by B.B. Pelletier

Gas springs in airguns is an interesting subject. I will need more than a single post to cover everything, but today I’ll cover the basics.

Terminology first

Gas springs are also called gas struts by spring makers in the UK. A quick search shows that even then, most of the manufacturers also use the term “spring” to make it clear what they are talking about. But gas strut is a correct term, if confusing. Gas “ram” appears to have been made up by airgunners. Someone has even gone to the trouble of making a Wikipedia entry for gas ram, so the confusion will be perpetuated. I will call them gas springs, and you’ll all know what I mean.

What is a gas spring?

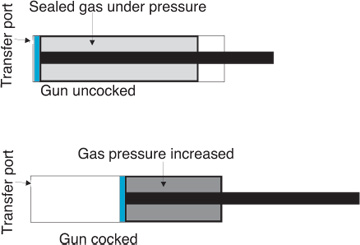

A gas spring is a sealed mechanism that uses compressed air or other gas to create a spring action. The mechanism installs in an air rifle in place of a coiled spring and piston. The gas inside the mechanism is under pressure all the time, but when the mechanism is forced to contract (by the cocking of the gun) the internal pressure increases. An internal piston compresses the sealed air or gas into a smaller space (see the drawing below). The gun’s sear holds the internal piston in place until it is released by the trigger. Then, the piston springs forward to its fully open length. As it goes, it compresses the air in front of it in the same way a conventional spring piston mechanism does. At that point, it acts just like any other spring piston unit.

A gas spring uses gas under pressure to perform like a coiled steel spring.

Benefits of gas springs

Gas under pressure never takes a set or breaks down, as I discussed in the post about coiled steel mainsprings, so you can leave a gas spring gun cocked a long time with no power decrease. Gas springs also use very little lubrication, and they aren’t as sensitive to low temperatures as coiled steel springs. These two benefits make gas spring guns valuable to hunters.

More benefits

Compressed gas weighs less than a coiled steel mainspring. The entire sealed gas spring unit weighs a little less than the steel piston it replaces. The net result is that guns with gas springs are lighter than guns with conventional steel mainsprings. You save almost a full pound with a gas spring. Because they are lighter, gas spring mechanisms also accelerate faster than conventional steel pistons, giving a faster piston cycle time. They DO NOT reduce “lock time,” however! That is an urban myth started by airgunners who don’t understand what airgun lock time really is. While the piston in a gas spring gun does its thing faster than a conventional spring piston, the pellet does not begin moving until the piston has come to a stop. So the time that the pellet remains inside the gun after the disturbing movement (recoil) and vibrations begin is exactly the same in both types of powerplants. However, because gas spring units have a lot less vibration than conventional coiled steel mainsprings, there is an advantage to the gas spring. With all these benefits, you might think gas springs are the only way to go – but wait until you hear the down side before making your decision.

Gas spring faults

Gas springs require more effort to cock than coiled steel mainsprings. A Theoben Fenman that develops 12 foot-pounds takes 38 to 40 lbs. of effort to cock, while a rifle of equal power and a coiled steel spring might take only 25 lbs. A Theoben Eliminator, better known in the U.S. as the Beeman Crow Magnum, takes as much as 60 lbs. of effort to cock. While that is about equal to the Gamo Hunter 1250, a powerful coiled-spring rifle, the Webley Patriot that develops almost as much power as the Eliminator only requires 50 lbs. of effort to cock. When I released the air pressure in my .20 caliber Crow Magnum, the cocking effort dropped to about 46 lbs., but the muzzle energy also dropped to around 20 foot-pounds. A .22 caliber Diana RWS 48 develops 22 foot-pounds with just 33 lbs. of cocking effort.

The Evolution is Theoben’s entry-level rifle. It takes the place of the Fenman mentioned in the text.

Gas spring guns have a sharper jolt when they fire. You can offset this by holding them very loose (as you should for best accuracy). If you hang onto one like it’s a firearm, prepare to get your cheek slapped!

If they’re so great, why aren’t they available anymore?

I’m not really sure. I do know that the Beeman RX-2 is a Weihrauch gun that has a Theoben gas spring inside. Beyond that, I don’t know.

There is more to cover – things like overpressurizing the gas spring, piston seal burnout, the unavailability of the hand pump to regulate the gas spring pressure, longevity and maintenance, best pellets and scope mounting, to name a few.

BB,

is ther no problem of leaking? When I look at the grafik, there must be two seals in the gas spring and if I leave it cocked the gas is under high pressure. After some time my car needs new shock absorbers and even my old office chair (gas lift) gets weaker.

Markus

Markus,

I will cover your concerns in tomorrow’s post.

B.B.

Hi B.B.

Thanks for the post. I look forward to your exploration of the gas spring.

My RX-1 is my favorite rifle. Just recently had it super gas charged and tuned by Beeman – not because the power plant failed but because the safety broke and wouldn’t allow me to fire. All you say I have found to be true. When I first got my rifle I could barely cock and fire it 20 times in a row without hurting my back, but after a month or so of practice the strength came and now I find cocking any of my other rifles to be a two finger operation. I have fired many tens of thousands of rounds without any spring related failures. I do feel that the Beeman tune smooths the cocking and firing cycle. I have never adjusted the spring pressure but find the heavier pellets to be the most accurate.

Thanks again, looking forward to more.

Springer John

Springer John,

Thanks for that report. It’s good to have current owners telling everyone how things are for them.

One question – does the RX-2 have an exposed Schraeder valve for adjusting the gas spring?

B./B.

BB,

One question,

Is there a way to get a silenced hw97k to the US?

PODEROSO

PODEROSO,

If HW MADE a silenced HW97 (they don’t), it might be POSSIBLE, however, a silenced spring piston airgun is not really very quiet. It’s like a silenced revolver, which is impossible because of the cylinder-to-barrel gap. The spring-piston powerplant makes about 80 percent of all the noise the gun makes. The muzzle blast makes the remaining 20 percent. So you would be silencing what is already the quietest part of the gun’s noise.

Now, Air Arms did exactly that. They put a baffled silencer on the TX200. All it did was reduce the noise a little. It did not silence the gun.

Silencers work only when there is a loud report to silence.

B.B.

BB,

There is a silenced hw97 model in europe.Check out the UK websites that sell this rifle.They say they have baffles in the muzzle.

PODEROSO

BB,

Check out this site and then tell ma what you think

http://www.airsportdirect.com/acatalog/WeihrauchHW97KUnderlever.html

PODEROSO

PODEROSO,

Okay. Sorry about that.

I don’t stay up on UK-only models. I’m sure they do have baffles, but my original statement stands. While the noise might drop by 10 decibels, the gun will not be silenced because the powerplant is where the bulk of the noise comes from.

B.B.

PODEROSO,

Well, it’s only 12 foot-pounds and it’s going to cost a lot more than a U.S.-spec gun after import. Where is the advantage?

B.B.

John,

If I’m seeing this right, you have a $29 airsoft gun. There are no upgrades. Be happy it shoots.

B.B.

PODEROSO and BB,

After BB explained that the spring piston guns dont have much muzzle report I belive that a silencer is not a big deal.I did some reaserch and PODEROSO is right about the UK silenced model (I checked over 30 web sites)but they are limited to 12 foot pounds and have a square section main spring while the US has amodel may not have a silencer it doesnt have the law 12 foot pound limitation that they have and also has a round section main spring.A silencer must be cool but I prefer other features that in my opinion are more useful than a silencer and we can get them here in the US.

CF-X guy

BB,

Awsome post. I’ve always wondered about the performance of air springs. I’m really looking foward to tomorrows blog. Great job! Thanks.

Jason

B.B.

I don’t know if the RX-2 has a provision for adjusting the gas spring. I would suspect that it probably does because HW seems to modify it’s U.S. models only at the request of Beeman and I can’t see any advantage to removing that feature. I know that Beeman no longer offers the power adjustment pump and gauge – they seem to be moving in another direction lately.

I wonder if any of the high pressure hand pumps for PCPs could be adapted to charge the RX series rifles.

Thanks

Springer John

As usual, an informative and interesting article, more so for me as it once again highlighted the huge gap, sales release wise, between out countrys. You stated that gas spring guns are no longer available yet they’re hugely popular in the UK and readily available in HW and Theobens. You can also buy gas ram replacements for a limited range of other springers.

We see a similar situation with Chinese models, the XS/QB79 has just arrived here and is being touted as “new” and “exciting”, but has been available in America for several years.

Theoben USA has been the official importer of Theoben air rifles for over a year. Not only do we offer the entire Theoben line up of handbuilt rifles, we offer at the very least the same high quality service as the previous importers.

I was the Senior gunsmith for Beeman for almost ten years, and have been in the airgun industry for over 24 years now.

In fact we offer an even faster turnaround now, as we are dedicated to Theoben exclusively. Should people want to contact us, or view the products they can go to our site http://www.Theobenusa.com or there are links from the Theoben UK website to us.

David Slade,

Thank you for posting this information. Now our readers will know where to get their Theoben airguns.

B.B.

what are the city of winnipeg regulations for airsoft pellet guns?

That’s a question best directed to the city of Winnipeg.

B.B.

Most times I believe you need to have a permit to own a silencer, even for an airgun. Robert Beeman wrote an interesting article on the legality of silencers on his personal website. He mentioned that in California it’s easier to get a permit for a machine gun than it is to get one for a silencer if you can at all. Silencers are legal in England and France as a courtesy for neighbors. I guess noise pollution is an issue there. But on the other hand in England and Germany, the maximum power for airguns is limited for some odd reason. Great info on this Blog. Thanks. Shawn

I have the RX-1 imported by Beeman. I also have the hand pump and the gauge. I’ve never lowered or raised the pressure, used it to only verify it was set correctly after sending it in for a super tune with special “super gas” (nitrogen) charging. I agree that the super tune did smooth it up a bit. I have fired somewhere around 10,000 shots with this gun. I bought it new in 1992 from Dr. Beemans Santa Rosa store before he sold. btw how the heck can i register?

RX-1,

What do you mean by register? What do you want to register for? Pyramyd AIR emails? The RSS feed from this blog? A Google account?

B.B.

I have fixed the “gas ram” mention in the Wikipedia airgun article (that is, after all, the point–you can fix it!). I’d also love to see your comments on the airgun section of the “Accurizing” article; just click on the “Discuss this page” link and leave your comments.

–scot

I have an RX2 and also have an adapter ordered to add air mine is on the low side of fps. Anyway has anyone done this if so let me know the correct procedure, also anyone know where I can get a manual that tells you how to do this they have to be around they use to sell the pumps and no longer do because some pepole were over charging there guns if you have an information for me let me know thanks Eddie

All Theoben gas springs, like the one on your HW rifle, used to be adjustable. That's how I learned that too much pressure also lowers velocity and will destroy your rifle.

My advice is to not add air until you confirm the velocity withy a chronograph. Then take some air out and see if the velocity increases.

Theoben stopped making their gas springs user-adjustable because too many people were overpressurizing them and ruining the guns.

If you want to read a report on this and see what I mean, read this:

/blog/2008/2/theoben-fenman-the-gentle-gas-spring-rifle-part-1/

B.B.

Hello BB I own a gamo hunter 1250.I like the advantages of the gas spring.With your opinion and anyone else with the experience with air guns, which do you feel is the better choice in maintence, long lasting and overall performance

It is impossible to compare all gas springs to all steel coil springs. However, in guns that are extremely powerful like your 1250 gas springs tend to do a better job longer than steel.

But when it comes time for maintenance, steel is easier to replace than a gas spring, simply because there aren't that many makers and you may not be able to find a gas spring replacement or maintenance for the one you own when you need it.

B.B.