by B.B. Pelletier

Part 1

Today, we’ll take the next step in evaluating the Air Venturi Pro Guide spring retainer system by testing a stock .22 caliber RWS Diana 48 right out of the box, then installing the Pro Guide system and testing that. Because many of you are interested in working on your own airguns, I decided to turn the disassembly/assembly into a tutorial.

Right out of the box, the first shot from the rifle shooting 14.3-grain Crosman Premiers was 646 f.p.s. I’m telling you that to reassure all of you chronograph hounds that a new air rifle needs a few shots to settle in. Shot No. 2 went 793 f.p.s.–a heck of a lot closer to the anticipated 800 f.p.s. average this model usually gets with .22 Premiers. I shot a dozen times to let the gun settle down, then a string of 10 after that measured an average of 797 f.p.s. – right in the expected range of 790 to 810 f.p.s., depending on the individual rifle. That works out to 20.17 foot-pounds with this loose-fitting pellet.

Now, it’s time to install the Pro Guide system. The rifle’s action was removed from the stock by loosening the front triggerguard screw and the one forearm screw. Then, the action was disassembled while the gun was held in a B-Square mainspring compressor. Don’t look for one on this website; they don’t carry it any longer, but you can make one for under $20. The two-part plans are located here. You absolutely have to use a compressor with this gun.

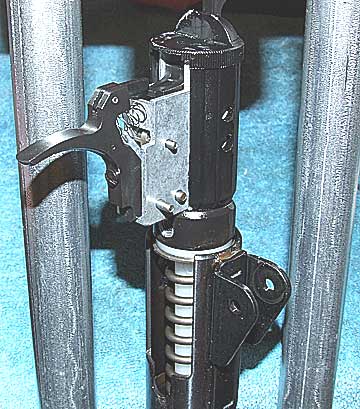

Once the action is out of the stock, remove the sidelever. These two pins held in by circlips must be removed. Remove the smaller pin first (on the left in this picture) and the larger hinge pin last. The linkage arm that connects the sidelever to the sliding compression chamber doesn’t need to be removed.

Once the action is out of the stock, remove the sidelever. These two pins held in by circlips must be removed. Remove the smaller pin first (on the left in this picture) and the larger hinge pin last. The linkage arm that connects the sidelever to the sliding compression chamber doesn’t need to be removed. The hinge pin has one washer under the pin head…

The hinge pin has one washer under the pin head… …and two washers inside the flange that holds the sidelever to the action. There’s one on either side of the sidelever hinge pin bushing.Once the action’s out of the stock, the sidelever must be removed.

…and two washers inside the flange that holds the sidelever to the action. There’s one on either side of the sidelever hinge pin bushing.Once the action’s out of the stock, the sidelever must be removed. It’s held on by two pins, each secured with a circlip on the underside. Remover the smaller pin first and the larger hinge pin last. Look for three washers on the hinge pin: one under the head of the pin and one on either side of the pin bushing.

When the sidelever is off, fold the linkage rod down along the barrel of the rifle, so the action will fit into the mainspring compressor.

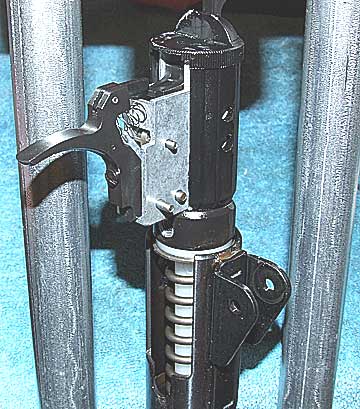

These two large pins located inside the sidelever flange must be drifted out of the rifle. Place your pin punch on this side. The action must be installed in a mainspring compressor with tension on the black plastic end cap before attempting to drift these pins.Secure the rifle in a mainspring compressor and put some tension on the black plastic end cap.

These two large pins located inside the sidelever flange must be drifted out of the rifle. Place your pin punch on this side. The action must be installed in a mainspring compressor with tension on the black plastic end cap before attempting to drift these pins.Secure the rifle in a mainspring compressor and put some tension on the black plastic end cap. There’s a flat shelf conveniently located on the cap. The next picture shows this flat shelf clearly.

Both pins have been drifted out, and all tension was taken off the end cap. See how far the factory mainspring pushes the trigger group and end cap? The flat of the end cap against which you can apply tension is seen at the top center of this photo. Because I was working on a gun while taking pictures, I cheated by using the flash.

Both pins have been drifted out, and all tension was taken off the end cap. See how far the factory mainspring pushes the trigger group and end cap? The flat of the end cap against which you can apply tension is seen at the top center of this photo. Because I was working on a gun while taking pictures, I cheated by using the flash.First,

drift the rear pin all the way out, then drift out the front pin. I’m not sure the order matters anymore with the T05 trigger unit; but, since it was critical with the T01 trigger, all airgunsmiths learned to do it in that order. These two pins are all that hold the trigger unit, which is sheathed by the end cap, in the rifle.

Here’s a comparison of the RWS Diana sear on the bottom and a conventional sear (Hakim) at the top. Since most spring rifles use the conventional piston rod hook-type sear, their triggers have been designed for it. The Diana sear was originally designed for three ball bearings to hold the piston inside the groove. The current Diana triggers don’t have ball bearings, but they have a hook system that does the same thing. This has no impact on the Pro Guide system, but it does impact a gas spring, which is why you don’t see one on the market yet.

Here’s a comparison of the RWS Diana sear on the bottom and a conventional sear (Hakim) at the top. Since most spring rifles use the conventional piston rod hook-type sear, their triggers have been designed for it. The Diana sear was originally designed for three ball bearings to hold the piston inside the groove. The current Diana triggers don’t have ball bearings, but they have a hook system that does the same thing. This has no impact on the Pro Guide system, but it does impact a gas spring, which is why you don’t see one on the market yet. Here’s the Diana piston in its entirety. See the swelling at the rear? It helps guide the piston inside the large receiver tube. It never enters the sliding compression chamber, which is why this piston is so long.

Here’s the Diana piston in its entirety. See the swelling at the rear? It helps guide the piston inside the large receiver tube. It never enters the sliding compression chamber, which is why this piston is so long.I removed the piston so I could show you some things, but you don’t need to remove it (it simply slides out). Once the factory mainspring and rear spring guide have been removed, the Pro Guide system can be installed.

The Pro Guide system is much shorter than the factory mainspring. Even so, you still need a mainspring compressor to get the trigger unit to align with the two pin holes.

The Pro Guide system is much shorter than the factory mainspring. Even so, you still need a mainspring compressor to get the trigger unit to align with the two pin holes.Next time, I’ll describe the assembly of the 48, including

a couple pointers that’ll save you some time and heartache. I’ll also report on the velocity of the gun with the Pro Guide unit installed. Please note, if I forget to mention it in the next report, that absolutely

NO tuning was performed on this rifle. If I hadn’t wanted to show those pictures of the piston, there would have been no reason to remove it from the gun.

Tom Gaylord, also known as B.B. Pelletier, provides expert insights to airgunners all over the world on behalf of Pyramyd AIR. He has earned the title The Godfather of Airguns™ for his contributions to the industry, spending many years with AirForce Airguns and starting magazines dedicated to the sport such as Airgun Illustrated.

Here is an oddball. I’m going to Alabama next week for work. While I’m there I’m going to cruise the local pawnshops (there are hundreds of them down there)to see if I can find any deals on pellet pistols. My question is can I put them in my suitcase and check them on the plane? I bought a couple guns down there before, but I drove so no problem. This time I’m flying. I’d like to get a pellet pistol or two home but not sure the legality of this. Has anyone ever flown with a gun before?

Any advice would be appreciated.

Aaron in MI

P.S.

BB – I did use the search function on this blog to see if you had already covered this but nothing came up 🙂

Way off topic and odd ball but I’ve run out of Google so a appeal to the firearms experts out there.

Last night my father in law gave me a Cartmell side by side percussion lock shotgun.

I found a little bit out about the maker, Thomas Cartmell. In 1850 they were official supplier to the Prince of Wales. There is a hallmark on the barrel that may be a leek. I can’t be sure.

Damascus barrel. Both hammers cock and drop when the trigger is pulled.

Any leads as to where I can look for more info.

It will NOT EVER BE FIRED AGAIN. I’s like to have it looked over and cleaned up id warranted.

Cheers,

Bruce

p.s. I bought a Ruger .22 pistol yesterday too. Quite a day.

Aaron,

Most carriers will let you transport handguns in your luggage. Check online for their rules, but they are usually:

1. You must notify them you will be carrying a gun. They don’t often make distinctions between airguns and firearms.

2. The gun must be inside a locked gun case in your luggage. They will want to inspect it before accepting it, so you will have to unlock it for them when you check in.

3. No ammo!

B.B.

Bruce,

You have a research project on your hands. I would start with the National Firearms Museum, a function of the NRA. The museum is a world-class exhibit and research facility located in Fairfax, VA. The curator is Phil Schreier.

Somebody out there knows a lot about your shotgun, but finding them may take some time.

B.B.

Many thanks!

I’m excited to learn about this gun.

My father in law has given me all sorts of neat stuff over teh past few years but this is teh neatest by far.

Hi B.B.,

I am trying to put in a new seal for a Diana 5.

What is the right technique to put in the new seal without the Dove tail wedge cutting into the new seal?

Do I need to heat up the seal in hot water so it is pliable?

What is your technique without slicing the sharp edge during a installing a new seal.

Thanks!

BeeKeeper

Hi,

I have read all your posts on the Iz Baikal IZH 61. I thought I read somewhere that you suggested that this gun needs little maitenance. I also read your posts regarding air gun cleaning and maitenance which talks about how steel barrels need to be cleaned and protected when new? I recently purchased an IZH 61 from Pyramid and have heard all kinds of conflicting information about how to maintain this gun from the airgun forums. I put about 50rds through it when I first got it but have not used it since because I read something about it needing to cleaned before use due to dieseling but have not found any consistent information on what to do with this gun and there is no information in the owners manual? I am new to airgunning and have no idea what to do here. I am in need of some exact directions on what is necessary to maintain this gun?

Please help…

Thank you so much,

T. Foley

B.B.

Nice read, great info for my brain file, but no thanks, I’m not tearing into my guns, I’m good with wood and cutting steel knives for the moulder, but I’m not going there…too much chance to screw up, for a clunk like me…

Maybe I’ll get the millwright to study up and become a gunsmith…

he’s good with the air systems on our tools… we will need someone for the Air Rifle range… let me know if any “tuners” or gunsmiths out there want to move to Ashland, Or. and join our team….

The lake was so very nice this morning, just like glass, birds everywhere, the fish are jumping and the cotton is high, so hush little baby don’t you cry….

(not really, but the hay is)

Wayne

T. Foley,

I’ll bet B.B. will say, just shoot it… it will clean itself with 500 shots or so..

Wayne

B.B.

So what is a spring retainer system anyway?

On yesterday’s topic of an index, this sounds a lot like librarianship, so it has my interest. My main concern would be the amount of additional work in putting an index together on top of producing the blog. I suppose if you generated a few subject terms for each day’s post and linked them to an index it wouldn’t be too bad. The hard part would be making the index retrospective for the 1000 odd posts already in existence. Another problem is editing the index as more material emerges. However, even the Library of Congress cannot index all of its holdings exhaustively or avoid all conflicts, so you needn’t worry about what is really an infinite task. If you just focused on indexing some recurring themes that might be doable. I’m perfectly happy with the blog as it is, but maybe this would benefit somebody.

That target chamber is a new one which I had not heard about among all the ways to accurize a rifle.

Bill, so you’re the owner of one of the 6.5 Grendel AR-15s that I read about. Sounds like this gun and ammo combination are as accurate as the gun mags say. I understand that Alexander Arms–the inventors of the Grendel–are also making a gas-piston version to improve the reliability of the AR system. That would really be something, but it sounds like the gas piston also subtracts some accuracy. I’ll be interested in seeing how this works out.

Matt61

BB,

regarding drifting out the two pins on the trigger group – having never disassembled an air rifle, I’m not familiar with the set-up and the photo appears to show what I take to be three pins. Can you further clarify which of the pins you are referring to? I.E. upper forward and rear pin?

Regards

BB – never mind. I mis-read your article. You obviously are not referring to any pins on the trigger group itself but on the receiver. Sorry for wasting everyone’s time here.

Aaron,

I have transported airsoft, pellet guns, and firearms on airplanes and have lived to tell the tale. It’s really not a big deal and pretty much as B.B. says. Here is the link to the TSA rules which were followed pretty closely in my experience.

http://www.tsa.gov/travelers/airtravel/assistant/editorial_1666.shtm

Note that you need a hard, lockable case. Also the TSA site claims that you can carry ammo–even inside the gun case–provided that it is completely enclosed in its own container. Mags and clips do not qualify. But I have never carried ammo.

At the check-in counter, they will have you fill out a red card acknowledging the presence of guns which you place in the case and lock it, and that is pretty much it. Nobody even inspected my guns to see if they were loaded. Be real careful about the pricing of checked luggage. I understand that they are charging for all checked luggage after the first piece, and this could really mount up.

Matt61

Bruce,

Does you father-in-law have a story behind the Cartmell he gave you, or any other information about where it came from?

There is a show on PBS called “History Detectives”. It is a show where each episode is built around historical items that people own. They research the items to find whether they are authentic and whether the stories behind them are true. You might be able to have your gun on the show if it has any historical significance. Check it out at History Detectives.

I would like to see Lewis & Clark's airgun on the show! This show seems like it could be one medium to help reduce prejudice against guns (including airguns).

.22 multi-shot

T. Floey,

I answered this back on the IZH 61 report, where you asked it first.

You do not clean airgun barrels unless the accuracy goes bad.

There is no requirement to clean your barrel.

If you do clean the barrel, you can only clean from the muzzle.

B.B.

Matt61,

Tour offer of help to catalog the blog has been noted. We are discussing how that will be done right now. I will be in touch.

B.B.

Beekeeper,

There are a couple techniques to avoid cutting seals. First is the shoehorn which means pushing the seal in with a screwdriver as it passes over a sharp edge.

The second is a thin shim that you wrap around the seal until it is past the sharp edge. It has to be long enough to pull out after the seal is past the edge. This one is used for blind edges.

A third technique is the break up the sharp edge with a slight chamfer.

B.B.

Fred,

You got it! Now that you know which pins to drift, you will never forget it.

B.B.

another loser of an airblog… Nothing compared to yesterday. Well, live and learn. At least bb is off back to his self.

This may seem like a dumb or boring question, but I’ll ask once more. Which paper type/weight(that would be commonly available at an office-products store) works the best for printing targets? By “best”, I mean which one yields the cleanest holes.

Thanks!

Brian

Brian,

What you want is short-grained paper. It isn’t common. A commercial printer will have it.

B.B.

.22 M-S,

His parents ran a small antiques store in Burnley, Lancs (as well as a farm and a greengrocers).

The gun was bought at an estate sale in Yorkshire in the early 1960s. His parents bought furniture and china and the gun caught his eye. He said he didn’t pay much, about the equivalent of 5 quid in new money.

Cartmell seem to have been in Doncaster S. Yorkshire and at times in Lancashire.

In a related note, I have been considering contacting “History Detectives” about another project of locating the two velodromes that were in Providence and Pawtucket in the early 20th century. I hope they send the blond…

Bruce

B.B.

Hm. Well, as long as you’re not relying on deep technical expertise in airguns from me…., sure. You can reach me at

connerm@morris.umn.edu

By the way, in library school one of the professors said that semantics in the computer science sense of interfacing language and software organization was the big area of the future. “If these ideas spring to your mind, dollars will spring to your pocket,” says he. Ha ha. I never went that route, but this could be fun.

Matt61

Bruce,

Sounds like one of those great deals. I see I am not the only History Detectives fan!

.22 multi-shot

Matt61,

That’s the spirit!

B.B.

Matt61,

Yes, I own a Grendel, and frequently shoot it and a friends Grendel. Wonderful rifles, very accurate. Alexander Arms builds quality firearms, as does Les Baer by all accounts. Sabre also has a good reputation, though I know of at least 2 Sabres which had some teeting problems. (Sabre gladly took them back for work with no complaints, though, and promptly fixed them!) Every one that I have seen or heard about says that their rifle is very accurate, maybe not bench rest accurate, but accurate enough for real world use.

As for traveling with firearms, the TSA site is pretty easily understood, but here are the 5 rules that I always fall back on, and I ALWAYS fly with pistol.

1) You must declare the firearm immediately at checkin

2) Firearm must be unloaded.

3) Firearm must be in a lockable, HARD SIDED case.

4) Ammunition may travel with the firearm, but must be in original packaging or in suitable aftermarket carrying case. (I travel with handloads in plastic cases and have never had problems.)

5) Ammunition may be in magazines, but the magazines must be enclosed in appropriate carriers or pouches.

They can be in the same case as the firearm.

Also, some countries limit the amount of ammunition you can carry with you, so check any other countries laws before leaving.

New York, New Jersey, Washington DC, and a few other places have local laws that pertain once you leave the airport, so make sure you know those local laws, especially if you travel with a handgun!!

Hope that helps!!

Bill

Matt61 and BB,

Thanks for the tips. I just got my itinerary from my boss and I’m flying Northwest and they have a entire section on there website about carrying guns in your checked luggage so it looks like I’m good to go. Now I just need to find the guns!! I appreciate your help!!

Aaron in MI

P.S. You might see me on here next week asking if the guns I’m looking at are good deals or not!! I’ve already got a great list of pawn shops in the area. I’ll probably sign on as Aaron in AL!!

BB,

This paper subject is interesting to me so I looked up short grain paper and came up with a definition of, “Paper in which the machine direction is the shortest sheet dimension.” Other sites seem to use something similar to this definition (fibers aligned with the shortest sheet dimension, etc.). I found a definition for short fiber paper that said, “Applies to paper or pulp containing a high proportion of short wood fibers usually from hardwood trees.”

Which do you mean?

Thanks,

Daniel

Daniel,

I mean the shortest sheet direction. It rips cleaner.

Also get the heaviest stock you can.

If that’s too hard to get, get construction paper.

B.B.

OK, here’s one I can’f figure out how to search for.

I need a QUIET, high powered rifle. I have about decided on the Condor, but all of a sudden the neighbor lady decided my breakbarrel was too loud, and called to complain. I’m probably still going to get a Condor or something of similar quality that Wayne talks me into, but now I also need a quiet gun!

So now I need a rifle that is the proverbial “PFFT” quiet. Does such an animal exist, and if it does, is it available in .22 with enough power to hunt rock chucks?

Bill

PS.

Yes I did run a search for “quiet air rifles or guns” and read about the talon.

Bill

Bill,

I shoot a silenced .22 rimfire with the best silencer available to the public. It still sounds like a CO2 pistol going off.

A pfft gun is one with a really high-tech silencer or an AirForce Condor shooting on lower power with an Airhog bloop tube. That goes pfft.

B.B.

BB,

I would use a subsonic .22 rimfire with a silencer, but I live in city limits and can’t shoot firearms.

Airguns are OK and I could use anything, without repercussions, but I don’t like ticking the neighbor off, so I’ll use the loud rifle when she’s away, and the quiet one when I have to.

I wasn’t aware of the Airhog bloop tube, have you written about them? I didn’t see it in the Condor review.

Bill

Bill,

Look here:

/blog/2007/11/surprise-a-quiet-condor/

B.B.

Where do I find info on the Airhog bloop tube, it isn’t on their site, at least that I can find.

I’ve read about them in your posts now, but always mentioned in passing, like everyone knows about them, but don’t see where to buy them!

Bill

Bill,

Airhog is slow to update their website. Give them a call and talk to them about it.

B.B.

BB,

Thanks for your response to my out of place comment on this blog earlier.

This kit is interesting to me in several ways, one being that the guides are Delrin, whereas most tuners go to great lengths to make steel guides. It would seem intuitive that Delrin would be better in terms of suppressing vibrations.

The design also shows some independent thought in light of the fact that it reverses the position of the factory guides (rear envelops the spring and front guide is inside), if I understand correctly.

I’m curious and even a little optimistic about the results of the changeover. It would be interesting also to do two or more guns and see if the results are consistent: Many times I see tuners complaining that one particular gun gets “tuned up” easily, whereas another of the exact same model proves difficult. Since manufacturing has advanced as far as it has, so that the guns should be within close tolerances of each other, I admit to some cynicism about the methodologies employed by these tuners, but I’ll willingly acknowledge my own ignorance as well.

BG_Farmer,

I though about that, as well, and I am going to tune two different guns. The next will be the RWS Diana 34 that I have had since it was new. I tested it for you and also used it to test the new Leapers scope base, so it has close to a thousand rounds on the clock. That should be revealing.

Your comment about tuning different guns is correct – they don’t all respond the same. Not even guns with reputations for being easy to tune, like the R1, will always respond equally well.

So – we will all see exactly what this new system can do.

B.B.

Thanks BB!!!

Bill

Hi BB,

Unrelated question here; I sit ok to leave a fully charged PCP in a hot environment like the boot of a car? Air expanding at higher temps etc…

Thanks JV

JV, I’m not BB, but I wouldn’t leave a full PCP in a car. The pressure will increase as the temperature rises. Even if it doesn’t cause the tank/cylinder to fail, it puts more strain on it and may put it past its working pressure.

.22 multi-shot

JV,

The fact that you ask the question tells you the answer. All gasses expand in heat. Air isn’t as bad as CO2, but it does expand. No PCPs other than the AirForce guns have a safety burst disc to relieve pressure, so they will blow up catastrophically when they let go.

B.B.

B.B.

I have studied and pondered the sliding plate mechanism on my TO5 trigger and really haven’t been able to figure it out. Its quite a bit different from the “standard” triggers that work with the piston rod with the hook. Those triggers, with the help of some on-line animations people have put up, are reasonably intuitive. But the sliding plate with the big holes the rods fit thru, and how it cocks (resets) and releases, escapes me. Is there a hint you can give me? I will study it some more.

BTW, I’ve never seen a T03 with the 3 balls, but I bet that one was tough to visualize too.

Thanks,

Lloyd

Lloyd,

Imagine three hooks in a circle.

The ball bearing were pressed into the grove by an inclined plane. You can see one disassembled here:

/blog/2008/5/diana-35-always-the-contender/

The large silver tube is where the inclined planes are located. They push the balls through the dark tube and into the piston rod groove.

B.B.

B.B.,

Nothing like a good picture to clear things up! A clever design that I am a little suprised works as well as it really does. Those heavy spring loads are tough to handle!

Lloyd

Lloyd,

Yes, that trigger is a good design. They never wear out.

B.B.