by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- The start

- Owner’s manual a bust

- Here he comes to save the daaaaay!

- Duhh

- Call a real man

- Once upon a time…

- … presto!

- Manuals and aftermarket support

- Analysis of the problem

Most days my blogs come from tests of airguns, ammunition and shooting equipment. They are straightforward and unfold in familiar ways. But ever so often a blog idea jumps up in my lap and licks my face like an excited puppy. That describes today’s report.

The start

It all started about 3 weeks ago when I went to fill my carbon fiber air tank, using my high-pressure Omega Supercharger compressor. I flipped the start switch and the fan came on but not the water pump. The Omega Supercharger is water-cooled and has numerous safety features built in. One of them is the compressor pump will not operate if the water pump is not on. That’s so the compressor pump will always be cooled — a reliability feature.

But now my water pump wasn’t coming on and I had to sort it out. That has happened several times in the past after the compressor has been transported any distance in a car, but I was always able to get it started eventually (meaning in minutes). This time was different.

Owner’s manual a bust

The owner’s manual that came with my compressor isn’t of much use. You basically have to know how to operate the compressor to make sense out of the instructions. And, no, there is no schematic!

I played around with the various safety switches and electrical connections for several days before calling my gun buddy, Otho, for assistance. I thought he might swoop in and fix it with a glance, like he sometimes does with other things that puzzle me.

Meanwhile I took my carbon fiber tank over to AirForce and asked them to fill it with their industrial compressor. It took that wonderful machine only 10 minutes, but the drive over to the plant and back was why I got a compressor of my own.

Here he comes to save the daaaaay!

Last Thursday Otho came by with his multimeter and we took the access panels off both sides of the compressor. I had hoped to find a loose wire that could be attached to an obvious connection, once the insides were exposed. Alas — no luck! Lots of wires, but none that were loose.

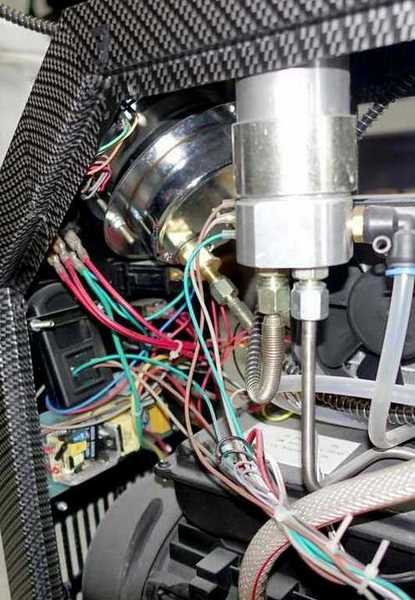

Next, we traced the wires from the front panel, where the names of the switches they are connected to told us their functions. Again no luck. I am going to show you a picture of the back of the panel, so you can see what we saw.

Lots of wires that all have to be checked at both ends! This is not as simple as I hoped.

I pulled on every wire at both ends, hoping to find a loose or broken connection. Again, no luck. Everything is wired well and all the wires seem to be doing their jobs.

Duhh

By this time I had spent a couple hours looking at the compressor and Otho had spent nearly an hour of his time, as well. We decided that the next thing should be a continuity check of every wire in the cabinet — hence the multimeter.

If all of this sounds involved, that’s because it is! Very involved! But how else are you going to do it? How else, indeed!

We put off working on it that day, but knew we’d have to tackle it real soon.

Call a real man

Otho and his wife were over at my house to watch a movie Sunday evening and one of their friends called. He wanted to take them to dinner but when he got to their house they weren’t there. So he came over to my house, and that’s when the lightning bolt struck! Otho’s wife, Marsha, said, “Why don’t you ask Joe to look at the compressor?”

Otho burst into a smile that threatened to separate the top of his head from the bottom. Joe, you see, knows about stuff — stuff Otho and I just putter around with.

Once upon a time…

Actually, war stories don’t begin that way, but this is a family blog and I can’t write the real lead-in for my war story. Other than the intro, though, war stories and fairy tales are exactly the same.

… presto!

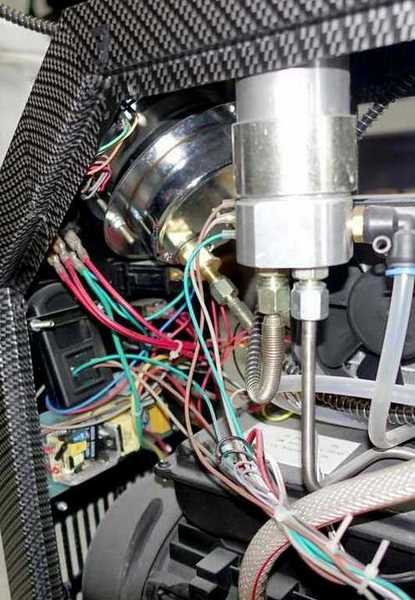

Joe looked at the compressor while I described its operation. Then he looked at the transparent water hoses in the back of the cabinet and noted the large air bubbles above and below what I think he called the water pressure sensor. Then he said, “I think it may be vapor-locked.” Instantly I was transported back to the summer of 1955, standing on the side of the road with my father and mother and sisters, next a hot 1953 Chrysler that had vapor-locked. I knew he was right!

Large air bubbles that were in the two transparent water hoses (were the arrows indicate) were the clue for Joe that the compressor water pump was probably vapor-locked).

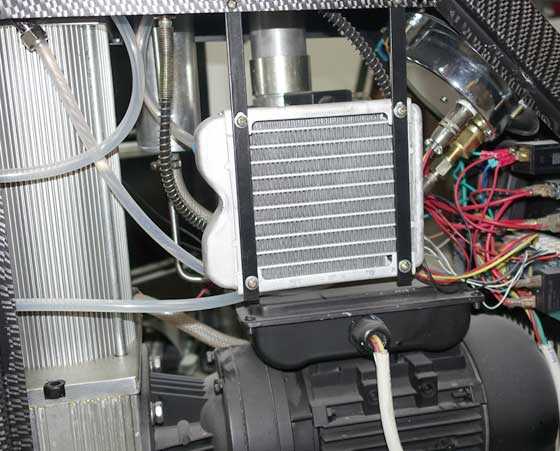

The other side of the compressor cabinet holds the heat exchanger where the fan cools the hot water. More transparent water hoses. Now, I know why they are transparent.

“I can hear the pump trying to run but it has no water to push. I think if we just turn the compressor upside down so these bubbles go back into the holding tank, the compressor will run again.” So he did. And it did. And that’s my little story — almost.

Manuals and aftermarket support

This was not a report about an air compressor. They are all different and each has its unique operating quirks. However, by a strange coincidence, Otho’s wife brought me a manual for a Freedom8, a simpler version of the Freedom F10 Shoebox compressor on this same Sunday evening. After spending time trying to fix my compressor, I was pleasantly surprised by this manual. It seems to be very well written and would be a great help to anyone with a problem like mine.

And here is today’s lesson. Manuals and after-sales support are far more important than people think. Sure, with certain kinds of products you don’t really need them. I mean, who needs a manual for an icecube tray? But when equipment becomes complex, users often need the technical information that should go with it to operate it properly, and to know what to do when it quits. Sometimes calling the manufacturer is impossible and the importer may be difficult to contact. That’s when good information comes into play.

Analysis of the problem

My specific problem (what caused the compressor to quit this time) is I don’t use my compressor often enough. I might fire it up once every 6 weeks, and this time it had been more than 3 months since I last used it. In that time, some water will evaporate. By simply turning on the water pump and running it for 30 seconds every week, I can probably keep all bubbles out of the water lines and avoid ever having this problem again. That’s the kind of stuff that needs to be in the manual.

I RAN INTO THE SAME PROBLEM WITH THE PUMP NOT PUMPING. I THOUGHT ABOUT IT FOR A MINUTE AND STARTED UP MY AIR COMPRESSER, LET IT GET UP TO FULL . TOOK A SMALL DAMP TOWEL, UNSCREWED THE WATER CAP. PUT THE TIP OF THE AIR HOSE IN , WRAPED THE DAMP TOWEL AROUND THE TIP AND PRESSED IT AROUND THE INLET TO KEEP WATER FROM BEING BLOWN OUT OF THE COMPRESSOR. TURNED THE COMPRESSOR ON AND GAVE THE AIR ABOUT 3 -2 SECOND BURSTS OF AIR . I FIGURED THAT THIS WOULD FORCE THE THE WATER DOWN INTO THE TUBES AND REPLACE THE AIR THAT WAS CAUSING THE AIR LOCK. IT DID AND IT ONLY TOOK ABOUT A MINUTE TO GET IT TO PUMPING. NO FUSS, NO MUSS.

The company probably depends on the notion that hardly anybody bothers to read the manual.

Errata on the first sentence of the section Duhh:

“By this time I had spent a couple hours looking at the compressor and Other had spent nearly an hour of his time, as well.” I think you meant, “By this time I had spent a couple hours looking at the compressor and Otho had spent nearly an hour of his time, as well.”

Siraniko,

Fixed. Thanks,

B.B.

B.B.,

See below reply to Alan on the Shoebox. That would be a very good article and show how Shoebox has evolved. With the info, which I am sure Shoebox would provide, you could do an all inclusive 1 shot article.

Even more cool, I bet they would provide the “why we did that”,…. “this mod. improved that”,…” we found that this worked better”,….. etc..

P.A. sells them,.. and has sold them. I bet that it might turn out a sale or two, or?….. just sayin’. 😉

Plus, in a side-sort-of-way, it would fit into the “history” of airguns. After all,…. you gotta’ have that HPA for shooting PCP’s.

Chris

Chris,

I saw that. It might be interesting.

B.B.

B.B.,

Cool !!! I might be guessing wrong, but I am thinking that Shoebox would do most all of your work.

A feature article would be the motivation,…. at least it would be for me. Heck,…. even call it a guest blog.

To me anyways,… it is a little miracle piece of equipment. Simply built, few parts, works perfect. But what even made me suggest it is that they have evolved,….. they keep making the product better, much like airguns,…

To me, understanding how a product works, how it has evolved, the thought process behind the improvements,….. is what builds a loyal customer and generates sales. I think,…. “Hey!,… they really care,… I want one of those!”

Hope to see something if you can work it in,…. Chris

Chris,

If you want to write a guest blog about the shoebox compressor, contact me at

blogger@pyramydair.com

B.B.

B.B.,

Thank you for the offer. I can write pretty well, but can not post pictures or many other things.

Plus,… I would not know all of the details as to how the Shoebox has evolved over the years. I would and will share my experience with the Shoebox anytime that the opportunity arises here on the blog for anyone that is interested in reading them.

Contact them and see what they say. Based on my experience with them,…. you will get all you need to post a top notch article. They answered any technical questions with full detail.

And while not sure, many newer parts swap with older ones. That would be of interest for anyone wishing to do possible upgrades.

Thanks again, Chris

Welcome to my world every day.

And that’s part of why I didn’t reply on yesterday’s blog. We have 3 people in the machine shop that do what I do. And that basically involves whatever comes about in the shop. There’s a guy on days which is on vacation this week. Well he actually wasn’t there last Friday. I’m on second shift and we have a guy on 3rd shift which he starts his week on Sunday night. Well he got hurt Sunday night.

He was taking a index drive off a machine that makes the collets that hold the part table to the next machining station or tool spindle. Yep it’s heavy maybe 20 pounds and you have to lay under the machine to take it off. And it’s about 3 feet up on the air above your head. And only enough room to get one arm up there to loosen bolts. Yep down and N his forehead and nose it came. He ended up with a cut on the forehead with 10 stitches a broken nose and 5 stiches and a concussion. So he’s out all week and I’m taking care of the whole shop this week.

But back to what happen. Guess what. No manual on the proper way to take that part off the machine to rebiuld it. And another problem the guy that got hurt has only been doing this stuff for about 6 years. He never done that job before. And he left out one important thing. Common sense.

I done that job many times and what I do is tie a nylon rope around the part that’s coming off and tie the other part of the string to something up on the top side. And here’s the most important part. I have somebody holding the rope tight up above. Once I get it loose and its ready to drop they have it secured and safley lower it to the ground.

And believe me I got many more crazy stories. I won’t even tell you about what the guy on days did to his multi meter when he was checking volts on a 3 phase motor contactor.

But yep know what all that trouble shooting is all about. And you just can’t believe some of the crazy things that are found. Sometimes my head is spinning it feels like by time to go home. Problem’s, problem’s, problem’s is what my day at work consists of. So wonder I even feel like tinkering and modding air guns. Well truthfully sometimes I don’t. I’m just glad to get them out on the weekend and shoot and enjoy them. Yes I’m glad I got my fab 4 as I call my airgun favorites I have now all worked out. Yes I’m glad. 🙂

No ma

And I have know idea how (No ma) ended up at the end of my reply.

Maybe somebody up there is try to tell me (No more).

And yes I’m glad I got a good job. But sometimes I just really do feel like No more.

GF1,

Just had a guy get hurt at work too. Very smart in many ways. Cutting a piece of 11 gauge channel and had a band saw still set at 90 degrees, but was cutting it at 45 degrees with a rigged up clamp set up. The saw caught, whipped the piece around and darn near took off the end of his finger above the nail. Blood, stitches, surgery, etc..

2 bolts would have set the fence up solid at 45 degrees. Common sense,….. or lack there of…..

Chris USA

Yep common sense makes a difference. And exsperiance don’t hurt either.

I love this kind of stuff. Every profession, world-wide, I’ve found has this kind of knowledge…somewhere. Usually it’s held by some old guy…, far beyond retirement age, like we’re all ever more rapidly becoming.

Having owned a photography business and a camera store for many years, I can say cameras have a suprisingly close similarity to the technicalities of air-gunning, including the idiosyncratic items themselves but especially the even more idiosyncratic owners thereof.

—Item: Did you know certain Nikon products automatically reset themselves to fire 3 blank frames every time the back was opened and closed? Or certain Zeiss twin lens reflexes wouldn’t fire with the folding viewfinder closed?

Or poking a finger through a shutter while trying a speed load is not necessarily fatal (to the camera anyway. If your subject is an oncoming velociraptor all warranties are null & void.)

I never charged for my kindly ministrations and “repairs” for such things, but I rarely divulged my back-room thumping either. As they say, it’s not so much a general thump but rather where and how much to thump it. Got a few free lunches out of it too.

Item: My 1955 Pontiac somehow needed a new windshield, ca 1967. Three trips to the junkyard with three unblemished 1955 Pontiac windshields resulted in three broken windshields…the damn things wouldn’t fit.

I belatedly consult with my Grandfather, a lifetime GM mechanic, and he looks at the Pontiac, contemplates for a moment and sez, “You know, yours was a special model hardtop, slightly lower and supposedly sleeker. Your windshield is one inch shorter than the standard one.” Grandpa is not referring to an open parts catalogue as he speaks. “But, he continues, one from a 1956 Chevy should go in slicker than owl-poop on a door knob.”

And it did.

Many years later, I found myself auditing a course in butchering bison…

Believe me, you really can’t make this stuff up, but nonetheless a story for another day.

Anyway, and not that I have much call for such things normally, I was discussing things with the Native American instructor. “Well,” he said, “I’ll confess I read this in a Playboy cartoon a while back but it seemed to fit the situation. Words to the effect of, ‘that’s the trouble with life on the prairie, you retire and end up giving a course to the kids on Buffalo Poop.”

But I’m really glad somebody knows this stuff.

When you started describing the problem with the pump not running, my first thought was is the water level low?

I don’t know why, but it’s the first thing that popped into my head.

Some times, it is the simplest things.

I would not have thought to turn the pump upside down to get the fluid moving, (some types of complex machinery don’t take to that well)

I would have just tried adding more water after opening the cooling system.

45Bravo,

Though I didn’t mention that in the report, I had already done that. But where you add the water is just an accumulator tank. If the bubbles are in the line they need to come up to that tank, where they lower the water level a little, which is what happened.

B.B.

Good article, good lessons and good comments thus far. I can only speak for the Shoebox company as I recently bought one. Good manual, far simpler in operation and build and even came with 6 re-build kits, which according to the manual are needed around 75-100 hrs. I only have about 8 hrs. run time at this point. No hour meter, so I just keep a little log of run times, with start and end fill pressures and time to reach fill. By this, I should be able to tell when it is taking significantly longer to get from point A to point B.

As for people and support, it seems that I have a 8/10 combo. I noticed no coils and made contact via e-mail. Very nice people, they happened to be on vacation at the time, but contact was maintained. In the end, the only thing mine lacked was a bigger pulley and a longer belt of the 10. They sent me a set for free. Their site has good videos and info. that will answer any questions that you may have too. Arizona, USA.

At any rate, that is my 2 cents for the day.

Can’t say enough good things about the Shoebox and the support provided by the company. The manual is indeed well written, but they go way beyond that. They also provide the following:

– Exploded parts diagrams of their compressors

– Trouble shooting flow charts

– YouTube videos of all maintenance and upgrade procedures

– Their own forum for asking questions and sharing information

– Rapid e-mail response to any questions, with very useful information

– Online ordering of virtually any replacement part you could ever need

In addition, Tom Kaye actively monitors the Yellow forum and is quick to answer questions there too.

I have a Shoebox Max that I have had for a bit over 2 years. I too keep a log like Chris does, and it has right about 85 hours on it with no loss in performance yet – I get about 6.6 cubic feet per hour out of mine the way Irun it (cooled inlet air at 95 psi, cover off with high flow cooling fans, and a few other things). When I do get around to needing to do that first o-ring change, I will be adding the silicone oil lube upgrade kit and an hour meter, and may try to add an electronic pressure switch too.

Through the whole experience, the Shoebox has been one of the most satisfying purchases I have ever made – and the after sales part has been a big part of that, even though I have had no problems at all. Peace of mind is a great thing . . . .

Alan

Alan,

I asked,… and learned a few things while talking to Shoebox. On there latest model, there is no venting in the removable cover. The fan blows air in and the motor sucks it out. They say this does a better job of cooling,……just an FYI. I will say, they seem to do very well at improving an already great product.

It would be interesting to see an evolution scale and what was done at each new phase.

BB,

My father-in-law has a set of problem solving rules. My wife writes an occasional blog (https://lordhastetheday.wordpress.com/2016/06/19/fathers-day-2016/) and she wrote about her dad’s problem solving rules for Father’s Day. I am copying what she wrote here:

Rule No. 1: There’s nothing wrong.

This rule has you examine your perspective and assumptions. Whatever it is, it’s doing exactly what it’s supposed to… you’re just looking at it wrong.

Rule No. 2: It’s the very simplest thing possible.

It’s not plugged in. It’s not turned on. Move your mouse, or replace the battery in your mouse. The light bulb is burned out. It’s out of gas. Blow the dust off of it. You didn’t push it all the way in.

Rule No. 3: Try it backwards.

Turn it around. Screw it the other direction. Flip it over. Then go back to Rules 1 and 2.

Rule No. 4: What was the last thing you did?

Undo it. Then go back to Rules 1 through 3.

This set of simple rules will solve a lot of problems. Having a set of rules or procedures to follow may also keep you from panicking and instead focus you.

David Enoch

Excellent set of rules/advice!

I would have probably messed up. If I would have noticed the bubbles, I would have take off the connectors at the top of each tube and tried to “burp” it. Then if that didn’t work, I would have tried to carefully tried to add all the water I could to each tube (from the top of the disconnected hose). I just hope I would have seen the bubbles before getting upset and using a bigger hammer (kidding…..sort of)

Doc

B.B.,

When I was a teenager my dad bought a low-mileage used ’71 Pontiac Bonneville. It had a 455 under the hood, and as “cool” as the car was, it was HOT enough to light a cigarette on the hood in the summer. It was so prone to vapor lock that my dad had extra keys made so he could park it, lock it, and leave it running until our shopping was done.

Despite the Ooooh! factor of that car, my dad called it his Great White Whale (white with white vinyl top).

Michael

Being an old car, gearhead guy in my younger days, I found that the non-stock solution to antique car vapor lock is to install an electric fuel pump as close to the gas tank as possible. This also helped when you stored your vehicle over the winter as the fuel evaporated out of the carburetor and you had to almost run the battery down to get the mechanical fuel pump to fill the gasoline lines.

If I may suggest a Rule No. 5 to DavidEnoch’s post: If it ain’t broke, don’t fix it!

Bob,

Oh, yes! I remember getting a number of junkers running again with an electric fuel pump!

B.B.

B.B.

I’ve had some similar situations working with laboratory instrumentation consisting of multiple modules each of which has its own power cord and switch. In those situations I discovered I couldn’t get the instrumentation to work simply because one of the modules was not turned on.

KISS for me. Why are things so complicated?

No side levers, no under levers, no PCP’s; just plain break barrels.

Everytime I shoot my friend’s Mrod, after the third or four shot, the cocking lever get stuck.

Everytime I shoot another friends AR-15, a bullet in the clip jams.

Just break barrels for me….

-Y

Yogi

I think your freinds Mrod needs some help.

Single shot tray or a magazine? Bolt not opening or bolt not closing?

I have had about 7 Mrods throughout out time and never had that problem. Not to say it can’t happen. Just wondered if anybody has looked at it.

GF1-

Mrod with magazine. He bought it used. When he shoots it it jams every 10-20 shots, when I shoot it it jams every 3-5 shots. Thank heaven for break barrels!

-Y

Yogi

Well there’s the answer. Maybe two more people should try to shoot it and by time the last person shoots it won’t jam no more. 😉

Yogi,

There is next to nothing to “jam” as you put it. If the spring on the mag is weak, then the mag may not rotate fully and you are trying to jam the pellet (between) the pellet chambers. There is a video on you-tube that shows how to up the spring tension. It looks quite easy and may be the fix for your buddy’s gun.

Plus, you can remove the mag and dry fire the gun, (with the bolt closed). If you do that (cock fully and close and fire), 20 times, the problem is in the mag.. In the .25, I have used 33.95’s which are quite long and have no issues. Something pointed though, or some other odd pellet may be too long and jamming things up.

Don’t know,… that is all I got for you. Chris

ChrisUSA-

The problem is pulling the bolt back…..

Glad it is not my gun.

-Y

I’m a great believe (to the tune of thousands of $$) in Amazon.

But I don’t buy anything complicated online. Whether it be a firearm/airgun/anything mechanical I purchase from a local bricks and mortar store…and not the big box ones.

Face it…I’m pretty sure I know how to turn the page of a book…or load a DVD (where Amazon comes in), but anything that can break down is a whole different matter.

Last summer my boys got into RC truck racing. They had saved up all their money to buy a couple of trucks ($400each) that they could have saved about $100 total buying online.

I made them buy at a local hobby shop.

About 2 months later one of the trucks decided to stop turning, and you could hear a grinding noise coming from the frame. Off to the hobby shop and within minutes the clerk had the steering box out of the truck and apart and showed us how the nylon gears had shredded. Showed us the metal replacement gears we could purchase (did it in both trucks) and 1/2 hour later we were up and running with better than new parts.

If we had purchased online we would have lost the truck for probably 2 months while in went in under warranty and would have ended up with the same nylon gears.

Getting licked in the face by a puppy is better than getting mocked and then slapped in the face by the bluebird of happiness which is a favorite line of mine from the blog. Ha ha. But I can’t say that this story is exactly encouraging about getting into pcps.

I’m a great believer in manuals even if they are often poorly written. How else would you know that the sight adjustments for a Ruger pistol are exactly opposite to those from a Smith and Wesson?

Matt61

Matt61,

They are nice,…. real nice. I have only one, the M-rod, but can only imagine what the “finer” ones shoot like.

I guess the best way I can say it is,…. if you have springers, and you have to worry about hold, rest, position and this and that,….. it all goes away with a PCP. Yea, there is a thing or two to learn,… but you seem to have no issue in that category. 😉

If the ol’ saying that it is 20% gun/ 80% shooter, that will flip with a PCP.

Deciding on what, and how much, support equipment is the biggest hurdle, at least it was for me. Plus the associated coin to be spent. Get past all that, and it is smooth sailing and better,.. and further shooting.

Feel free to ask if ever deciding to go there,….. just went there,….. Chris

Off topic again. Lol. Anyway I know there are bunches of scopes I’ve a nice UTG 4x16x44 30mm. What wish to know on a Air force Talon SS what would be something not so powerful yet nice to plink and up close bug busting… yes know bout bug busters just wanna get all of ya professional opinions :). Would be backyarding or hallway shooting I’ve not 33 ft for a decent but what have is ok.

Thanks for the input.

Rock

Rock,

I do not think you mentioned you had PCP’s,….. do you? Looking at getting one? I am pretty sure the Talon SS is for “reaching out there”,…. so to speak. There are other (gun) options that may be better for closer up, if that is what you are limited to most of the time.

Can get long distance setups of 100yards plus in sis yard. But yea had Marauder but talon really screams at me so gotta have it. Just wanted a scope option for close. Bug busters are kool but eye relief don’t think work so great on talon w/buster. Have range scope already and 3x9x 40 too just asking to see if have options others know of.

Rock,

Cool,…. at least you can “go long” if you want to. My first scope was a UTG, side AO, 4x12x44 and worked very well at 41′ indoors. I shot it ALOT,.. since the first gun I got was in Winter. I am sure there is other things out there that might be better. For the buck,… the UTG’s are a very good value in my opinion.

Do you hand pump for PCP’s or do you have an auto pump,.. such as a Shoebox or something?

Have scuba setup and gonna grab Airforce pump when can. But first the scuba hookup for talon…. have tank and Marauder hookup. Be posting on airgun classified as no longer have Marauder.

Not in da money so to speak so gotta go slow as the money flows. And it keeps getting dammed up in bills go figure. 🙂

Rock,

Been there,.. done that,…. heck,… still there. Do what you can. Wishing you the best in getting it all together. I recently got a M-rod, so still learning. Very happy with going PCP though.

Yea love my Marauder but after reading about Talon. Returns to Crosman gonna cover my Talon just not the extras will need. As in fill station n pump for outings.

Think ya gonna enjoy ya Marauder. If Tom wasn’t such a good cheer leader for all these awesome guns I may never gotten into it. All his blogs and comments from everyone sparked me just wish I was 21 n not 51 lmao

Good luck to ya and everyone.

I have that very scope on my Anschutz 1907, and I couldn’t ask for more.

Matt61

Yea on my Marauder it was very kool but fuzzy under the 33ft and my eyes not cooperate lmao is also kinda why wanting a close up option besides open sites.

Punchin Holes, no need for me to blueprint an AK action. It’s already been done. There are plenty of online reports about American-made AKs by IO and Century Arms getting close to 1 MOA. They do even better than the Arsenal guns from Bulgaria which are supposed to be the gold standard. This is historically consistent since Americans have taken European designs and made them more accurate. This was the case with the conversion of the Mauser 98 into the Springfield 03, and it appears to have happened with the AK. According to one book I read, this is part of America’s tradition of marksmanship.

Evaluating a gun depends on the criteria for evaluation. If one believes in the assault rifle paradigm of rapid-aimed fire within 300 yards, it’s hard to beat an AK. The question is whether that paradigm still holds. With the advances in optics, I’m not sure that it does, and one might want combat accuracy that goes further.

Matt61

Matt61– According to captain Crosman (the book of the Springfield ( 1933 ) , most of the credit for the 1903,s accuracy goes to thew ammunition.

Matt61– Captain Crosman, in his

1932 book–” the Book of the Springfield” credits the accuracy of the 1903 to the ammunition. Right on page one, he wrote–“The Springfield has received a great deal of credit as the worlds most accurate arm, which should have gone to the wonderful ammunition made for it.” He further wrote-” any time the Mauser works can be persuaded to use the small tolerances found in National Match arms and to use American match ammunition, then the results almost equal to those obtained with the Springfield will be obtained.” In Crosmans opinion (and mine too), the changes made to the 1903 made it inferior to the Mauser 98, as a battle rifle. Ed

As an aircraft troubleshooter for over 40 years I’ve learned a few things. Most problems are either mechanical, electrical or hydraulic (fluid), sometimes combined. Mechanical problems are usually visible or audible. Electrical problems are usually open circuits or shorts and Hydraulic problems are usually leaks ( internal or external ) or air in the system.

A pro can trouble shoot something ‘On paper’ and simply approach the problem to ‘verify it’ with appropriate test equipment.

Good operating / maintenance manuals with charts and diagrams are an absolute must. You must ‘know how it all works’ and where the parts are located to fix it. Without them, or some experience, you are just hunting in the dark. Experience, and an analytical mind go a long way.

Once you know how it works and the sequence of events that must take place for it to operate troubleshooting is a lot easier. It’s just a process of elimination. Which part would cause the problem if it did not work properly.

Most companies don’t want you tinkering with their products and want you to return it to them for repairs. Especially those “Little Black Boxes” on aircraft, so they don’t provide much info on fixing them. Things with circuit boards usually require test equipment.

The saying goes “When all else fails … RTFB ! ” ( Read The ‘Fine’ Book ) or something close to that and a ‘little’ knowledge can be a dangerous thing.

On the other hand, it sure feels good when you fix something yourself so looking for something ‘Obvious’ can be rewarding. As long as you remember, ” A man’s got to know his limitations “.

Just dawned on me …. RTFB may no longer be appropriate? Perhaps RTFCD or RTFi should be the new Acronym ?

“And here is today’s lesson. Manuals and after-sales support are far more important than people think.”

Roger that, B.B.! As an engineer, I’ve been called on to write manuals for products several times. The problem is, if you are the engineer who designed the product, and you have used it and trouble-shot it a bazillion times, there may be a lot of steps in your head that won’t make it into the manual (but should); sometimes you are better off to have someone else sit down with “your” manual and see if they can perform all the operations.

One time, in Israel, I was working on teaching an antenna class and one of the students told me he was having issues with the antenna test set. I walked over and said, “Oh yeah, here; you just need to do this,” and proceeded to hit a bunch of key commands. He got a bit angry, and pointing to the manual (yes, sadly, the one I had written) said, “What you just did is not in the manual!”

Since we were in Israel, I pointed to the manual and said “Tanakh” (their written Bible, what Christians call our Old Testament) and then to my head and said “Talmud” (their Oral Tradition, which wasn’t written down till about 160 AD); “Sorry; I haven’t gotten it all written down yet.”

Showing an understanding of their culture got me a good laugh, and bought me some time to upgrade the manual; but really, I should have caught that stuff the first time around.

Bottom line: you are so right, B.B., tech manuals are very important! =)