap the rifle on the bench

- Time to stop and think

- Oil the rings?

- High flashpoint oil

- Today’s lesson

Today you learn something about precharged pneumatics (PCP).

What was Part 14 about?

I said at the end of Part 14 that the Air Venturi Avenge-X PCP rifle was fixed. I said it no longer leaked. That was true for a week and then the leak came back and this time it was worse. What did I need to do? The Pyramyd Air Cup was approaching and I didn’t have any time to work on the airgun because I was writing additional blogs to put into the bank for the trip.

Research

When I returned from the Cup the reservoir had leaked down completely so I started looking into things to do. I thought it was a bad seal under the reservoir gauge that I had tightened, but when I looked at that seal this time I saw no real damage. But I replaced the seal anyway, just in case. The Avenge-X comes with a set of o-rings and seals for the entire rifle, so I had all the parts

Replace gauge seal

The wood stock had to come off to replace the gauge seal — only so the wood wasn’t damaged. I will say that taking off the two screws that must be removed to get the stock off the receiver is a bother. They are two different sizes and only a half millimeter apart. Air Venturi — make both screw heads the same size! Once the stock was off replacing this seal was extremely simple.

The reservoir gauge seal is super easy to replace.

Rifle held — almost

After the seal replacement the rifle held air for a few days then started leaking again. I put soapy water around the base of the reservoir gauge and could see no bubbles so the leak was somewhere else.

Soapy water revealed the leak was not the air reservoir gauge seal.

I aired up the rifle and the air leaked out slowly. It took about a week to drop all the way. I could not hear a leak. I went online and one fellow said his Foster fill nipple was faulty. So I pulled mine and found a hardened o-ring. Maybe that was it?

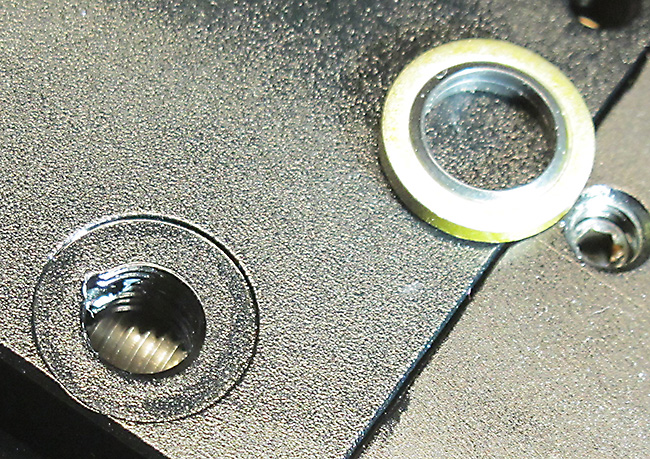

The o-ring cracked when I tried to remove it. There was no resiliency. You can’t see it in this picture but I could see that the ring had taken a square shape, indicating it had hardened.

The new ring was fresh and perfectly round in cross section. But when I put the Foster fitting back in the rifle and filled it, all the reservoir air came back out the Foster fitting. There was something wrong with the fitting.

I searched online for a replacement Foster fitting for an Avenge-X and found none. So I asked Tyler Patner where I could buy one. He asked if I had replaced BOTH o-rings on the Foster fitting and I told him I only saw one. So he sent me a schematic of the fitting and I saw two parts that I had not seen on mine. They were at the rear of the fitting, so I removed mine and, sure enough, they weren’t there.

My Foster fitting was missing a rear part and a second o-ring (arrow).

Tap the rifle on the bench

I’ve seen this sort of thing before, so I tapped the muzzle of the rifle on my workbench and, sure enough, both those parts came out. The smaller second o-ring was fresh and pliable.

And there on the left are the two Foster fitting parts I had not seen before.

This o-ring and part were dry so I applied some O-Ring Super Lube before assembling the complete Foster fitting into the rifle again. This time the Foster fitting worked as it should but the rifle still had a fast leak that I could now hear. It lost a thousand psi in about 30 minutes and it sounded like it was coming out the rear of the air reservoir.

Time to stop and think

I had some things to ponder at this point. First — this air rifle is relatively new. I received the rifle in October of 2023 so even with shelf time and transportation it can’t be more than two years old. Why had the first o-ring in the Foster fitting hardened? The only answer I can think of is it was made from flawed material, because o-rings shouldn’t harden that fast. It probably still worked, though I am glad I replaced it.

Next — why had the rear part and its o-ring remained in the rifle when the Foster fitting was removed? Answer Because they were dry. That rear part slides in and out of the Foster fitting like a valve, but there is no spring moving it. Only air pressure makes it move and when it gets dry it can stick.

My next question was — were the other o-rings in the rifle also made from flawed material and did I need to replace them all? Before doing that I did something that is very uncharacteristic for me. I asked someone.

Remember when I told you that spring guns are easy for me but PCPs and CO2 guns are my bane? Well, Ian McKee is the opposite. To him PCPs are simple. So I talked to him.

Oil the rings?

He asked me if I had oiled the rifle when I filled it. Well — not really. Ian says that o-rings need oil on them to keep their seal. When he said that I remembered a couple reports I had read about o-rings earlier this year. I looked at both of them again and neither one mentioned oiling them. Funny thing is, I wrote them and I am the cheerleader for using Crosman Pellgunoil in CO2 guns for just that purpose. Funny that I never saw a great need for oiling PCPs.

So with Ian on the phone I put three drops of high-flashpoint silicone oil into the female Foster coupling of my carbon fiber tank and filled the Avenge-X. Then I listened as the hissing sound of leaking air diminished and finally stopped.

High flashpoint oil

Use only special silicone oil with a high flashpoint for this. Silicone chamber oil is good. The cheap stuff from the hardware store is for squeaky hinges — not for high-pressure air.

I dropped three of four drops of high-flashpoint silicone oil into the female Foster hose coupling, then connected it to the Avenge-X and filled it.

I fired the rifle several times to distribute the oil to all seals and o-rings and then set it aside for observation. The reservoir tube was hot after the fill so I waited 30 minutes and checked the gauge again. It had dropped 200 psi, which means the rifle is now holding. I filled it to 3,500 psi and a day later it is still at that point.

Today’s lesson

Instead of wasting a month fiddling with the Avenge-X and replacing a few small seals I could have fixed it in five minutes by oiling it as I just described. If you have a leaking PCP this is something to consider.

This is exactly what I’ve done for the past 25 years for PCPs. I took my old aa410 apart when the pressure gauge failed and no rust at all from years of hand pumping. Just pure silicone oil drops when filling

Edw,

Yup!

shootski

B.B.,

I know that both RidgeRunner and a few others have stated this many, many, many times.

I even told you and the Readership about fixing the leak on my neglected early 2008 Benjamin Discovery just a few months ago. It had held 2,000 PSI for years until i brought it out to get reacquainted and it started leaking at the gauge port area. It took a few drops of RWS Chamber Oil and a few fills over a few days and it was back to holding 2,000PSI fills.

to all you PCP owners a drop or two into your fill port/Foster fittings and hoses will not only keep your guns from leaking for years but your hose fittings as well; most have O-Rings.

If you or someone else haven’t contaminated your air tank, reservoir, or cylinder with salts or organics you will probably never have a corrosion problem with them either!

shootski

I have one word for this whole thing, Pathetic. This should have been done when the air rifle was assembled. How much can they save on a few drops of oil.

Each & every ‘o’ ring used on aircraft comes in a sealed package with complete information and a shelf-life date. It’s not useable if the packet was found opened.

I hope they don’t buy them in bulk and leave them exposed.

Checked my Aveng-X, holding good at 1500psi, however my Western Sidewinder is at ‘0’ psi. Not so pretty good.

Got away from scheduled maintenance in my retirement, not too much is critical anymore. But neglecting airguns could get costly. I think it was the downfall of my FX Independance. Lack of lube inside.

Bob M,

Of course, the manufacturers buy them in bulk and leave them exposed. Airguns are not as critical as aircraft.

A little silicone oil injected into your Sidewinder may be what the doctor ordered. It will certainly not hurt.

Tom,

So PyramydAir should be looking for a high temperature silicone oil for its PCPs to brand and market as the equivalent of Crosman Pellgun Oil, but for PCPs?

Siraniko

Siraniko,

They could do that, but since they already sell several silicone oils for that purpose I reckon they figure it’s taken care of.

BB

It would not be a bad idea.

So, is it one drop per fill or a couple drops per year, or a couple of drops when it starts leaking Air? Does extra oil get blown out like a CO² gun? Can one put too much oil?

Roamin,

I would say more is better.

BB

RG,

I use a couple of drops every few fills. If you should happen to use too much, the excess will be blown out.

Like the Harley manuals, this is something that is not mentioned, but some learn anyway.

B.B.

Very knowledgable PCP shooters at my range say that o-rings should be replaced every 2-3 years. I mentioned this once and you said Phooy! Thanks for this blog, you made my weekend! lol…

Would using pellgun oil be a good idea for PCP’s like it is for CO2’s?

-Yogi

Yogi,

I guess I don’t know everything, do I?

Pellgunoil is made with petroleum and should not be used in high air pressures because it could detonate. In CO2 combustion isn’t supported so Pellgunoil is safe.

BB

B.B.,

“…I don’t know everything, do I?”

To be expected.

You are only The Godfather of Airgunning® and not God the Father.

The Yogi springer demon is testing you….

shootski

😉

Yogi,

NO! Pellgun oil is petroleum based. You would be asking for a major explosion with HPA in PCPs. Use only high temp silicone oil in PCPs.

You should also keep Pellgun oil away from sproingers. I apparently had one of the seals in my CFX go out and allowed some of the petroleum lubricant into the compression chamber. That was impressive. My CFX made a loud bang, much smoke and destroyed every seal in it.

Great report, thank you! Is the construction of the foster fitting fill port typical of most of them? I can see how those parts that you found (that stayed in the gun) could act as a check valve. I have a Benjamin Marauder that has a sticky check valve. It usually takes about a thousand psi difference to open it up. Making it more difficult to top off the fill unless the gun is actually getting quite low on air. Adding a little silicone oil a couple of times, like you show, hasn’t improved this noticeably. If it doesn’t get any better soon, I will probably see about replacing it. So your report is timely for my situation.

This topic reminds me of your issue with the Rov-Air compressor that you sent back a little while ago. Have you learned what the problem is yet?

Elmer,

Most foster fittings are much shorter. Some have the check valve as an internal part and most have a spring to assist in closing the valve.

Thanks RR.

Elmer,

Are all Foster fittings like this one? I don’t knoiw but my guess is they are.

The RoveAir compressor? At the Pyramyd Air Cup I met the man who will be fixing it. He broke his wrist before coming to the Cup and won’t be able to repair most things for a while. That’s as much as I know.

BB

Elmer Fudd,

The construction of the foster fitting on the Avenge X fill port IS NOT typical of most of them.

The typical Foster fill fitting in PCPs is the foster fitting with a sliding check that is made from a screw/bolt blank with an O-Ring on the head end with NO Spring assist.

The lack of a spring is why a quick opening of the bleed screw is needed to slam the slide check closed due to back pressure/flow.

https://www.portlandbolt.com/technical/faqs/bolt-blanks/#:~:text=Bolt blanks are headed bolts,the necessary amount of thread.

shootski

Thanks Shootski, it appears to me, in BB’s photo, that the bolt blank and O-ring are the separate parts that stayed in the rifle until he bumped them out. They appear to fit onto the end opening to form the check valve. I think that there must be a cylinder inside that part of the rifle with enough clearance for that device to open. And an opening for the air to enter the pressurized air holding chamber. Are you saying that most foster fittings have the check valve built inside the fitting?

Elmer Fudd,

Crosman, Benjamin, and Quackenbush airguns i own all have a KISS Foster Fitting with the slide check inside the Foster Fitting. That fitting end is housed inside of a fill port assembly that provides a STOP for the slide check during the fill; often including a sintered metal filter. It appears that some manufacturers have turned to complexity for some reason with springs and extras that, in my opinion, are a failure to understand that simpler is typically better in the long run. As i stated elsewhere today the key to getting the non spring assisted Slide Check to function properly is to depressurize the fill device QUICKLY on completion of the fill.

NO bleeding it down to avoid making the cats jump!

shootski

BB,

As shootski has pointed out, I have recommended using silicone oil in filling PCPs. The Edge had a slow leak, but after an application or two of silicone oil, it stopped. I had the exact same issue with my brand-new Maximus. A little silicone oil fixed it right up.

Not only will the oil help to soften the o-rings, but it will migrate to the leak and help to seal it. This second part is pure conjecture on my part, but I do believe it is the case.

This does not have to be done every time you fill it as is recommended doing so with Pellgun oil in CO2 airguns, but every few fills should help. Pure speculation on my part, but I imagine it will also help with internal corrosion.

I myself only use a few drops when I do such. If you should get excessive you need not fear. What does not coat the o-rings and internals will be blown out. This will also lubricate the barrel, at least until the next pellet goes down range.

BB,

Friday before the weekend is really a very good time to bring this subject up. All PCP owners need to be aware of this. With the weekend to discuss this, a goodly portion of these folks will discover this “trick” and hopefully will take this to heart and do such.

FM is one who needs to do this with the Maximus Brothers, though have done it in the past – suspect not often enough.

FM,

Are they leaking down? If not, they do not really need it, but it will not hurt. It will help to keep the o-rings soft and pliant. As I have said, the next time they are shot the excess silicone oil will likely be blown out.

Two are leaking down though very slowly – the .177 and the one you allowed FM to adopt. Have given them a dose of chamber oil in the past, but probably not enough. Will get a Round Tooit and shoot them soon after giving them some “medicine.” Honeydoos, work, weather and life in general have thrown wrenches into FM’s shooting schedule.

On top of that we’re looking at more rain and gloomy weather to come down here – though thank God we’re not as waterlogged as other much more unfortunate areas.

FM,

I do hope that a little silicone oil will be all that is needed to fix both of your Maxes and you find a little trigger time soon.

B.B.,

This discussion is a good reminder for us to lube our PCPs as described. I read the summary and got up to lube my leaking AA200T cylinder even before reading the comments. It’s highly unusual to tear myself away like that. Having read the comments, I’ll go lube the sticky female fitting and give the rest of the PCP girls a few drops at the next fill up. Knowledge is air power in this case.

I added a total of about six drops of RWS Silicone Chamber Oil in and gave it some air from the tank, in two doses. The leak was so pronounced, that at 50 bar (725psi) the plastic cover of the pressure gauge started to squeal and I could change the pitch a little by touching the edge of the housing. I’ll see if I can play the Theramin part of “Good Vibrations,” by the Beach Boys when I add more air. Actually, I hope no air comes out.

Thanks to everyone involved in today’s blog for sharing their experiences.

Regards,

Will

Will S.,

Well, we are waiting to read if this fixed your leak or not.

If not, you may have a seal that is just too far gone and will need replacing.

RR,

I left the tank standing on its end to see if oil would migrate to the the leaky end overnight. Today, the tank filled to 75 bar (25 bar more) and the gauge cover started squealing. This time, the squealing only stopped when I touched the edge of the gauge, so no music could be attempted. I added more oil, but I think you’re right, the leaky seal is too far gone to hold useful pressure. It leaked down to 50 bar after a about fifteen minutes.

This is a nine year-old tank and I already bought a replacement for the rifle. But it would be neat to get the old one back into shape as an experiment! I still need a strap wrench to see if I can budge the gauge.

Will

Will S.,

In some of these air rifles there is a “block” inside the air reservoir that the gauge screws into. There are two o-rings on this block on each end of it. The gauge may have a seal on its end where it screws into the block. You may be lucky and get away with replacing this particular seal.

Will S.

Could it be the gauge itself?

https://blog.wika.us/products/pressure-products/burst-pressure-what-it-is-and-why-wika-chooses-not-to-publish-it/?doing_wp_cron=1728235507.2791380882263183593750#:~:text=A gauge’s burst pressure is,parts from the gauge internals.

Good info.

shootski

B.B. and Readership,

Oxygen is the killer of O-Rings and lots of other things.

Open storage of O-Rings is not a good practice. Seal them into an airtight container and toss in an Oxygen Absorber packet: https://www.uline.com/BL_288/Oxygen-Absorbing-Packets?pricode=WY121&AdKeyword=oxygen absorber packets&AdMatchtype=e&gad_source=1&gclid=EAIaIQobChMI0ab7iYL1iAMVhZxaBR20vSdoEAAYASAAEgK9QPD_BwE

One other reminder is too fast fills will also kill O-Rings by cooking or actually burning them… DON’T RUSH YOUR FILLS! Once the reservoir feels warmish your O-Ring is already cooking.

shootski

BB

This reports deals with a question I have brought up way too many times on this blog. How much and how often should silicon chamber oil, if any, be used when filling a PCP. There still remains two opposing schools of thought by folks who are respected for their pcp expertise. Nobody wants to step on toes.

Deck

Decksniper,

I have two pair of steel toe Flight boots one new in the box my other pair is well broken in and the owners of a Magellan Certificate. I hope folks don’t worry about stepping on my toes if they are of the no chamber oil school and have over three decades of actual PCP experience. I’m willing to hear their fact/experience based stories.

May your PCP’s hold their gas always!

shootski

Decksniper,

If all you want to know is how much to use that is different for each PCP. You could experiment by shooting air blanks at a plain white sheet of paper when you see high flash point silicon oil stains on the paper you have more than you need.

How often you add some quantity depends on how many times you shoot since each shot will blow out a little of your lube and any emulsified condensate.

shootski

Deck,

As I said, I am a babe when it comes to PCPs. All I do know is this worked.

BB

Deck,

Just do it. You know you want to. What can it hurt?

The truth is you should not need to do it very often, however it does not hurt anything if you “overdo it”. The excess will be blown out.

Shootski & RidgeRunner

I have been following your advice and Gunfun1’s. So far no problems with any pcp’s. No conpressor problems either. The opposing expert commentor stated the case for pcp regulator problems created by any oil. If he sees this he has the right to respond or not.

Thanks for your responses.

Deck

Decksniper,

Ah yes! The regulator issue i remember now.

I believe i said this before that regulators come in different designs and are made of different materials. But… basically they are VALVES that regulate the input or output pressures. If the internal operating friction changes then that might cause the pressure presets to be altered. If the valve body/valve seats are effected in some negative way by the lubricant (Most, if not all, high flashpoint silicon oils are very inert.) that might be a problem.

i would love to have my toe(s) stepped on. It is worth it if we all learn from it.

shootski

Shootski

Yes it would be helpful if someone with long experience with many pcp’s would speak up. But experts learn new tricks too. Hope this subject gets fleshed out fully.

Deck

Deck,

I’m working on fleshing it out as we speak. Have patience.

BB

B.B.,

I look forward to what you find and suspect a large number of your readers do as well.

I have been thinking about how this very topic has been covered a number of times and yet can not seem to find an acceptable to most answer. It got me digging in my notes from flying and i found this: Anchoring Bias

Anchoring bias is a cognitive bias that makes us rely on the first piece of information we learn about an event or subject. When we then develop a plan of action or make estimates about something, we interpret the newer information from the reference point of the anchor instead of seeing it objectively. This can skew our judgment and prevent us from updating/correcting our plan of action or predictions.

How do you get rid of anchoring bias?

1 Identify the anchor. The first step to prevent anchoring bias is to recognize when you are exposed to an anchor that might influence your judgment.

2 Seek alternative perspectives.

3 Adjust your thinking.

4 Test your solutions.

5 Reflect on your process.

6 Practice regularly.

I found in flying that many students, especially in Emergency Procedure Practice, would jump on the identification of the cause all to quickly and often apply the incorrect procedure with no result or in fact making things worse. Most emergencies did not require instantaneous identification and action (those usually were an ejection or bailout) by slowing down in all other cases the situation normally didn’t get worse in that short interval and more often ended with proper identification of the fault and application of the correct procedure and a safe recovery of crew and aircraft. For the students it resulted in a grade other than a DOWN resulting in further training and a refly or two.

Item six above is very important for success as is number two: Seek alternative perspectives.

shootski

B.B. and Readership,

I have one more important item.

In the section titled: Rifle held — almost

of B.B.’s Blog the photograph of the fill fitting seems to have a Bleed Flat on the lower set of threads (Tom can you confirm that please?) some Foster Fittings have that and some don’t. The purpose is to keep folks safe if they don’t depressurize (completely) a pressure vessel and start removing a fitting. If it happens to you… you will usually stop removal when that type of safety fitting begins HISSING. IF there isn’t a relief flat or groove in the threads you will instead hear a LOUD BANG and hear the fitting bounce off things (YOU) in the way of the missile.

That safety relief feature should be way more common in PCPs than it is!

shootski

shootski,

There are two flats on the threads of that Foster fitting. They are there for the wrench that loosens or tightens the fitting. There is no bleed flat. I hope to show another fill nipple soon and it is different.

BB

BB,

I sure do enjoy hanging out on this blog. I learn so much and it usually happens every day.

B.B.,

I looked more closely at your Avenge X fitting;

I believe you are correct!

I take all my praise for the manufacturer back! LOL!

shootski

PS: i was suffering from Anchor Bias.

OK folks, here is MY experience, which is very little, concerning regulators and silicone oil. I applied silicone oil to stop my Edge from leaking, which it did beautifully. Every few fills I would use a few drops more, just because.

The AirForce Edge is a regulated PCP. It is the only regulated PCP that AirForce made. The silicone oil did not seem to affect the regulator at all. Someone else is in possession of that particular Edge now, but I have not heard of any problems with such.

I for one will continue to use a few drops of silicone oil periodically when filling my PCPs, regulator or not, until I learn otherwise. Does silicone oil affect the performance of a regulator? I do not know, but my experience so far says no.

B.B. and Readership,

The linked article is a good basic grounding in fittings:

https://www.powermotiontech.com/technologies/fittings-couplings/article/21181910/the-basics-of-small-bore-fittings

shootski

B.B. and Readership,

This one is really fun: https://www.wika.com/en-us/lp_differential_pressure.WIKA

How much does the atmospheric pressure effect you pressure gauge reading?

+/- 1%, 15%, 5%, 3%

On your tank, cylinder, compressor, reservoir, vehicle tire.

shootski

Just to add a little food for thought. I’m not even a PCP novice, yet, but I read somewhere (probably an article in HAM) regarding how even the “standard” foster fitting may not be all that standard if you look at any number of manufacturers’ tolerances. Some build in more play than others do. So perhaps that’s another area where perhaps the seals and o-rings have to be pliable enough to make up the differences in tolerances? But if you have substandard or inflexible seals, the air leaks through?

Roamin,

Yes from HAM, there are issues with “standard” foster fittings, to refresh your memory and to add for others here it is, https://hardairmagazine.com/?s=foster+fittings there are issues to be aware of.

Mike

Hey B.B., i’m glad the oil fixed your airgun, mine started leaking last week at the fill nipple (replaced bottom o-ring was flat and brittle) and i thought the fill gauge was leaking too so i replaced it too. it would only hold 3200 psi then. Found out it was leaking from under the barrel at the place where the AS/AT/AW Connecting Seat block matches up to the receiver. talked to pyramyd air tech and he gave me this link to parts page (https://www.pyramydair.com/model-schematic/m/air-venturi-avenge-x-classic-wood-stock/5774#16645) there are 2 o-rings that I replaced flat and brittle, and it was a booger getting it back together, but its holding air now. thanks for all the info.

dear tom havent recieved reply haveing trouble with 79g renued all seals but gun wont fire when co2 introduced popit valve james have not used gun since purchase seames like to much pressure with valve spring & co2 combined can you sugest ,how strong is valve spring can push valve with thumb when no co2 in cylinder but isvery strong yours ted ,tedvause84@gmail ps am in australia

ted,

I’ve contacted reader 45Bravo whose name is Ian McKee. He is the S&W 78G expert.

BB