This is the next report on Jordan Thompson’s VZ 35. We know him as Starboard Rower. Be sure to read parts 1 and 2.

He talked to me about his VZ 35 at the Arkansas airgun show and I asked him to write this guest blog about it. This is an air rifle we seldom hear about!

If you’d like to write a guest post for this blog, please email me at blogger@pyramydair.com.

Take it away, Starboard Rower.

VZ 35 training rifle: Part 3

The VZ 35 with bayonet.

by Jordan Thompson

This report covers:

- Basic operation

- Ammunition type

- Caliber

- Technical Requirements Evolve During 1935 Development

- Personal experience

- Velocity test #1

- Oil the Piston Seal

- Velocity test #2

- Velocity test #3|

- Final thoughts

In parts 1 and 2, we dug into the VZ 35′ s history. Today, we will begin taking a look at its performance. Let’s start with a discussion about ammunition and caliber. Then we’ll investigate the velocity of this particular specimen.

Basic operation

Recall that this rifle was the result of a military contract. The Czechoslovakian army needed a training rifle that would closely emulate the handling of its firearm cousin, the VZ 24.

The call for design proposals in 1934 prescribed ten different technical requirements for the air rifle’s design. This included bolt operation, safety operation, trigger pull weight, rifle weight, sight distances, and 4.45 mm round shot.

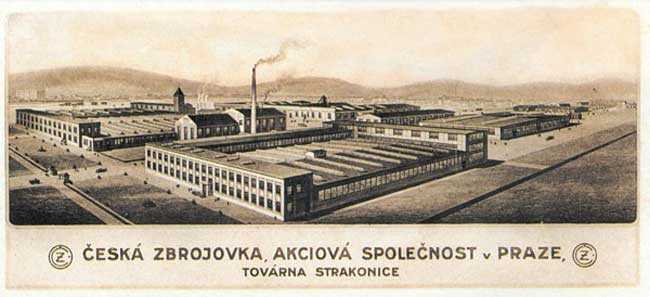

The Czech factory where the VZ 35 was made.

Ammunition type

Today, we would say that this air rifle uses round lead balls. These are not the same as BBs, though both are spherical and that leads to some confusion in terminology. Modern BB’s are typically steel and 4.4 mm (.173-inches) in diameter.

A spherical shape offers some advantages to a repeating airgun, in that it allows for more reliable feeding. In this case, the VZ 35 has a gravity-fed hopper. The round ball simply has to drop into position with each operation of the bolt. Orientation does not matter, as it would for a diabolo-shaped pellet.

Caliber

The VZ 35 is most often referred to as using 4.45 mm ammunition. We see 4.45 mm in the original 1934 Vojensky Technicky Letecky Ustav(VTLU) call for proposals referenced above. VTLU is the Military Technical and Aviation Institute. We also see 4.45 mm referenced in many secondary sources of information today. These include websites, blogs, and the rare publication.

I believe it is more accurate to say the VZ 35 uses 4.40mm ammunition. I’ll offer a few reasons.

Technical requirements evolve during 1935 development

First, technical requirements evolved during the airgun’s development. The original 1934 call for 4.45 mm rounds was almost certainly with an eye towards Sellier & Bellot’s No. 10 round ball ammunition, readily available at the time.

Field trials of the VZ 35 were conducted in Milovice during the Spring of 1935. Milovice had a large infantry school and proving ground. It was the Czechoslovak equivalent to Aberdeen, Maryland in the U.S. Sellier & Bellot initially provided 60,000 4.45 mm rounds for testing. Performance of the early pre-production airgun with this ammo was disappointing.

The Czech army wanted an air rifle with which to train.

Experiments were then conducted with different bore diameters of 4.39, 4.41, 4.44, 4.46, and 4.48 mm. They also tried smooth and rifled bores. Ultimately, a rifled bore with 12 grooves was selected.

Many more refinements were conducted in close collaboration between Frantisek Myska (designer from the Strakonice factory, and Captain Zeman Františka (representative of VTLU). These refinements were focused on improvements to accuracy, reliability, and durability. The VTLU required an endurance test of 50,000 rounds. To put that in context, it’s closest competitor in 1935, the Haenel Model 33, was rated for 17,000 rounds.

In the end, even the ammunition itself was modified. They settled on a metallurgical composition of lead alloyed with 2.5% antimony. Unfortunately, it is not clear from contemporary sources what the final ammunition/bore diameter was. However, it is accepted today that the VZ 35 uses a smaller caliber than the later VZ 47, which was 4.46 mm.

Personal experience

In my VZ 35 a 4.40 mm round simply fits better. I sourced it from JG Airguns. You can find other ammo advertised as being compatible for the VZ 35/Haenel 33 and similar inter-war airguns. But trying them, I can feel resistance when the bolt probe pushes the round into the barrel. It can get stuck in the barrel during firing. Or worse, can leave fine shavings of the ammo coating behind in the hopper.

The bolt probe at the bottom of the hopper shoves the ball into the rifled barrel.

Ammo that I have tried unsuccessfully include:

The copper-jacketed H&N Pazisions-Rundkugel 4.45 mm lead round ball.

H&N 4.45 mm Precision round balls didn’t work in my VZ 35.

New-old-stock VZ 47 Czechoslovak army surplus ammunition. This ammo is sealed in a Sellier & Bellot tape, and labeled as 4.45 mm.

VZ 47 ammo, which is 4.45 mm, also failed to work in my VZ 35.

Clearing a stuck round was a good opportunity to clean the bore. After six or seven patches, some JB Non-Embedding Bore Cleaning Compound, and a final bit of Ballistol, I knew it was clean. The bore felt smooth and consistent.

After cleaning the bore with JB Bore Paste and Ballistol, the bore felt smoother.

If my VZ 35 is typical, I’m calling it a 4.40 mm caliber airgun. Notably, The Blue Book of Airguns agrees — 4.40 mm.

Velocity test #1

When I first purchased the gun, I shot an initial test right out of the box.

I used the JG Airguns 4.40 lead round ball. These average 7.1 grains. Thirty shots total. I won’t bother showing the shot string. The average velocity was 368 f.p.s. with an extreme spread of 184 f.p.s.

I got these 4.40 mm round lead balls from JG Airguns.

The chronograph told a sad story.

Ouch! This airgun works. But that extreme spread is far too wide.

What should we make of the velocity? Well, let’s compare it to the original 1935 trials at Milovice. The VTLU called for a speed of 135 to 140 m/sec, where the spring had to endure the first 25,000 shots without the speed dropping below 125 meters per second. By comparison the Haenel 33 velocity was documented as 80 meters per second. That’s considerably slower.

Using the lowest target value of 125 meters per second, that equates to 410 f.p.s. So, my gun is shooting below spec.

Oil the Piston Seal

I suspected the leather seal on this gun was bone-dry. Externally, it appears well cared for. But it may have been decades since it was last fired. Who knows? I love the mystery of these old guns.

I oiled the seal with SAE 30W non-detergent oil, using a needle oiler. After quite a few drops I leaned the gun up against a wall, muzzle down, to soak overnight.

I oiled the leather piston seal with 30-weight non-detergent oil.

Velocity test #2

We’ll use the same JG Airguns 4.40 lead round ball at 7.1 grains. Thirty shots, again. The average this time was 423 f.p.s. with an extreme spread of 73 f.p.s.

This is better. The rifle has reacted well to oiling. I now suspect the leather seal is largely intact, or at least present in some form. After 86 years that is all I could hope for.

Velocity test #3

Three months later I tried again. Would the leather seal be better conditioned? Once more, I oiled the piston seal, overnight. Same ammo; same thirty shots. This time the average was 419 f.p.s with an extreme spread of 51 f.p.s.

We are not seeing significant improvement. I believe the oil has done its job and we will now move on to other things.

Final thoughts

The extreme spread is still just too much. The hopper seal is visibly degraded. It is now suspect number one. Before moving on to accuracy tests, I’d like to get it cleaned up and a fresh seal in place.

I am evaluating cutting my own leather ring, or perhaps sourcing a rubber one. We have seen examples of both in photos of other VZ 35s. Interestingly, rubber appears to be original.

I will also need to take care in removing that old gunk, which was probably a prior owner’s attempt at a repair. I wouldn’t be able to sleep if I marred the beautiful finish!

“Before moving on to accuracy tests, I’d like to get it cleaned up and a fresh seal in place.”

Starboard Rower,

I hope that works out well; I am looking forward to the accuracy tests. I am enjoying this series of reports on this beautiful rifle. Keep up the good work! 🙂

Blessings to you,

dave

Starboard Rower/Jordan,

Where did you drop the oil to access the piston seal? Does it go near the hopper? Wouldn’t the oil flow down the barrel if you stored it muzzle down after you placed the oil?

Siraniko

PS Section Caliber 2nd paragraph 1st sentence: “I believe it is more accurate to say the VZ 35 uses 4.40 mmammunition (mm ammunition).”

Siraniko,

Fixed, Thanks,

BB

Siranko,

Great question. There is a dedicated hole on the right side of the spring tube. It’s very small. But a needle oiler is just the right size and can be inserted here.

StarboardRower

Rower,

That’s the air intake hole I believe. I didn’t show it because I couldn’t find it referenced in the text. And yes, it can be an oil hole, too.

BB

Siranko,

The hole is positioned well behind the seal, with at least a few inches to spare. I sometimes “feel” the spring when inserting the needle.

This diagram might also be helpful to indicate relative positions of the hole and seal.

It doesn’t show the hole. But it does allow us to approximate it’s position relative to the piston head. We can safely say the hole is behind it.

With the gun leaned up against the wall, muzzle down, the oil is above the seal. Gravity does its work overnight. I put a rubber potholder beneath the muzzle, expecting that some oil would drip out. Just like you said. But each time the potholder had been dry.

StarboardRower

SR,

I was wondering what that off white stuff was in the hopper. It most definitely needs to go. You might be able to find an o ring that will work. Another possibility is a length of well-oiled leather boot lace.

There is a Webley Service MK II from the 30’s here that would really like to meet your VZ 35. She is a push over for good lookers in uniform.

P.S. If that gunk in the hopper appears to be Great Stuff or something similar, you might try getting it off with acetone. Be very careful to not let this stuff get inside.

RR,

That gunk is a mystery! Perhaps I will learn more about it. But it needs to go as part of any proper repair.

I think I will go the O-ring route for now, assuming I can find the right size. The digital calipers will be coming out. I need to start taking measurements of ID, OD, and depth (thickness). The recess seems surprisingly deep.

An oiled leather lace is a good idea, and may be a backup plan once I can’t find the O ring. 😉

StarboardRower

SR,

I too would try the o ring route as there are o rings in every size imaginable. The trouble becomes finding them. Hence the oiled leather lace.

BB,

Is there a way to search by dates? I ran across this blog:

Tuning up an older airgun

by Tom Gaylord (B.B. Pelletier) September 16, 2020

Using TIAT, you tuned up a friend’s Gamo Whisper and mounted a “new” scope on it. You made reference to testing it the next day.

RR,

As far as I know there is no way to search this blog by dates.

BB

Ridgerunner, if you find a post you’re interested in, and then want to see the next day’s post, you can click on the link that takes you there right after the text of the post and above the P.A. “related posts” section. For example, this post is 4436, and there is a back arrow that is a link to yesterday’s post. In yesterday’s post, there is a forward arrow linking to today’s post. Alternatively, you can probably search for the date all spelled out in quotes in the normal search box and see where that takes you or use an Advanced Google Search.

RidgeRunner,

Google Advanced Search will get you close. I did a search for blog entries from October 10, 2010 to October 20, 2010 and here are the results:

https://www.google.com/search?as_q=&as_epq=&as_oq=&as_eq=&as_nlo=October+10%2C+2010&as_nhi=October+20%2C+2010&lr=&cr=&as_qdr=all&as_sitesearch=https%3A%2F%2Fwww.pyramydair.com%2Fblog%2F&as_occt=any&safe=images&as_filetype=&tbs=

Once you get into Google Advanced Search put in the blog address as to where you want to search:

/blog/

In the box that says Numbers, enter your date range and hit search.

RR,

/blog/2020/09/how-to-mount-a-scope-part-1/

SR,

Great report on “the old gal”. How you researched all the various ammunition types is pretty amazing.

Thanks,

-Yogi

Thank you!

Lots of trial and error. I’ve learned a lot about wiring payments to central Europe in the process. 🙂 Not just for the ammo. But for payments to libraries for scans of books, etc. I need to tell my wife it would save a lot of trouble if I just flew over there… 😉

For other vz. 35 owners out there, save yourself the trouble. The “4.4 RB” JGA ammo is the way to go.

As an aside, I am beginning to think this gun may benefit from sorting ammo by size. But I will save that discussion for the accuracy test!

StarboardRower

Excellent report! I don’t think the hopper has, or needs, a seal. The yellowish goop around the top of the hopper looks like dried up old lithium grease. I can’t envision how a seal around the top of the hopper helps with velocity. I think the rifle likely needs a new piston seal. The only other possible place for a seal would be at the breech, but I think this rifle just relies on the steel bolt to bore fit.

Your research is just top notch. That rifle is amazing.

Derrick,

To the best of my recollection, what you say is correct. There is no seal around the loading hopper. That is dried grease which should not be there. All the hoppers I have seen have been dry.

BB

Derrick/Tom,

I believe the hopper does have a seal.

I’ll offer two reasons, though I’ll need two posts to respond. (The blog is limited to posting one image at a time.)

The hopper lids have a circular recess. I can’t see any other purpose for it. Here, we can see an “empty” recess in a another vz. 35. I do agree with Tom that there are many examples today that appear empty like this. But I believe that is due to degradation and age….

StarboardRower

Try firing it with some tissue paper over the hopper. If it puffs up you’ll know there should be a seal there

Ade,

I will do that. Thank you.

StarboardRower

StarboardRower,

I believe the seal is made of rubber and is not for pressure sealing purposes but to minimize the noise when closing the hopper lid.

Siraniko

… and here is an image of one with a seal present. We see it set in the recess in the lid.

It is not uncommon to find seals in place, though the type and condition do vary in specimens we see today. I believe some are repairs/replacements.

This is an educated guess, but I believe a dark rubber seal was original based on seeing it in multiple examples. But this is speculative on my part. I will look for another photo to share.

StarboardRower

Starboard Rower,

I have to echo the remarks of the others, great job in doing your research! Your sensible evaluation process is interesting to follow. Maybe your 85- year-old piston seal is just fine! Wouldn’t that be cool?

A correction: Under the Czech training photo, third paragraph, …lead allowed (alloyed) with 2.5% antimony.

Something I learned while working in a pewter shop: Antimony added to the Lead hardens the metal a bit but alloying soft metals with Antimony makes them better for casting. Contrary to the behavior of other metals, Antimony expands a little as it changes from liquid to solid., so the alloy fills the mold cavities better. Neat-o, huh?

Will,

Thank you for that! I have no knowledge of metallurgy. I really had no idea how alloying it with antimony helped.

StarboardRower

Very good, enjoyable report on quite an interesting air rifle; just love the history behind these and similar training arms – excellent research. Reminds FM why he is fond of his ’41-’42 Gustloff-Werke .22 rimfire trainer, which has been nicknamed “Baby K98” as it was used to familiarize trainees with the 7.92mm field-issue version. It is a “footlocker model” as the GI who came to own it cut off part of the upper stock so it would fit in his footlocker after disassembly then shipped home – fortunately the stock was restored expertly at some point.

The Czechs make quality products and it shows in the engineering of the VZ35. One of the bonuses scored by Adolf when he managed to snatch Czechoslovakia was the country’s arms industry. Some Czech tank models were superior to the ones then in use by the Wehrmacht and greatly helped to “flesh out” the Panzerdivisionen for the Polish, Western and Balkan campaigns as well as during the first 6 months of Operation Barbarossa in 1941.

FM,

That sounds like a cool trainer!

Have you seen this book? It’s an excellent resource on German pre-war trainers, most of which were .22 caliber like yours.

I just checked my copy. Is yours a KKW model (Kleinkaliberwehrsportgewehr)? If so, there is a section devoted to Gustloff-Werke produced models starting on page 274.

https://simpsonltd.com/training-rifles-of-third-reich-germany/

Highly recommend the book. It’s almost 700 pages long. Lots of photos. Includes about 35 pages dedicated to air rifles used by the Germans too. Including the vz.35. 🙂

StarboardRower

That is one to add to the home library; thank you for that reference and link! Not sure if mine is a KKW; it is a near-clone of a K98 except for the caliber and bolt/receiver. It is single-shot, no magazine and missing the cleaning rod which seems to be the case with the ones I’ve seen. The Gustloff-Werke emblem is stamped on the receiver. Funny thing, my first Pyramydair purchase was a replica K98 sling for this rifle.

As you found for your VZ35, would love to find period German .22 rimfire ammo to go with the rifle but never ran into any.

BB, this is a really nice ‘replica’ airgun. It reminds me of the Swiss trainer you have also. It would be nice if there was a co2 kit for old dinasoars like the Springfield. Now, the young men over there will need to train with RPG7’s and Stinger’s as well. A bad place to be right now,but they probably have good gas masks at least.

R

Awesome read! Can’t believe you got those original testing documents! Did you have to translate them? Your discussion of ammunition sizes was fascinating. I read the 4.45 in the original documents and other places and assumed that was it. Ironically I purchased JG 4.4 round balls for my Haenel 28R repeater and they were too small, rolled out the barrel. I have been using the H&N’s 4.45 and they have worked. Definitely have to push them in, but they cycle? What issue did you have with them? Curious? I will have to try the JG’s if they push in like you said that is the ticket. Only issue to me is I’m not sure these are as consistent as a H&N product. But I’m not going to win a target contest anyway! Lol. Thanks for your efforts. Great reading. These rifles are so incredibly well made.

Here are pics of my recently purchased VZ35, very similar to yours.

https://imgur.com/a/AzuYi3s

Here are pics of my first VZ35 I have had for a few years. It is a very late model from the serial number, no crest. The custom stock had to be contemporary and may be German as by then they were taking much of the production of the factory. They outlawed the Military CZ35 in Czechoslovakia, The fine detail of the carving is pretty amazing.

https://imgur.com/gallery/nOXMHfO

45flint,

Yes, LOTS of translating!

I use three versions of Google translate. For quick convenience, the Chrome browser has an a translate function built in. Google’s dedicated web portal (https://translate.google.com/) is another, and I tend to find it results in slightly different translations. A third method is the Google Translate phone app, that gives a live translation using your phone’s camera. This is the least reliable translation, though it is most convenient for hard-copy books.

I have a new appreciation for professional researchers!

The information on the 1935 development/testing came from a series of articles in 2005 from the now-defunct Czech “Shooting Magazine”, written by the now-curator of the Military History Institute in Prague. It’s a whole story and worth a read!

My H&N 4.45’s tried to get stuck in the barrel. Here’s the shot string, first time I tried them. Granted, I did not sort ammo and just pulled straight from the tin:

01. 223 (already not good)

02. 147

03. 77

04. 61

05. 63

06. 100

07. 36

08. DNR

09. DNR

10. DNR (…at this point I found a few stuck in the bore.)

Let me know the results you get with the H&N 4.45. If they work – great! I agree they appear much more consistent, which I assume would translate to accuracy.

Thank you for those pics. And congrats on the purchase! I have to say, I wondered when we would hear from you! 🙂 You are the other reader I know with a vz.35. I’ve seen your posts elsewhere in my research – particularly the first one you had. The new one – it’s in great condition. Looks like late production from the original Czech army orders, based on the year and serial number. Prior to German occupation.

Looks like your hopper lid has the same yellow gunk? Hmmmm…

StarboardRower

Yes the hopper has some yellow gunk I assume it glued the gasket. My sport model had a O ring fitted perfectly. I’m going leather on the military.

45flint,

Any markings on that vz. 24 bayonet?

You can usually find:

A year of acceptance on metal tang, in the handle….

Manufacturer run on the ricasso… (Unfortunately this is not very helpful.)

And often, but not always, a divisional assignment mark on the ricasso too. This is often overstamped on top of the manufacturer mark.

Mine is a 1935 acceptance in Brno, “S10” divisional assignment. There were 12 divisions in the Czechoslovak army at that time. “S10” means that it was assigned to a division whose headquarters were in Bánska Bystrica. the full list is:

S1 Prague

S2 Pilsen

S3 Litoměřice

S4 Hradec Králové

S5 Czech Budejovice

S6 Brno

S7 Olomouc

S8 Opava

S9 Bratislava

S10 Bánska Bystrica (mine)

S11 Košice

S12 Uzhhorod

StarboardRower

No marks on the Bayonet. On the the sheath. Tgf? E3 a symbol 40

So 1940 after German occupation

TGF is a German code for the manufacturer. There were hundreds of these three letter codes in use during the war. They were an attempt by Germany to conceal origins of captured arms from the Allies. Most have been reverse engineered so that we know their meaning today, although there is a small percentage that are still a mystery. Even small parts producers were assigned such codes.

TGF was for the Zbrojovka Brno plant, which means “Brno Arms Factory” or “Brno Arsenal”.

These codes are random letters and not acronymns in either German nor Czech. They are often found as stamped onto firearm receivers from the late 1930’s through the end of the war. The Germans imposed their use on occupation-production too… adding codes for “new” factories under their control.

The E3(symbol)40 is rare. I have not seen one with a 40 stamp… although I agree, if it follows convention that would be 1940 production. Can you share a pic?

Today, the vz. 24 bayonets and sheaths are almost always mismatched. It’s quite common to have a sheath from one manufacturer and year of production, and the bayonet another.

Looked under magnification and it looks like 1948! After the war? Did the continue making them? May be why the bayonet has no markings!

https://i.imgur.com/p2dPAng.jpg

Interesting! I do not know about post-war vz. 24 bayonet production. I think the Gunboards forums would be a good place to research it, however?

They did make bayonets up to 1950. The communists went back to the German TGF code.

Here is a mark on the vz.35 I can’t figure out. It is typical of other specimens however. Mine is not unique.

Does yours have this mark? Do you know anything about it?

No both mine have no markings there.

StarboardRower,

Great and high quality reporting on this historic piece!

I agree with you that the hopper lid needs some form of seal but not for any pneumatic reason. The great loading drawings show a probe (likely hollow) chambering the ball after it drops out of the hopper and sealing the hopper in the process. I rather think the lid seal is to keep the mud, dust, and sand of the training field out of the bore. The collectors wouldn’t be concerned about REAL/Training World conditions. I remember getting the Paraloft to sew up caps for my M-16 magazines to keep out the SE Asian areas nasty dust. Along with running my actions dripping with oil contrary to the US Army’s doctrine (hey! I was US Navy and an Aviator to boot; what did I know about running my guns!!!) I never had the commonly reported in country issues with Stoner’s rifle!

My aircraft always dripped oil all over the USAF Ramps too! I knew the engine(s) was low or out of oil if there wasn’t big black stain on that Inspection CLEAN Air Force Concrete… Lol!

shootski

Excellent report! I find these vintage airguns fascinating.

“I wouldn’t be able to sleep if I marred the beautiful finish!” Me neither! You probably know this, but I am reminded of a recent comment from someone who used bronze or brass wool (as opposed to steel wool) to remove some rust, because it would be less likely to scratch the remaining finish. Perhaps that would be useful to remove some of that gunk. Heat from a blow dryer may soften it too. I learned that trick from 45Bravo.

Now a question: how did you keep the JB paste from getting everywhere? And how did you mange to get it all out once you were done? I am having a hard time visualizing that with the round ball magazine in the way. My experience with cleaning airgun barrels is limited to breakbarrels, which are easy, and barrels which I removed from the gun, which also makes it easy.

Roamin,

You’re right. Clearing a jam is a little more tricky here.

I started by cocking the bolt handle, so that the rod was retracted from the hopper. That left it clear and out of the way. I did NOT return the handle back forward into battery… that would have pushed the rod forward again.

I then measured the distance from the muzzle to the hopper, so I knew about how far I needed to go with a cleaning rod. I then measured the same distance on a .177 cal. cleaning rod, and put some masking tape there to mark the spot.

I inserted the cleaning rod from the muzzle end. I pushed the jammed round back towards the hopper. Once the tape got close to the muzzle, I went REALLY slow, until the round eased itself out of the bore and back into the recess at the bottom of the hopper. I could now turn the rifle upside down to tip it out.

The JB paste was lightly applied to 1″ cleaning patches. I didn’t use much. I ran about half a dozen patches until they came out clean. Then I ran one or two patches dry. I didn’t seem to have any trouble with paste being left behind.

Then I applied some ballistol to fresh patches… maybe just 2 or 3. Once those came out clean I called it done. Maybe a dozen patches in all?

Heat from a blowdryer… thank you for that. I am hoping to do the job without bristles. Even brass feels like a risk to the finish! But you are right… if needed, they will be better than steel.

StarboardRower

Makes sense now. You did not use the JB slathered onto a bronze brush as B.B. has often recommended. You used a much lighter application, probably on a patch through a loop (not a jag). Whatever might have been left behind would be cleaned out by the first few balls fired after cleaning. Did you feel any roughness smoothing out as you cleaned the bore?

Yes. Just on a patch, through a loop.

There was no roughness at all in the bore. It felt smooth from the start. And just as smooth when I finished. No tight points or inconsistencies that I could feel.

Cleaning the bore probably had no effect on performance. It was fairly clean already. It was just a good opportunity to clean it when I had a jam, and see what condition it was in from the previous owner.

In general, I find it is not important to clean airgun bores. Firearms need it, to remove the residue left behind from combustion (and especially older guns that may use corrosive primers in old surplus ammo). But in airguns that is no issue.

While I generally agree with you, I have recently acquired a few older air pistols (only 40 or so years old, so mere babies compared to your rifle), but I have found one that just wouldn’t shoot (10 meter groups of 3″) but after removing the barrel and a though polishing (20 strokes with JB on a bronze brush) the groups shrank remarkably, to less than 1″. You could literally feel the rough spots smooth out. So I am going to give the other pistols the same treatment. I also found that this type of cleaning can accelerate the break-in period of a new airgun. You never know what crud or corrosion is lurking inside a barrel unless you borescope it or clean it.

Roamin,

I am replying here to your last response, since the blog caps threads at this “depth”.

Thank you for sharing that. I will look at bore cleaning more seriously in the future for accuracy and performance issues. Even if it’s not on this gun, your experience suggest there is improvement to be found!

Only 2 rifles that were actually accepted into the military for training that had military acceptance marks on the rifle. The VZ35 and the Anschutz Hakim. Finially have them both with the VZ35 addition. The Hakims tend to look like they have been to war, but very well made rifles.

https://i.imgur.com/cKPEW3a.jpg

Curious if anyone know the wood the stock is made of on the VZ35? Not one I’m familiar with? Ash?

I have seen two written references to the wood species.

One is a Czech blog post from 2011 that says it is “birch”. This was just one person’s comment. No reference was given.

A better source is from a 2005 Strelecky Magazin (Shooting Magazine) article, that describes the 1934 vz.35 development and trials period in significant detail. That source says technical requirements called for “elm or beech, with acceptance for small knots, for the stock and butt.” I believe this is a credible source.

I suppose a modern-day lab could sample it to confirm? That’s getting a bit serious. Even for me. 🙂

I will say that the wood and grain appear remarkably consistent across examples I have seen today. Whatever it is, I have only seen tight grain and no knots.

Just fitted a leather casket to my CZ35 loading port. See pics. Leather punch for interior hole had to cut around that for outter ring. Sanded for thickness. Pressure fit worked fine.

https://imgur.com/a/pq4oaXW

I love it! Thank you for sharing that.

Where did you get the punch?

And did your order the exact ID and OD? Or did you over/undersize either? I might need to follow your footsteps…

Interesting what caliber is this rifle? Finally got my VZ35 to my basement range. Had some H&N 4.40 lead balls and the H&N 4.45 copper coated same as you pictured. The 4.40’s shot fine but we’re rolling in the barrel. The 4.45 worked perfectly as the rod did have to push them in. Have no idea why the difference in mine and yours. My very late model Sporter also takes the 4.45. My rifle is a Brno E so different factory? Another telling test would be to Chrony the 4.45 but my Chrony doesn’t work well inside and it’s 10 degrees outside. Test for a warmer day. But these pellets were going pretty well by the sound of it.

This is good information. It sounds like our barrels might be slightly different? Yours sounds a bit closer to the original spec to me. 4.45 mm. Although I can’t say why the Blue Book of Airguns cited 4.40, more like mine, unless they had one that was “tighter” too? I’d love to hear from any others out there with a vz.35…

Or perhaps, it just comes down to manufacturing tolerance of the ammo? I have a feeling I’m going to have to sort ammo for the next test. It’s going to be time for the BBgage… it measures from 4.35 to 4.44. About right.

Some more thoughts after further observations. One thing that could be checked is a retrieved ball after firing to see the rifling marks. I did this about a year ago and the 4.45 ball had what appeared to be normal rifling marks on the ball? That said I was retrieving a semi smashed ball from my trap. One fired into water or some other non deforming medium would be best. I did notice now that my Sporter which shoots a little lighter did have some very low shots periodically which I think may have came from a tight ball? I think tolerances in this type of ammo is pretty problematic? Diablo shirts are just more forgiving? I don’t have a micrometer. Also I often wondered if some of the higher speeds recorded are due to little engagement into the rifling? I am looking forward to warmer weather so I can shoot more outside and use my Chrony. Haven’t had a chance to fire my JG balls yet that worked for you, will be telling as well. Continue to appreciate all your research and articles, great stuff.