Spring gun tuning: Part 1

Spring gun tuning: Part 2 – Building a mainspring compressor

Spring gun tuning: Part 3 – Mainspring compressor continued

by B.B. Pelletier

Enough build-up. Today, the disassembly begins! I’ve selected a Beeman R1 to tune for you. That means I’m now going to get specific about parts and how they come off, but I will make provisions for other airguns, as well. What I can’t do is provide complete disassembly instructions for every spring gun made because there isn’t enough time and I haven’t taken all of them apart. I’ll provide general instructions for different categories of guns, and you’ll have to be clever enough to follow along and to figure things out on your own.

Before you start

Is this a project you SHOULD do, or are you a person who goes halfway and quits? If the latter is the case, DON’T START! I will not assemble any basket cases for anyone, nor is Pyramyd AIR responsible in any way for your actions. I am doing this series so those who want to learn about their spring gun powerplant – can. I make no guarantees to anyone about anything.

First

Make certain the gun is neither loaded nor cocked. You’ll be sorry if you get the gun partly disassembled, only to discover that it’s cocked. It can kill you if you don’t handle it carefully, so take NO CHANCES.

Remove the action from the stock

The R1 has two forearm screws and two screws through the triggerguard. All four are removed, and the triggerguard comes off before the action is removed from the stock.

R1 action removed from stock. Sights have been removed.

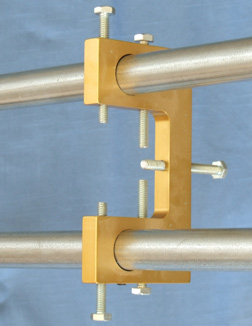

B-Square’s mainspring compressor is lightweight and very adjustable. Can you identify the headstock, bridge and tailstock?

The bridge uses five bolts to enclose the rifle’s action and keep it from moving when the mainspring is decompressed. The bolts on top will pass over the action. I use a heavy leather belt around the gun to keep from scratching the metal.

I’m using a B-Square mainspring compressor, and the big thing with that one is to restrain the middle of the action. Since the bridge is different than the one found on homemade compressors, you have to spend a little time snugging the middle of the gun. Also, make sure you allow enough travel in the headstock so the mainspring can be decompressed all the way. If you don’t, you’ll have to assemble the gun again and adjust the compressor.

What if you have no idea how far the mainspring will travel to decompress? Well, that happens when taking apart a gun that’s new to you. Don’t trust what anyone tells you, because your gun may have an aftermarket spring that’s a lot longer than they say. What I do is allow a maximum of five inches of headstock travel when I’m not familiar with a certain gun. The worst I have seen was about 4 inches of travel on factory FWB 124s (all of them) and also once on a tuned HW77.

Tomorrow, I’ll put the rifle in the compressor and remove some parts!

BB Pelletier – Help! My 15 year old son foolishly (and stupidly) returned an empty (no BBs or projectiles around) Marksman 2000 Air Pistol to his friend on the summer school bus. The boys were taken to the office, police called (closed the case, did not find that toy warranted a police report, returned toy to school), told to write and sign an incriminating statement, and were kicked out of summer school. I have to go before the North Country Union High School’ s school board this Tuesday to fight for my son. Joshua said that air guns were not considered weapons by the US Constitution. I’m hoping that you know where this is located and can tell me how to help prove that the item in question is a toy. The school’s weapon policy states that my son must be expelled for no less than one year…

I need help to prove that this unloaded BB gun is a toy. My son make a really stupid choice but I don’t want this on his permanent record nor do I want him losing a year of school.

Thank you,

Suzanne Pelletier

Montgomery, VT

I’m not a lawer, but things like the BATFE do not cover air-powered arms are easily found on the net, not that that is ny help. Local laws in the U.S. can and usually are more restrictive as to what type you can posses, and where they can be legally transported and discharged. There are places where anything that is above .177 caliber are illegal and can put you in jail. Other places have restrictions on how many foot-pounds it can deliver, and not just the U.K.. And that is just the legal side.

Schools can have their own rules as to what is and is not acceptable to bring on to school grounds. Whether or not it was legal IS irrelavent. I believe that your only choice is to plead your case first, and go up the chain of command from there. Unfortunatly we live in a paranoid society that fears the pocket knives thought of as tools just a century ago, so I am not hopeful for your son’s record, although it can only help from here. I can only offer the advice to not bring it to show anyone, even if it is in your trunk.

Since the local police thought it not worth a report, it was probably not illegal, so getting a lawer might not help at this point, and if you have no luck with the school board you might be stuck.

If it all goes wrong, hope that it is a learning experience for your son, and move on. Animosity toward the educational system for one moment of thoughtlessness onn your sons part is pointless, and social change is the only thing you can realisticly hope for to prevent things like this in the future.

Good luck, and keep cool.

Suzanne,

Unfortunately, the law of the land probably doesn’t apply in your case. A school can make policy of its own regarding behavior, and guns are a very hot button today. There are cases in which preschoolers have been suspended and even expelled for making a gun bt simply shaping (pointing their index finger and making a shooting sound) their hands and seeming to shoot at another child.

What your son is telling you is, unfortunately, not that clear. He probably refers to the Second Amendment to the Constitution, which reads as follows:

“A well regulated militia, being necessary to the security of a free state, the right of the people to keep and bear arms, shall not be infringed.”

Now that may SOUND like it means firearms, but it doesn’t say so. And airguns were being used as military weapons by the Austrian army at the time it was written. No one has EVER interpreted the amendment to include airguns to my knowledge, but it is still not clear.

HOWEVER, this is immaterial for two reasons. One, the issue is school policy, not law, and, two, your son is a minor and not yet a franchised citizen of the United States. As a minor, I don’t believe he has the full rights of a citizen, yet.

I believe the best defense is to appeal to the good sense of the members of the school board. What they probably have is a “Zero Tolerance” policy on this issue. While that SOUNDS like a prudent thing, it is actually absurd when taken to its logical conclusion. For example, a glue gun is a gun, so if the policy simply states that no student may posess a gun of any kind on school property, a suit could be probably be brought against the School Board if they tolerate glue guns (or staple guns or heat guns) on school property. They will react by attempting to rewrite the policy, but zero tolerance policies are usually flawed in some way.

I am not a lawyer, so please use what I say with your own best judgement and consideration.

I hope this incident turns out well for you and your son.

B.B.

You’re in VT, Suzanne, and I’m in NY, so take this in the way I mean it, a suggestion and nothing more … I am not a lawyer, but am an owner of a .22 air rifle that can take small game if I were to bother with camo-ing every inch of my being and sitting statue-still for hours waiting for it to wander into my field of fire … NY Dept. of Environmental Conservations hunting regulations do not classify air rifles as “weapons”, if you read then with an eye toward seeing between the lines … so I suggest you see what VT hunting regs say … and since the previous comments mentioned school policy being a separate world from the pure legal aspects of this, I’d try talking to some self-defense schools about what ordinary everyday items found in school board members’ own pockets and desks can be used as weapons by out-of-the-box-thinkers … car keys, ball-point pens, etc. … so they’d better think long and hard about a zero-tolerance policy on hot-glue guns in the art classrooms and empty air guns on buses… an empty air rifle can be swung like a baseball bat too, but do they ban the bats from the diamond ? Do they allow protractors and compasses (whichever is the gadget with a pencil and a point on the other adjustable arm) in the math classes for geometry ? Would they remove all the mops and brooms from the janitorial staff on the grounds that they could be used as a “weapon” in self-defense against an after-school vandal ? Those math gadgets are pointy and could be dangerous too IF MISHANDLED, which the air gun your son had seemed to NOT BE … he at least made sure it wasn’t loaded, which is a point in his favor you should emphasize … might not get you very far but might lessen the “sentence” imposed on him by the kangaroo school board court system. And if all else fails, campaign against those board members next election.

THANK YOU for deciding to use a Beeman R1 to refurbish. I own one that I bought ‘used/good condition’ back in 1994. I have been considering getting the gun rebuilt/tuned. I recently stumbled accross your blog… YES! I’d much rather do this stuff myself if I can. Please use plenty pics as applicable, as they help a lot with understanding. Thank You!

SM Pelletier,

I feel for your situation… and facing a 1 year expulsion, in my opinion, is definitely the wrong punishment if your son meant no criminal intent or harm. I also feel like the Marksman pistol (while underpowered) is NOT A TOY, however, regardless of how I feel, what is defined by federal and VT law, and applicable school policy as such is what matters and that’s why you need an attorney, first thing monday morning. There is a lot of fear, paranoia, and “zero tolerance” out there, especially since Columbine, so the best advice I can offer is to get an attorney ASAP!!! Good luck