by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- So what?

- The most important thing

- What gives accuracy — the barrel

- What gives accuracy — the trigger

- Safety

- What gives accuracy — the breech lock

- Powerplant

- Sights

- My idea

- Between the lines

This is the start of a series that I think will be quite different. The inspiration comes from the SpaceX company that has now successfully put two astronauts on the International Space Station. SpaceX has significantly reduced the cost to build rockets and launch payloads, making space exploration more affordable. Elon Musk determined that he could buy the materials to build a rocket for just three percent of what the Russians wanted for theirs. That was what put him in business.

So what?

What does any of that have to do with airguns? Everything, I think. Because it illustrates just how much can be accomplished when there is a plan and when the schedule is not artificial but is based on realistic forecasts. This report is not meant to criticize any company or person, but it will also not permit the hardening of attitudes that stifles progress.

We are going to design an ideal airgun. In fact we are going to design a couple of them, and I am starting with the spring-piston powerplant. This will be an air rifle

If we are successful, we will design an air rifle that can be manufactured at low cost and yet have all the things shooters desire. I will start the conversation, but you readers are as much a part of this as I am. So — speak up!

The most important thing

I think the most important thing about an airgun is that it hits what it’s shot at. Power alone is not important because power without accuracy is meaningless. Beauty isn’t of chief importance because, while it might satisfy the taste, if it can’t hit the target it won’t get shot. Ergonomics aren’t that important because it can fit like a glove — if it doesn’t also hit the target it’s not going to be picked up. Price is not the primary importance because if it can’t be relied upon to hit the target, who cares how cheap it is?

Nobody made me full ruler and controller of anything, so if you disagree with me on this point, make your case. I’m not saying that power, beauty ergonomics and price don’t matter; I’m saying they only matter once there is an accurate airgun to apply them to.

What gives accuracy — the barrel

Accuracy is not just the barrel, but it certainly begins there. Crosman has learned that if they first ream the inside of the barrel tube before they rifle it, they get the best results. Sig has learned that the barrel doesn’t have to be choked — as long as the bore size is relatively uniform from breech to muzzle. Add that to what Crosman has learned and we know what must be done to rifle an accurate barrel. AirForce has learned that by cutting a progressive leade into the rifling at the breech, pellets will load straighter and deform less when shot. Add that to what Crosman and Sig have learned and we start to see the beginnings of good barrels.

FX has learned that it is possible to swage in the “rifling” from the outside of the barrel and lower the cost to make a barrel. But, they also know that a barrel rifled this way will be very picky about what pellets it likes. The barrel will be very accurate with a certain pellet within a certain range of initial velocities, but that range must be maintained. Oops! Perhaps we have gone too far.

I could go on and talk about lapping the barrel after rifling. Bartlein laps before rifling and again, after rifling. Their barrels are considered some of the finest in the world. But for our project, I think lapping after rifling is one step too far. It takes a $100 barrel and makes it a $250 barrel rather quickly. If the reaming process is run slow enough and the tools are kept sharp enough to prevent chattering, I think we have gone as far as we need to.

What gives accuracy — the trigger

An accurate air rifle needs a good consistent trigger to realize its maximum potential. But it doesn’t have to be a 50-gram trigger from a 10-meter rifle. I have told you of the benefits of the ball bearing trigger that certain vintage Dianas have. They were great for their day, but that day has passed and those triggers contain far too many parts to be economically acceptable. We also know that Rekord triggers have been superb for nearly 70 years, and the Air Arms version is the highest evolution of that design in production. Ivan Hancock used to make and sell a brass version of the same trigger that was called the Mach II, and that handmade version was perhaps as good as the design ever got.

But we don’t need a trigger that good in our ideal air rifle. Let’s turn our attention to Sig, instead, and look at their Matchlite trigger that’s in the ASP20 breakbarrel rifle.

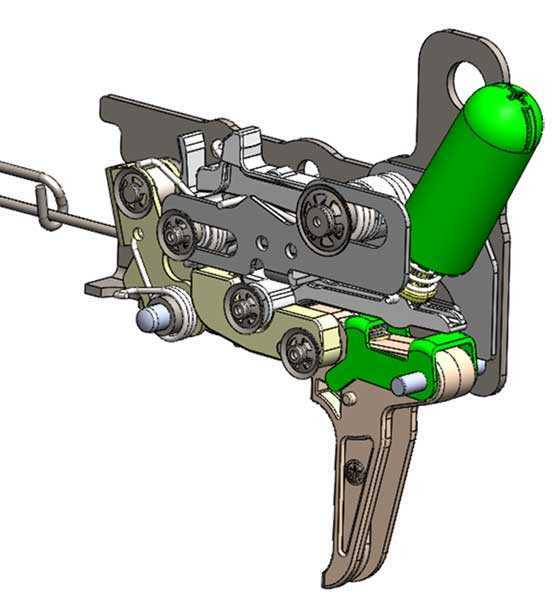

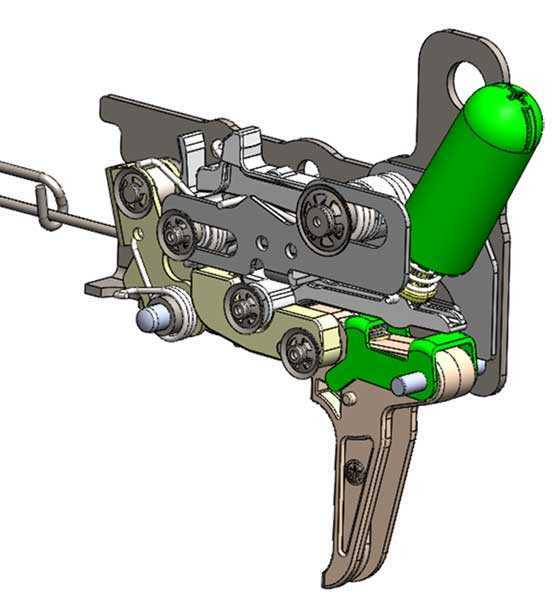

Sig Matchlite trigger. Graphic provided by Sig.

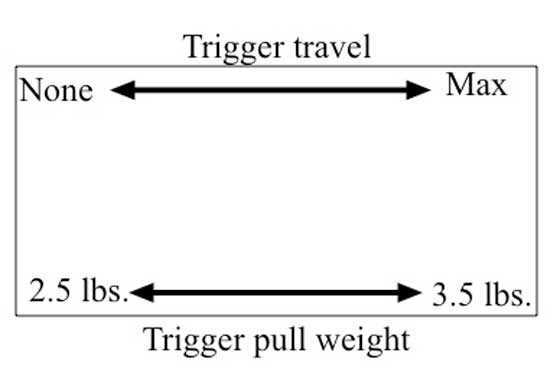

Sig produces an American-designed airgun trigger that’s ideal for our project rifle. Ideal, only we can’t use it unless Sig also builds the rifle. What it demonstrates is that the Rekord is not the only good airgun trigger design. The Matchlite cannot be adjusted as light as the Rekord, but within the box of its performance it’s good enough for the rifle we are building.

The adjustments on Sig’s Matchlite trigger work inside the bounds of safety. You get a light trigger that the lawyers are okay with.

What we need is a trigger with the adjustability of the Matchlite but with simplified design. It needs to have fewer parts and should retain some adjustability. And it should have a positive trigger stop.

Safety

Yes, there should be a safety. It should be ambidextrous and manual.

Design the breech so one hand has to pull down on the muzzle of the barrel to fully access the breech for loading. That’s your anti-beartrap. You just made the shooter part of the safety equation.

What gives accuracy — the breech lock

Sig also showed us that a breech lock can be built that locks up a breakbarrel like a bank vault without an overly aggressive detent. Their Keystone breech is light-years better than any other one on the market. But is that the only way to do it? I think not. I think with some thought a different type of lockup can be created that doesn’t infringe on the Sig patent — unless Sig decides to built the rifle I’m talking about!

Spring-gun manufacturers other than Sig haven’t been investing any thought in how to lock a breakbarrel breech or how best to reduce friction in the pivot joint without allowing the base block to wobble when the barrel is closed. Through corporate hardening of the attitudes they have put progressively heavier detent springs and more aggressive chisel detents into the hinge joints. I can think of a system right now that would lock a breech solidly and be nothing like the Sig Keystone. And I am not an engineer!

Powerplant

The powerplant is where this project really takes off. In the recent report on the Beeman R10 you learned that the piston stroke is where power lives — not the diameter of the piston. Now, stay with me on this.

Why do people love the FWB 124? After the accuracy, the one big reason for liking the 124 is how easily it cocks, relative to the power. So, let’s do this — let’s reduce the piston diameter to around 20mm, and let’s increase the stroke to around 90mm. Let’s reduce the power of the mainspring to a third of what it is now to create a breakbarrel that cocks with 15 lbs. of effort, yet puts out 12-13 foot-pounds in .177. Can it be done? I’m not sure, but it would be something to strive for.

The Vortek PG3 tuning kit suggests what kind of powerplant parts are needed to do what I’m suggesting. Knowing that up front means designing a powerplant from the beginning that meets the specification for light cocking, reasonable power and vibrationless operation. Button the piston during the design stage and make the buttons easily replaceable (they literally fall out when the piston is out of the spring tube!). Or, take a page from the TX200 book and put a rotating nylon ring front and rear on the piston with no possible spring tube contact of the piston body in-between.

What if the piston wasn’t made entirely of steel? What if the body was nylon with a steel head? The loss of weight would combine with the lighter mainspring and tighter powerplant tolerances to eliminate vibration.

What a powerplant like this gives us is a rifle that doesn’t weigh a lot. That’s why I say it should be a breakbarrel — to keep the weight off. I’d like the rifle to weigh no more than 6 lbs. And lighter is better. That means a synthetic stock. I want a stock with a 14-inch pull, a sculpted pistol grip with a palm swell that fits both right and left-handed shooters equally well. It should have a very slim forearm that’s not too deep. We save weight plus get a rifle that feels right instead of a fencepost! Fill the butt of that stock with sound and vibration-damping compound, or cross-braces that create the feeling of a solid butt without the weight.

Sights

I have spent a lot of time discussing good open sights with you, and several readers have taken up the crusade. Ditch the fiberoptics, or at least make them either optional or an included part that doesn’t have to be installed. The basic front sight should be a square post that is sized to match a square notch in the rear. But — make the sights removable so options can be installed by the owner.

Sure — give them a Picatinny scope base on the spring tube — BUT — make it a screw-on option!

The rear sight should be easily and positively adjustable for both windage and elevation. There are plenty of good rear sights on the market today, so this should present no challenge.

My idea

There — that’s my idea for a new spring-piston air rifle that I believe would be very popular. It’s nothing like what you are ever likely to see, but if each feature/component were done right, and that means as close to what I said as possible, I think the world would have a new icon to celebrate.

But who says I know what everyone likes? Well, I sort of got it right with the Discovery, didn’t I? I missed on the Rogue, but what Crosman brought out under that name bore no resemblance to what I briefed them on. I was in the hospital while that one was being put together. And the Bronco was reasonably successful. At least people liked it once they shot it.

Between the lines

If you know the airgun industry you can read between the lines of today’s report. Some companies are in better position to execute such a new spring gun than others. But the sad thing is when the ammo trucks arrive at the battle a half hour too late for resupply. Let those who know understand!

Now, you readers take it from there. Or tell me why I’m wrong and what needs to be done, instead.

I read Hector Medina’s blog too, he is an employee of Diana. They definitely listen, but the r&d and sales departments are definitely at different ends it sounds like.

I think FX really has it done right. Choose a caliber then add on to the platform with all the adjustment you need from 17-35.

I doubt any Springer could do the same as well. But refinements happen there as well, and the aftermarket fills the void that the manufacturer can’t justify, like buttoning, spring guides, deburring things…

B.B.,

Ok it seems you have the barrel figured out along with the trigger and breech lock. I would beg to have a dovetail to allow mounting of a peep sight that will then allow securely fitting a Picatinny rail for those who need a scope. I would opt to increase the powerplant diameter to 22mm (based on the experiments and experience of the British boffins) that would allow a shorter lock time. I would prefer using a metal spring instead of a gas strut for the powerplant. A light piston favors low weight pellets. I assume this will be a .177 limited to around 12fpe? This will be a lightweight already having a smaller diameter tube and synthetic piston. Further weight reduction if you use a soda straw barrel as a liner into a synthetic outer sleeve. Breech block must remain made out of steel. Gamo produced a junior air rifle that utilized a plastic breech block that cracked after under a year of use. Should the transfer port be the traditional offset or inline? TCFKAC seems to have most of these things set up except for the trigger. Maybe Mr. Ed Schultz can convince them to use an entirely new trigger design?

Siraniko

Hi Siraniko,

I like the soda straw barrel idea to reduce weight and maybe even costs. But I would suggest using a carbon fiber tube instead of any synthetic. Because the carbon fiber will aid in barrel rigidity and reduce overall harmonics. Harmonics can be a major issue with springers.

Carel

Carel,

That’s a good idea. Carbon Fiber tubes are very stiff. Although to make the entire sleeve out of it would be prohibitive the closest thing would be to use it as the outer sleeve with some other tight fitting synthetic material as the filler between the soda straw barrel and the carbon fiber sleeve.

Siraniko

Hi Siraniko,

I have seen people epoxy carbon tubes quite successfully onto barrels. One of the things this sometimes eliminates is pellet fussyness. The epoxy would work as a the filler you suggest.

Some pellets with a certain speed will exit the barrel at an inopportune (or variable) moment in the barrel harmonic vibration, and can spin off target. After installing the tube I have seen these rifles will suddenly group great with a greater variety of pellets. Kind of cool. And makes sense when you think about it.

Best regards,

Carel

Carel,

Carbon fiber and a layer of epoxy is an excellent idea. In addition to the benefits you describe, much research has already been accomplished in the manufacture and application of carbon fiber, from high-tech bicycles and tennis racquets to musical instruments. In the past carbon fiber automatically added a great deal of expense to a product’s manufacture, but I wonder if in 2020 costs might be significantly lower because of ever-advancing technology.

Michael

A 3/8” dove tail to mount a peep sight would be nice. Williams makes a fine target sight in this regard. Great barrel lock up is a must with receiver mounted sights and I would submit the Walther LGV style is hard to beat.

Reading between the lines my understanding is that we are trying to make a cheaper, slightly modified ASP20. Quite a tribute to SIG…

Leaving that aside can it be made at a fraction of its cost? Well, one more time the answer could probably be given by SPA (what a coincidence regarding the acronyms!!!). If Diana trusts their brand, Sig could do it too. Or if we see it the other way around, we are asking a Chinese Airgun company to finetune an existing product that it hasn’t come to our hands yet. So much for the commercial war between two countries.

Good day to you all.

Bill

Bill,

Just because Diana trusts their brand does not mean SPA is the best. The price to the Diana Group is going to be one of the major issues considered. Then quality. I myself would not go with any of them. Now the AV Avenger does have my attention. It is an upgraded Nova Vista Liberty, who also makes the Aspen/Freedom.

RR

I mentioned SPA exactly for the price issue, since B.B put it as the reason for this conversation, and to my knowledge SPA seems to be the biggest Chinese name for either copies or innovations. Remember the talk we had about their M30 and LCS/HUBEN platforms? As far as qc I would agree to the point that you get what you pay for.

Bill

Hi B.B. and all,

I have thought about this a bit and find it quite interesting. This is a bit long but there is a TLDNR list below.

I have read about a tuner in the UK that does modifications like this to existing rifles and sleeves down the cylinder diameter quite substantially. Actually as I recall a bit below your 20mm. He does stretch the stroke I believe. This allows him to use very light springs so the rifles cock very light. But they do put out up to 12 foot pounds and shoot practically as movement free as a PCP. Maybe someone here recalls the name of that guy, I tried googling but did not find the articles. It would be a great idea to look up his designs for inspiration, as he has some quite innovative ideas that verifiably work, as there have been reviews of his work.

As a second point I would like to note that making the shooter hold the barrel down to be able to load, would be a deal breaker for me. I think that is over the top, unless you have a shot out, worn sear, Chinese breakbarrel from the 70’s.

I do a lot of shooting and open up a lot of air rifles of a lot of vintages, and in a well designed breakbarrel that has not been messed with or damaged, you really do not have to worry about the sear slipping and the barrel popping into your face. That being said holding down the barrel for loading is probably slightly less annoying than an auto safety.

There is a lot of focus on SIG, but I also see a lot of potential for the Walther/Umarex brand. As their Terrus rifle would potentially also lend itself very well to these modifications. I am still a raving fanboy of their LGV line.

The locking latch on the LGV rifles provides a solid lockup for a breakbarrel, though I am sure it can be modernized.

Also if were are talking marketing and cost wise, maybe the open sights should take a backseat. Yes there should be the option for open sights (I need no convincing of the greatness of open sights).

But realistically I think most people buying a super accurate spring rifle in the 12 foot pound range will want to scope it. So in the base model perhaps the focus should be on that, a stripped rifle with a sleek look; a nice barrel weight or small moderator on the end of the barrel instead of the open sights, and a rail on the back. And then as an upgrade the open sights version, or maybe an open sights kit that goes on the rail also? You could have the front weight or moderator screw off and have an optional accessory with a rail that will take a front sight tunnel perhaps.

Vortek kits are well engineered, and I think all manufacturers should start sleeving their springs in such a fashion, it really makes all air rifles I tried them in smoother to shoot. So yeah that is a great idea to incorporate.

TLDNR:

– Practical application of sleeving down cylinders has been shown to be effective and efficient.

– Please no holding down barrels, that is annoying and probably not even necessary

– Maybe the focus should be on a scoped rifle as a base; most people want that

– Vortek kits are the best and should be in every air rifle

Best regards,

Carel

Carel,

I’m following the work of UK tuner Tony Leach aka Airguntech. He sleeves down the piston chambers to 22mm. Haven’t seen anyone do 20mm routinely yet.

Siraniko

I believe his name is Tony Leach.

-Y

Yep you are right guys, Tony Leach.

Cudos on knowing your stuff.

Carel

Carel,

Tony Leach is the guy you are looking for. Search the https://shooting-the-breeze.com forum.

Wow!

You guys caught on! Thank you for your good ideas. This is the sort of thing the industry needs!

B.B.

B.B.

I like your rifle already, BUT…..

No cheap synthetic stocks! The stock should be able to help reduce the amount of vibration that the piston creates.

However Lothar Walther does their barrel is good enough for me!

Articulated cocking lever, if properly engineered will help reduce cocking effort and this will enable a shorter slot in the stock fore-arm which will help with vibration.

Target weight should be 7lbs unscoped, for 12 fpe, anything less will feel like a child’s toy.

-Y

Hi Yogi,

I also really like a nice wood stock and it is also true that weight will eliminate a lot of vibration. Just look at the old match LGV from the 60’s.

However wouldn’t it be cooler to reduce vibration in another way than with more weight?

The new ‘what would stoner do’ ar-15 is only 5 lbs unscoped and is optimized for field and competition. And it is by no means a child’s toy…

Rifles are getting more and more lightweight, and if they lose none of their performance, why not?

Also if it becomes a successful rifle you can be pretty sure there will be an aftermarket for nice wooden stocks. And you can always put more weight on, or in. But like we all know from after the holidays it is usually harder to take it off…

Carel

Carel,

Agreed. I love the look and feel of wood, but synthetics also provide for a maintenance free stock as well as uniformity of weight and appearance.

Michael

Carel,

Ah, a beautiful piece of walnut. Nothing like it.

In many ways synthetic stocks are indeed much better.

Lightness has its own issues. It is hard to aim a rifle freehand when it is very light. Also, I have fired a light gas sproinger and a light .308/7.62 NATO. Neither was a pleasant experience.

Physics. It’s the law.

How about a stock that is as light as possible but has access for users to fill with materials of their choice? And change as needed—like many do with pellets? Ha, there’s a crazy notion—pellet storage for the bug out rifle ;P

I’m in the lighter weight camp since my preference is for unsupported offhand shooting (although I’m amazed how my Fortitude groups shrink to dime size at 25 yds when supported!! Its magical!!).

I also like synthetic since then I’ll be far less concerned with damaging a nice wooden stock that will remind me each time I look at the scratch/nick/dent.

Yogi,

What happened to your shot counter? 😉

No need on a break barrel. I have 2 thumbs, that should work…

-Y

Yogi,

I don’t know. Gamo and Hatasn have multi-shots out there. TCFKAC did, but it was apparently a flop and disappeared. If you get that Chinese abortion of an air rifle with the two barrels AND equip it with multi-shot magazines, you could lay down quite a barrage. It could become quite difficult to keep track of which shot your were on.

BB,

When I had my CFX, I filled the synthetic stock with foam to reduce noise and vibration. This could easily be done in many synthetic stocks. The internal brace idea would add considerable cost.

The barrel lock up like the LGV or HW35 for examples is something I myself would really appreciate. The barrel lock up on my FLZ Militia is awesome to use. With a light pull the barrel lock opens.

Many of the old gals around here have small diameter, long stroke compression tubes. They can be a dream to shoot. Some speak of lock time, but I seriously doubt that the increased time of the longer stroke is really an issue.

The smaller diameter would also lend itself well to a centered transfer port. The efficiency of the centered port I believe has been demonstrated and this would help with the reduced “power” of the lighter springs.

The smaller diameter of the tube would also aid in the attachment of sights. NO GLOWY THINGYS! The idea of removeable sight kits is fantastic. Weihrauch offers upgradable front sights. A good quality, inexpensive peep similar to a Williams that can be added would be the cat’s meow.

Eleven millimeter dovetails are a must. The Picatinny rail becomes an easily installed and removed option. A removable stop block similar to what is on my Webley/Hatsan Tomahawk is a must. By removing and turning it around I two options where the stop is. If I use just the screw I have a third option. Those who are industrious can make their own stop block whatever length they desire.

The trigger. So many sproingers have such horrible triggers. A properly made single stage is so much better than any of the monstrosities out there now. I have not had the pleasure of pressing a Sig trigger, but I have the Rekord. If you must entertain the attorneys, do such with a removable stop that limits how low you can go. You just do not advertise it. If you have enough gray matter to figure it out, you will likely not be involved in litigation.

Your idea for the barrel is good. Take the best from the various manufacturers and put them together. Forget the soda straw barrel idea. They can be thinner with a carbon fiber sleeve, but carbon fiber sleeves can add considerable cost also. FX has demonstrated that their system is very expensive. If you reduce the barrel thickness, it will need to be inserted and “glued” into a polymer sleeve to help keep cost and weight down. A problem with thinner barrels though is they must be handled more carefully so as not to be bent or damage the breech or crown.

Why do you say a centered transfer port is more accurate?

-Y

Yogi,

I did not say it was more accurate. I said it was more efficient. Now it just so happens that most of the sproingers with center transfer ports and barrels are more accurate, but that is due to quality.

RR,

I’m from Missouri, prove it!

-Y

Yogi,

It’s about efficiency. Here’s the article: /blog/2008/10/the-air-transfer-port-part-1/

Siraniko

That article from BB simply states that port location in the center is more efficient, but there is no experimental data to back it up. I’d like to see some data before I accept BB’s statement.

BB,

As has been pointed out, there is the issue of vibration. Over the years many manufacturers have attempted to eliminate this issue. Most have gone with the gas sproing, a relatively cheap, simple method to greatly reduce vibration and increase power all in one package. Mass has also been used to reduce such.

I myself would prefer a properly constructed metal sproing system. Buttons, sleeves, guides and bearings all working together makes for a very dependable vibration free system.

One of the biggest bugaboos with the sproinger is the most infamous multidirectional recoils. I have had sproingers try to jump out of my hands. The laws of physics makes this a most difficult issue to deal with. You have the initial backward recoil of the piston being released. Then you have the forward recoil of the piston reaching the end of its stroke. Then you have the backward recoil of the piston rebound…

I have seen several methods attempted to tame this beast, from the sled to the shock stop. Perhaps a lightweight hybrid will work. Keeping the power level down will be of big help.

Please make it accurate.

First thing – Picatinny/Weaver rails!!! NO dovetails!!! Why manufacturers haven’t already adopted this across the board for springers is a mystery! The best way to stop scope ring travel. One problem with PCPs is hammer bounce. The best way to tame it is with a free flight hammer. Why not apply the same principle to the piston? With a gas spring, is there really any need for preload? The gas spring could be designed to absorb the sudden stop without damage. As for vibration, foam bedding helps. Easy to do with the proper set up on a synthetic stock. And since this is supposed to be an inexpensive gun, I believe a synthetic stock is the way to go. NOT a space age faux-tactical, but more traditional style. Similar to the Maximus/Fortitude one. My two cents for now.

Mobilehomer,

A slight bit of preload helps to keep everything in place. The gas spring has less vibration, but what a recoil. Reducing the power level would help immensely. An NP2 type piston may help also.

I for one am not convinced gas springs are as reliable as metal springs, most especially over long periods of time. I have some pretty old gals around here that work just fine thank you very much. Now if you are going to trade out airguns like people do cars, who cares.

A metal spring does not necessarily need a lot of preload, most especially if you are using a long stroke. Just a touch to hold things in place. That preload on many sproingers is really lazy engineering and manufacturing to raise power levels so that we customers can break the sound barrier. The TX200 has almost no preload.

Mobilehomer,

I insist on dovetails being present because I can only afford to shoot with peep sights which require dovetails for installation. I agree if this would be exclusively for scope use that a Picatinny rail should be installed. I may be in the minority in your eyes but I cannot afford to keep buying scopes that break.

Siraniko

Siraniko, how about a rail with a short section of dovetail in the middle?

Mobilehomer,

The best compromise I can think of is that there will be a 3 inch section of dovetail at the rear and Picatinny in front with provision to attach additional length of Picatinny to adjust for proper eye relief.

Siraniko

While we are designing the Rifle, why not design a good peep sight that fits on a standard picatinny rail. The rail could attach directly to the rifle as low as possible. If you want a standard rear iron sight, can’t one be designed that can also be attached to the rail? Front sights should be interchangeable to work with either. Scope? Red dot? Reflex? Same system, and remove front sight. Barrel Droop? Perhaps a different rail with built in incline of different degrees.hopefully the new lock up will cure barrel droop. If you want things to be less expensive in the long run, go with standard parts.

B.B.,

You definitely got a snowball rolling down a hill with today’s blog. I love the sort of brainstorming (if that word is still used) it has started. It also got me wondering how Rich Shar has fared with his endeavor. It has been long enough since I heard anything that I suspect he has stopped pursuing the 50 fpe springer of his plans (or “steel dreams”).

Michael

Michael,

Who cares if the kids are still using “brainstorming”? Us old geezers still know what you are saying. The kids are mostly off chasing hypersonic velocities anyway. When they come back to earth they can use whatever words they want to describe kicking ideas around to solve what we already have. 😉

:^)

BB,

Back to the Edge for a moment. Yes, you are pushing the pellet faster, but would not a tighter spread increase the accuracy, giving that everything else is equal? When pushing a .50 pellet/slug/bullet down range, what is 25 FPS? When pushing a .177 down range and the variance of the thickness of a gnat’s wing on the target separates the winner from the losers, that is quite a spread.

RR,

I don’t know. So I am experimenting.

B.B.

BB,

Thank you.

BB

Oh boy, this series is going to be a goodun!

Count me as preferring accuracy first, an LGV inspired barrel lockup lever, a manual safety, and a Sig like trigger but adjusts down to 2 lbs or has a non advertised removable governor. I do like holding the barrel down in order to load a pellet because I shoot lots of different springers and a couple don’t have antibeartrap. Years of firearm safety did not teach me to hold on to the barrel of a springer when loading. I learned this from your blog. I think your ideas on sights are right for most buyers even if I prefer a globe insert front and aperture rear. Just allow the option. Since accuracy is rightfully the number one objective glow sights are out. Larger dovetail rails with stop holes may be a good addition for easily mounting a Picatinny.

Interesting stuff here about barrels that are wed to one pellet vs barrels that shoot many pellets well like my HW30s. Harmonics is another variable. Has anybody found that weighted rubber rings that slide up or down a barrel actually make a difference?

Deck

Deck,

Keep a hold on that barrel. Better safe than sorry.

The dampeners do work.

https://limbsaver.com/collections/firearms-products/products/sharpshooter-x-ring-barrel-dampener

RR

I have two LimbSavers barrel sleeves. Sounds like you have used them to advantage. Firearm or air rifle?

Deck

BB ,

I like the idea of lightening the piston . I say a polymer piston that has a metal insert for the sear . The button for the seal can be polymer . Another route is to groove the piston for 2 o rings and eliminate the button type seal . The o ring seals will be common and available. Thus eliminating a proprietary part . The idea of reducing the bore also lightens things up . Make the piston out of a polymer that is impregnated with Moly or Teflon , this eliminates the need to lube the OD of the piston. Make the mainspring guide of the same material and fit the spring tightly and the gun will not buzz. This eliminates the grease on the spring guides and it will be good for the cold climate hunters .

Gene Salvino

Gene,

You will need a rubber baby buggy bumper on the end of the piston. One similar to the FWB300. Gunfun1 has replaced the metal ring with o rings and says it works great.

Besides the obvious basic components. At first i was going to say hunter, but i dont think that is a correct representation. I remove pests & predators. Any how i prefer any rifle i own has open sights even if i don’t use them. I like shooting with iron sights and even though I own every kind of rifle i need, i have one more rifle that i want as an actual target shooter or plinker and i have wante it for a very long time an HW95l .22 as much for the purity of it and those nice sights as much as any other part of it.

That rifle just seems to check every box the only other contender in this class at least that is as good or better HW35 stainless. Thats just my opinion everybody has the things they like.

BB, I think the CZ634 fits almost all of your criteria. It is lightweight, accurate, good trigger, break barrel, locking breech, I can’t remember if the safety is manual or automatic. It is only about 9 FPE. I think CZ would be the manufacturer I would contact and they would only have to change a few things to make this rifle.

David Enoch

Some interesting concepts here, but most of them don’t match up to what I’d really want.

My ideal break barrel is almost an evolution of the Diana Giss system, which fixes some of the flaws of those excellent Diana rifles (complicated to service, limited muzzle energy etc). I’ve been designing it over the last few years, and will soon be finishing the prototypes.

It will be:

– Completely recoiless action (like Diana Giss/ Park RH91-93/Whiscombe)

– New trigger design. (The best way I can describe is a mashup of Diana 75 and Air Arms CD).

– Breech lock up like the Theoben break barrels twin bolt design. Simple/cheap to machine and works very well

– Breech running on 4x oil impregnated bronze bushes for low friction and long life

– 28 or 30mm piston bore with short stroke (makes a lot of sense when applied to the recoilless design). I’ve shot multiple reduced diameter tunes and not found one I like yet. I much prefer my 25mm TX200 for competition use.

However this does fall down in a couple of areas:

– Cost will obviously be relatively high

– Complexity. Although much simpler to work on than a Diana Giss rifle, it is a bit more complex than a simple recoiling break barrel

– Weight. It has more parts, so must weight more. At the moment its going to be about 9lbs. This could come down to 7.5lb using high grade aluminium or titanium in certain places, but then cost goes up.

About 75% of the prototype parts are next to me now. Just waiting for a few more deliveries before I can finish the build and test for the first time!

cooper_dan,

Wow! That will be interszteing to hear about when it’s ready!

B.B.

B.B.

This is promising to be a very interesting series – just what us arm-chair engineers love!

In reading the comments I see different disciplines making suggestions that support their specific perspective – which is perfectly understandable.

This blog is great to start the discussion for a generic “spring piston” rifle but I think that we will eventually need to have a couple of categories as rifles for plinking, pesting/hunting and target shooting have different requirements.

Most people equate a break barrel setup for spring piston rifles but my suggestion would be to avoid the pivot point, breech and locking mechanism and go with a side-lever design. With a side lever the barrel could be a light tube (multi-caliber?) with a shroud, barrel droop should be less of a concern, the sight radius could be the length of the barrel and receiver and the stock geometry is unrestricted.

Cheers!

Hank

Hank

Hank,

Yes there will be several categories. I was just trying to start with the most basic one. If someone can get that straight, the others should be easier.

B.B.

B.B.,

When I replaced the wood stock on my deer rifle with a synthetic one it reduced the weight significantly and the felt recoil by at least half. I don’t think the synthetic stock was designed to reduce recoil but it did.

A synthetic stock could have a significant improvement in harmonics and recoil and still be light. Some computer modeling should be able to design a stock that does more than just fit the shooter.

Don

Don,

That is something I didn’t consider. Good idea!

B.B.

Don, I like great walnut as much as anyone, but I like your idea. It makes me think of all the recoil reducing features built into some shotgun stocks these days. Also there are lots of options in firearms that have adjustable stocks. Look at what Savage and others are doing.

I have wondered if a barrel design similar to the Dan Wesson pistols wouldn’t be an advantage in a rifle. Technology now seems enough that a carbon fiber block/barrel shroud could be used to insert a variable caliber tube barrel and eliminate the harmonic issue or at least design the harmonic out of range operation by placing it in tension in the shroud. The shroud could contain an integral moderator. The barrel could be simplified by having the breech seal in the compression tube, so the straw barrel is uncomplicated. With a transfer port replaceable by the user, a barrel and “jet, if you will”, optimized to caliber, could be sold as a set, replaced by the user. Shims could be used in the power plant to vary the power for a caliber change or a dedicated spring could be optioned for the rifle. This used in a low effort to cock power plant, seems like it could work.

B.B.,

What do you want? I want a rifle that will be usable for various sized shooters…especially the YOUNG ONES that will ensure our sport will continue for decades to come!

Most of the requirements you have outlined are supportive of that; but for one: “I want a stock with a 14-inch pull, a sculpted pistol grip with a palm swell that fits both right and left-handed shooters equally well. It should have a very slim forearm that’s not too deep. We save weight plus get a rifle that feels right instead of a fencepost….” Most of that is good but stock length that YOU want is too personal an issue. What you need to put in your requirement is the manufacturer should provision for a stock that fits, can be made to fit, the primary user. That could be on an exchange basis, a putty and cut/rasp here DIY approach, an adjustable with some or all the bells and whistles to include adjustable comb heights, cast on/off and more.

We NEED MORE youngsters to join the shooting sports and stock fit is one of the big issues. Not that a properly fit stock wouldn’t help most of us! Which is why you are so adamant about that 14 inch LOP…am I right Tom?

Grow The Sport is #1!

Just my my opinion(s,)

shootski

shootski,

I did think about that, but decided to simplify it more. If they get everyuthjiong else rigfle a smaller or larger stock should be no p[roblem.

B.B.

B.B.,

I thought you probably would have.

I just couldn’t resist getting the plug in this tread; hopefully some manufacturers and wholesale/retail buyers will remember the benefit of growing youth part of the Sport and not just competition.

I look forward to the rest of your work on this blog topic.

Thank you,

shootski

B.B,

I wonder if a single pump (break barrel, side lever or under lever) rifle with 12-18 ft-lbs could be designed with todays CAD tools, so that it would have reasonable cocking force. Just store the energy in the compressed air rather than the spring and avoid piston recoil forces. – Don

Don,

Can a single-stroke pneumatic be that powerful? Not as of this time.

B.B.

B.B,

It seems doable. What if, one stroke of the under lever caused several cycles of the pump mechanism at a decreasing rate that allows for a constant resistance to the under lever. Just need the right arrangement of levers, cams, gears, variable pitch screw or what not. – Don

Don,

Who is going to pick up this thing, Hercules?

Probably the most complex single stroke pneumatic ever designed so far is the Webley Paradigm. It was a hybrid between a single stroke pneumatic and a sproinger. It was very hard to cock, very complex and only put out about 12FPE.

RidgeRunner,

I suppose you are right. But, some innovative engineering might make it in a useable form. With over 1.1 million views of the Wesley Paradigm video, there is some interest. – Don

https://www.youtube.com/watch?v=pJGKkL7vxy4

B.B.,

Well if you order an HW50SYN (the synthetic stock version they have yet to make =>) to shave 0.8 pounds off the usual wooden-stocked rifle, and then send it to that Tony Leach guy to have him put in one of his skirtless pistons

https://www.airgunnation.com/topic/22mm-skirtless-conversion-review/

…then you might be off to a good start. =>

Looking forward to the rest of this series,

dave

If we didn’t cover “not pellet picky,” I for one would definitely like that to be a feature. Nothing like shooting away with CPHP 😀

A mag fed, two stage cocking, side lever. Make it a little lighter than my Umarex Synergis.

One way might be to make a true bull pup, no lighter perhaps, but the main mass is much closer to the users torso, so offhand shooting should be nice, not front heavy. Recoils the natural way, like a fire arm, as the piston moves towards the shooters shoulder; the scaled up P1 concept. The piston sear happens to be in the right location too. Maybe not bench friendly, because of it’s compact size. The bull pup is radical change. Otherwise, manual safety, ambi pistol grip style stock. Life is short, get wood, its just better. I like the fast lock time of the gas ram. No idea how reliable they are.

I guess I see allot of warmed over already been done better before, but I like the classics. I like the mechanical honesty of R.R’s old BSA rifle he shared a while back.Make those! Plastic is just the way it is now. The Walther Reign is an example of a plastic PCP bullpup that may have the ergos right, the cocking lever, and the ambi mag too. If you can stand the plastic, and the 8 bolts or so to get in the thing.

Rob

I think you are pretty much spot-on, Tom. IMO, barrel design is pretty good currently, although cost to manufacture could be improved with new processes as FX has done. I think design effort should be focused on the powerplant. Piston lightening seems to be the thing to do as some of the Brits have done. The TX200 is a good design, but the piston between the seals could be lightened easily by either changing materials (no plastic please, titanium?), drilling lightening holes in it, making a skeletonized piston or whatever. The whole system need work including the spring, seals, transfer port etc. Why does the FWB300 work so well? It has a cast iron piston ring that lasts forever and a wimpy spring. True, the power level is low, but that could be a basis for a new system. Finally, please do not make a cheap looking gun. I like the traditional walnut and deep blueing. I detest bead blasted metal surfaces and ugly plastic stocks.

The more I think of this idea, the more I think of a modular gun that one can order with a customized configuration. Order yours with a walnut stock and peep sights, I’ll take mine with an adjustable synthetic stock and a scope, but I’ll order iron sights as a backup plan. My other idea would be that I want a rifle that closely duplicates the feel of my deer rifle for realistic practice the rest of the year, same weight, balance, trigger, dimensions, etc.

I need .22 caliber, 22 to 25 fpe and let’s scrap the break barrel all together. Side lever or under lever, eliminate the lockup issue, fixed barrel AND YES a Piccatinny rail, there is no reason on God’s green earth for anything other than a Picatinny rail… and up-gradable universal mount sights . Fiber optics are for shot guns!