by Tom Gaylord

Writing as B.B. Pelletier

Part 1

Part 2

Part 3

Part 4

Part 5

This report covers:

- The bevel is the key

- How to test for sharpness

- Setting the bevel

- How to move the blade against the stone

- The center sharpens first

- A progression of stones

- Shaving is the best test

- Blade shape and thickness

- Inventing the kydex sharpening guide

- Tie-in to airguns

- Singing blades

- Summary

Today I will tell you how to sharpen a straight razor. In the three months that I have been exploring this subject I have discovered that sharpening straight razors is a lot like learning about airguns. Of course the two have almost nothing in common, but what I’ve learned is there are many people talking about the subject without really knowing what they are talking about — or they have such poor communication skills that what they do know they cannot possibly pass to another person. That’s so like the field of airguns! There are people who can shoot extremely well, but for the life of them they can’t tell anyone else how to do it.

The bevel is the key

In airguns one important thing is how the gun is held. With straight razors it’s how well the bevel is set. I have spent three hours trying to sharpen one razor — all because I didn’t set the bevel right to begin with. I have done this on two separate occasions — each time wearing holes in my fingers from contact with the water stones for such a long period of time! The last time this happened, only two weeks ago, it finally dawned on me what I was doing wrong. I corrected myself and had that razor shaving sharp in 15 minutes. I wasn’t using a stone that was aggressive enough for the blade.

How to test for sharpness

I test every blade for sharpness, both before and after sharpening, by placing the edge against the pad of my thumb. This is a common practice in the community of people who sharpen razor blades. There is a “feel” to a blade that’s sharp enough to shave. The feeling is, if you were to slide the blade any distance, the thumb pad would be cut deeply. I would rate it as similar to a safe-cracker’s fingers working a combination lock or a gunpowder technician handling nitroglycerin. It is a learned feel and I won’t say more than that. Two weeks ago a friend showed me his knife that he said was razor sharp. I felt the blade this way and told him it wasn’t even close.

I’m pressing my thumb hard against a shave-ready blade. If I were to move the thumb one millimeter (0.04-inches) I would be cut deeply! Just by touching the blade this way I am able to evaluate the sharpness to incredible accuracy.

Setting the bevel

If I am starting with a blade that needs complete sharpening, or one that has some damage, like chips out of the edge, I begin setting the bevel with a 220-grit water stone. If the blade I’m sharpening already has an edge that’s just dull, I start with a 1,000-grit stone. And, if the blade is already somewhat sharp — which is far sharper than most knives ever get — I might start with a 4,000-grit stone. Whatever stone I start with, the object is the same. I want an even bevel along the entire edge of the blade on both sides that runs from the point to the heel. That’s the entire length of the blade.

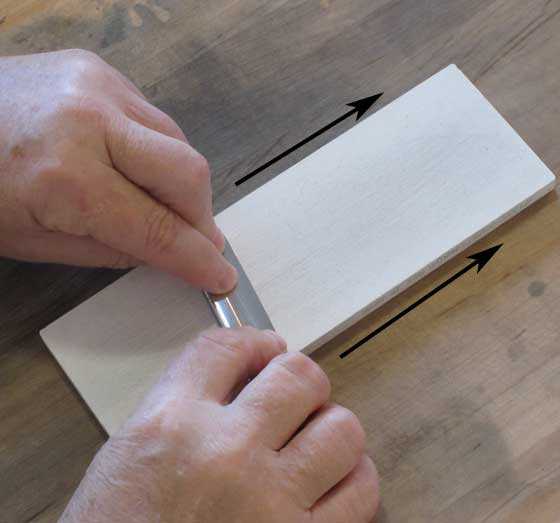

How to move the blade against the stone

This can be done in a variety of different ways. The edge always leads the spine when you sharpen on a stone. You can push the blade away from you, or you can turn it around and pull it toward you. You can also move it in either direction while making small circles on the stone. You can even move the blade in an arc. Just be sure to sharpen each side with the same number of strokes. The object of setting the bevel is to get the edge of the blade to meet in the middle. That is what I was not doing when I spent three hours chasing the edge in the section above.

I push the blade, edge-first, away from me. The edge and spine both touch the water stone. My fingers are pressing on the heel and point, to get them to make contact with the stone for an even bevel.

The center sharpens first

After sharpening about 40 straight razor blades I can tell you that all of them sharpened in the center section of the edge on both sides first. The point and the heel on both sides had to get extra work on every blade I have sharpened. This is done with finger pressure on the part of the blade you want to contact the stone. You don’t need to worry about the center because, once it gets a bevel, it will remain. It might get wider in the center, but that is controlled by the thickness of tape on the spine. You build up tape in the middle of the spine, opposite the place where the bevel is getting wider.

A progression of stones

Once the bevel is set, the razor is run through a progression of stones, starting with the next-finer grit above the bevel-setting stone and moving through 4,000, 8,000, 12,500, and finally 20,000-grit. After that I strop on a cloth belt impregnated with chromium oxide paste that has 0.5-micron particles. No source agrees on how these particles equate to grit sizes. I have seen everything from 30,000-grit to 61,000-grit. Let’s just call it very fine.

As I move to each finer stone I use fewer strokes. Setting the bevel will take hundreds of strokes. The next-higher grit will take about 60 strokes per side and above that about 30 strokes/side. The final stone might get only 15 strokes a side. Also I will stop putting any pressure on the blade after 4,000 grit. This is a judgement thing. I don’t want to give any exact numbers, but as the stones get finer the strokes per stone get fewer and the pressure on the blade lightens up.

The razor starts getting shaving sharp with the 8,000-grit stone. It will shave at that point, but will pull some hairs, too. At 12,500 the hair-pulling stops. So why do I go to 20,000? Because someone recommended that I do. Does it make the blade any sharper? Undoubtedly. Is that extra sharpness worth it? Probably not. Will I still do it? Without a doubt. Got to make that pricy stone worth the expense.

Shaving is the best test

There are several ways of testing a razor. I talked about the thumb test already and there are several different tests involving the cutting of hairs. But the best test is shaving. That’s why we sharpen the razor in the first place. The thing about shaving is every man’s beard type and skin type is different. So the best test we have is also quite subjective. But shaving with straight razors for three months has taught me some fundamental things.

Blade shape and thickness

The first straight razor I ever shaved with entirely was one made by George Wostenholm, a Sheffield maker, in about 1840-50. It has a thick blade that cuts whiskers with almost no feel. At first I thought it wasn’t cutting, but when I felt my face I was surprised to feel the whiskers gone.

It was a reader who put me onto heavy Sheffield blades from the middle of the 19th century and they share similar characteristics. They all have thicker blades and many have the round points that I now realize are for comfort. I love these kind of blades so much that I designed a blade and commissioned a maker to make it for me. I could not afford the Sheffield blades that are one inch tall (that’s sixteen 16ths in razor talk), because they sell starting on ebay at $600 and go quickly up over one thousand dollars when they are in good condition. So, I had a knife-maker friend make me one, instead. I got what I wanted and it opened a whole new profitable business for him! When a local barber saw my blade he ordered two like it to give as gifts.

These heavy English blades are smooth and make it much harder to cut yourself. Think of this kind of razor as the training wheels of straight razors. They are the exact opposite of the modern deeply hollow ground blades.

The top razor was made to my design specifications. I bought it, and the maker made the bottom one as a gift for showing him how to make straight razors. The top one shaves like a dream! The bottom one has yet to be tested.

Inventing the kydex sharpening guide

In the process of making my razor, I also taught him how to sharpen razors, which he has to know if he’s going to start selling custom blades. I showed him how to tape the spine to protect it during sharpening, but then I got an idea. What if he made a guide out of kydex for the spine of each blade he makes? He makes knife sheaths out of the stuff, so he knows how to work it and he has plenty of it on hand. I have since sharpened five more of his blades — all with kydex guards, and they work perfectly.

The kydex guide slips over the razor’s spine and aligns the same every time. Each blade must have a guard made custom for the best fit.

Tie-in to airguns

If it hadn’t been for all the writing I do about airguns, I never would have thought of the kydex blade guide. It’s the same sort of thing as buttoning pistons for smoother operation.

Singing blades

One of our readers put me onto “singing” blades. These are blades that are so thin that when you pluck them like a guitar string, they ring like tiny bells. When you strop one it sings on the strop, as well. Once I discovered what they were I found two among the blades I own. Here is why that is important. The singing blade gives the closest, smoothest, most controlled shave of any razor I have tried. But you don’t want to start out learning to shave with one! They will cut you quickly if you don’t know what you are doing. A singing blade is like a Diana 34P. If you know how to shoot it, it’s incredible. If you don’t, it can be horrible. You don’t give a pupil a Stradivarius and you don’t learn to shave with a singing blade.

This JA Henckels is a singing razor.

Summary

I think that’s it for this series. As a reminder, I did this to remind myself of what it feels like to enter a new hobby. That worked very well and gave me loads of fresh ideas for this blog. What I didn’t expect was that I would also enjoy shaving with a straight razor as much as I do.

Great write up, B.B.! This was my favorite line:

“…there are many people talking about the subject without really knowing what they are talking about — or they have such poor communication skills that what they do know they cannot possibly pass to another person.”

Sadly, that applies to just about every subject! There are non-knowledgeable know-it-alls everywhere! =)~

Hear Hear!!

Well said to you both!!

Kevin in CT

Thank you =D

B.B.

Did you carve your turkey with a straight razor?

Hope you had a good one…

-Y

Yogi,

I bet he could of “shaved” some “razor” thin sandwich slices from the leftovers!

Sorry, couldn’t resist.

David H.

B.B.,

Just curious, but with one of the razors that have a longer blade, like the Henckels in the bottom photo, do you ever use the entire length of the blade when shaving or just the end.

Also, is “J.A. Henckles” the correct spelling in the caption for the bottom photo?

David H.

David,

The correct spelling is J.A. Henckels.

Thanks,

B.B.

David,

To answer your other question, I seldom use the heel of the blade. The toe is always in use.

B.B.

B.B.,

Good to hear that you developed a few more ideas for the blog on writing this series.

Siraniko

PS. In the section: Shaving is the best test. 5th sentence, “The thing about shaving is every man’s bread (beard) type ….

In the section: Summary. Last sentence, “What I didn’t expect was that I would also enjoy saving (shaving) with ….

Siraniko,

Got ’em. Thanks!

B.B.

B.B.,

You are now skaving instead of shaving?

I attribute this to the Thanksgiving food taking all the blood from the brain and your eyesight.

Siraniko

Siraniko,

Skaving? Yes, well, that is a very technical term. I guess I shouldn’t have used it without an explanation. 😉

Thanks again,

B.B.

B.B.,

Another fine article in the series. I like the hand made ones,.. yours and the gift. I noticed both shields are different. Q: Is one yours and the other the knife makers?

Q: Also, are the tangs stamped or signed? I see something, but can not tell if it is deliberate markings.

I like the file work on the spines and tangs. It looks good, somewhat rustic and I suppose it has some functionality that aids with grip.

Q: Finally, does the knife maker have a web site? If so, perhaps you could provide a link to that.

Good Day to you and to all,…. Chris

Chris,

His name is Michael (Tank) Fisher. Here is his website:

http://tbarkcustomknives.com

All the tangs are signed. The filework does help with the grip By “shields” I assume you refer to the inlet6 escutcheons in the handles. Yes they are different. Tank hand-makes each one when he makes the scales. All the tangs are signed.

B.B.

B.B.,

Thank you. Saved the site to favorites to check out later. I was not sure about using “shield”, but I was in a bit of the morning rush. I do believe that is a common term for them, though maybe not the proper one..

Chris

BB—-Those kydex guides are just like the steel guides that histologists used when sharpening microtome blades in the past. The last time that I was in a histology lab was in 1961. The pre-sharpened disposible microtome blades have probably replaced the hand sharpened ones in modern labs.——–Ed

Ed,

Well, there is nothing new under the sun, is there? 😉

B.B.

BB

Nice summary worth filing away for anyone wanting someday to try shaving with straight razors.

I may have missed it but how do you keep tape from embedding in stone grit? If it does it has to be removed one would think. Oh, and the only reason singing blades are more dangerous is playing the music?

Decksniper

Decksniper,

The tape doesn’t embed in the stones. The black plastic backing does come off the tape, but it can be rinsed away easily with a squirt of water.

B.B.

B.B., you thought this was the end of the series, but we’ll see about that. We may have just taken our first step into a larger universe. I take it that your sharpening test involves sliding your thumb along the blade and not at right angles. I don’t know if I’ve ever sharpened a blade that would qualify for this test. My latest blades would have you racing to see how fast you can run your thumb down their length with no discomfort.

Also, I see that the advice to lead with the edge runs diametrically opposite to what I learned which is to always have the edge trailing. This, too, is no surprise as I’ve learned that in any field of expertise you will have top authorities making completely opposite claims. Jack Dempsey says that your punch must land on the last three knuckles of your fist. Karate masters who break bricks and boards say that you must absolutely use the first two knuckles. And a Russian commando who laid me out with a punch like a surgeon said that you hit with all the knuckles!??? The student must just get used to these competing viewpoints.

As for myself, my own knife-sharpening has taken a modest step forward. For the longest time, I was dressing my sharpening stone to eliminate a final pencil mark about a centimeter long that simply would not disappear no matter what I did. After what must have been a total of three hours of rubbing, I finally inspected the surface of the stone, and reflection of from the layer of water showed that a small, triangular region of the stone, right around the pencil mark, seems to slope away from the rest of the surface. I would take months to bring the rest of the stone down to that level. Discovering this is my modest step and just in time. My boss popped up while I was reading today’s post and asked if I would be interested in sharpening her knives. Yeow! Now my comfortable career may be riding on my sharpening skills.

Also on the subject of knife-sharpening, much attention is given to the correct angle that will produce the sharpest blade. But I seem to recall that there is an inverse relation between sharpness and durability. The sharper your knife, the faster it will go dull. Is that true? If so, that is a problem since you want both qualities. Even at the height of my knife-sharpening, my Mom complained that my edges would not last long. It would seem to be possible to combine the two. The ultimate test of the knife-makers guild which I once mentioned includes chopping through a 2X4 and then using that same knife to slice paper and tomatoes. Nevertheless, I continue to think there must be a tension between the two qualities for anything short of this grandmaster level. Could it be that a larger sharpening angle allows the edge to last longer? So maybe you can balance the two qualities simply by choosing a compromise sharpening angle. I once played with this notion by inventing a fantasy combat weapon. It would be made of some extremely hard substance like steel, but rather than being smooth like a baseball bat, it would be cut into facets running axially the length of the striking surface. The facets would be joined by bevels that would be so perfect that they would be as sharp as a razor giving you a weapon combining the heft of a club with the sharpness of a sword. True the large angle between facets would prevent the weapon from sinking into the target which is one thing that blades do, but it would do some serious damage on the surface. Needless to say, this never got made and was just a thought experiment about blade design.

ChrisUSA, as you can see, without persistence I would never have survived my many screw-ups. With the boss involved, it is now general quarters on the knife-sharpening. If you were to visit California, you are not likely to find me in my Russian camo, as I use it for concealment. But if you do visit the area, I would be glad to show you the local shooting range. I actually have a long list of shooting vacations I would like to do with blog members. There is, of course, the Texas airgun show. There is a 600 yard former rifle range near our Olympic level shooter and blog reader, Victor. There is the walking blackpowder trail shoot with BG_Farmer in Kentucky. Also, I’ve heard great things about the CMP’s 1000 yard shooting park which has electronic displays so you don’t have to walk to the target to see your results. Has anyone visited there?

Matt61

Matt,

Nooooo! I DO NOT slide my thumb along a razor blade to test for sharpness. I might do it with knives, but never with a straight razor. I said in the report that if my thumb moved even by a millimeter I would be cut deeply.

B.B.

I meant to say that you test movement along the direction of the blade, not at right angles. Only with my blades could you move your thumb.

Matt61

Chris U,

You ask for an update when I went to 42 yards (my range limit) shooting my Crosman 1322 with the Maximus barrel. Well here are the results.

I used Falcon 13.42 grain pellets. Oh and I usually lube all my pellets. So far the Falcons have been the best but that was at 25 yards. I may try some others at 42 yards.

For the first group of ten shots using 11 pumps I got a 1.06 – inch c2c group. I was zeroed in at 25 yards and used 3 mil-dots at 12 power or about 2 inches of holdover at 42 yards. It was a round and well distributed group. Not bad but I thought it would be better. I think I am pushing the boundary of the power plant to keep the pellet stable at this distance.

For the next group of 10 shots I used 12 pumps to see if a little more power was any better. This group had a c2c of 1.19 inches about the same. There was a surprise though 7 pellets fell in 0.47 inches. I think with more work and consistency on my part I can get the groups a little smaller. With 12 pumps the group also was about 1/4 inch above the 11 pump group.

Below is a picture of the 12 pump groups at 42 yards.

Don

Don,

Very nice. I am surprised. That is very respectful. Yes, the higher fps should help to stabilize things. I never discount sub groups. That is a good indicator that things could get better. Repeated test under the same conditions, over time, will tell the story. Please keep us posted as things progress.

Don,

That is/was one heck of a lot of pumping! Hat’s off to you for all that work. I would think that that alone would have some impact on accuracy,…. tiring of the shooter. 😉

Chris,

That is a lot of pumping but today was only 23 shots with one pellet. Usually I shoot 60 or more shots to test different pellets of different techniques. The 13xx series are very easy to pump especially with the stock instead of the pistol grip. While sitting; I rest the butt on my right leg and hold the stock as close to the breech as I can with my right hand. I pump with my left hand. I started pumping air guns at about 8 years old, there is a rhythm I have developed that seems to reduce the pumping effort.

I think that a key to good consistent pumping is to make sure the pump handle is all the way open at the top of the pump and to pause there for a fraction of a second before starting the compression stroke. I try to carry the momentum from the beginning of the stroke to the more resistant end of the stroke.

Hitting the top of the pump stroke hard puts a lot of strain on the pump pivot pin so I go up easy and then have a short pause to make sure the air flow into the compression chamber has competed filling the chamber. I know you said it’s kind of anal but there are many variables and I try to minimize what I can.

If the pump seal is not air tight you need to really close the compression stroke fast so you don’t loose air.

Don

Don,

I do not recall saying that was anal,… but if so,… ok. I usually reserve using that term to describe me! 😉

Everything you said makes sense. I have only had the 880, but I do like multi pumps because they are so smooth shooting. All that pumping has to be good for the chest, arm and hand muscles too. Maybe we should all have one?,… just on that point alone.

B.B.

For PCP and CO2 rifles do you think bags or a rest is better for bench shooting?

Don

Don,

For PCPs and gas guns definitely a bag. There is zero feedback from a bag. A rest will sometimes have a mind of its own. I always test PCPs with a bag.

B.B.

Don,

A Barber dime? You tryin’ to upstage me? 😉

B.B.

Thanks

I don’t know a Barber dime from any other ones. I found some old coins in my Dads stuff the other day when I found the old straight razors.

I thought it was cool, I don’t think I can upstage you if I tried.

I have been using that dime for quite a while I guess my photos were so bad nobody could see what kind of dime it was.

Dod

Don,

Yep, that’s a Barber. I have found them in the ground while coinshooting (metal detecting) at the University of Maryland, but I don’t have a nice one like yours.

Here is what an uncirculated one looks like

B.B.

B.B.

My Dad was running a dredge in the Santa Ana River in Southern California in the 1930’s he saw some shinny things coming out the chute and stopped the Dredge. He had dredged up a strong box full of coins. He figured it fell off a stage coach while crossing the river. In the 30’s coins from the late 1800’s were not special to him and he spent most of them. They were mostly dimes.

I don’t know if this one came from the strong box or not.

Don

Don,

What a cool story! 🙂

B.B.

Hi Tom

Nice to see someone keeping old arts alive. Apologies for this being off topic.

I’m hoping for a little advice on the purchase of an air gun. I’ve been reading your work here and there for a long enough to have a great appreciation for your expertise.

I’ll throw in some history to add interest. As a child I pined for a pellet gun for a number of years before finally being given one for Christmas at around age 10. Although just an inexpensive off brand springer, it became the thing my life revolved around. It was a rare day I was not out in the bush with it. I had a Collie / Dingo mix dog (yes it was half wild Dingo) that would find me whenever he had located a squirrel, knowing what my pellet gun could do to satisfy his passion for the kill.

For some reason squirrels sent him into a state of fury. He would come to me, his mouth in a lather, panting, mouth sometimes bleeding from biting branches, trying to climb the tree to get at the critter. The scolding chatter from the squirrel enraged him all the more. It was not unusual for him to jump high and catch the squirrel in the air after my shot. We made a good team.

I’m semi-retired now, with some time to renew my interest in airguns. Over the years I’ve collected a half dozen or so inexpensive plinkers, including springers, a Daisy single pump, and Crosmans in CO2 and nitro piston variants, all in the .177 I grew up with. I’d like to step up to something better.

I doubt I will hunt much. I intend to punch paper, and may set up a field target course on my property with the idea of having fun with grandkids.

Obviously airguns have come a long way. I’ve read enough to have some understanding of the newer technologies, and looked at quite a few reviews of various guns. While I likely won’t enter competitions, I’d like to own something accurate enough to be capable of competing in field target. What I crave most is accuracy.

My conclusion so far is that PCP is the right powerplant, preferably regulated. The added expense of filling I will live with. It will have a quality scope as my eyes no longer allow for ease with open sights and I enjoy shooting with a scope.

Of course if money were no object I’d simply order something like what’s being used by the winners in field target competition. But that would be extravagant and I am not. So I’m hoping to find the threshold. Accuracy without spending more than I need to.

The Umarex Gauntlet strikes me as the most affordable regulated PCP entry, and has bonus features. Its a repeater and has a large removable reservoir. Amazing at $300. Reviews show impressive accuracy.

But my budget is not so limited as to forgo a step up. The one I have in mind is the Walther Rotex, for around $650. It is very close in features to the Gauntlet. I believe the German craftsmanship is worth extra, not only for the esthetics, but I would hope, knowing this company is capable of building very high end guns, it would improve odds of winding up with a more reliable gun that can be a treasure passed down to grandkids, and reduced odds of receiving one that does not shoot well.

I did consider the Crosman Maurader but am somewhat enamored with the regulated concept and to buy their custom regulated version I would be spending more than the Rotex. The Rotex seems to me a better, more refined value.

Of course every shooter is different, and even every gun of a certain model will be different so I have no illusions of anyone being able to say “this” is the best choice. Just some feedback on my thought process and any suggestions would be much appreciated.

Idaho,

You have found the right place. I look forwards to hearing more from you in the future. Time is a bit short this AM, but I am sure you will get some good feedback. The Fri. blog is the best because it runs 3 days. I have the .22 Maximus and a. 25 M-rod and love them both. There is much to choose from. Too much. The only advice I can give at the moment is that some of the newest models have not been time tested, at least a few years. Parts availability and modding capability might be other things to consider. That does not mean that they are not good though. I think PCP’s are the best choice as they are just plain easier to shoot well.

Best wishes on getting started on a new adventure,….. Chris

Thanks Chris. I’ve seen a lot of good content from you here. I do like the modding capability of the Crosman offerings. Not so excited when I read about outsourced barrels with accuracy problems, presumably to meet production demands. I suppose one can always purchase replacement barrels.

I may look at their site to see it they offer LW barrels on a Maximus or Marauder.

Idaho,

I have not see nor heard of outsourced barrels on the M-rod or the Maximus. I think that you would be hard pressed to find a bad review on the Maximus barrels. I have heard of some (maybe) issues with the .22 M-rod barrels. Be careful of adding cost. Before you know it, you will have a bunch wrapped up in a modded gun and just could have bought a better one,… just a word of caution for thought.

One added thought,… give some thought to weight. A 10 # + rifle is ok for bench shooting, but a 6.5# scoped rifle is real nice too. Like I have said before,… it is one of those things that you do not appreciate,…until you do.

Again,… best wishes and I look forwards to hearing more from you,….. Chris

Chris,

Might be just speculation but this was in the comments of the “Getting Started” article.

September 12, 2017 at 10:33 pm

GF1,

(first part edited out)

Back to the the Marauder .22 barrels I dont know what is going wrong, some were very good. Too many were not good at all.

Don

Reply

Gunfun1

September 12, 2017 at 6:54 pm

Don

And I got thinking about when we was talking the other night about the Marauder .22 rifle barrel and accuracy.

I think Crosman outsources the .22 barrel. Not 100% positive but pretty sure that’s what I remember.

Reply

B.B. Pelletier

September 12, 2017 at 7:33 pm

Don,

I agree. And in .177 the Marauder is mighty quiet!

B.B.

Idaho,

Yes, I have seen the same comments. Gunfun1 shoots a lot and has had a lot of air guns from low end to high end. The Maximus barrel is made by a different method and I have heard nothing but good things.

I see from your comments that you are considering some higher end stuff too, which I would be inclined to lean towards, however I can offer no real experience with any. The reason I mentioned Gunfun was that he had some higher end stuff that he was not happy with. So maybe run some thoughts by him incase he has had some experience with the brand or maybe even the particular model.

I admire you for doing your homework. I do the same and have never regretted it. I am sure that you will be happy with whatever you end up with.

For my filling. I use a Shoebox 10 and a Guppy tank. If I were to re-buy, The AV pump would probably be it. If you get something that fills to a 3000+ and has a large on-board tank, then the AV pump and a larger tank would be the choice. What I have works fine for me though.

Best wishes and keep us posted as you near a choice on gun and gear.

Idaho,

Well, you have done your research. That tells me you have given your choice a lot of thought.

I have never tested the Rotex, so I can’t tell you anything about it, but I’m sure you have read the comments of those who own them. And you have learned to filter all comments gotten from the internet.

I would say go with your gut on this. You will always wonder if you made the right choice. What not find out? As my wife used to say — “It’s not a life-saving decision.”

B.B.

Thanks Tom. I’m amazed you find time for all the replies. Others have chimed in with info that is interesting and gives me more to research.

The Brocock Compatto unregulated is an entry level English made gun I’m also considering. I got looking at shot strings and noted that unregulated guns can have quite a flat sweet spot to allow for 50 shots or so. Being owned by Daystate I would expect solid design engineering and quality control.

That said every review I see on the Rotek is very good.

Someone pointed out your “Getting Started” article I had not found, and is excellent. I’ll take my time and read more for a while. Things are changing so fast who knows what tomorrow will bring about!

On the scope side, I will likely go with the UTG bubble leveler you referenced. When making use of mil dots I think the bubble will be nice, and I know I will enjoy 16x for targets.

Idaho,

You have selected the right scope. You will love it!

B.B.

Idaho,

I just looked up the Compatto. That is quite nice and priced good too. Looks good, repeater, low in weight. Being a semi-bull pup, I suppose that pistol grips are the norm, but I have also realized that I prefer one for a traditional length rifle, often called a “thumb hole” style stock. That is something that I had forgotten as I have not been in the market for a few.

Still reading. It’s not easy to get the real scoop out of all the marketing, and reviews for reward. I do think the Compatto may be a legit entry level to hgher quality guns. The connection to Daystate I’m doubtful of now, as I think it is limited to a shared owner. They are not produced in the same factory.

And as for the Walther Rotek I believe it belongs in a similar category to the Gamo Urban. A category I will describe as a “parts hybrid”. The trigger is clearly not up to higher end Walther standards, being plastic, and is likely made by Umarex. Other parts may be as well.

Not that this is a bad thing, its just confusing. Its great to have fine barrels, as I believe they are the primary determinant of accuracy, but there’s uncertainty regarding quality and reliability of other parts. What is really becoming clear is that you really do get what you pay for. By that I mean if you want parts built to tolerances that are a step up from mass production, in a well engineered package unlikely to produce anything but great accuracy, be ready to part with a G.

It’s a bit of a hard pill to swallow when that money will buy a fairly high end powder burner, but in actuality when you want the best accuracy in either category it will cost.

The same is true in other technology. There’s a threshold where small increments of improvement require higher cost components and labor that result in a steep price curve.

In addition to the Compatto, I’m now having a look at the Air Arms S510 Xtra FAC. As far as I can tell there are no outsourced parts. Air Arms seems to have a proven pedigree in field target that I would think should enhance long term value. Value retention I believe should be a consolation for those making a higher investment.

Idaho,

I admire your taste for quality. The Compatto looks to be good for off hand and some walk about pesting. I love the 510 line-up and the FAC Xtra looks be the king of the bunch. You seem to have a very good handle on things.

Oddly, I have found the research phase of buying is a lot of fun. Frustrating at times, but fun.

For me, I have to like the looks of something. That is just me. The .25 M-rod would be the exception, but then it got a new RAI stock and 6 position within 1 hr. of opening the box. Length of pull, LOP, is something I have come to appreciate. I added Limb Saver butt pads to the TX, LGU and Maximus. That adds 1″. Slip on/off, hold great and look great. The M-rod has that 6 position plus has the 360 adapter than can set the butt L, R, Up, Down. 6′ 3″, long armed me finds that I prefer 15 1/4″ to 15 3/4″. This was something that I picked up as time went on and refined my shooting.

Best wishes again and keep us posted. No rush. I have done serious research well over a couple of months before.

Hi Chris,

Thanks for following along. It’s nice to have someone with some knowledge to converse with during the research.

Your guns are interesting. It’s tempting to go that route and do a lot of tinkering. But I think you can see where I’m headed. The 510 had me captivated. Until I got looking at shot strings and thinking about regulators. Many owners are very happy with their unregulated high end guns, but it seems to me one should look at this option. Sadly, a regulated 510 is to me a bit silly as it results in the pressure gauge reading regulated pressure, not tank pressure.

Looking at other options lead me to the HW 100. I cannot find a drawback to this gun apart from price, which is comparable to the 510, and in the world of high end guns, its still near that entry point of one G. My search has likely ended.

The final decision is caliber. So I studied airgun ballistics some and learned that .22 offers some advantages. This was helpful:

https://www.youtube.com/watch?v=7IjK26Giaic

In addition, the US version of the HW 100 is tuned too hot in .177 for pellet stability and needs detuning by turning the hammer spring tension down. Not hard but may lead to some disruption of regulation.

Downsides of .22 I can think of are cost (still way cheap compared to powder burners), and a slight disadvantage in field competition (.177 fits through the holes better). I already have a big selection of .177 but I think I’ll order in .22, especially since the pellets that shoot well are well known so I don’t have to experiment a lot.

Any thoughts on caliber?

Also, do you post on any forums with pictures? It would be interesting to see some of your collection.

Idaho,

I do not post on other blogs. Nor do pics. You did well to post on the current blog and hopefully you will get some good feed back this weekend. Vana2 has 1(?), maybe more of the HW100’s.

On tanks, look for one that has 2 gauges on top. That way you have a smaller one to show tank pressure 100% of the time and a larger 2″ one that will be what you watch as you fill. That is better than watching the gun.

As for regulation, I did the reg. on the Maximus and it does show only reg. pressure. I do not know how other stock reg. rifles read. There is options to leave it out entirely.

Caliber?, all mine are .22. They are easier to load than a tiny .177 pellet. They carry more FPE down range too.

See you over on the current blog,…… F/S/S

Hello Idaho,

Another gun to consider is the Gamo Urban. It isn’t regulated in the traditional sense but it has very,very good shot to shot characteristics for an unregulated gun. It also has a BSA barrel and can be had as of Saturday for as little as $220.00. Googling will find that price for you. Don’t think it was a Holiday Sale and I found it in more than one place.

Thanks. That is one I have not seen and will look at it.

From what I can tell this is a BSA Buccaneer, badged as GAMO. It’s downside is a GAMO trigger, but quite a steal to buy an English built gun at that price.

Reviews show good accuracy as would be expected from a BSA powerplant and barrel.

Only in .22 though. $50 BSA mag. Not a complete deal breaker…

Idaho,

I got my Gamo Urban a few days ago and have been wringing it out as best as I can considering poor weather. I’ll be posting the info an the 12/15 blog if you are interested.

I’ll check it out for sure. The BSA barrel should make it a real shooter.

I have a Wolverine on order but will be looking for a second budget friendly PCP.

Idaho,

Not sure if you read this report?

/blog/2017/09/getting-started-with-a-precharged-air-rifle-part-2/

Don

I guess I’m not so good at looking as my searching did not turn up that article. It is excellent so thanks very much. There was nothing on the technical side new to me but a good summary and a lot in the comments to consider. I have made some notes to follow up on.