by Tom Gaylord

Writing as B.B. Pelletier

Sig Air Super Target (photo provided courtesy Sig Sauer).

This report covers:

- Breech seal

- What caused the tear?

- Another sealing tip

- On to the trigger

- Pull weight

- Trigger blade location

- How short can the blade be?

- Adjust stage one

- Adjust stage two

- No overtravel

- Success!

- The breech

- Summary

Part 3 is usually when I test accuracy. Don’t get me wrong — I want to know about this pistol’s accuracy as much as anyone. But there is something I need to do first. Today is adjustment day for the trigger on the SigAir Super Target. I promised that last time and there is a lot we can do to this trigger. Before we begin that, though, I have something to clear up.

Breech seal

When I showed the breech in Part 2 reader Vana2 noticed that the breech seal was torn. I hadn’t seen the tear until he pointed it out. It was very small and located at the top of the breech where it’s not easy to see anyway.

When the picture is enlarged like this the tear looks big, but when it was sitting in the gun I didn’t even see it. That’s a dental pick I used to remove the o-ring.

I doubt the tear had any affect on the velocity test because this seal is under a lot of compression when the breech is closed, but I knew I had to replace it. Ed Schultz from Sig was reading the comments and he emailed me that there is an extra breech seal in the pistol case. Indeed there was! Everybody gets a spare seal with their new gun.

What caused the tear?

I picked the old seal out of its groove with a dental pick and installed the new one in less than a minute. But if I wasn’t testing the gun for you I wouldn’t have changed it. It was sealing just fine. The stability we saw in the velocity test told me that.

Why was the seal torn? Was there a burr? The best tool for finding small burrs is to run your fingers over the areas of concern. I did that and found nothing. In WWII the rivets on the skins of US fighter planes were inspected this way — not officially, but by the workers who discovered their sense of touch was more sensitive than a gauge. My 8th grade English teacher had been a Rosie the Riveter who worked on the production line for fighters, and she told me that story.

So I felt for burrs. All the places the breech seal comes in contact with are as smooth as glass. I think this seal may have just been cut by some other means and was never noticed. I sure didn’t notice it.

Another sealing tip

When an o-ring fails in this way there is something you can do. Take the o-ring out and turn it over, so the side that’s not torn is sealing the gun. Since the tear is so small that will fix it every time, as long as the o-ring is fresh and supple.

On to the trigger

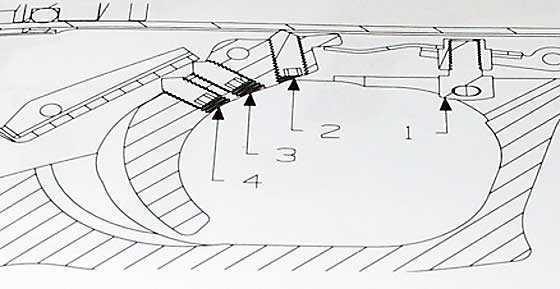

The Super Target trigger has 4 adjustment screws. Screw 1 adjusts the trigger pull weight. Screw 2 positions the trigger blade. Screw 3 adjusts the length of the first stage, which stops at what the manual refers to as the wall. It’s really the beginning of the second stage. Screw 4 adjusts the length of the second stage — an instruction at which BB Pelletier says, “Whaaaaat?” The second stage isn’t supposed to move, in the world I live in. We shall see.

The Super Target trigger has 4 adjustment screws. Screw 1 is for pull weight. Screw 2 positions the trigger blade. Screw 3 is for the length of stage one and screw 4 is for the length of stage 2. Graphic from Super Target manual, courtesy of Sig Sauer.

Pull weight

The manual says to use the 1/8″ Allen wrench that’s included with the gun to adjust screw 1, but on my pistol this screw has a slotted screw head and the graphic shows that, as well. A common flat-bladed screwdriver is the ticket. Be careful, though, because there isn’t a hole through the triggerguard and you have to come in from the side to adjust this one. If you slip you could scratch the frame of the pistol.

I very carefully tested the pull weight before adjusting and this time it came to 1 lb. 15.8 oz. I Part 2 I measured it at 2 pounds, even. I tightened the screw (turned clockwise) one full turn and tested the pull again. This time it averaged 2 lbs. 1.4 oz. over five pulls. Another half turn and it measured 2 lbs. 1.5 oz. average over 5 pulls.

I then went back to the start point and adjusted 1-1/2 turns lighter. The average let-off over 5 pulls was 1 lb. 7.9 oz. I stopped there and left the trigger as adjusted because at this point the second stage let-off is very crisp.

Trigger blade location

This screw and the other two that are in the trigger blade are the 1/8-inch Allen screws. This adjustment moves the trigger closer to your hand or farther away, as seen in the pictures below.

This is as short as the trigger blade can be adjusted.

Here the trigger blade is adjusted out pretty far. This is where I like it.

Adjusting the position of the trigger blade changes the length of the first stage pull. It’s like the wall (beginning of stage 2) stays where it is and as the blade moves farther out, it’s all stage 1.

How short can the blade be?

When I adjusted the blade in close, I got to the point where the pistol could no longer be cocked. I then moved the trigger back out until it did cock. That’s how I know where the closest adjustment point is.

Adjust stage one

Okay, I just lengthened the first stage pull by repositioning the trigger blade. Now with this first stage adjustment screw I can make the first stage as long as I like within the limits of the adjustment. So — can I now adjust all the first stage out and get a single-stage trigger pull after repositioning the blade? Let’s see.

To adjust the first stage shorter turn the 1/8″ Allen screw counter-clockwise, which is out. And the answer is yes, the trigger can be adjusted to a single-stage pull by adjusting all the travel out of the first stage. You are starting at the beginning of the second stage when you start to pull. HOWEVER — when you do this the pull of stage two becomes long. It’s not creepy (starting and stopping intermittently as the trigger is squeezed), but it’s definitely moving. So, can that movement be dialed out with the stage 2 adjustment? According to the instructions it is theoretically possible. Let’s see.

Adjust stage two

To make stage two shorter the adjustment screw is turned counter-clockwise. So that’s what I did.

Wow! Instead of bringing stage 2 all the way to the start of the trigger pull, this adjustment put stage 1 back into the trigger. I eventually reached a point where there was all stage 1 and the gun wouldn’t fire.

No overtravel

There is no overtravel adjustment, so don’t look for one. That said, you probably won’t miss it because this trigger seems to stop all on its own.

They tell you that stages 1 and 2 are interdependent (adjusting one affects where the other one is adjusted) and I have just seen that they are! So now I will adjust both stages 1 and 2 to where I like the trigger to be — a long stage 1 and a crisp stage 2 with no movement. Is this possible?

Success!

Yes, it is possible. We know that because the pistol came to me that way. But this can be a very long and frustrating endeavor because adjusting each of screws 2, 3 and 4 affects the other. My advice is either don’t do it or go very slow, which the manual tells you.

Summary

Why did I devote almost an entire report to adjusting a trigger? I did it because the Super Target trigger is one that can be adjusted so fine. If you give me a bathtub full of champaign don’t get mad when I take a sip!

Accuracy testing comes next. I know I can’t wait to see what this beautiful air pistol can do. So, stay tuned!

BB,

It is indeed a nice piece of eye candy. It sounds as if that trigger is going to make it a top contender for entry level target.

I like seeing more choices for affordable, accurate air pistols. It seems that most air pistols these days are going for the replica shooters. Sproinger pistols are really not as accurate as I prefer and can be a bit much to fiddle with. Of course I do have a couple of nice ones though. 😉

My Izzy has really spoiled me for SSP pistols. A PCP would likely be great, but they are very expensive and of course need support equipment. The Chinese have a couple of CO2 pistols that look promising, but since I live where it gets kinda chilly at times and the wife does not let me shoot inside, CO2 never really caught on with me. The cost of CO2 starts adding up after a bit also.

If one of these happens to stop by RidgeRunner’s Home For Wayward Airguns I am certain it will be invited to stay.

RR,

Not shoot inside? Assuming you have the space,… a 499 is just sublime! The peeps are a blast to use and the thing is crazy accurate. My indoor 499 range is at 24′. 10 shots and 1 single hole—-ish. I can shoot all my guns inside,… even the .25 PCP’s and the .22 at even (5) feet. For the .25’s,… I use a 4×4 “wall” hardwood backer. For the .22,.. an 11 gauge steel plate holds up just fine. All contained in a 1/2″ OSB box. My “long” range is 42′.

What is really nice is that you can chrony indoors in the Winter too. Good for collecting data on a new gun. Good for judging tuning tweaks too. 2 “reasons”. Read on……

But hey,… if “The Boss” says NO!,… then no it is. ((Unless)),… you can come up with (logical “reasoning”) to do so????

Really though,.. the 499 is a real treat to shoot when the snow is falling. 😉

Chris

Chris,

Thanks for bringing up the 499. I may be the only person reading this blog that did not know about the Daisy 499 muzzle loading BB Rifle. It is accurate and looks good.

/product/daisy-match-grade-avanti-champion-499?m=617

/blog/2018/08/ten-meter-accuracy-test-daisy-499-versus-haenel-310/

Don

Chris,

LOL! I am afraid that when the boss says no, that’s it. There will be no excuses or exceptions.

Now if I stood at the front door and shot into the corner of the kitchen, it is almost exactly 10 meters. Ah well.

Hi B.B.,

I ordered my SIG AIR Super Target direct from SIG Sauer, and received it last Friday. If I may, I would like to share a bit of my experience with it.

I know that you generally do not like to compare one gun with another. However, because I own both a SIG Sauer P210 Target (the firearm on which much of the styling of the Super Target is based) as well as a Chiappa-made FAS 6004 (the airgun that shares many of the Super Target’s internals), I think I can offer certain comparisons that may be helpful.

First, I want to note a correction to some misinformation that has appeared in a number of early reports on the new Super Target regarding its basic specs. Upon receiving mine, I weighed it and measured it, and found that the length was just slightly longer than the advertised 10.25 inches. However, the weight was 33.1 ounces—considerably less than the advertised 40 ounces—and almost a quarter pound lighter than the P210 unloaded.

(Also, another blog had noted that the Super Target’s weight was attributable to being made of carbon steel, but this is incorrect. I went over the Super Target with a quality magnet, and found that the frame, and overlever were made of a non-magnetic alloy. Only the barrel, certain parts of the trigger unit, and overlever latch [the “hammer”] are made of steel.)

I can confirm that the Super Target largely mimics the grip angle and general contours of the P210. And while the weight is a bit less, the balance is almost the same. The wrap-around grips of the firearm are checkered, while the two walnut panels of the airgun are smooth; though the feel is still very similar. Of course, the Super Target lacks most of the controls found on the firearm, such as the safety, magazine release, etc. However, the trigger of the Super Target can be adjusted to very closely mimic that of the P210. As received from the factory, the trigger’s length of travel for both the first and second stage was essentially on par with the trigger on the firearm, though the second stage pull weight was slightly less. It can of course be adjusted heavier. I think, therefore, that in these respects, the Super Target is a very suitable trainer for someone seeking to improve their skills with the P210.

(In fact, that was the reason I purchased the Super Target. Although the P210 will digest just about any kind of ammunition, using anything less than the high-end stuff is about like putting regular gasoline into a Ferrari. The problem is that the cost of premium ammo can add up in a hurry. The Super Target is a more cost-effective alternative—and a fun one at that!)

How otherwise does the new Super Target compare to the P210? Well, obviously the shape is somewhat different in order to fit the powerplant inside the airgun. Also, the sights are a bit different. Although the rear sights on both the firearm and the airgun are similar in shape, size, and manner of adjustment, the plain black front sight on the airgun differs from the discrete green fiberoptic front sight on the P210. I do not find this a significant difference, and I prefer the plain black front sight for shooting paper targets anyway. (Also, I should note that the Super Target’s front sight is molded into the frame—a change from the FAS 6004, which has a replaceable front sight.)

The aesthetics of the Super Target live up to that of its inspiration. All the angles are just as smooth and refined as the P210. The matte black finish is excellent, and the frame evidenced very few discrete tool marks. This was a big step up from the FAS 6004, which came from the factory with a dull finish that was uneven, scratched, and prone to wear.

The operation of the Super Target also evidences some improvements over the FAS 6004. The latch to release the overlever on the Super Target is genuinely ambidextrous, and is much more robust than that on the FAS 6004 (which sports a very small and somewhat flimsy stamped metal catch alongside the left side of the gun). In opening the overlever all the way to pump the Super Target, it is easy to appreciate some of the refinements that SIG Sauer brought to the original design. At the end of its arc, the nose of the overlever on the FAS 6004 scrapes against the pump piston. The overlever on the Super Target has a redesigned profile that eliminates this problem.

The performance of my Super Target is very similar to what you have experienced. I chose a lightweight, lead-free pellet, the H&N Green wadcutter (weighing in at 5.25 grains). While I suspect that some of the concerns about lead dust have been overstated, I figure that it is better to be as safe as possible since I am shooting indoors in a house with a young child and pets. With these lightweight pellets, I achieved some remarkable consistency. Discounting the first few shots (when some of the factory grease was still being blown out the barrel), I got a low velocity of 372 fps, and a high of 380 fps—an extreme spread of a mere 8 fps (over a string of 15 shots). The average yields 1.64 fpe. (Just a note: I did oil the pump head and dryfire the Super Target five times before measuring the velocity.)

The sights were close to being on target right out of the box, needing just a little adjustment to get on the bullseye. I am by no means an expert shootist, and I am still experimenting with the best hold, but five-shot groups under an inch at ten meters were manageable. The consistency I see suggests that a more competent marksman (with better eyes than mine) could achieve some really outstanding groups. Needless to say, this is a very accurate airgun! It will be interesting to see what kind of results others can achieve with SIG AIR’s newly-released lead wadcutters.

In conclusion, if you will pardon another comparison, the Super Target is a modern take on a target shooting trainer evidencing the same elegance, refinement, and precision that is shown in the older all-metal-and-wood single stroke pneumatic pistols like the Beeman P2/Weihrauch75. But it does so with the stylishness and recognizable profile of the P210. Given all it has going for it, I believe that the Super Target will, in time, become a true classic in its own right.

Sorry for such an extended post . . . I don’t mean to go overboard. Thanks, B.B., for always having such helpful and informative reviews! I’m really looking forward to your post on accuracy.

Duke,

Welcome to the blog.

Wow — a guest blog on your first post! You’re going to be a great asset here. Thanks for all the insights.

B.B.

Another good looking design! I bet it’s more comfortable than a P1, and more recoil- less than one too..

Why is the frame latch on these guns not a self centering design? On the P1, the barrel latch is a round bar that the the spring loaded release catches. Over time it wears in but it is not self centering, there is some side to side play of the top strap that the barrel is attached to, and I think this is dependent on the bushings of the pivot hinge.

I would say after many thousands of pellets, there is very little to no freeplay on my pistol, which is a compliment!

For top accuracy, a better barrel lock, like on the Walther LGV rifle might be the way to go.

Happy shooting,

Rob

Hi Rob,

I wondered the same thing myself until I examined the internal design of the Super Target. The air port behind the barrel is contained in a trapezoid-shaped metal block that wedges into small cutouts on the inside of the overlever. This design prevents any side-to-side play. The overlever latch (the “hammer”) only needs to apply downward pressure to keep everything perfectly locked together. The lock-up is just as solid as any other air pistol I have used.

I must say on Sig’s behalf, they did put put a centering breech on the ASP20, maybe even a better design

than the barrel lock on the Walther? On the other hand, they welded the shroud on the barrel. How can we check the crown? I would offer this pistol with a spring option, make it a truer firearms trainer, just like the P1.

I have given up hoping for a two power level spring rifle in this lifetime.

Rob

B.B.,

That’s cool that this pistol has so much that can be done to the trigger; I hope it proves to be a tack driver.

I was really impressed to read this:

“My 8th grade English teacher had been a Rosie the Riveter who worked on the production line for fighters…”

Wow, I’ll bet she had some other great stories she could tell. Thank you.

Take care & God bless,

dave

Dave,

I’m sure she did. But I was just a kid and that’s all she ever told us.

B.B.

Exact same trigger as the Chiappa FAS 6004. Chiappa make this for SIG. The 6004 with a sporter grip sells at the same price point.

It does look nice, but it’s a 6004 with different cosmetics and grip dimensions.

Off topic:

On the matter of getting a Grandchild a first bb rifle,…. skip the Red Ryder or anything even similar. Go for a 499. 5 x easier to cock (supposedly? good for a small youth?) and 10 x more accurate then a Red Ryder. Plus,… with the peeps,…. it introduces the concept of using a scope.

That is my 2019 Christmas youth gift recommendation,… for whatever that is worth? 😉

Chris

Chris,

Thanks for bringing up the 499. I may be the only person reading this blog that did not know about the Daisy 499 muzzle loading BB Rifle. It is accurate and looks good.

/product/daisy-match-grade-avanti-champion-499?m=617

/blog/2018/08/ten-meter-accuracy-test-daisy-499-versus-haenel-310/

Don

Don,

It is easy for all of us to overlook the longtime top performers with the “absolute blur” of constant new offerings. I am not sure that there is even one bb rifle out there that will outperform it.

You would never regret getting one.

Chris

Chris

Or open sights. Peeps are cool sights.

GF1,

I would hold open sights in a category of their own. Peeps are much more akin to using a scope. All 3 have their crossover points.

I would say it is most important to get someone up and running and shooting well first,… and then,.. if they want a “real” challenge,… try doing the opens well or as good as peeps or a scope. Only my opinion.

Now B.B.,… being the self confessed “dinosaur” that he claims to be,… will disagree. 😉 I will say,… he does do a pretty good job of staying ahead, (or at least even) with the pack. 🙂

Chris

Chris,

I may be a dinosaur, but perhaps I’m a velociraptor.

B.B.

B.B.,

Perhaps. Much like an Eagle or a Hawk. Stay above and watch the entire scene play out below. All through well experienced eyes. When opportunity presents itself,… you pounce.

Yup,… Velociraptor works for me! 😉

Chris

Chris

My opinion open sights need learned first before the other sights. Like dot sights, peeps, scopes or whatever.

There’s more than just target shooting. By that I mean shooting at one piece of paper hanging on a board. Open sights teach you how to use peep sights or a scope or dot sights. Try it and you’ll see what I mean.