by B.B. Pelletier

In the time since I wrote Part 4 of this report, hundreds of Benjamin Marauders have been shipped. Though there is still a huge backlog of orders, the Marauder is now out there, being tested by real people like our own Derrick, who won Marauder number 100 in Crosman’s Summer House contest. So listen to them–not me–when it comes to accuracy, quiet operation, trigger performance and everything else.

However, I promised you I would return to the Marauder to finish my report, because there were a few details I needed to clear up. One was the trigger, which Matt very much wants to read about, and the other was a test of the production valve that Crosman sent met. This report will hit the trigger hard and begin our look at the new valve.

Trigger

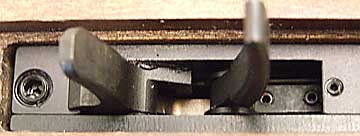

I mentioned the trigger in the general description, but never really gave it the attention it deserves. Today I will. The Marauder trigger is two-stage and adjustable for the length of the first stage pull, the location and length of the second stage pull, the location of the trigger blade at rest and the trigger pull weight. According to the owner’s manual, changing the trigger pull weight does not affect the sear engagement.

When Crosman sent me the new valve to test they sent it in an assembled reservoir that had a trigger attached to it. So the trigger I had on the rifle I tested for you before (Parts 1 through 4) has now been changed. I took the rifle with the new valve out to the range yesterday to sight it in and noticed that the new trigger is set similar to the first one, so I will adjust it now, as I explain the process to you.

According to my RCBS trigger-pull gauge, the trigger on the gun now breaks at 1.5 lbs. To access the adjustment screws, remove the trigger guard. The pull-weight screw is in front of the trigger blade and is a 1/8″ Allen screw. Turning clockwise increases pull weight and counterclockwise decreases pull weight. Just for fun I turned the screw in several turns and increased the pull weight to 2 pounds, 4 ounces. Most of this weight is loaded into the first stage, so stage two becomes hard to sense when the weight is high.

Then I turned the screw back out and dropped the trigger pull to 12 ounces. The return spring functions perfectly and I can feel stage two easily. If the weather were cold I might increase the weight to 24 ounces, for safety’s sake, but in the warm months it’s ideal the way it is.

The pull weight is also governed by where you place your finger on the trigger blade, since it is a lever. I find it natural to hit the blade about in the center, so that’s where I hook the trigger gauge for measurements.

You can also adjust the location of the trigger blade, fore and aft, to suit your hand. I found that it is right for me, so I left it alone.

First and second stage lengths

Two screws behind the trigger blade adjust the lengths of the first and second stage pulls. Each takes a wee-teeny .050″ Allen wrench, as does the trigger location adjustment. These two screws adjust together, so changing one automatically changes the other. You will have to adjust both screws until you get the first stage stopping where you want and the second traveling as far as you want.

Trigger performance

This is a world-class trigger, make no mistake. The let-off weight remains the same from shot to shot, so you can get used to the performance.

Well, that’s it for the trigger, except to note that an overtravel stop would be nice. Now I’d like to begin my report on the gun’s performance with the new valve. Except that when I reached the range I had no idea what fill pressure Crosman had set the new valve to, nor what power level they set up. So there I was on the 50-yard range without a clue about what I was shooting! And that was sad, because I watched three out of five Kodiaks sail through THE SAME HOLE at that range. The other two shots opened the group to 1.25 inches, so until I get control over what I’m shooting, I cannot finish this report.

A note on barrel cleaning

Ray Apelles, who was one of the developers of the Marauder, discussed barrel cleaning with me. Ray pointed out that there is an o-ring INSIDE the barrel, just in from the breech. It seals the bolt after it has pushed the pellet into position. Well, I hardly want to run JB Bore Paste down a barrel that has an o-ring! So cleaning the Marauder barrel will be limited to cleaning patches pulled through with a flexible cable. I did put some diver’s grease on that o-ring, however.

Let’s test the rifle!

Today, with the help of the chronograph, I will discover how this gun has been set up. So the first thing to do is to fill to 3,000 psi on my tank gauge, and to note where the needle on the gun’s manometer rests at that pressure.

A fill to 3,000 on the gauge mounted on my carbon fiber tank resulted in a nearly identical reading on the gun’s manometer. So at that pressure, the rifle agrees with a tank gauge that I know to be reasonably accurate.

With that fill, I began shooting Crosman 10.5-grain Premiers. I was so amazed by what I recorded that I’m printing the entire string here.

Shot Vel. Notes

1 893 3000 psi

2 911

3 926

4 921

5 931

6 932

7 936

8 931

9 943

10 938

11 944

12 939

13 940

14 946

15 949

16 948

17 948

18 952

19 946

20 950

21 941

22 942

23 944

24 942

25 938

26 941

27 934

28 932

29 935

30 931

31 933 2400 psi

32 929

33 929

34 926

35 926

36 921

37 922

38 918

39 910

40 910 2300 psi

41 907

42 907

43 903

44 896

45 891

46 893

47 887

48 889

49 878

50 875 2000 psi

To my eyes that string is incredible, because it shows a valve efficiency seldom seen in a PCP. Usually, when a gun drops off the power curve, which for a 50-yard shooter might be around shot number 31, the way this rifle is set up, the velocity drops off rapidly. But this gun hangs on through shot 43. If you were shooting at 35 yards there might be 40 good shots per fill. In fact, my strategy would be to fill to 3,000 and shoot four magazines before refilling for everything short of long-range accuracy testing.

For those shooting long range, I would fill to 2,900 psi and shoot 27 shots. That should net you an extreme velocity spread of about 20 f.p.s., give or take.

Conclusions

Now that I know how the rifle is shooting, I will adjust the velocity to clip off the final 30-40 f.p.s. and see if I can’t get a shot or two more per string with an average around 900 f.p.s.

"This is a world-class trigger, make no mistake. The let-off weight remains the same from shot to shot, so you can get used to the performance."

That Crosman copied from Theoben. It's not their own design! So please don't make it sound like they designed it. Same goes for the magazine.

http://www.theoben.co.uk/files/Series%204%20Trigger%20Instructions.pdf

http://www.theoben.co.uk/product.php?productid=55&cat=18&page=1

Paul,

I've seen the same design on Air Arms rifles, too, so don't be too sure that it originated with Theoben. The British makers use each other's designs all the time. And now they are affordable.

B.B.

B.B.,

Don't get me wrong I love the Marauder & have one on the way June 25 from PA. I just want to call a spade a spade if you know what I mean. Theoben's U.S. patent for their 20 year old magazine design ran out late last year & the Crosman version is an exact copy. Air Arms & BSA are similar looking but different because of the Patent. The Crosman trigger is one straight blade from being a exact copy. I assume this all helped keep the cost down, why re-invent the wheel, right?

http://www.air-arms.co.uk/PDF/S410%20MANUAL%20ISS12.pdf

I just am not hearing all the same negative remarks being made if this were a Chinese rifle with copied parts.

In any event I hope this is the new standard for all Crosman products.

13 days until I get mine!

Great reporting as usual by the way.

Paul

P.S. I think a good comparison review would be between the Marauder & Blizzard. What do you think?

B.B. Can the Marauder be "de-gassed" like the Discovery?

The Marauder can be degassed, plus it comes with the degasser tool. For the Discovery, you have to buy the degasser separately.

Edith

Paul,

The Blizzard is more powerful than the Marauder. A direct comparison would be difficult. But I will report the same things, like power, accuracy and the main controls like the trigger.

B.B.

The more I read about the Marauder the more it becomes my choice for my first .22. Very good post BB!

PA is showing an in stock date of 6/25 for a Marauder but I'll bet you if I ordered one I wouldn't get it. My guess is they already have more orders than what is coming in on 6/25. Their in stock dates are confusing me and are somewhat misleading. I've had this happen to me a couple times. I've even had in stock dates advanced a couple times on the same order and that just isn't possible, in my mind, with out them knowing they were that under stocked at the time I ordered. If they already have more pending orders than what will be stocked on their next date then they won't really be in stock, will they? Don't they use a computer?

-C

CJr,

The longer you wait to put your order in the queue for the gun, the less chance you have of being on the list of people who will get a gun from the next shipment.

The way companies take orders is a on a first-come, first-served basis. If 150 people put in an order before you put in yours & only 100 guns are expected it, you might still get your gun out of that order. How? Credit cards are not processed until a product is ready to ship. By the time the gun is in stock, some of those credit cards won't be approved because they're over their credit limit, some will have bad numbers due to typos, others will have gone past their expiration date and some people will have cancelled their orders when their wives see the confirmation email! The figures I used are ones I just made up, but the reasons are valid.

The best thing you can do is place an order as soon as you can & wait to see if enough guns came in to satisfy all the orders.

Edith

Paul,

As B.B. said the Evanix Blizzard is a lot more powerful than the Marauder… here is a shot string with JSB 18gr. .22 cal

with a 225 bar fill:

1089, 1083, 1076, 1079, 1070, 1069, 1063, 1056, 1045, 1049, 1048, 1043, 1036, 1034, 1025, 1019, 1016, 1007, 1004, 1000 (165 bar) 995, 992, 982, 977, 973, 966, 958, 953, 949 (150 bar) 932, 924, 914, 911, 898, 899, 891, 875, 872, 865, 861, 849, 847, 845, 832 (110 bar)

As far as power goes, at 20 yards.. those 18 gr .22 cal pellets come out the back of 1-1/2" thick lumber!! just like a .22 cal rimfire does!

Accuracy is hit and miss.. from a bench rest at 20 yards it will give you a 3 shot 1/4" one hole, then the next shot could be 1/2" off any direction, which might be alright for hunting.

It's for sure designed to be a hunting gun, not many shots per fill, but at least there is no valve lock and it's a steady decline.

The finish on the stock is actually better on the Blizzard than the Marauder I got.

The trigger on the Blizzard is adjustable also and I've got mine down under 2 lbs .. it's nice and crisp..

The noise level of the shrouded Blizzard is not bad, but it's slightly louder than a Air Arms S410 in .22 cal, and a lot louder than the .177 cal Marauder, which is even quieter than my AAs410 in .177..

.. I would guess that the Marauder is the quietest gun on the market without an aftermarket LDC.. you won't need one with it for sure!!

Wayne,

Ashland Air Rifle Range

B.B.

I wonder if you saw my comment a couple days ago, (I posted some shot strings with and without coconut oil).. about the oil somehow helping with the valve lock on the Marauder..

Somehow the first shots were just as high as highest which was around shot 15 with the oil.

Without the oil, the first shot was 59fps less than shot 23..

What the heck is going on.. Oil on pellets should have no effect on the valve.. should it?

I'm going to try it again with different pellets..

Wayne

Ashland Air Rifle Range

Wayne,

I did see your comments, plus Edith related them to me when I returned.

I'm surprised as you at the velocity difference, but I think sealing the air is a good guess.

The JSBs, being pure lead, don't need any oil usually. But the harder Premier do if shot at higher velocities.

B.B.

Edith,

Thanks for your reply. I agree with all your explanations as to why I MIGHT get a product but I still don't understand why I DON'T get a product unless, like airlines, they over book and none of your explanations take effect. They should know, when I order, where I stand on that f-c-f-s list and let me know if they're "booked".

I would be willing to wait for a back order date if I thought it would be honored but for them to know they already have more orders than product and not tell me is not right, and to move the date out means they "goofed". I think someone needs to take another look at that process.

-C

B.B.

The Marauder is sounding more and more like my long term money saving project! Seems like Crosman is really coming back up in the world. By the way, is the new Nitro also on your to do short list?

Chuck,

Pyramyd AIR often doesn't set the dates. They are given them by the manufacturers. The Edge, for example, has changed its shipping date many times over the past year.

B.B.

Fused,

The Nitro is on my short list all right. I have shot it on two different occasions and I'm rarin' to go!

B.B.

As a left handed shooter I want to comment that the gun is comfortable for a left handed shooter. The bolt – and a very nice solid bolt it is, and smooth, as I recollect – being on the right side of the gun is not a problem for me. I am used to holding a gun with my left hand on the pistol grip, my trigger finger laying along the side of the stock, of course, and doing the same things right handers have to do with the right hand – be it loading pellets or clips, cocking bolts, adjusting scopes, etc.

-C

BB,

Yeah the nitro looks great! Is that a built in suppressor or just a jacket like the Gamo Hunter Extreme. Who makes gas springs for crosman? That Marauder is great, but I'm going to hold out and see if Crosman can make it smaller and lighter.

Shadow express dude

B.B.

I've got some things going today, but this weekend I'm really going to test this out further..

Maybe I'll find another one of the guns with valve lock and see if it is effected by oiling the pellets..

The effect of tightening up the spread of feet per second, seems to be real and repeatable..

.. but the weird part is that the high end is lowered… in this case by about 12fps.. go figure.. I would think just the opposite would happen.. the oil should increase the fps..

really puzzled..

Wacky Wayne

Ashland Air Rifle Range

SED,

The Marauder is not that heavy or large.. the stock is kind of thick at the pistol grip for me, and it's thick in general… it's way bigger than the disco..

I'd bet there will be aftermarket stocks by July.. and of course there are many custom stock makers now that would start on one for you.. a custom thumbhole like on the AAs410 would be super nice!!

.. but it's not nearly as large or heavy as the Evanix Blizzard, which is a real tank when you get a nice scope on it!!

Wayne

BB,

"Pyramyd AIR often doesn't set the dates."

Yes, I'm sure that accounts for some incidents.

-C

Chuck,

It's a tough thing for a retailer to gauge the exact time a shipment will be there.. the manufacture slips sometimes.. especially when it's a first run on a new product..

It's important for them to build up a large pool of customers, so when they finally get that first run out.. the first cashflow can payback part of the capital investment to launch it..

It's a delicate balance for them, risking customer dis-satisfaction if they promote too much and can't ship on time!

The retailers end up taking the hit for the game the manufactures play with the money..

just a guess… from another manufacture

Wayne,

Naturalyards LLC

Of course the retailers play the game too!!

Here is the story of how I got a Marauder last week..

About the time of the "Shot Show" in Jan…. one of the retailers, not PA, posted that they would have Marauders in a matter of weeks!

I fell for that and placed my order.. (making sure they wouldn't run my card until they shipped, because I'd heard they had done that to some folks)..

Well, they didn't get them in of course.. but, since I was on the list, I got one of six they did get it two weeks ago..

So, Edith is right.. just get in line!

Edith, can you ask PA if they will ever put the Marauder on the dealer page.. is this one they will never wholesale?

Wayne,

Ashland Air Rifle Range

Wayne,

Is Blizzard as loud as a CFX (.22) or a RWS 34?

Thanks,

Jim

Any word on official release of the Crosman nitro series?

Jim,

I don't have the CFXs or the RWS 34 anymore.. but from memory.. I'd say the Blizzard is about the same as a powerful springer for noise (not counting the sound barrier!).. maybe a little less.. but keep in mind your getting the power of a .22 cal rimfire out to 50 yards!!

Wayne,

Ashland Air Rifle Range

Wayne,

I asked about the Marauder being available for dealers & will let you know what Pyramyd AIR says.

Edith

Wayne,

Pyramyd AIR says the Marauder will eventually be available for dealers. They did not provide a date.

Edith

Another part of the equation concerning backorder has to do with forecast purchased.

In the camera biz (which I'm in) a manufacturer is always playing a guessing game as to how well recieved a new product will be.

They think they have a camera that will be a hit…so they produce 100,000 units. But lo and behold it gets a couple of bad reviews…or a competitor brings out a better camera two weeks earlier. All of a sudden they have 20 million dollars worth of stock sitting there.

That's the way it used to happen.

But now they've all smartened up (and I imagine it's the same with airgun manufactureres).

They think they have a 'hit' that will sell 100,000 units. So the produce 25,000…feeling that if it's as good as they feel people will be willing to wait a month for them to catch up.

But instead the pre-production units they've sent to the testers get rave reviews and before they're ready to launch they have 500,000 firm orders.

But it all boils down to the fact that they underproduce because in todays economy, a 20 million dollar dud can mean the end of a company.

And when something is getting the great reviews the Marauder has been getting, with, I imagine thousands of pre-orders, all the dealers can do is speculate as to when you'll get yours.

CowBoyStar Dad

Wayne,

As always, we appreciate your input. It complements the grandmaster ie. B.B.

Jim,

CowBoyStar Dad,

I've got some camera equipment coming my way. I'm told there are 15-20 film camera's, 8-10 digital cameras and around 25 different lenses. Quality equipment, i.e., hasselblad film, leica digital, zeiss lenses, etc.

Could you recommend an outlet for this used equipment other than ebay?

kevin

Wayne,

Oil nearly always slows pellets down. It increases the drag.

The film of oil make more contact with the barrel than the naked lead pellet would.

B.B.

Kevin,

My buddy. Mac, got rid of all his film equipment recently. He sold off many Hassies and lenses, accessories, etc. They were sold by an agent on Ebay who has a very smooth operation.

Because this was Hassleblad equipment, he did well, but the prices are nowhere near what he paid for them.

If you are interested, I can get the name of the contact for you.

B.B.

SED,

Yes, the Nitro barrel shroud is baffled. The gas spring is an entirely new unit.

B.B.

B.B.

Thanks, that explains it sort of..

..but why wasn't the whole string lower with the oiled pellets? The oiled pellets showing a much tighter spread upping the low side and downing the top side..

More testing in order folks.. try it at home this weekend.. it's not hard..

..run some strings with your favorite dry pellet and PCP..

.. and then with a natural oil that Edith listed a few blogs ago in the comments.. ..

..I like the coconut oil because we use it for healing dry skin, toast and cooking…

..and it gets solid at 70 degrees, which gives it some advantages over the other oils, I suspect…

..and hope to find out for sure..

So test away people.. let's get away from the toxic pellet lubes and find out about this valve lock

potential solution.. if it could be one.. I don't see how.. it just looks like it for some darn reason!

Wayne,

Ashland Air Rifle Range

If you, or someone you know is adept at e-Bay it is probably the best place to move gear.

We have gotten out of the used market where I work because even close to a million population (Edmonton, Canada) we are too small a market to effectively move film gear. We now move all our used gear through KEH Camera (keh.com). Because they specialize in used and have a huge internet market they offer very good value on used gear.

CowBoyStar Dad

Jim,

Thanks, I'm having fun sharing the testing I'm doing for the rifle range anyway..

And I hope that it helps and doesn't confuse things! Like it seems is happening now! .. sorry about that:)

and.. BTW.. THE Grandmaster ie. B.B. deserves all the complements we can send his way!!! so keep them coming to him!

With all the work he's doing for the hobby (for us) right now.. he needs all the pumping up he can get..

Traveling and being away from a wonderful wife like Edith must be a real drain.. so filler up folks!

Let them both know how much we need what they do, and thank them for it!!

Wayne,

Ashland Air Rifle Range

Apparently the Marauder cannot be imported into Canada because its shroud is considered to be a silencer. People up here are not happy.

For more see http://www.airgunforum.ca/forums/viewtopic.php?f=1&t=28053

I love my disco (My first PCP) Now I am saving my pennys for the Maruder can't wait.Also some time ago I asked you about A toy rifle (Replicas By Parris) if you would like to have it for your collection just let me know where to send it. Thanks agan Tom.

dial up dave,

What a nice offer. I'm going to pass, only because Pyramyd AIR just sent me 17 rifles to evaluate from a new manufacturer. I'm knee-deep in guns at the moment.

Maybe some lucky young girl or boy with understanding parents might like that?

B.B.

BB,

That is one fancy trigger unit. Personally, I don't have a problem with designs being similar — there's more than one way to skin a cat, but a few that work better than others:). I'm warming to the Marauder myself, must be getting caught up in the mania:).

Wayne,

If your results hold up to further testing, it will be a good thing. A loss of 12fps (more than half of which is likely below the margin of error for the measurement) is an inconsequential tradeoff for the kind of consistency you are seeing. I have to admit that I prefer the smell of petroleum to coconut oil, though. 15W40 on toast?

BG_Farmer,

Are you kidding me.. you PREFER the smell of petroleum to coconut oil?

what smell? maybe when cooking…

..but I haven't noticed any smell as it burns up when I fire the pellets… or maybe the coconut oil doesn't burn up under compression fire.. because it has a high burn temp.. that's one reason why it's good for cooking.

MAYBE IT'S EVEN OK IN SPRINGERS.. IT MIGHT NOT DETONATE!

more testing is in order.. help me out folks.. let's solve it this weekend!

Wayne

Ashland Air Rifle Range

I put some Marauder scope mounting info up on

http://www.anotherairgunblog.blogspot.com

The scopes that need high rings to clear the objective lenses were messing with my head placement.

It's just a short piece.

B.B.,

i have a quick question… you said that there's an O-ring in the beginning of the barrel, according to Crosman. wouldn't that mean that it wouldn't be a good idea to dry-fire it? i would thing dry-firing it would wear out the O-ring, am i right? just wondering. i wanna know every detail about the rifle before i get it, just because i'm that way. i like to read the manual, or whatever i can get as info, before i get the gun, so i can just take it out and shoot it. i wouldn't think this would be in the manual. so can you dry fire this gun, even with the O-ring in the barrel? this is probably a stupid question, but i'm new to PCP's. i do know paintball though, and do know that O-rings are delicate. i'm just thinking raw air spitting at an O-ring would be a bit damaging over time.

thanks for the info, and great articles/blog posts,

John W.

John W.,

Any almost PCP or multi-pump can be dry-fired without risking damage to the gun. At worst you breaking in the trigger group.

DB

B.B.,

I would greatly appreciate the contact information on the "agent on Ebay who has a very smooth operation" that your buddy Mac used. I'm so sorry this is so off topic but this is a crisis and I'm as far away as you can get from being a camera guy.

CowBoyStar Dad,

Thanks for the heads up on keh.com.

kevin

Wayne,

I really do have a weird aversion to the smell of coconut, especially in suntan lotion and pina colada's; something like diesel, however, doesn't bother me at all. Most people are probably the other way around, so I think you have a good idea, and the pure oil may not have the smell I'm imagining.

Wayne,

My wife & I were discussing the benefits of coconut oil this morning. She said it is indeed preferable for cooking as (if I remember right) the coconut oil is good for up to 300 degrees F. Olive oil shouldn't be cooked with as it changes in a bad way when heated high…causes cancer and other forms of indigestion.

BG_Farmer,

"I really do have a weird aversion to the smell of coconut, especially in suntan lotion and pina colada's"

HHHMMM… is there a story behind this? a beach story perhaps?.. please share.. or is it too painful:)

Yes, try the pure stuff without the extras!!

Wayne,

BB, I notice the links to all the previous parts at the beginning of this blog. But people dont start reading from part 5 down to part 1.

Would it not be easier if at the end of part 1 you put links to part 2 and at the end of part 2 you put links to part 3?

John W.,

When the bolt is forward to shoot, the o-ring is protected by it. The air doesn't "spit past it," as you put it. It exhausts ahead of it, and if there is no pellet in the way, the air keeps going away from the o-ring. The air transfer port is in front of the bolt and o-ring in question.

The only time the o-ring sees air is when there is a pellet in the barrel. The pellet stops the compressed air from going forward. The compressed air then tries to escape back past the bolt, but the o-ring swells in its groove and stops it.

B.B.

Ishaq,

Yes, that would be easier. Can you loan me your time machine? ; )

B.B.

Kevin,

I'm contacting you on the cameras.

B.B.

Wayne:

What else can you reveal about the Blizzard? (Seems like B.B. is "buried" in new rifles to test, so I need to appeal to others for information).

Looking at the shot string PA posted, I was thinking that it would be a nice squirel / bird hunter in the 40 – 60 yard range. The Infinity I have is fantastic, but its velocity falls in a way that gives a very shallow depth of field after the first clip.

regards,

Jane

Good Morning Jane,

I'd be happy to play with the Blizzard some more.. you know I was thinking of you when I was running that last string, knowing you like the Korean airguns…

They are very powerful and the Blizzard is fairly quiet for all that power… But you give up number of shots in trade.. the good thing looks to be a steady fall from the peak power at first shot..(no valve lock)!

I haven't shot it at distance yet, just 20 yards indoor.. I'll do that today and try oil vs non-oiled new JSB 18 gr.. but at first glance from the shot string, I'd guess that 2 magazines of 10 shots is all you'll get at most without much loss of POI..

Although shot 21 -30 are still about a 45 fps spread and end at 949fps.. that's still some foot pounds with that 18gr pellet!! but lets see how much they carry out to 50 yards today… and the grouping..

Later,

Wayne,

Ashland Air Rifle Range

coconut oil… very interesting. Can not wait to see how this works out. Love the idea.

BB,

want to sell your extra Murauder trigger group?

If you do contact me at here or at disco.2.2@sbcglobal.net.

Goal is to retrofit it to my Disco. Word is that it will fit with a small amount of work. Disco trigger group is only marginal at best.

DB

ah thanks… that clears up some things. now that i think about it, it really is a stupid question that i asked. sorry i kinda feel like i wasted someone's time now. but thanks for the info. for the record, i'm getting the Marauder soon. i'm going to wait just a bit longer to see if the price can fall a bit more.

Sorry to go off-topic, but I've never commented on the blog before. I'm new to airguns, and I've got a report and a question.

Report: I've got an RWS 34 Panther in .22 caliber, and need a scope on it. I bought the UTG droop-compensating mount, a Leapers 4×32 Bug-Buster scope and Leapers Space Age 1" Weaver-style rings. The rings were specifically recommended by the Pyramyd customer-service folks. Turns out that the scope is too short for the objective end of the scope to clear the base mount, and the rings aren't tall enough to prevent physical contact between the base mount and the scope. Can't move the scope forward because of eye relief issues.

Question: What rings do I need to use this scope with the flip-up lens cover (which adds to the diameter of the objective end of the scope)? Pyramyd offers UTG High, Medium and Low models, but provides no dimensions to help choose a set that works.

Thanks,

Warren

B.B does that O-ring ever come in contact with a pellet. If it does, then do you think over time it will become an issue?

Wayne,

Long story about the coconut. When Volvo has some time, maybe he can help me ghost write it — might be a big seller:).

How solid does the barrel attachment on the Marauder look to you? I went back to look at the full-length picture, and it still looks to me like the length of the barrel will make the joint at the receiver extremely vulnerable, and I don't have a good idea of the structural sturdiness of the barrel/sleeve and receiver. I know free floating barrels hold up well when the receiver and barrel are made out of steel, but I'm guessing the Marauder is made with lighter materials. Is the s410 made the same way or is the barrel band functional on the AA?

Warren,

call PA customer service back and explain your predicament. They should take the rings back and send you the right height (the height of the rings you have should be specified on the packaging as well as the sales slip so perhaps medium if you have low rings). I've never heard a complaint about PA not helping out their customers, on this blog.

Kevin, you might want to check out Amazon.com and open an account there (they sell more than books) or Craig's list. I have an account and have been very successful selling my son's and wife's no longer used textbooks.

Fred

Jane,

Blizzard Report..

I set up the same type boards that the Blizzard put the .22 cal JSB 18gr all the way through 3 out of 4 times at 20 yards indoors.. at 50 yards outdoors with a light wind..

I used dry pellets for this test.. started with the .22 cal 18gr JSB heavy..

FILLED AFTER EACH 30 SHOT TEST TO 220 BAR ON THE GUN.

The scope was still adjusted to 20 yards, with that same pellet, and the first 10 shot mag grouped nice at 1-1/4" about 1/2" above center on the 1" dot I had sighted in on from the jerry rigged bench rest.. (depth to back of pellet avg 3/4")

The next 10 shot mag. laid 8 out of 10 on the dot, with 2 that opened it up to 2" (darn, could have been me).. Avg depth still almost 3/4")

Third mag started a nice 1/2" wide line from the dot down to about 1" low of the bottom of the dot.

Next 21gr Kodiak (dry)

The first mag made a 1-1/2" vertical group starting 1" below the dot..(good depth to back of pellet, same 3/4"!)

Next one continued the 1-1/8" wide line, dropping to only 1-1/4" below the dot.. (depth held up the 3/4")

Third mag continued and only added 1/4" drop.. (depth to back of pellet dropped only to 5/8")

Next Eunjin 28gr.. dry

The first mag made a wild 3-1/2" group about 2" low of the dot.. (but the depth was 1/2")

Second mag tightened to 2-1/2" centered about 2-1/4" low of the dot..(again, the depth was almost 1/2")..

Third mag about the same and lowered the group only 1/4".. (depth to back of pellet dropped to 3/8")

Seems the groups tighten up a little between 200 bar and 150 bar…

The real good news for me is none of the pellets were sideways (like a lot of powerful PCPs), in the wood, nice clean round holes!!..

This is a better barrel than the AR6 I sold long ago.. I'm keeping this one!.. especially with the super nice looking thumbhole stock I got!

And although the JSB 18 gr gave slightly tighter groups.. I think the 21gr Kodiak will bring just a little more foot lbs at the mussel AND out to 50 yards.. really either will preform very well..

And if your close up and accuracy is not as much an issue.. then the 28 gr Eunjin will deliver the most foot lbs

If one could have the valve regulated better, you'd have a tack driver I'd bet..

It's getting late to do the test again with coconut oil on the same pellets.. but some time soon..

Wayne,

Ashland Air Rifle Range

Josh,

It sounds like the pellet is pushed past the o-ring by the bolt, and not fired past it.

To all,

I am totally lost. I've been shopping for a gun for a while, and I've only established a few basic guidelines:

1) I will be shooting at a range of 10-15 meters at a Gamo Field Target Squirrel.

2) I will be shooting informally, and I have no need for a Feinwerkbau (not that I'd complain if someone gave me one)

3) I'd prefer to avoid an extremely hold-sensitive gun, as I don't think my form is what it used to be.

4) No CO2! This is why I stopped shooting my Nightstalker. I got tired of having to go buy more CO2 canisters.

5) This may have already been implied, but I need a gun capable of reliably knocking the target over when the killzone is hit.

To give an example of how lost I am, I've been looking at the Benjamin Discovery, Benjamin 397, Avanti 853, Daisy 953, and Gamo Recon. Can somebody lend me a hand?

kiwi90,

budget?

low.. Vince has a nice RWS92 for under $100.. a slight step above the Recon in power..

mid.. disco a good choice

next level mid.. wait for the Marauder.. or Evanix Blizzard has pleased me a lot this weekend

Wayne,

Ashland Air Range

Kiwi, I looked up the squirrel target on pyramydair and it appears that one user reported problems knocking it down with a 400fps air pistol at 7-10 meters. He seemed to have no problem with an R7 at 20 meters, and the R7 is in the same general power category as the RWS92. Power-wise, it looks like it puts out close to twice the power of the Recon.

If you're interested, email me at vfblovesnancy@yahoo.com.

And we're looking at significantly under $100. Probably more like $65.

BG Farmer,

Time is not on my side, but if Wayne keeps up with the coconut oil I may need to cave. I will work the verbiage below in testing:

“the narrow waist and the delicate curve leading to the skirt of the Crosman Premier gleamed in the dim light as it wore nothing but coconut oil. My mind imprisoned by the fragrance took me back to the summer of 1981 ….”

Volvo

I knew I forgot something. My budget is $500 at the most, but I'd prefer under $300. I don't care if the finish isn't perfect, as long as it shoots well and won't break. I was originally not looking at PCPs, but after reading several reviews warning about the pumping difficulty of the 6-8th pumps on the 397, I decided to throw a PCP onto the list.

Vince, I don't know much about the RWS92. Do you know anywhere where I could read up on it?

Kiwi90,

If pretty is not on your list and noise is not a factor, get a Disco with the pump. You’ll replace CO2 with muscle power and the accuracy is good. Since it is a single shot it will digest any pellet.

.22 cal is probably the best choice given the power, but .177 is the target shooters pick.

Volvo

Kiwi90,

Good question which should generate alot of advise for you. Naturally a PCP needs a source of HPA, either a pump or a tank. If the pump breaks or the tank runs dry no air no shooting. If you go Discovery you'll come close to your $500 throwing in a decent scope and the stuff to also run your gun on CO2. The Marauder will bust your budget.

Springers are hold sensative. Some more than others. Ask Vince where the RWS92 falls in that category.

The Benjamin 397 or 392 with a little care will last for decades. You can scope them or put a peep sight on them. Accuracy wise very good.

If it was me I'd say Vince the cash is on the way and PA send me a Benjamin 392. You'd still be below budget and would have 2 guns to play with. Please let us know what you do along with your thoughts on what you were expecting verses the reality of what you've got. Thanks.

Kiwi90,

The RWS92 is discontinued now, these are close outs..

Read up on the HW-30 on the PA site.. I've owned 6 of them and more of the RWS92.. and there is not that much difference in them.. and for sure not equal to the price difference! You could sell it if you don't like it, for more than Vince is selling them for.. and Vince has been through it, so it should shoot good!

And like Volvo said.. the Disco is the next level up.. and where your budget works.. with the pump or scuba tank setup included….

But if you want to save awhile longer.. the ten shot magazine Marauder for more accurate shots per fill.. or the ten shot Blizzard for less shots per fill and less accuracy, but more power.. a lot more power!!

You'll be into the last two about $700 or so..

Wayne,

Ashland Air Rifle Range

The RWS92 is the same as the Cometa 220. You can find reviews here:

https://www.reviewcentre.com/reviews4173.html

and here:

https://www.reviewcentre.com/reviews5036.html

If ya wanna talk more about it, please email – I don't want anyone to think I'm trying to use this forum as a classified ad site!

Mr. B,

I was almost set on the Benjamin, but I read this review of the Blue Streak (I know, not the same gun, but from what I've read, they're close) saying that "As a close-range hunting rifle, the Blue Streak excels; as a backyard plinker or all-day shooter, you'll have to go for a PCP or spring gun."

Wayne,

Is the HW-30 you mentioned the Beeman HW30s or a Weihrauch gun? Also, I'm thinking I should avoid a repeater because I don't want to sink into a habit of shooting off the rounds too quickly.

Vince,

I'll shoot you an email.

Volvo,

I knew you were the man for the job…Wayne needs to have another business smash hit, so he can buy more s410's:).

Vince,

I just saw recently that JM has a new run of Cometa 400 springs (also fits other guns), in case you missed it; sounded like you had several 94's the other day.

Kiwi,

From what I've read, the RWS 92 is a nice looking and easy to shoot gun. Should be plenty of power for plinking up to 20-25 yards, and little noise. Vince and Wayne are straight-shooters, so they aren't going to lead you astray, and the price sounds very good.

Volvo,

Coconut oil is great for massage too..

Put on soft music.. Barbra S will do fine..Undress your pellets slowly..

Don't rush them.. they can be shy at first.. soft light helps..

Ok, they are naked on the massage table.. be sure you warmed your hands first.. dip your hands in the oil… slowly rub them together allowing the pellets to hear you, so they won't be surprised by your touch..

Ok, now you can roll your fingers into the depth of the waist bands.. until they are completely relaxed and ready for the ..

..FREEZER!!!

Wacky Wayne..

You write so much better.. just giving you more ideas..

yup….daisy 953 knocked squidger down aka the gamo ft target squirrel at 10 to 15 meters.

20 meters was a little slow, but ok.

past that you may need to tilt the target back a bit.

Advantages, quiet and affordable.

For more range the disco would probably rule, but would be louder and 3x the price.

Anyone know what springer that would perform the closest to a daisy 953 for the same money?

Kiwi90,

The HW30S is a Weihrauch rifle and a fine one. Modest in power, it would probably better the Daisy by a few fps. Next in line is its big brother the HW50S which is a good all around rifle for both target and hunting. Both the HW rifles will make you smile as you lift them from the box. Single shots made of hardwood and steel, they will not disappoint. However, you asked for non hold sensitive. Any Springer is going to require a consistent hold for a consistent point of impact. As a rule of thumb low power and heavy weight will be easier than high power and low weight to shoot accurately.

Many people find multi pumps pneumatics like the Benjamin tiring for long shooting sessions. Not that they are without merit. Just not ideally suited due to the job as you read.

If you could find a pre owned 12 ft lb PCP that would actually be the ideal tool for you, unless a new Crosman model for target is nearing launch.

Volvo

Kiwi and all

the 953,853 are accurate enough but power is questionable at 15 yds or more.

the 397 will need more pumps but I doubt that you'd have to pump to full power

~4-5would probably do the job pretty well.

Why hasn't anyone suggested the AirForce

Edge?Is the cost too high?seems like it would be better than the Disco for the 10 to 15 yrds. mentioned.

Finally I have to suggest you get the RWS

from Vince first,The price seems good and I can vouch for his skills at making springers shoot nice:)He can probably give you some good tips on which pellets it likes too.I wouldn't worry too much about hold sensitivity

with mid powered guns just think of it as a bit more challengeing than MSP or PCP without the extra pumping or hardware

Just my .02 on a rainy weekend

JTinAL

DB,

The Marauder parts belong to Crosman. They are on loan.

B.B.

Josh,

A pellet is pushed past the o-ring by the bolt during loading. It's not an issue.

B.B.

Kiwi

Can you rig the target so that it takes only a lighter hit to knock it down? Make it more "hair triggered"??

twotalon

Vince,

A comment Wayne made about Eunjin pellets key holling, I think at or mabye past 50 yards when being shot out of one of the more powerful PCP's, has really got me thinking about twist rates. Do you think a faster rate of twist would stabilize the longer heavier pellets? If so could you set me up with a 24" barrel that would fit my Talon SS or point me in the right direction?

Thanks much!

Mr B.

Twotalon,

I read that someone did that, but I'm not sure, as I haven't purchased the target yet. I figure I'll do one big order with free ground shipping.

Also, I'm not positive, but I believe I have the equipment needed to fill a PCP from a tank. I have an HPA tank from my paintballing days, and a remote line so I didn't have to attach it to the gun. The remote has a quick disconnect that appears to be the female for the nipple on the PCPs.

Kiwi90,

I have both a Disco and a 953. At 10-meters the 953 is hard to beat… at $75 it is real hard to beat.

The 953 is better balanced and shoulders nicer than the Disco. The 953 is a iron sights but… it is set up perfect for some nice after market sights. A scope works too… but it is just not really powerful enough to demand it.

The Disco demands a nice scope. It will shoot very hard out to 50-yards and beyond. So a nice scope is critical.

The Disco is loud unless you tune it down to shoot slower. Mine is tuned down a bit. But the factory setting makes it bark. The 953 is very quiet.

The 953 is easy to cock and only takes one stroke per shot and it comes with an optional 5-shot clip that feeds very nicely.

If you only looking to kill a steel squirrel at close range then buy something low powered and quiet. If you think you may also want to kill a varmint or two then step up to Vince's gun or the Disco.

That is my very humble and very limited thoughts.

DB

BB,

Thought as much… but if for any reason CR lets you keep it… remember I'd like to get it.

DB

Vince,

I have a problem with the TF97 you passed to Herb and he in turn passed it to me.

Problem is I really like it. Was wacking tin cans in the back yard at 30 yards today… using the factory iron sights and it was just pure fun. Plus it is the only gun that will shoot the CRHP pellets. Have about 4,000 in stock and my Disco will not eat them. It spits them out sideways every time.

Can I hang on to it a while longer and then caugh it up to the next lucky shooter?

BTW… I heard Herb ask you… but didn't catch the answer; did you tune the trigger or was it this nice when you got it. This trigger seem very nice to me. Not match grade or anything like that. But it is better than the trigger on my Disco even after the mods.

DB

DB.

AMEN! well said..

Kiwi90,

Since you have the air set up pretty much licked, and you want to do the steel target thing (you start small, but you soon go crazy, believe me!)..so … You'll end up with at least the Marauder in .177..

But, now I'm really liking the advice that Volvo gave you to watch the yellow classified for a used PCP like Air Arms S400 single shot or s410 side lever with power adjuster.. I think there was an AAs400 last week for about $600..

Really, the Marauder, if you can wait for one, is hard to beat.. I'm more & more impressed with each mag I shoot!

So if your not ready for one of those great PCPs… then while you save..grab a real good inexpensive springer like that RWS 92 (650fps) light recoil.. or the RWS94 (980fps) with harder to control recoil for that small steel kill zone!!

Wayne,

Ashland Air Rifle Range

DB,

When I sent that TF97 to Vince, it was really garbage.. It was so bad, I didn't want it back.. But Vince makes anything into a shooter!!..

I was convinced it couldn't be saved and it cost so little.. I told him to give it away and we came up with the pass it around game..

Seems like you should keep it until someone else wants to play with it.. It's of so little value, and the shipping is 25% of it's cost each time it moves.. so I would say… enjoy it amigo!!

Wacky Wayne

Wow, a lot of input. Regarding PCPs, I was wondering if anyone had an approximate of how many fills I'd get off of a 48 cubic inch, 3000 psi tank.

JTinAL,

I have had an eye on the edge, but it is close to the top of my budget.

Well I got MY Marauder a couple of days ago, but haven't had the chance to play with it yet, as I'm trying to sort out some problems with some other of my guns first right now, because I KNOW that once I start playing with my Marauder… ALL my other guns will be sitting for a while since there are so many variables to test out on this great gun.

I do have two questions though…

I plan to use this for my long distance gun, so what is the furthest distance you would say this would be consistently accurate at, & what reasonably priced $80.00 – $150.00 scope would you recommend?

Thanks,

BBA

BBA,

How long is a piece of string?

There is no one correct answer to your question. And there are many answers. What does "accurate": mean?

The Marauder is fully capable of shooting 100 yards and doing so very well. But only in a windless environment.

On a calm day I can usually get several 5-shot groups under a half-inch out of perhaps triple the number of groups fired. In other words – 10 groups may give 3 that measure under a half-inch.

B.B.

BBA,

As far as a scope is concerned, get the biggest magnification you can afford. I like these two:

/product/leapers-5th-gen-4-16x50ao-rifle-scope-illuminated-red-green-mil-dot?a=1808

/product/leapers-5th-gen-6-24×50-ao-varmint-rifle-scope-illuminated-mil-dot?a=338

B.B.

B.B.,

I understand, & understand that your answer is as much as anyone can hope for, & is what I needed to know. Thank you.

By asking that question, I was trying to ascertain what power scope would do the job for that gun, & you have answered that very well.

I actually have the first scope you mentioned, so I think I'll buy another one, since it IS a very nice scope for the money & it's nice having the same scopes when you can, to simplify things when it comes to remembering operation & adjustments.

Thank you. You've been a big help once again. 🙂

BBA

B.B. I just read an interesting article on Silencers and Airguns.

http://www.beemans.net/silencers_on_airguns.htm

While the Marauder doesn't have a silencer per se, it is designed with components which effectively silence it. The article discusses that even built in or permanently attached silencers (and names barrel shrouds directly) may be considered a silencer.

I look at the shroud as a way to protect the unsupported barrel from damage, but others may not. The internal baffles may be considered as barrel weights for target shooting, similar to the Avanti Legends, but weights can be made differently without dampening characteristics.

I'd like to shoot a quieter rifle, so my neighbors don't need to share my target practice and plinking as much, simple neighborly consideration. How is the Marauder seen in legal eyes? I'd prefer to not be a test case in a new legal ruling on silenced airguns.

Bristolview,

There has been no legal issue with the Marauder yet. I suppose they (the BATF&E) consider that the TX 200 Mk III has been around for a decade with the same baffled shroud and they did nothing about it, so now isn't the time to act.

But I really don't think it's a problem.

B.B.

B.B. or anyone who can answer my question,

I just recently bought a Marauder from Pyramidair. How would I adjust the gun to work at max velocity on a .22 caliber? I do not own a chronograph, so if anyone can give me step by step instructions… I know how to take out the action and all… but the manual does not tell how many complete revolutions to turn with the wrench. Thanks!

The manual doesn't tell you how many revolutions to turn the screw because it takes a chronograph. Every rifle is different.

However, turn the screw in all the way then back it out five revolutions. You will be up as far as it is safe for you to go. If the screw comes out before this, turn it in 1.5 revolutions.

B.B.

Thanks B.B. By the way I have another question. I read a review on this gun in .22 on americanairgunhunter.com and the avg velocity for a CP .22 pellet was 880fps. Is this as powerful as this gun gets even if you crank up the power to the max? Or can it get up to 950-1000 fps like advertised? Or is that speed only attainable with super lightweight pellets? Thanks.

-Robert

Robert,

At 880 the CP generates 24.6 foot-pounds, which is about the maximum for the Marauder with a pellet of that weight. Those higher velocities must be with lighter pellets.

B.B.

Thanks B.B.,

Ugh… I think I have to go and buy a chronograph. Having to guess the velocity of my gun is driving me nuts! I already spent a lot on the Marauder so I guess I have to go look for a cheap chrony now…

-Robert

Robert,

Don't go too cheap. I'd suggest the blue Chrony and the also get the printer to go with it. They have both been very useful for me and make it easy to capture history for future comparisons if you think your gun is starting to age or break down. You may think jotting numbers down on a piece of paper with pencil is sufficient but it will grow old very quickly.

Robert,

Yes, a chronograph is almost an essential if you want to stay on top of the technical side of your airguns.

I know it is an expense, but look at it like buying a good reloading press. I hated spending $100 on my Rockchucker (used, a decade ago) but I use it like a bench vice now.

You really won't regret the purchase, unless you shoot the chrono, like all of us have done sooner or later!

B.B.

Hey guys,

I was thinking I should buy a Benjamin Marauder in .22 caliber. My Gamo Big Cat is too loud and scares the neighbors haha. Should I also heard that Mac1 airguns will "tune" each Marauder (as in make sure it works as advertised) before shipping it out. Would you guys recommend I take this offer? Does this tune actually make a difference? Or should I just buy it off of pyramidair?

Shaun

BB and Cjr,

I was planning to go on a hunt next month for tree squirrels so i need to make a trajectory chart to tape on my gun. Do you think programs like Hawke ChairGun can accurately make these charts? I only have a medium sized back yard so I cant measure out further than 30 yards. Thanks.

-Robert

Robert,

Chairgun is a good program that can get you close. There's no substitute for actual shooting and ranging in the field with your set up shooting the pellet that your gun prefers.

IF you plan on squirrel hunting next month and IF you plan on shooting past your normal 30 yards, it would pay to get out in the field and practice at that distance. You may be surprised at what your favorite pellet shooting at the normal distances of under 30 yards does at longer range (Hopefully pleasantly surprised, but..who knows?)

Doesn't take that long to shoot in 5 yard increments from 30 yards to say 50? yards.

kevin

Robert,

I don't know about what Chairgun software can do, but wne I shot field target, here is how I dealt with tree targets. Look at the linear (groud) distance to right UNDER where the squirrel is in the tree. That determines your trajectory! It's that simple.

The squirrel may be 40 yards away, but actually only 25 yards if you use this method. Hold for 25 yards and you will be dead-on!

I used uit and I know that it works.

Where it doesn't work is when the squirrel is farther away (25+ yards) and sitting lower in the tree. Then you have to adjust, because you are not shooting up as much.

B.B.

Kevin,

I live in a socal suburb so there arn't many fields around here. I'm thinking the only place i can shoot out to 100 yards is the nearest hunting zone. The thing is, I don't really want to spend two hours sighting it in from 20-100 yards. I want to get up early, drive there with friends, and start hunting at like 6am.

Hopefully, chairgun won't be off by too much. I just wanted to know if it actually worked because I was a little skeptical of it's ability to give me pinpoint accuracy at first.

-Robert

B.B.,

Hmm.. I don't quite get what you mean. So if the squirrel is actually 40 yards away. And I hold for 25 yards won't the POI be off by a little as opposed to if I just held for 40 yards? Sorry I'm asking so many questions. I have never been hunting before and this is my first airgun. Is there an article or something I can read for this information? You guys answer my questions well but your answers just keep sparking more questions.

-Robert

Robert,

I've never used Chairgun so I won't be much help here. I do all my shooting at 10m targets. I haven't gotten into hunting yet. Even at 10m it's difficult to impossible to zero in with a new rifle or scope without actually firing the gun at a target. I don't see how it could be possible to do it at longer distances without actually shooting. Someday I'll be asking you for that answer 🙂

-Chuck

Robert,

The squirrel is IN A TREE 40 yards away. But if he fell out of the tall tree, the spot on the ground where he would land is only 25 yards away. Aim as though he is 25 yards away instead of 40 yards, because when you shoot UP, your pellet is not dropping as fast as it does when you shoot straight ahead.

B.B.

Come on somebody! The question is should the reader buy a Marauder tuned by Mac-1 or should he just buy a stock Marauder from Pyramyd AIR. Maybe you have laid off this question for fear of the competition to PA, and I thank you for that, but does anyone have an answer for this reader?

I would sound prejudiced if I tried to answer him, so I need you guys to take this one.

B.B.

Dear "should the reader buy a Marauder tuned by Mac-1 or should he just buy a stock Marauder from Pyramyd Air"

First off, I only shoot at 10m targets so keep that in mind while weighing my answer. I have shot it 50yds and 100yds on one day.

I bought my Marauder straight from PA. I wouldn't let anyone else touch mine but me. So, I vote no, but then I've never shot a tuned Marauder.

How much does a tune cost anyway? Enough to buy a really good scope?

-Chuck

Chuck,

The tune costs 50 bucks. It's not really a tune. He just says that he will make sure it is accurate and performs as it is advertised. He also does an accuracy check and checks to see if there are any burrs or anything. Basically he just checks to see if the product is as good as Crosman says it is before he ships it.

I don't know man. I've heard some really good things about Tim from Mac1 from a lot of different sources on the internet. BB could you answer it haha? I know you will probably say Pyramidair but maybe if you have a good reason… I am pretty much in the middle. So if you think Pyramid would be a better choice disregarding the price difference, I will take your word for it because you seem to have a lot of insight and knowledge with respect to airguns.

Shaun

Shaun,

Okay, I'll answer. Tim McMurray is a great airgunsmith. He does remarkable things with some guns. His LD modification of the Mark I comes to mind.

But the Marauder is a gun that I don't think needs a "look." Most of them arrive in perfect condition. For the few that don't, Crosman is poised to jump on them and fix them for free. Yes, it is a little more troublesome if you have to go that route, but in my experience, very few Marauders ever do.

B.B.

Shaun,

If it were me, I'd buy a .22 caliber Marauder from Pyramyd AIR and send it to Greg Davis and have him tune it (including adding the delrin harmonic band) to shoot 18 gr JSB pellets.

If you want a .177 caliber Marauder I'd buy it from Pyramyd AIR and shoot it. If you have problems (overwhelming majority do not have problems) I'd send it to Crosman and have them fix it under the warranty.

kevin

I've been trying to sort out some computer issues or i would have responded to this sooner.

I think Tim at Mac1 does great work! I've dealt with him numerous times, & have always been very happy.

But, I bought mine from PA.

Why? Simple… I say try it FIRST & SEE if it needs anything done to it BEFORE you spend any extra money.

You may, or even most likely… will find that it works perfect for your needs, & THEN some, & don't need to do anything to it at all.

PLUS, if you do decide that you want to mod it… why not see WHAT it is EXACTLY that you want done to it BEFORE you spend the money.

That way, if you DO mod it, the money will be going where you KNOW it's needed or wanted.

Just my $.02

BBA

Shaun,

Well, the tune is cheaper than I thought so you'll have to save a few more bucks for that scope, but I'd like to say mine shoots one holers straight from PA. I would not send mine in for a tune. I like the idea expressed on previous comments to get it, then shoot it (at least 500 shots), then decide if it needs a tune. Where were these tune guys when I bought my 1077?

-Chuck

Guys,

Thanks I think I am going to get it from PyramidAir now. It seems like the better choice. Man.. I hope I get one that works perfectly haha.

Shaun

BB or anybody else,

When comparing the Talon SS to the Benjamin Marauder, which is better with regards to accuracy and velocity? I know there are a lot more factors to these guns such as price, weight, etc. But I wanted to know which one is more accurate or more powerful in .22 caliber shooting a jsb diabolo exact pellet.

Tim

Tim,

Get the Marauder if you're planning to use air and not CO2. It's a quieter, it's a 10 shot, and it's very accurate. The Talon SS is accurate (I have both guns) but Marauder is better.

I suggest you repeat this question on the current blog post to get more opinions. The current post will always be at:

/blog//

Cut and paste this into your browser and then bookmark it and use it every day to get the new day's article.

-Chuck

Chuck,

Thanks for your response but the only two things I care about are accuracy and velocity. I can live with reloading every round for the talon ss if it means that the gun will be more accurate and will give more foot pounds. I know it might be hard, but which of the two guns do you think is more accurate and/or will give me a higher velocity with the same .22 pellet?

Tim

Tim,

If I had to choose right now which rifle I'd keep, the Marauder or the Talon SS, I'd keep the Marauder. I, personally, am more accurate with the Marauder. I can usually shoot 10 shot groups inside 1/4" in my 10m indoor range from the bench.

Please know that no one can tell you for sure which gun will be better with the same pellet, or any pellet, except you. Every gun is different and your shooting style will be different with each one and it's up to you to find which pellet is the best for each one.

However, that being said, I can give you a starting point by saying that I have found that both my Marauder and my Talon SS like the Crosman Premiers in the cardboard box. They are both very accurate rifles with that pellet.

What you should know, however, is that my Marauder is a .22 and my Talon SS is a .177. My Marauder is using HPA and my Talon is using CO2. Not exactly apples to apples is it?

The .22 Marauder is advertised at 1000fps on HPA. Mine gets pretty close to that, over 950fps, with the CPs at 14.3gr.

The .22 Talon SS is advertised at 800fps on HPA. I have no experience with this configuration. I mine is .177 and uses CO2 and it delivers around 650fps with the CPs at 10.5gr.

I have to ask, though, what is your goal? What do you want to do with the gun. Target, hunt, brag?

In my opinion the Marauder is all you'll need for target and small game and what I've learned on this blog is that a .22 should only be used for hunting game smaller than a raccoon. The Marauder will be excellent for this, also.

-Chuck

Chuck,

Again, thanks a lot. I am going to be using this gun mainly for hunting and occasionally for target shooting. So, accuracy and power are very important to me.

By the way I found something that really sparked some interest. I looked up some marauder and ss power tests on the internet and I found one for each from this website. Marauder: http://www.straightshooters.com/ourtake/ottestmarauder.html

Talon SS: http://www.straightshooters.com/ourtake/ottestmarauder.html

The Marauder has a higher power from the muzzle but when the 50 yard measurements are made, the SS has a higher power with the same .22 pellet. This is really confusing me. If these results are true I think I will pick up a Talon SS.

Tim

I have read through all the blogs and related webiste comments I can find so far and I am unable to find anyone who has yet to respond to the performance of a Marauder on C02 other then you get around 4-5 tank fills from a standard 20 oz bottle.

I use my Talon SS and Condor on C02all winter long for indoor shooting and go to compressed air for summertime pest control.

I expect to use the Marauder to same way, but would like to hear any comments related to C02 performance, etc. etc.

Marauder CO2 guy,

I have a Marauder but can see no reason to want to convert it to CO2. Do you have any info on the benefits of going to CO2? From my perspective all I see are minuses with few pluses based on your described usage.

Tell you what, if you go here:

/blog//

and post your question you should get more responses. This address is always the current blog post where there is a large community of readers.

This blog encourages off topic questions on whatever the current posting happens to be so don't be shy.

Someone there may be able to answer your question better than me. And I'm interested in their responses, also.

Marauder CO2 guy,

Also, when you go there make sure you scroll to the end of the current days post to enter your question. There are several days postings on the same "page".

-Chuck

Marauder CO2 guy and CJr,

Check out this link for the gun running C02 http://www.network54.com/Forum/581291/search?searchterm=M+rod+on+CO2&sort=match

It seems to me that it would well–maybe 700 fps, no pumping, accuracy the same, not good for cold weather, requires the degasser and a way of filling the gun. (PA sells both)

Mr B.

Tim,

CJr hit the nail right on the head, on everything. I think he gave you the best advice anyone could, & I can't think of anything to ad to his advice.

Personally I don't think you'll find a better .22 cal. PCP for the money than the Marauder.

IMHO, the only thing that could possibly make that gun better, is if it were semi-auto, but that's just me wanting EVERYTHING. lol

I think the Talon is a great gun, but I wouldn't even think of trading my Marauder for it.

The Marauder will do anything you could ask for from a PCP & better than any other PCP in it's price range & even more expensive PCPs.

Take it from someone who's had as number of PCP's…. Get a Marauder, put a decent Leapers 3-9 or 4-16 power scope on it, find the pellet it likes best, & you WILL love it!

BBA

i know you need to leave some pressure in the resevoir to hold the seals, but can you leave 2000 psi or so if you are done shooting for the day or do you need to get it to a lower level for storage for a day or two?

thanks,

tncruiser,

Yes, it is advisable to do so.

I leave my precharged rifles filled to maximum all the time.

B.B.

Hello BB, i am considering buying a marauder in .22, but the deal is i do a lot of long range shooting (+ 100yds ), and so i need heavy pellets at decent speeds, giving say 30 FPEs of energy, wich is a 21g kodiak at about 800fps.

Is the marauder capable of this kind of power (or more)?

Can i adjust it for 3000psi fills, open the speed regulator, and expect to get my 30FPEs? and if so, what shot count could i expect from this setup (keeping the ES below 40fps)?

thanks in advance for your help.

Michael

Michael,

Why do you think power equals accuracy?

30 fpe's in a slight wind still won't equal accuracy with a 21 gr pellet (kodiaks).

No matter what you fill the marauder to it will still shoot the same velocity and have the same shot count since it's an unregulated gun.

Think about the analogy of your car that needs fuel. No matter how much gas you put in the tank it still will only go 120 mph.

The marauder, in perfect conditions, can be a long range shooter.

If long range shooting (100 yard +) is your goal, you need a 60+fpe gun that can buck the wind.

kevin

Hi Kevin, and thanks for your reply.

I do Not think power equals accuracy. But out of experience, i do know (because ibe seen it time after time), that a heavier pellet is more accurate at large distances(100yds+) than a medium weight one. Assuming of course, the rifle is accurate with them! And it is FAR less influenced by wind. Also,

a heavier pellet retains energy & velocity better.

As for needing 60+ FPE for 100 yards, i respectfully disagree, ibe been shooting at those ranges every weekend for over 3 years now, and i use a gun that puts out 21g barracudas at an AVG. of 840fps, for about 33fpe. And i get excellent results.

You see, my rifle likes 2 pellets, kodiaks (barracudas), and premiers.

At say 30 ~ 40 yards, there eint much diference in results. But try them at 110yards, and throw in a little wind, and the kodiaks are the absolute champions.

As for your comment about "No matter what you fill the marauder to it will still shoot the same velocity and have the same shot count since it's an unregulated gun."

I know changing fill preasure by itself wont produce dramatic changes in velocity (unless you get valve lock of course hehehe), but i was under the impression that the marauder has a "velocity adjustment screw" and opening that screw is what i meant when i said "open the speed regulator".

The rifle DOES have adjustable velocity. right? or maybe i am mistaken?

thanks!

Michael

Michael,

With regards to "adjustable velocity" do you know about Greg Davis?

I like kodiaks too but have you tried the jsb 18.1 gr. in your marauder?

kevin

Kevin,

Im sorry but, who is Greg Davis?

As for trying the jsb´s on the marauder, i dont own a marauder (yet).

Like i said on the firs post, im planning on getting one, thats why im asking if it can be configured to shoot heavy pellets like kodiaks at 800fps+.

In any case, i want to know what is the top energy this rifle can be configured to give, before i buy it.

i have heard great things about those 18g jsbs, but i havent had a chance to try them yet.

Michael.

Michael,

I don't know what energy a Marauder .22 can produce. I only tested a .177.

You might check on the Crosman forum and ask someone who owns a .22.

http://www.network54.com/Forum/275684/

Yes the velocity is adjustable. A transfer port limiting screw is adjusted in and out to interrupt the flow of air.

B.B.

Michael,

I just did a bench test for you with my .22 Marauder. These results are not official Marauder specs they are just what I got with MY rifle, using MY chrony, in MY indoor 10m range. Results may vary based on your driving style and driving conditions.

For my first test I filled up to 2500psi and shot the boxed Crosman Premiers 14.3g. The highest velocity was 913.85fps, after 10 shots it was 892.17fps and that was also the lowest. After 10 shots the pressure was 2100psi. That calculates to 26.47fp and 25.28fp respectively. These shots were virtually oneholers and it took 6 stacked shots to pierce through the 1" duct seal pug.

My second test I refilled to 2500psi and used Beeman H&N Match Wadcutters 13.74g. The highest velocity was 931.65, after 10 shots it was 912.55, the lowest was shot 8 at 910.49. After 10 shots the pressure was again 2100psi. This calculates to 26.51fp and 25.31 for highest and lowest velocity. These shots were all over the place within a 1" group. I would not recommend these for use in the Marauder but I'm stuck with them now.

I'm going to repost this comment on the current days bolg because I think there might be more people who would be interested in this.

I would suggest you always go to the current day's blog post to post your questions. Do not be afraid of being off topic because we welcome that with open arms.

Go here every day and you will always be on the current days posting. There are more than one day's postings here so be careful you don't scroll too far to get to the comment link.

Here's the link, hope to see you there:

/blog//

-Chuck

To Anonymous,

Greg Davis is a very well respected airgun tuner, who just so happens to really know Marauders & as far as I know, has been THE guy to get the most out of them with his tunes.

He is very knowledgeable & does incredible work!

Just go to the forum B.B. suggested & look for Greg. Either do a search or just make a post asking about him.

He can be reached here;

greg.granitegallery@powerc.net

Tell him Mike in Vegas sent you.

Good luck & tell us how he did for you. (I think you will be VERY happy with his work!)

BBA

Greg Davis has a website on the Network 54 servers that lists his prices and services available. Here are a couple of threads showing 50 yard groups and 100 yard groups from a Greg Davis tuned Marauder.

Happy reading 🙂

BB, Chuck, Bobby, BBA, thanks a lot for your help & information.

My mind is made up, and ill be ordering my marauder very soon.

Those 100yrd shots at the can we see in that post, is enough for me.

Thanks guys!

Anonymous Marauder,

When you get your Marauder don't forget to join us on the most current days blog and tell us what you think and how you're doing.

-Chuck

Shure thing Chuck, when i get it ill tell you guys about my impresions & tests with the rifle.

Thanks again for your help guys.

Michael.

Anonymous,

Good to hear. I know you'll be very happy with it, especially with Greg's tune.

Keep us posted.

BBA

It does not matter whose design Crosman used in making the trigger or any other part of this air rifle. Once patent protection run out anyone can make the item. All inventors who patent their invention have a set time for protection. After that it is up for grabs if you want to use the technology.

There is nothing wrong with what Crosman has done. Take the best pieces from some other makers and incorporate them into their own product. Smart & effective.

Very different from the Chinese who often make direct copies of the entire rifle. Crosman has not done that. A very big difference.

New to pcp new to airguns period. Have 1077 shoots great far as I'm concerned. Have also powerline008 love killing Kans with it too. Was gonna get a Discovery then found the Marauder and gotta have it. Not a fountain of knowledge as some of you appear to be Just avg Joe plinking no Chronographs pellet weights figures do I wish to share nor can I. Its been fun reading I on here and hope to enjoy my marauder if and when I Kan afford till thenn its 008 & Kans and more watching of the chatter

Rock Dawson

Rock,

The Benjamin Marauder is a great PCP. The value is terrific.

Please join us on the current blog, where you can ask any question on any topic. We are a friendly bunch of guys and would love to have you join us.

/blog//

B.B.

marauder kan be filled with a scuba tank or with a pump… witch is better? have read a few reviews about the pump some have not been so pleasing with breaking and such… a tank would cost close to or just a lil more soooo been wondering what would be my best bet as far as lasting fill after fill i dont mind pumping but if its gonna be breaking after a short time then tank seems way to go but… also just wonder if the ones who had the bad pumps is that just bad luck or is it a problem with most pumps as ive read good reviews too so kinda up in the air about it… sorry for the bad puctuation but really didnt pay so good attn in english:) and sentence strukture, spelling so forth i like the letter k:) your comments suggestions would be great, thanx rock

Rock,

The pump is very robust, as long as the user maintains it. The biggest thing he has to do is keep his hands off the pump–period. Just use it and bleed it with the brass screw at the base.

My first pump lasted 11 years, then failed in an instant when I let someone else use it. he exhausted the bleed air on the dirty ground and got dirt on the pump shaft. It destroyed the pump instantly.

If you are a tinkerer, better go with a scuba tank.

B.B.

thanx again for the grand advice… umm one more of many im sure maitenance what would all of ya suggest as to a good box-o-junk to clean protect n so on. have heard of snakes, crown savers, rods, pellet clener and other stuff. ohh and should i get a tool set? have a gun sock already do they last forever or do they need re-soaking in silicone after time or sprayed whaterver. again thnx for all have shared with me so far

rock

rock,

You're posting on a year old blog where only two or three people are monitoring. Come over to:

/blog//

This link will always take you to the current day's blog article and you can ask your questions there where there are a hundred(s) of readers. Don't be afraid to ask off topic questions. We all do and it is accepted no matter what the current topic is.

-CJr

Rock,

We don't really clean airgun barrels all that often, unless they need it because the accuracy has suffered. Read today's blog for the cleaning solution. For what Mac does to the R1 you need a one-piece cleaning rod and brass brushes. You also need a cleaning jag to push several patches through the bore.

Forget bore snakes. They are for firearms.

But with a Marauder, you won't be cleaning before 10K rounds unless you add something to the pellets.

You gun sock will retain its silicon for years.

No need for a tool kit.

B.B.

Hello guys,

I'm from Europe, Belgium and own a Benjamin Marauder .22 since the february 2011. It is my second PCP and I found it a a lot better than my BSA Lonestar .22.