This is the actual rifle I’m testing. I won the lumber lottery with this one!

This report covers:

- Gun is prepared

- 25 lbs. of number 4 buckshot

- Caps

- Hole punch

- Where are we?

- Powder?

- Bore butter

- Firing

- Didn’t exit the bore

- What’s next?

- Summary

Today we start loading and shooting the RMAC .22-caliber black powder breech loader.

Gun is prepared

We prepared the rifle to shoot in Part 2, so it was ready to go. However, I wasn’t! There are lots of special things to know and do with this little gun before it will shoot.

25 lbs. of number 4 buckshot

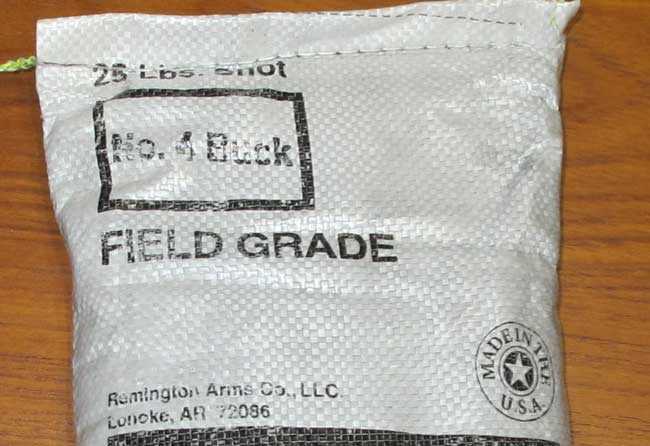

I received a 25 pound bag of number 4 buckshot the evening before this test. I measured the diameter of one ball (had to run out and buy a new battery for my dial caliper but that’s another story) and it measured 0.225 to 0.2355-inches in diameter.

Twenty-five pounds in the shot bag.That is a lot of lead balls but fortunately a reader is buying half of them from me.

That’s what they look like. The black on my skin is a coating that keeps the lead from oxidizing. But I still wash every time after handling lead.

Caps

A lifetime supply of caps came with this rifle. They come 72 to a box and they don’t look like anything I have ever seen. The amount of powder in each cap must be 3-4 times as much as in roll caps.

Many boxes of these special caps came with the rifle I bought. RMAC recommended this cap above all others.

Hole punch

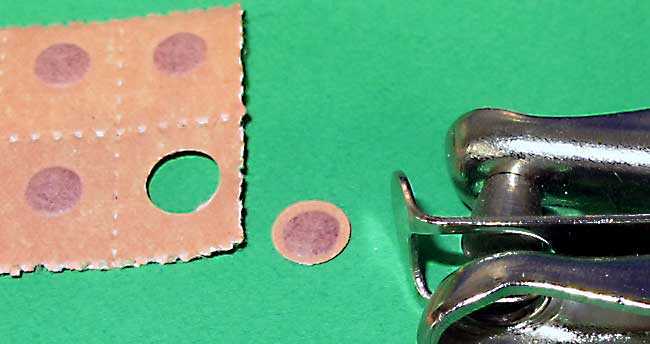

You use a paper hole punch to punch out each cap. Do this carefully, because the cap powder charge is almost as large as the hole punch!

As you can see, the powder in each cap is nearly the size of the hole punch.

When the cap is punched out, it can be loaded into the steel cap cover that serves as the firing pin to ignite the cap.

As you can see, the punched out cap fits the cap cover pretty well.

Where are we?

Okay, at this point in time I had spent a couple hours, because I had to run out and buy a new battery for my electronic caliper. I did that because I wanted to measure the size of the ball before it was shot and again afterward. However, life got in the way.

I loaded that cap cover onto the breech and tried to rotate it inline with the hammer. That’s where I discovered that the thickness of just a single cap pushed the cap cover to the rear far enough that I had to put pressure on the cover to get the breech to rotate and align with that barrel. That’s not a good thing, because if, in doing that, I set off the cap (by pressure — remember?) and the breech is loaded, I will have a problem on my hands. The gun will fire with the breech not in line with the barrel. That’s never a good thing.

I went slow and pushed the cap cover gently and finally got clearance to rotate the breech closed. Then I pulled the hammer to full cock and fired.

WOW!

The explosion was loud. So these caps, as old as they are (50 years?) are still working. Time to load the rifle.

Powder?

The instructions say you can either load 5-6 grains of 4F black powder or 1.5 grains of Bullseye smokeless powder. I opted to go with black, and I used Pyrodex P, which is a replica black powder pistol powder that’s equivalent to 3F black powder. I didn’t want to overload the rifle the first time around, so I used a 0.3cc Lee powder scoop that dropped 3.2-3.3 grains of Pyrodex P with one level scoop. That much powder didn’t fill the chamber in the breech very much.

The powder dipper threw 3.2 to 3.3 grains of Pyrodex P.

The powder charge did not fill the chamber very high.

Next I put a number 4 buckshot into the chamber and rammed it down on the powder with the loading tool. It went very deep into the chamber.

The ball went deep into the chamber.

The lead ball is supposed to go below the top of the chamber. It has to, for the chamber to rotate closed and line up with the barrel. But what you see in the picture above is too deep — a fact I was about to learn.

Bore butter

A reader suggested that I use Thompson Center Bore Butter over the ball instead of vegetable shortening, so I did. It’s easy to smear the stuff over the loaded ball. It keeps the bore cleaner from the black powder residue.

Firing

With the chamber loaded I placed the cap cover with a fresh cap on the end of the chamber and carefully rotated it closed. Like before the chamber did not want to rotate into alignment with a cap under the cover. This time the chamber was loaded and I proceeded cautiously.

I had set a fresh block of duct seal in front of my bullet trap in my office so I could hopefully catch the bullet for measuring. I also set up the sound meter to record the sound at firing.

When the chamber was aligned I cocked the hammer all the way and squeezed the trigger. Nothing. I cocked the hammer once again and squeezed the trigger again.

BAM!

The sound of the RMAC rifle was recorded at 114.6 dB in my office — where we agreed it should be at its quietest. That is louder than a standard speed .22 long rifle cartridge fired in a non-silenced rifle in the same room. I was wearing electronic earmuffs, so I didn’t hear most of it, but my phone did.

Wow! It’s not quiet!

Didn’t exit the bore

Then I looked for the hole in the duct seal so I could dig out and measure the bullet. There was no hole! How could I have missed from 2 feet?

I tried to rotate the breech to reload and found that it was stuck. Now I knew where the bullet was. I put a cleaning rod down the barrel and pushed the bullet back into the chamber, then I disassembled the chamber from the rifle. I had to push that bullet out. But it resisted me.

I tried a heavy paper clip. No dice. I took it to the garage, put it in a vise and tried a thin pin punch. Again no dice. I tried a larger pin punch, but no again. The small size of the flash hole limited the size of punch I was able to use. Okay, if I can’t go through the back I’ll have to try the front.

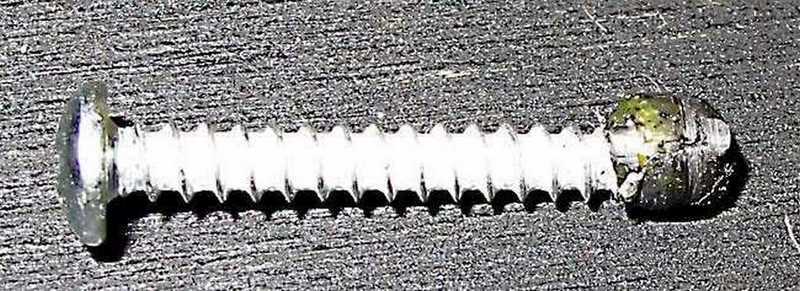

I drilled a hole in the ball, being careful not to touch the side of the chamber. Then I screwed in a wood screw and worked it around. The ball became quite loose and I was able to pull it out with no damage to the breech. About a month ago my neighbor, Denny, convinced me to buy some magnetic Delrin vice laws that were ideal for this work.

The screw got the ball out easily.

What’s next?

Obviously 3.3 grains of Pyrodex P are not enough to force the buckshot through the breech that swages it down to .20 caliber. I looked in my collection of black powders and replica black powders and found a partial can of 4F black. I will use that next.

I will also try to get 5-6 grains of powder into the chamber behind the ball. Apparently it’s needed. And I plan to still catch a ball so we can see what it looks like and measure it. But all that is in the future.

Summary

Maybe it sounded simple when I described in Parts 1 and 2 how this rifle works, but I’m finding it anything but. It’s more involved than loading a cap and ball revolver, which until now I thought was a pretty involved process. Nevertheless, it will make an interesting series.

BB

I figured it was going to need alot of pressure to swage that ball.

Thinking the gun will be accurate though when all is said and done.

So how was the West Won?

Certainly not with this technology…

-Y

B.B.,

That’s really playing safe while working a powder charge for an unknown rifle. Do you move up to 4-4.5 grains of Pyrodex next? Will a small air pocket matter if you did a light load and did not ram the ball that deep into the chamber?

Siraniko

Siraniko,

Generally speaking, that is not a very good idea. The way this breech is built and the small charge there is, you might get away with it. With say an hundred grains like you might have in a rifle, you could blow the breech apart. The projectile should always be “rammed home”.

RR,

That would have been my answer, as well. Thanks,

BB

BB,

Bummer. I am glad I did not know what I was doing when I shot my 1851 Navy Colt. I would have hated having a ball stuck in the barrel. I always just filled the chamber and rammed the ball home.

RR,

That’s also what I used to do.

BB

In two places (second sentence under “25 lbs. of number 4 buckshot”, first sentence under “Where are we?”) you refer to needing a battery for your “dial caliper.” I suspect you meant “electronic caliper.”

Airgun Geek,

I am sure he did, however with us old geezers habits have become vices. (Mumble, mumble. That young whipper snapper. Always mouthing off. Mumble, mumble, mumble)

Geek,

Yep. Why would I need a battery for a non-electric caliper? 😉

BB

BB,

You might have needed the battery for the illuminated magnifying glass used to read it. 😉 – Don (another old guy)

Well folks, I have to say the results of the little drawing I had was quite interesting. There was only two “bids”, one for each box and one abstention so the two bidders would win.

The winner of box number one is thedavemyster.

The winner of box number two is Airman of the Board.

Derrick was the abstention and thus earns an honorable mention.

I would like all three of you guys to send me your mailing address to burke 93 at tds dot net. I am sure you guys can put that all together.

Hang around, this just might happen again.

Thank you, Ridge Runner! Very generous of you. I will contact you with the email provided above.

“The winner of box number one is thedavemyster.”

RidgeRunner, wow, that’s cool; I never win anything, LOL!

I just sent you an email; thank you! =>

Yay! I’m not a winner!

BB,

I could not stand it. I would have to see if I could have a breech block made to take a percussion cap and save those caps for an “emergency”.

Then I would have to rework that stock and / or get another one made for it because I would be having a grand old time with that thing.

I am just a wee bit leery of that swaging. I know they used to do that, but not a whole lot. Of course, there is not that much here. Certainly not enough to worry about a hand grenade going off in your face. Now a blow back around the breech block is possible. Safety glasses for hot gasses is a good idea. It rhymes also.

You need to use a volume measure for black powder not weigh it. It would have filled the chamber then.

BB-

Rather than jumping straight to 4F powder, I believe I would increase the Pyrodex P quantity. You obviously have the room in the chamber and would maintain the time/pressure curve.

This is entirely too much fun. I think I would wear a face shield over my safety glasses until I was sure this thing was safe. Keep posting about this one!

David Enoch

BB

Would you refresh my memory on the subject of pressure (squeezing) setting off the cap? If gradual pressure applied can ignite it then there seems to be no safe way to reload this rifle. But RMAC would not have put the rifle in the streams of commerce even in 1970’s. I’m missing something.

Thanks,

Deck

Deck,

Good question.

Read Part 8 of the series Reloading 22 rimfire cartridges. Specifically look at the part titled Toy caps are sensitive.

I suspect RMAC was not aware of the sensitivity of toy caps to the same level as I am, because they never tried to do what I did.

BB

/blog/2021/03/reloading-22-rimfire-cartridges-part-8/

BB

Thanks. I reread part 8 of reloading .22 rimfire. If either black powder or Pyrodex is as easily ignited by squeezing as toy caps, there is an accident waiting for an opportunity to happen. They must not be as dicey because too many lead balls have been rammed down wheel gun cylinders on top of powder without incident.

Deck

Deck,

The nipples are always the last to be capped. No explosion is probably. I didn’t say possible, because anything can happen with percussion caps.

BB

Black powder and Pyrodex are pretty stable, unless you add a spark. It does not take much of a spark either.

BB, ” Dont count your chickens before they hatch..” What are the odds the kid on the box will get it right? How do you like yer eggs?

Maybe it works just fine, but I will lose that cap cover for sure.

Yes on the safty glasses, and a Diana 27.

I’m watching this one carefully.

Rob

“Didn’t exit the bore”

B.B.,

I feel for you, man! And that pic with the ball on the screw reminds me of the first time I fired off a #11 cap in a muzzleloader match, but felt no recoil.

I waited to see if it was a “hangfire,” then pushed a pin through the nipple to make sure the fire from the cap could reach the powder…but I felt no powder. A quick removal of the nipple showed that that was because there was no powder; in the heat of the match, I had rammed a patched round ball down the bore BEFORE dumping in my powder charge (and if I’d looked more carefully at the mark on the ramrod, I would have realized that).

I had to put the screw on the end of the ramrod and work that ball out; and that .50 caliber ball stretched out a bit, because it was in there pretty tight.

I saved that ball in my desk as a reminder to NEVER make that mistake again.

However, sadly, I did the same thing a few matches later, LOL! =)~

Ah, the joys of black powder shooting.

Likely, the only reason it hasn’t happened a third time is due to match cancellations due to this pandemic; but I’m hoping to get the ol’ smoke pole off the wall this winter and his a few matches…muzzleloaders are fun.

But this little rifle you have here looks like she’ll be a hoot once you get her cookin’. I hope she proves to be accurate for you, too. =>

Take care & God bless,

dave

Dave,

I would settle for a Hawken, but I want a Virginia rifle.

Dave

Happened in the heat of battle too.. Imagine the anguish.

Loading and shooting black powder replicas is as fun as it gets. That and watching a steam locomotive coming by at speed blowing that whistle. It’s been 60 years or more since I’ve seen that sight but I’ll never forget it.

Deck

Thedavemyster and Airman of the Board, you packages are in the mail! Enjoy!

Thanks again!