The HW 50S breakbarrel from Weihrauch.

This report covers:

- Thanksgiving

- Remove the stock

- Phooey!

- Trigger comes out first

- Remove the 4 tabs

- Tabs not under tension

- Tab tool

- Remove the end cap

- Remove the mainspring

- Spring bent?

- Barrel off and piston out

- Summary

Thanksgiving

This is a reminder that tomorrow BB Pelletier will be taking the American holiday of Thanksgiving off. So there won’t be a new blog. I will be back on Friday with a new one. Happy Thanksgiving!

Today I take the HW 50S apart to install the Vortek PG3 tune kit. I discovered some interesting things as I went, including something I have never seen before, so come along and watch.

Remove the stock

The first step is to remove the barreled action from the stock. Since the rifle has only one forearm screw on the bottom, there are just two more stock screws in the triggerguard to remove and the action comes free of the stock.

Phooey!

With the stock off I saw that the HW 50S end cap fastens like the R9 end cap. Four tabs must be driven out before the end cap can be rotated inside the spring tube to clear the small flange that holds the end cap in the tube. I don’t like this system because the first disassembly is always harder. Confused? Follow along.

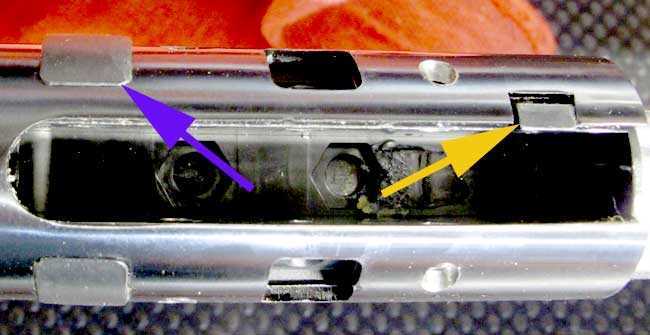

The powerplant is out of the stock and we see the four tabs that must be pressed out to remove the end cap. But first punch out the two crosspins and remove the Rekord trigger and safety.

Trigger comes out first

Step one is to drift out the two crosspins and remove the Rekord trigger. After it comes out don’t forget the safety and its coiled spring.

The Rekord is lubricated with the same thin Weihrauch grease that’s on the inside of the powerplant. When I install the tune kit I will clean and lubricate the trigger like I did for the trigger of the HW 30S. Since I wrote an entire report on just that I won’t do another one this time.

It’s impossible to see that all the silver parts except the trigger blade are covered with a thin coat of Weihrauch grease. Most of of the grease (except for what’s on the piston hook on the left) will be removed and the sear, in the window at the bottom right, will receive moly grease.

Remove the 4 tabs

The next step is to remove the four tabs that prevent the end cap from turning inside the spring tube. They don’t hold the end cap in the tube against the force of the mainspring. That’s done by a very small flange at the rear of the cap. But if that flange should rotate when the last tab is removed, the mainspring will launch the end cap, so it’s time to break out the mainspring compressor and make the job safe.

The end cap is inside the spring tube, so I use a long socket to push on the center of the cap while I’m removing the tabs. And here is a word to the wise.

Tabs not under tension

The four tabs are not under tension from the mainspring. So you don’t need to push on the end cap at this time. In fact, pushing makes the tabs harder to remove — ask me how I know, ha ha. The small flange at the rear of the cap holds the cap inside the spring tube against the mainspring. So get the action in the compressor securely right now, but put no additional tension on it.

Tab tool

You do need a tool to push out the tabs because they have to be pushed out from the inside, where the trigger was. A small Allen wrench with a short leg will work for this, but all my wrenches had legs that were too long. So I grabbed an old nail and made a tool by bending the end. Insert the small end of the tool in the tab hole from the inside of the end cap and use a screwdriver to press on the back of the tool. With a rocking motion on the tool the tab will come out.

My tab removal tool is a nail bent 90 degrees.

Tabs do not come out easily the first time they are removed. But as they are removed and replaced time after time they wear in and get easier to remove.

Once a tab on one side pops out, use a thin pin punch through the tab hole to push out the tab on the other side. That’s easy.

The thousand-word picture. The tab on the upper left (blue arrow) is coming out from the tab tool. The yellow arrow points to the small flange that holds the end cap inside the spring tube.

All four tabs have been removed from the spring tube. The end cap can now be removed.

Remove the end cap

Now we discover why the barreled action is in the mainspring compressor. It’s time to remove the end cap and let the tension off the mainspring. To do that put a little more tension on the end cap with the compressor and push the small flange out of its notch in the spring tube. A thin-bladed screwdriver behind the flange is perfect for this.

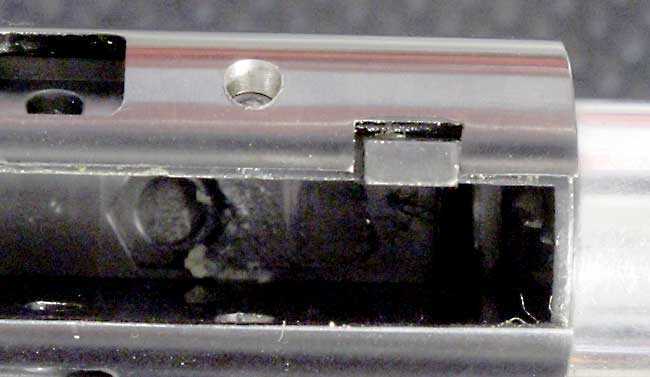

The small flange is its slot in the spring tube, holding the mainspring back.

Now, use the mainspring compressor to put a little tension on the end cap. Then rotate the flange out of its slot.

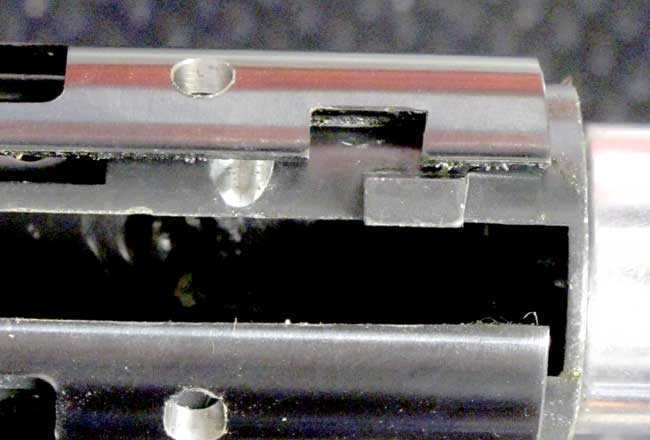

The flange is out of the slot, allowing the end cap to be removed from the spring tube. This picture shows the small angle of the slot and the corresponding angle of the flange that ensures it will not rotate out while it’s under tension.

Relax the compressor

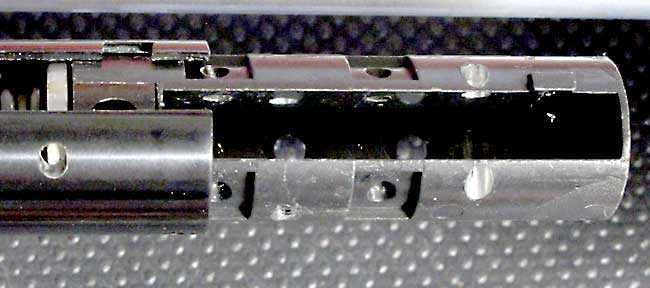

After the end cap is free to move you can relax the tension on the mainspring compressor. The cap will back out of the spring tube almost two inches.

The mainspring is fully relaxed and the end cap is almost two inches out of the spring tube.

Remove the mainspring

You can now pull the end cap out of the spring tube. The spring guide and mainspring will come out next.

Spring bent?

You may remember that there was some buzzing in this rifle during testing and I thought it was due to a bent mainspring like we had in the HW 30S. When I examined the spring outside the rifle, though, it rolled straight. Only the last coil on the spring guide end seems to be bent and not very much. I’ve never seen just one coil out of alignment like this.

If the mainspring is bent at all, it’s only the last coil where I have the pin punch pointing. That last coil looks out of alignment with the other coils.

If this coil really is out of alignment, it doesn’t seem to be out enough to have caused all the buzzing. I think the buzzing was caused by general loose tolerances of the powerplant parts. Fortunately I will be replacing the spring with a new one from the kit.

Barrel off and piston out

The barrel pivot bolt can now come out and the barrel will come off the mainspring tube. Then the cocking link can be removed from the piston and the piston slid out of the tube. This is necessary because I bought a new piston seal with the kit.

Summary

Well the rifle is apart and that is where I’ll leave it today. Next I will install the Vortek kit and we’ll see what happened.

BB,

Maybe if you applied TIAT before you took it apart we would have known if the buzzing was caused by general loose tolerances of the powerplant parts. Then again you were going to change the innards anyway.

Siraniko

B.B.

Why are the tabs hard to remove the first time? If you get replacement tabs will the first time removing them also be difficult? Will you deburr as you go along?

Happy Turkey Day everybody!

-Yogi

Yogi,

I don’t know about the tabs. Probably not because you put them in first.

BB

BB-

Errata- section- ‘Trigger comes out first’, Photo caption, second sentence- ‘Most of of the grtease …….’

Paco,

Got it. Thanks,

BB

Siraniko must be testing us…

B.B. in the section entitled “Tabs not under tension”:

“In fact, pushing makes the tabs harder to remove — ask me how I know, ha ha. [I]The small flange….”

Excellent report, B.B., and great pictures. Thanks. It’s fascinating to me how differently the HW50 is put together versus the HW30.

About the photos…THANK YOU for using blue and yellow arrows. Like BB, I am also color blind and if red arrows had been used I wouldn’t have been able to see them.

rk,

And don’t get me started on red and green. I usually cannot tell them apart. I could never disable an explosive. “Cut the red wire, but whatever you do, don’t touch the green wire.” “Ooooooh!”

Michael

Roamin,

Yep, that looks like a Siraniko test to me, too. 😉

Fixed it. Thanks,

BB

I hope we passed. I better re-read….

BB,

Having an imagination that allows me to visualize things, I see a great deal of tension on that little tab. I know the side tabs and the trigger pins will keep the plug from slamming into your face if that tab should shear off, but it still gives me a quiver. For all you folks out there, for that to happen is almost an impossibility. It is just that my imagination runs amok sometimes.

I do so enjoy seeing the engineering that has gone into these airguns. So many people cannot grasp what they are looking at. The years of experience that has brought these to such a level. This is one of the reasons I like these old gals here at RRHFWA. How did “they” solve this issue or that issue over the years to arrive at what we have now. Also, why in the world did some of these ideas go away?! The only reason I can think of is cost.

I wish all of you a most blessed Thanksgiving!

B.B.,

Above Siraniko comments about TIAT (Tune in a Tube) and the loose tolerances = a little buzz. Are (too) loose tolerances something that can well-remedied with TIAT?

Also, I am curious about the grease Weihrauch coated all of the trigger parts with. Why? Might it be to prevent corrosion? Those look like stainless. A different philosophy (than B.B.’s) regarding lubrication?

Michael

BB

Happy Thanksgiving day everybody and do give thanks for many blessings.

TIAT alone stopped the buzzing in my HW50S. Readers could first try it and if not completely satisfied then go for the kit.

I too wonder about the factory lube. I’m guessing you chose to go with your own proven recipe lube while the rifle was apart.

Deck

Hey Deck,

Did you disassemble your HW50S for the TIAT or just brush some in to the spring through the slot?

My HW50S does buzz a bit but it’s far from being broken in.

I’m going to leave the the rifle assembled, flush out the factory grease with some naphtha and apply a coat of thinned (to “oil” viscosity with naphtha) Red Tacky grease to the spring chamber.

Hank

Hank

I didn’t do anymore than remove stock if that. I am away from home and don’t remember if spring is accessible enough with stock on. I did do two applications of TIAT about 3 months apart as I was careful not to overdo it. No lube change was made otherwise. I can think of no good reason for doing anything else. A Bubble scope is mounted and it competes neck and neck with its smaller HW30S buddy for accuracy.

Deck

Deck,

I’m curious how well the TIAT will work, have a kit for the HW50S if I need it.

I put a Hawke Varmint 3-12×44 on the .22 HW50S and lighter Hawke 4×32 AO on the .177 HW30S.

As you say, neck and neck accuracy wise. I’m enjoying both of them.

I keep a couple of tins of pellets handy by the basement door and shoot half a dozen shots each time I pass by… well, sometimes a lot more than half a dozen, I’m easily distracted 😉

Hank

Hank

We have the same caliber Weihrauchs. My HW30S does well with most premium pellets at 10 meters but at 25 yards best groups are with JSB Express 7.87 grain and AA Express 7.87 grain. My HW50S likes AA 16 grain domes and Field Target Trophy.

Deck

Hank

May want to look at Ham review for HW30S kit published today.

Deck

Thanks Deck!

I’m at the plinking, familiarization, break in stage right at the moment so it was a quick sight-in and get to the shooting part 🙂

Thanks for the pellet suggestions, I’ll try then out. I’m shooting Crosman pellets for now as I have a good stock of them. The cold weather has arrived (below freezing at night and most days – the beaver pond has frozen over) so searching for “the golden pellet” will probably happen in the spring. Mean time the pop-cans are getting a lot of abuse LOL!

I’ll check out the HAM article. Appreciate the heads up!

Hank

FM has a lot of respect for those with natural and learned abilities to take things apart, fix what needs fixin’ and then reassemble correctly with everything working as intended afterwards. Having said that, this is a good report which helps amateurs understand the workings of their sproingers a bit and the engineering behind the design.

Still, in FM World, the following rules will ALWAYS apply:

1) Do no harm.

2) If it ain’t broke, don’t fix it.

3) If you have to ask “is this a lug wrench?” leave the tool and job alone and let the experts handle it.

Happy and Blessed Thanksgiving to everyone – stuff the turkeys, not yourselves. 🙂

FM,

You said “and then reassemble correctly with everything working as intended afterwards.” I would add, “with no parts left over.” ;o)

And, regarding lug wrenches, by the way, some of us consider a butter knife to be a multi-tool. ;o)

Happy Thanksgiving!

Good point. And sometimes you have too many parts installed…as in the time FM was trying to rebuild his MGB’s SU carburetors – carburetters for our UK friends – and he shoved in more parts than needed…the rebuild kit included parts for more than one version of those carbs and FM was attempting to make sense of conflicting instructions in two different repair manuals.

Still remember the note written in the job sheet from the shop which actually rebuilt the SUs per specs: “Customer attempted to rebuild carbs. Oh boy!” Oh, walloped wallet!

For those not familiar those four tabs are peened into place at the factory after they are installed, this is why it’s difficult to remove them the first time and get easier each time they are removed.

Chachoze,

Wow! I didn’t know that. I learned something. Thanks,

BB

B.B.,

I like the detail and especially the pics; I think even I could take an HW apart after reading this report. 🙂

Wishing a blessed Thanksgiving to you and all the readers here,

dave

P.S. Oh, and one more thing to thank you for B.B.: thank you for the advance warning that the firearms ammo shortage would cause even more firearms enthusiasts to get airguns and stock up on ammo, thereby causing a shortage of pellets. Thanks be to God, I stocked up as soon as I read your warning! Hence, I’ve got lots and lots of pellets…yay! 🙂

Dave,

Yes. If you see pellets you like are available, don’t hesatate!

BB

BB et al

It is my hope that you and all my friends, here, have a wonderful Turkey Day with their friends and/or relatives. As the world changes, it is good to remember that we still have much to be thankful for.

My best wishes to all,

Ed

B.B. and Readership,

Happy Thanksgiving to all of you who celebrate tomorrow and I wish you a Horn of Plenty filled with pellets, bullets, (slugs) and most of all lots of time to shoot those airguns!

For those who don’t celebrate tomorrow may you still have a bountiful supply of Pellets!

shootski

Was pleasantly surprised to walk into a Bass Pro yesterday and found a fairly bountiful supply of .177s and some .22s, including RWS .177 target pellets. FM gave himself a Thanksgiving treat. FM happy.

FawltyManuel,

Glad you found some more pellets for your Horn of Pellets!

Shootski walked into his MCX (Marine Corps Exchange) on Monday and found the gun counter had a sale going on and lots of ammo in stock to include .44 Magnum which has been in short supply for many months EVERYWHERE! So I asked for a case and found out I was limited to 2 boxes per caliber…so I got 2 each 9mm, .380ACP, .22LR, 5.56 NATO .7.62 NATO, and .44Mag. Then I asked if the limit was per day? You guessed it! On Tuesday I was back and walked out with another bunch as well as on Wednesday, they are closed today so Friday will be another try…at some point thay will run out : (

I never have let my supplies of ammo get low but this current period of shortage has made keeping my inventory at comfortable levels difficult!

The indoor range I frequent has really been hurt by the ammo shortage causing low hourly/day shooters; i suspect that if they didn’t have us annual members, local police department training and new shooter (especially all the 1st time women shooters) training they would have already folded.

I hope we have a return to a more normal shooting environment and Shooting Ranges survive the double whammy of COVID 19 as well as the shortages!

shootski

To All,

Happy Thanksgiving and may your pellet shelf ever be full!

Siraniko

A blessed Thanksgiving morning to all!

I want it. I need it like another hole in my head, but I want it. The truth is I do not have a sproinger in that power range. I have my Webley / Hatsan Tomahawk which I do believe is somewhere between the HW95 and the HW80. I am seriously thinking of bringing the power level down some to help calm her down a bit. If it works, she will be awesome and if I screw it up, I can pitch her over the hill without feeling too bad because I do not have much in her. She does have a real nice walnut stock though. I could always get another Hatsan to drop in this stock. Sounds like a project for this winter.

As if I do not have enough projects here at RidgeRunner’s Home For Wayward Airguns, I intend to continue my campaign for air pistols and air rifles that look like they should be in a syfyalienspaceinvaderblowemup movie. Some of them are already well on their way there. Take a look at the Chinese made Diana Chaser/Air Bug/Bandit/Beeman Whateveritis. It would not take much to make that look similar to a Klingon Disruptor. Use the Chaser syn stock, add a couple of 3D printed parts and away you go.

Some of these pistols only would require a new body mold for them to pop out the syfy weapon and drop existing bb/pellet mechanisms in. Just think what you could do with the Steel Storm. I just wish I could get my hands on a decent 3D printer.

Ah well. A most Blessed Thanksgiving to you all!

Design one like this, RR. 😉

Another fine example of bad gun handling. That front sight I might add looks like it was cut off of a late 60s Cadillac.

Roamin Greco,

I was thinking 1955 or 1956 Caddy!

Happy Thanksgiving,

shootski

You are probably right. I wasn’t born yet, so I was sort of guesstimate. Happy Turkey Day to you too.

Happy Thanksgiving everybody.

Happy Turkey Day to all – of course, celebrate as you like, just in moderation.

Happy Thanksgiving to everyone! Enjoy family and friends without limits, and the table stuff in moderation. (Advise to myself.)

And a belated thanks to B.B. for an excellent article – and pictures – on this fine rifle. On that topic, the only thing that I do not like much in the HW 50-S is those tabs. It seems that facilitating maintenance or repair work is very low in the designer’s priority list. Not unlike most current cars, by the way.

It would be nice if someone in the Weihrauch engineering dept. would read this blog and help us understand the compromises that are an integral part of every design. Oh well, one can wish . . . .

Henry

Wishing a blessed, happy, and awesome Thanksgiving to all!

And, I just wanted to let Chris USA know, “You are still on my daily prayer list for a complete and total healing…by doctors, by medicine, or by God’s direct intervention.”

I was catching up on my goal to read the entire blog, and I just read this timeless post that reminded me of the recent on set shooting where Alec Baldwin tragically shot and killed one person and wounded another.

/blog/2006/12/what-are-airsoft-guns-used-for-part-1/

It’s cool to read the old blogs and see what has changed and what hasn’t.

The computer must still be groggy after Thanksgiving. No new blog yet. Then again I won’t mind if Tom decides to make Thanksgiving vacation into a long weekend.

Siraniko

Well, I reckon I will just go back to bed.