by B.B. Pelletier

The Air Arms S400 MPR FT rifle still has a surprise for us!

This special report about the Air Arms S400 MPR FT rifle was unplanned, but blog member Coax asked for it. Today will serve as the best lesson I’ve ever written on how to properly use a chronograph, because I made a huge mistake and the chronograph straightened it out for me.

Coax told me about a transfer port limiting screw that could be turned out to increase the velocity of the rifle. I was unable to locate it from his description, and we went back and forth several times before I found it. At least, I thought I’d found it. Therein lies the huge mistake I made, and the save made by the chronograph, all of which should be a good lesson in pneumanology.

The “secret screw”

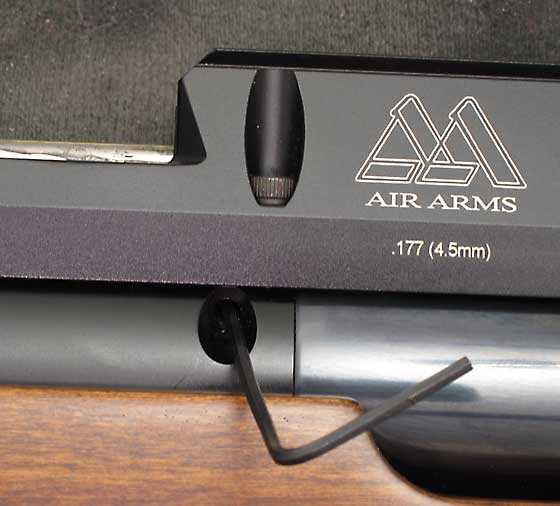

Below is a photo of where the power-adjustment screw resides. But don’t just loosen the screw in that picture or you will be guilty of the same huge mistake I made. Because I did loosen it 2.5 turns and I got results. They were quite positive and I was already writing today’s report in my mind, after recording each of 99 shots, when I discovered a huge mistake. I will share those results with you now, but please don’t act on them until you’ve read this entire report, because that screw isn’t the one to adjust this rifle!

After much communication, I finally located the “secret screw” that Coax is talking about. But I got a huge surprise, so please read the entire report.

I filled the reservoir to an indicated 190 bar. I read the scale on my AirHog carbon fiber tank, which I know to be reasonably accurate. Then, I began shooting Crosman Premier lites, which were featured in Part 2 of this report.

Shot Vel.

1….. 784

2….. 791

3….. 783 (lowest velocity recorded)

4….. 785

5….. 792

6….. 790

7….. 785

8….. 790

9….. 784

10…..788

11…..791

12…..791

13…..795

14…..791

15…..791

16…..787

17…..787

18…..789

19…..795

20…..794

21…..796

22…..800

23…..791

24…..794

25…..792

26…..800

27…..793

28…..795

29…..799

30…..798

At this point, I’ll reflect on what we’re seeing, even though it’s not the result I was after, nor had I done the right thing yet. If you go back to Part 2, you’ll see that when I filled the rifle initially, I filled it to 190 bar on the tank gauge. The manometer on the rifle read lower than that — about 180. The initial velocity was in the 764 f.p.s. range with the same Premier lites that were used in this test, so turning out the small screw on the right side of the receiver seemed like the right thing to do. Because, as you can clearly see, the rifle started out 20 f.p.s. faster and averaged about 791-792 f.p.s. for the first 30 shots. The maximum velocity spread was 17 f.p.s. for this 30-shot string.

So I continued.

Shot Vel.

31…..797

32…..797

33…..795

34…..796

35…..804 (about 170 bar)

36…..800

37…..806

38…..800

39…..803

40…..796

41…..802

42…..800

43…..802

44…..797

45…..802

46…..800

47…..801

48…..814 (fastest shot)

49…..802

50…..808

51…..803

52…..799

53…..800

54…..802 (150 bar)

55…..799

56…..800

57…..801

58…..802

59…..799

60…..801

Okay, we’re up to 60 shots on this fill and no sign of the power dropping. Also, we’ve dropped below the 150 bar pressure level, according to the onboard pressure gauge (manometer). In this string of 30 shots, that is from shot 31 to shot 60, the average velocity has climbed to just about 800 f.p.s. That’s 16 f.p.s. faster than the average of the first 30 shots, so the gun’s increasing in power. The maximum velocity spread for this 30-shot string is 18 f.p.s.

Let’s continue.

Shot Vel.

61…..810

62…..804

63…..808

64…..808

65…..806

66…..807

67…..806

68…..810

69…..804

70…..805

71…..802

72…..805

73…..809

74…..801

75…..806

76…..804

77…..807

78…..806

79…..799

80…..802

81…..799

82…..800

83…..797

84…..802

85…..795

86…..799

87…..792 (125 bar)

88…..791

89…..791

90…..793

91…..791

92…..794

93…..791

94…..785

95…..785

96…..786

97…..784

98…..784

99…..783

The final string shows the end of the power curve and the rapid drop-off back to the lowest velocity recorded in the beginning. Now I’ll analyze the entire string of 99 shots as I would see them if I were using the rifle to compete in field target.

The rifle really came up on the power curve at around 170 bar indicated on the rifle’s manometer. That was at shot 35. I would fill to that level, after making a permanent mark on the gauge, so I could find that level easily when filling again. If I consider shot 84 to be the final good shot in the gun, I would have from shot 35 to shot 84 as a useful string. That’s 49 good shots, which I would round up to 50 shots. I would have 50 good shots in the gun that went as slow as 795 f.p.s. and as fast as 814, for a total shot string variance of 19 f.p.s. That’s pretty good; and if you check back with Part 2, you’ll see that I’ve actually raised the average velocity of the rifle by about 15 f.p.s. over the useful string. So, adjusting the “secret screw” did change the performance of the rifle.

Only that wasn’t the secret screw! After completing this exhausting test and evaluation, I was wondering why Coax said the secret screw was INSIDE a deep threaded hole. Clearly it wasn’t on my rifle. Unless…!

Oh, my, gosh! I ran that whole test and never even touched the real secret screw! That screw, which Coax apparently is missing, is only the cover for the real screw. That was the huge error I made.

The real transfer port adjustment screw is located deep inside the hole that remains when the cover screw shown at the top of this report is removed. The Allen wrench is a 0.050-inch size.

Saved by the chronograph!

Here’s the real lesson for today. Because I had that beautiful, pressure-related velocity curve indicated in those 99 shots shown above, I didn’t need to waste any time once I adjusted the real screw. I filled the rifle to only 170 bar as indicated on the onboard manometer and started the second test.

Then, I turned the real power adjustment screw out one and one-half turns and shot a 10-shot string.

Shot Vel.

1…..882

2…..891

3…..886

4…..883

5…..893

6…..886

7…..885

8…..888

9…..885

10…..883

Avg. 886 f.p.s.

Next, the screw was turned out 1 additional turn.

Shot Vel.

11…..895

12…..897

13…..895

14…..892

15…..891

16…..895

17…..895

18…..895

19…..894

20…..886

Avg. 893 f.p.s.

The screw was turned out one additional turn.

Shot Vel.

21…..893

22…..900

23…..903

24…..888

25…..894

26…..892

27…..896

28…..892

29…..896

30…..891

Avg. 894 f.p.s.

What I learned

First, I learned that this was indeed the true power adjustment screw. Second, I learned that turning it out about two full turns is all that’s necessary. After that, the velocity increases are not significant. I finished the 30-shot series with about 140 bar left in the reservoir, so there are about 15 more good shots in the gun.

Taking the second string average as a power input number, the rifle now generates exactly 13.99, which is close enough to 14 foot-pounds of muzzle energy with this pellet. Use a heavier pellet and get more power because this is a pneumatic.

By referring to the chrono data chart that also had the pressure indicated, I didn’t need to waste any time running up to power. I knew where the power band was located, even when I was increasing the airflow. The valve still works the same, regardless.

That’s the power limit of this rifle. I imagine I could get up to 16 foot-pounds if I used a very heavy pellet, but the best pellet is always the most accurate one. Whatever that one produces is the practical maximum for this rifle.

WOW! You earned your money testing this one, but it’s obvious you had a lot of fun doing it.

-Chuck

Not only ventilation holes but …. SLANTED ventilation holes! Oh be still my trembling heart! I’m glad I can’t afford this.

Careful readers of my posts will know I’m not the biggest guy in the world. And, I love the Daisy anniversary edition Red Ryder BB gun. Well, in 9 days or so, I go pick up my Henry “youth” lever action .22 which I’m willing to bet is just about as close in measurements to my Red Ryder and you can get…. without buying another Red Ryder.

It will be my night-time coon and possum gun.

I let the land owner here shoot my Red Ryder and the end result was, first he bought out the local “super” Wal-Mart’s supply of BBs then over to Tractor Supply for 4(!) Red Ryders (since Wal’s was out of ’em).

Two is one and one is none……

BB,

flobert,

I love those lever actions! Also the pump shotguns. I think Hollywood and TV has something to do with this. I grew up with those first TV cowboy and detective shows. There’s just a touch of cool watching them get cocked with one hand.

You should get the Walther Lever Action rifle Pyramydair sells, also. Virtually the same heft as a Henry and accurate, too. It’ll fill the void til you can get outside.

-Chuck

OOps, I meant to leave a comment there for BB. Oh, well, never mind.

-Chuck

I watched plenty of The Rifleman but as an adult, not a kid. Mom would have hated that show. In fact I think it was the phasers that kept Star Trek on the forbidden list for so long.

I like levers because, that tubular magazine holds plenty of shots, no fumbling with magazines at night if it’s that big a family of coons to dispatch. Or whatever. It’s a lot less clumsy to work a lever than a bolt for quickish repeated shots. Some of the rounds I shoot won’t cycle a semiauto, or cycle it reliably. And I didn’t want to look into the black hole of “gadget-itus” that goes with having a 10/22.

I’m thinking of filing out the rear sight notch to make a “bold” sight picture, and putting a flashlight mount of some kind on the fore end. I can do really neat work!

The lever .22 to get is the Marlin. It’s the best of the best.

Mike

I agree. However, it’s $500 or more, they’ve stopped making them so I’d have to have the shop look around and find me a used one, etc.

Frankly I like the little “youth” Henry. Gun fit is a big thing with me. And I intend this to be a night-time, run around in the trees and bushes coon and possum getter.

BTW it’s looking like CB Longs, if you “dum dum” the tips just a bit, can do amazing damage. And they’re very quiet.

I’ve got shallower pockets than BB does, so it’s the Red Ryder for me.

I have a sneaking suspicion the Henry Youth I got (have to wait to pick it up) and my Red Ryder will turn out to be very close in measurements.

The Henry has a MUCH easier action to work and a nicer trigger!

In fact it’d be neat to do an article on the two, I guess it’s 1000-word minimum, good pics, accuracy tests at least if not velocity tests (I don’t have a chrono)?

BB,

What a great read this morning. I love that S400, but probably never get one do to the cost and I’m not that into field target. Finally finding that adjustment screw has me relieved!

Flobert,

Wow! 4 RR”s? Sounds like some fun to be had to me!

ka

Love this gun…but sadly can’t justify it.

Flobert, 5 years ago it was a Red Ryder (for my son) that got me hooked.

A friend of mine recently picked up Henry…mighty purty gun.

B.B.,

You’ve been busy. Lot of time spent testing guns recently. I sure appreciate the in depth look and your willingness to experiment with each guns nuances. No question in my mind this is a large reason for the enormous number of your loyal blog readers.

What airgun took the place of your Walther LGR when you got rid of it?

Sounds like a large portion of your gun collection is being refreshed. Hope you’re having fun with the process.

kevin

Kevin,

I can’t remember what I got for the LGR. Maybe it was a Diana 75, because I had one of them around the same time.

I go through a lot of airguns just so I can get to know as many as possible. Trading seems to be a good way to refresh the herd.

B.B.

BB,

As I understand it, this adjustment screw is similar to the transfer port adjustment screw buried under the stock on the Marauder, correct?

I had been wondering if transfer port adjustments would change the valve characteristics in an indirect manner – by changing the pressure curve on the outlet side of the valve (by changing the downstream restriction in air flow) – thereby impacting how long the valve stays open and thus shifting the power curve.

I had been planning on experimenting with this, but based on what you say there is no need, so thanks for saving me the time and pellets (and pumping!).

Given this, I sure wish there was an easier way to change the transfer port setting on the Marauder. I have found that the gun not only has pellet “likes and dislikes”, but that it has different likes and dislikes at different power levels. It puts H&N FTTs into one ragged hole if I keep the power under 20 ft lbs. but sprays them at 25 ft lbs and up. I like how I have my valve set now (~30 ft lbs with Baracudas), but at this power level it only likes Baracudas (JSB heavies are good too, but I think the repeating function nicks the soft skirts and causes too many fliers). I would love to be able to easily dial it down for indoor target work with the FTTs, and back up for pests with the baracudas, but don’t think the little screw is up to that kind of constant use anyways (let alone the hassle of taking the action out of the stock constantly), but I do love it otherwise.

Thanks again for the great insight.

Alan in MI

BB What feature of the action/valve does that screw adjust?

As usual, thanks for all the info and the close-up photos really tell the tale of the degree of finishing and precision of the various parts of this gun. $$$ ? yes, QUALITY?, YES!

Brian,

The screw extends into the transfer port, so when in it impedes airflow and out it allows it to flow.

B.B.

BB,

Thanks for taking the time to do the test. I find the adjustability a good feature and allows the shooting of heavier pellets under windy conditions. It is quite an accurate rifle. When set to the same power level as my wife’s EV2, it is more accurate out to 35 yards and only gives up a tad at 55 yards.

Well, I would say that this post was quite the advertisement for the Rogue. What would be the equivalent procedure there to adjust power–pushing a few buttons? When did you say that we can expect a report on the Rogue? (There is a name that I like by the way.)

B.B., well if you are shooting SMKs in your Garand than you must be a millionaire too. 🙂 And since the first thing I will do with my new reloading skills is to shoot SMKs, the price won’t really matter, but I will have better accuracy and satisfaction too.

pcp4me, that is an interesting comment the other day about elite shooters obliterating the center dot offhand. Actually, when I watch YouTube, it mostly focuses on their shooting form not the targets. In any case, I think the terminology of dots can be misleading. The dot is truly small but in comparison, the pellet diameter is not. It would be possible to obliterate the center dot with the outside edge of a pellet as much as any other part of it. This implies that shooting out the dot can be done as long as you can keep your pellets in a hole of two pellet diameters or .4 of an inch which is 4 MOA. And you should be able to clean the target with an even larger hole, maybe 5 MOA (measured from the edges; that would be 3+ MOA ctc). This is good but doable and not anywhere near consistent .08 ctc or sub MOA shooting which I continue to believe is not really possible offhand.

Brian in Idaho, yes I had thought about the fact that the Japanese are a homogeneous tribal culture as a reason for their orderly behavior in the midst of disaster. On the other hand, tribal homogeneity did not stop Haiti from descending into complete chaos after their disaster. As far as that goes, Japan underwent centuries of continual civil war in the medieval era, so they are no strangers to internal violence either. As for us, I have no doubt that many good citizens would show their best in a comparable disaster but I don’t know if I could predict the same uniform orderliness. That was certainly not on display in the New Orleans hurricane. You have a point about how the Japanese are accustomed to waiting in lines in their dense population, but studies indicate that the original reason might go much further back. There is a theory that the collective behavior of Asian cultures is rooted in the dynamics of rice growing which are extremely complicated, much more so than wheat crops which sustained Western culture. Rice simultaneously enabled large populations but also enforced intense discipline to make sure that people would not starve by screwing up the rice crop. Anyway, that’s the theory.

Anyone know why the 1911 .45 ACP is apparently not used at all for handgun hunting? I can’t believe that at handgun hunting ranges which must be quite short that the .45 ACP gives up that much to the .44 magnum which is a legitimate hunting round. Or is it that simple?

Matt61

Matt61

In the latest CZ USA 2011 catalogue, there is an article about taking a mountain lion with a Dan Wesson custom .45 ACP. As you noted, the author/shooter made the same observation, “why isn’t this done more often?”

Matt,

Crosman will be giving me one of two pre-production Rogues in April. I will have it until the end of June, I believe.

I’m blogging it and also writing a feature for Shotgun News.

Because I was there with Lloyd before the Rogue was started I will be able to give you some insight into how it works. It is elegant, yet a simple idea. Not so simple to build, though.

B.B.

Matt,

I realize that you can obliterate the dot with slightly LESS than a two pellet group size. And you can score a 10 with slightly MORE than a two pellet group size as all you have to do is touch the center dot. Basically a .177″ ctc group would get you all 10’s as might a .185″ ctc or slightly larger group. And that kind of accuracy might get you wins at national level but you couldn’t even compete at world class level with that kind of accuracy!

The guy I talked about CENTERING the pellet in the 9 ring without touching the edges at all 90 times out of 100 and only cutting the entire edge of the 9 ring about 5 X out of 100 is the world class shooter. And those groups are on the order of about .02″ ctc!! It can be done. It has been done!

I CAN’T DO IT!

If you understand the Japanese and their civilization at all, you’d understand why they don’t behave like the U.S.. If you understand the U.S. and our civilization at all you’d understand why we don’t behave like the Japanese.

-Chuck

The figures listed don’t give enough information. They are meaningless. What bullet? What weight?

What velocity? I can tell you from shooting lots of both that the modern duty loads for the .45 ACP are more powerful than the .40 S&W.

Mike

Completely unrelated to today’s topic:

Long-time reader, finally getting to own some airguns (took a while to convince the wife). I have no desire to be a collector or a hunter, I just want to enjoy shooting paper/cans with some cheap/quality guns. I bought a 1377 as a first gun, and am enjoying learning that I am WAY less accurate than the gun is. I bought the 1377 because it is a good “do-it-all” gun. I would like to follow that trend with all of the power plants, in both pistol and rifle frames, for under $100 a gun. However, I am having some concerns regarding spring guns.

A lot of the personal blogs and forum postings I see follow this trend: “I got the gun in the mail, and immediately broke it down, cleaned, deburred, lubed and re-assembled. Hopefully I can get 2K shots out of it before I break the main spring or have to replace the main seal.” Granted, most of my attention has been on Chinese guns (due to good bang/buck ratio), but is this really what needs to happen to own a modern spring gun?

I own a motorcycle that I specifically purchased because it requires significantly less regular maintenance than other bikes. I will oil/lube/care for whatever needs it, but I would HATE to own anything that needs CONSTANT maintenance to be usable. Should I stay away from spring-powered guns? Is there a spring gun available that is accurate, “powerful” (pest control), cheap (under $100), and reliable?

I also tend to shy away from break-barrel guns because of horror stories I hear of barrel droop, aim-point creep, and loose barrel-locking mechanisms. This limits me to side-lever and under-lever guns, of which there are not many choices. Is that also a stigma of the past, and something that current modern guns don’t exhibit?

Thanks for the info and re-assurance.

Jim,

Modern springers, for the most part, are well made and will operate for years with minimal maintenance. I think there are some folks out there who think they know better than the factory and just have to fix/tune/mod their new gun for it to be satisfactory. I bought an R1 in 1984 and over the next 25 years put about 10-15 thousand shots through it. No maintenance required at all except a new breech seal and mainspring last year because it had lost about 150fps velocity. Never had to tighten the barrel pivot bolt. It will still put five shots in a hole you can cover with a dime at 25 yards.

Cheap springers, like any cheap gun, on average will wear out faster than better-built ones, but even some of the low-priced Chinese guns should last for years with proper maintenance and use.

Paul in Liberty County

jmdavis984,

Welcome!

Boy, you sound just like me from a few years ago – especially the “convince the wife” part!

Unfortunately, the situation you described with fixing spring guns is dead on at that price range. I started with a Crosman Quest, and by the time I got it shooting well with a new trigger, fixed the broken spring (by sending it for a professional tune for better accuracy), my $115 gun cost me upwards of $300 – and that doesn’t include the new scope to replace the cheap one that came with it that broke after about 700 shots (the mainspring died at about 1000 shots). If I were to do it over, I would go with the RWS 34 since they are better made and cheaper in the long run. While it does suffer from barrel drop, it is a repeatable drop, and with the right mounts your accuracy will be like the 1377 – better than you can shoot (or me in my case). I would not be afraid of break barrel guns from an accuracy standpoint, especially in a slightly better gun.

If you are willing to build your own spring compressor and dive into the gun yourself, you can save some money. I eventually had to do it as the second spring broke (after about another 3000 shots), and I thoroughly enjoyed the experience.

Welcome again to a great hobboy, and we are all willing to help here.

Alan in MI

JMDavis,

first, welcome to our blog and thewonderful world of airguns. I have bad news for you.

This sport is addicting so it is very likely you will end up with numerous airguns.

There is no cure other than an empty wallet. As in anything else, you get what you pay for.

The cheap guns are cheap because, well, where to start – low quality of metals, materials, design, tolerances.

You really get what you pay for. Barrel droop isn’t the problem you hear about.

It really only comes into play if you scope the rifle and then, there are mounts you can buy

that will correct for the barrel droop. I own several RWS’s (Diana’s) that are known for barrel

droop and have no problem with them. They are among the more accurate in my collection.

They are also the hardest to shoot and you must develop your technique. We use what is called the

“artillery hold”. Read about it here:

/articles

Good luck and hope you keep coming back.

Fred PRoNJ

The very cheap guns are the Chinese made rifles. You can get lucky and buy a very good one or the opposite. Crosman,

Beeman and I believe Gamo sell Chinese made guns but Crosman it appears tries to monitor quality control a bit better.

Crosman also has a higher line of American made which are every bit as good as the German made rifles

(Weiruch and Diana/RWS).

Best and cheapest breakbarrel rifle is the RWS 34. You can see it here:

/product/diana-34p-air-rifle-synthetic-stock?m=1041

I’ve read those horror stories too but of the 9 rifles I now own, I’ve never done any of that.

One rifle had a leaky “o” ring at the breech and that’s been that.

jmdavis984,

The deburring and lube tuning procedures that you refer to are generally done to accelerate the break in

process that all spring guns will need to go through before achieving their designed accuracy.

You don’t necessarily have to do it, it will just take longer for all of the parts to mate with each

other (generally 500 to 2000 pellets are recommended). Once broken in, they should be good for many

thousands of shots presuming you match them with an appropriately weighted pellet.

B.B. has many posts on this subject already.

That being said, your “under $100” price point will definitely place you in the shallow end of the quality pool,

so I would recommend buying from a reputable dealer like PyramydAir because you might have to return one or two

before finding a keeper. If that thought bothers you, then you can either up the budget or move over to

something besides spring piston guns such as CO2 or multi-stroke pneumatics.

I would recommend something like the Daisy 22SG for your purposes.

It will handle small pest duties and generally be more accurate than you are out to about 20 or 25 yards fairly easily.

Plus, you shouldn’t have any issues with maintainence whatsoever with it.

Alternately, you might look at the

Crosman 2260

if you are willing to live within the limits of CO2 (i.e. won’t work outdoors in cold weather very well).

Crosman 2260

Fixed the link

jmdavis,

Wow! Is this blog for you!

All you want to do is buy it and shoot it? Don’t be afraid of breakbarrels. Be afraid of the people who think all airguns need to be rebuilt before they are shot.

RWS Diana 34 (any of them, but the 34P makes the most sense to me. This is your do-everything air rifle. Just buy it and shoot it. Forget maintenance because it seldom needs it.

Air Venturi Bronco. I designed it for guys like you. Just load and shoot 25,000 times before worrying about maintenance. Don’t change anything, just load and shoot.

IZH 60 or 61. Same thing, except the mainspring will bend in 10K shots. And these are sidelevers.

Want other side- or underlevers? Watch Thursday’s blog.

And welcome to the blog!

B.B.

jmdavis,

I overlooked your $100 criterion. For that kind of money I think used may be the best way to go.

Getting top quality for $100 is difficult, but if you can relax your power requirements and just get a rifle that will be fun to shoot, I go back to the Bronco.

Pyramyd AIR has used Broncos in stock right now for $107.

B.B.

jmdavis,

You got some good advice here.

http://www.network54.com/Forum/79537/thread/1300233050/Bought+a+Bronco+Rifle+%24106.99+Shipped+%40+PA

Only my personal experience.

Bought a Slavia 630, new about 4 years ago. Price about $180…not cheap, not expensive. Never opened up, though I do put a drop of chamber oil down the transfer port every 500 or so shots. By my estimation has 5000+ rounds through it and it shoots like a charm.

Also have 4 chinese guns (though 3 are the same…the AK looking BAM). All have about 2000+ shots and are running perfectly.

I agree with those who say that too many people just feel that gun can’t shoot properly without a teardown.

Methinks they just like to tinker.

jmdavis984,

Welcome! Glad you stepped into the light.

You’ve already got a lot of great advice about guns. For your price range and your stated use I’d like to offer my two cents on powerplants:

CO2-temperature sensitive and costly compared to others. Very little hold sensitivity so they’re accurate.

Multi-Pump (like your 1377 and the benjamin 397 & 392). Cheap to operate, very little to go wrong (minimal moving parts), Very little hold sensitivity so they’re accurate, pumping them between shots gets old fast when all you wanted to really do was plink at cans and targets

Spring gun (break barrel, under lever or side lever/car door). As has been said, better quality = lower maintenance and greater accuracy typically. Stick to Air Arms, HW (Weihrauch) and Diana (RWS) and you’ll be happier. There is hold sensitivity in a spring gun. How temperamental they are about a hold almost always depends on power (higher power = more refined hold by you) and quality. A “jumpy” mid-powered/high powered springer can be tuned to tame some of the jumpiness. It’s not absolutely necessary but can make the gun more shooter friendly. Don’t be afraid of break barrels. They’re my favorite to use while plinking and shooting paper since they’re easier to load and cock.

kevin

JMD, the problem with everything you mention is your price point. The Crosman Quest will fill all your needs for under $100 – provided you get a good one. If you don’t, you’ve got a PITA on your hands.

But that’s because you’re trying to buy an awful lot for the money… which makes me wonder if you wouldn’t be better off buying something used. Airguns might lose 30% of their value as soon as they become 2nd hand, and if you get one from a reputable seller you’re getting one that’s already been “tested”.

Thanks for all the replies. It looks like, at least for springers, I’ll need to increase my budget to get something that fits the bill, or go used. That is a little disappointing, since it is pretty easy to get quality CO2 and pump guns for under $100. I’ve already got the QB78D (TF78 Deluxe), Crosman 2240, Daisy 22SG, and Beeman P17 on my “to purchase” list. And, as is the case with motorcycles, by the time I am ready to buy, something new and exciting will be out for me to lust after. As soon as someone finds an SSP that gets 800 fps in .22 and costs $150, let me know.

jmdavis984,

I don’t know what you mean by SSP, but the Titan GP from Crosman shoots a .22 at close to 800 fps, and costs around $150. Mine is very accurate and shoots with good authority. Also, I’ve tried 3 different scopes on it, and had absolutely no problem with barrel droop. I have had problems with one or two other rifles, but a thin strip of magnetic tape in the scope rings worked perfectly to fix the problem. I’m very happy with my Crosman Titan GP.

Victor

Victor,

SSP = Single Stroke Pnuematic

JMDavis,

If there was such an SSP, we would all have one already 😉

Alan in MI

Alan in MI,

Thanks! I’m horrible with acronyms.

Victor

Make no mistake – you CAN get quality spring guns for under $100. The Gamo Delta and Recon ‘spring’ to mind (sorry!). The problem is the power that you want…. that’s where the rub is.

Welcome and you have a whole lot of reading to do here! See all the posts you created already!?

I have bought quite a few cheap rifles over the years, and have not been very happy with the results. That’s why I bought so many…looking for something that was not junk.

Even the more expensive guns usually have a little something that could use a bit of touch up, but there are fewer serious problems.

Tearing down a new gun may not be necessary (any price range) but there can be times that you will catch and fix a serious potental problem before it is going to cost you a lot.

You take your chances and hope for the best, but the odds are more in your favor if you don’t get a cheapo.

twotalon

I started with a used Gamo CFX I bought for $150 at the Roanoke show two years ago. I regularly shoot 10 shot groups at 20 yards you can cover with a dime. There are some nice ones out there for not too much if you look around.

B.B. Would you have Mac get in touch with me? I would like to talk to him about some of his 10 meter rifles.

Ridgerunner,

email me at blogger@pyramydair.com

I need your email address to put Mac in touch with you.

B.B.

Hoping to find an airgun that will humanely dispatch armadillos, one a new husband on a budget can justify to his (so far, still) loving wife. Will a Panther 34, advertised at 800 fps do the job? Do I need to move to a Disco, about 75% more cost for an advertised additional 100 fps? Do I need more than the Disco to humanely take out the bone-encased pests?

Is there a good scope for the anticipated night-time shooting?

All information is welcome,

Jim

B.B. must know a few fellow Texans that wack armadillos on a regular basis. Maybe he has heard what should work.

twotalon

Jim,

Would suggest a flashlight and cheap, but accurate rimfire for the budget minded. An armadillo is a tough customer.

kevin

I’ve never seen a live armadillo in person. Why are they considered such pests that people feel that they have to kill them? Are they like rats? Just asking.

They are diggers. If they decide to forage in your lawn you will have a mess.

twotalon

Prime ingredient on the cover of:

https://www.amazon.com/gp/product/images/1563523566/ref=dp_image_0?ie=UTF8&n=283155&s=books

NOTE: the book is a parody created by professional food photographers, one is not expected to actually eat the “recipes”. (As I recall “Marching Through Georgia” consists of pig noses and chicken feet on a bed of lettuce)

Jim,

You had me thinking of a few rifles to satisfy your requirements until you said Armidillo. Forget it. You’re only going to cause non-humane pain for the critter for under $100.

-Chuck

Jim, buy the very best airgun you can afford. Even if you have to save a bit to do it. You will be much happier in the long run. A .22 will be better for all round pest control. Go for a quality gun or two, not numbers of less expensive ones. Maybe your wife will get interested and shoot them too. I was fortunate in that area. My wife knew I was into guns and hunting when we got married and the chances of me asking permission were…….well……….”0″.

Mike

Jim,

So many people tell me that .22 LR just bounces off a ‘dillo that I’m reluctant to recommend any pellet gun.

B.B.

Time for a .50BMG or a 20mm ? A fully loaded gravel truck appears to work…it imbeds them in the road pretty good.

Seriously…

I hate to say this , but treating your lawn with some nasty pesticides should discourage them. No bugs or grubs = no food. No food = no pests.

twotalon

Jim,

In all seriousness, armadillos aren’t terribly fast critters. You might be better off with a good machete or even a stout stick. This guy used a bucket to catch his: https://www.youtube.com/watch?v=Nqh_e62bt80&feature=related

Much as I was hoping for a legitimate reason to add a Diana 34 or a Disco to my collection-looks like that will have to wait. OTOH, I’m starting to picture moving through the field with a machete & maybe a stout mag-light, practicing a little Filipino stick & knife! That probably won’t come to reality – too likely to turn an ankle in one of the many holes the ‘dillos have left behind. Plus, anti-grub chemicals just seem so much more practical. No fun at all, but more practical.

Thanks to all,

Jim

Jim,

Another welcome to the blog. There are a lot of very knowledgeable folks who post here that are very willing to help with any air gun questions or problems you might have.

Bruce

Jim,

I put $98 worth of gas in my truck today. Welcome to the disease!

caveman

M. Pelletier,

Sorry to bother you with a question with little relevance to this post, but I was wondering if you could offer me some advice on my first purchase. I’m currently debating between the Daisy 747 and IZH 46m for use in a thin-walled apartment, and I was wondering if you could comment on whether the IZH would be too loud for this application.

Also, do you know of any rifles that would be similarly quiet. I recall you mention a few years ago that the IZH 61 is the quietest air rifle out there, how does it compare to these pistols?

Thank you for your help!

Matt,

The 747 is the way to go. The IZH 46 is too loud for thin walls.

The IZH 60 and 61 are indeed quiet, but the 747 is about as quiet.

B.B.

M. Pelletier,

Thank you for your quick reply. I had been hoping that the Izzy would be quiet enough, but I guess I’ll pick up the Daisy instead.

Follow up question: Does the difference in trigger pull warrant paying extra for a 747 over a 717? (I’m not terribly concerned about the barrel). Also, what type of BBs would you recommend for these guns?

Thank you!

Matt,

The 747 is much more accurate than the 717, so only get it if accuracy matters to you.

None of these guns use BBs. They all use lead pellets. The web page where the guns are listed on the Pyramyd AIR web site will have links to the right ammunition.

B.B.