This report covers:

- Rings are tied to scopes

- Spider silk

- Fogproof

- Centered reticle

- Einhakmontage

- Weaver bases

- The 1970s

- The ship hit the sand!

- Nowhere near finished!

Today we pick up the series on scope rings in around 1940, where Part 1 left off. Let’s now see how scope rings have progressed since then.

Rings are tied to scopes

I said in Part One that this series was not about scopes, but as I researched today’s report I saw that they cannot be separated. I will have to discuss the advancements in scopes to fully explain the advances in the rings that hold them.

Spider silk

Let’s start with spider silk. You learned that scope reticles were often made from single strands of spider silk, the stuff from which the arachnids make their webs. I mentioned spider silk in Part One but I didn’t go into detail. What I will now tell you is that spider silk is up to five times stronger than steel, on a weight-for-weight basis, but it’s not as strong as Kevlar. It’s also extremely ductile, being able to stretch up to five times its length before breaking.

I’m telling you this for several reasons. First, because of its ductility, spider silk can withstand heavy recoil, even when generated rapidly. Steel wire that’s thin enough to be a reticle wire can’t take that abuse. So, in the 1940s and later when steel started being used in scope reticles, it had to be thicker, and if it was in wire form it could only be used in scopes that went on rifles that recoiled softly. Read that as rimfire scopes.

Fogproof

In the late 1930s the Lyman Alaskan scope was available. But it wasn’t sealed against moisture and fogged heavily in the field.

The most popular US sniper scope in the war was the Winchester A5. It had a 3/4-inch tube and used the externally adjustable scope mounts I showed in Part One to adjust for windage and elevation.

This Springfield M1903 rifle is mounted with a Winchester A5 sniper scope. Note that the rear scope mount is externally adjustable.

In World War II (1939-1945) Weaver made their 3-30 scope that was water-resistant and fogproof. To fogproof it Weaver sealed the lenses and filled the scope with nitrogen.

Weaver 3-30. Note that it has internally adjustable windage and elevation. These are all-steel scopes that are still being rebuilt for use today.

The 3-30 had a 3/4-inch scope tube and its rings were attached to the rifle by drilling and tapping holes. The Germans had Zeiss scopes of similar quality but they were unaffordable for most US hunters and, with a war on, they were unattainable.

The U.S. Army bought 36,000 Weaver 3-30s for use on sniper rifles. They were rugged and held up well under battlefield conditions. But they used a single metal post that moved up and down as elevation was adjusted. No crosshairs in this one!

After the war Weaver used the lessons learned during the war to innovate the Weaver K-series scopes. In 1947 the K4 with a one-inch steel tube came to market. This meant that scope rings had to be made for the larger tube. But scope rings were still attached to rifles by drilling and tapping mounting holes, which is why you see so many vintage rifles with such holes.

Centered reticle

It wasn’t until 1956 that the first centered reticle came out — again by Weaver. I used to own a German Nickl scope that cost $1,500 in the mid 1950s and its reticle moved up and down as elevation was adjusted. My Soviet scope that was made for an AKM has a reticle that does the same thing.

1950s KV series first affordable variable scopes early scopes had 2 settings. You switched from one to the other — either or. In the 1960s KV scopes became infinitely variable.

In 1956 Weaver fielded a scope that had a constantly centered reticle and was nitrogen filled. By the ’60s hunters started trusting scopes over iron sights.

Einhakmontage

This is a series about scope rings and it wouldn’t be complete without a mention of the German Einhakmotage. That’s a one-hook mount to the rest of us. What is it?

The German one-hook scope mount they call an Einhakmontage. Yeah, at the cost they command you aren’t likely to see one on an airgun.

The front mount is held by a sliding spring-loaded plate located in the base that pushes against two angled hook feet on the bottom of the ring that pass into vertical slots in the mount base. Push small buttons on both sides of the scope base to the rear and the front ring lifts out of its base. Swing the scope to the side and the rear ring detaches from its base. This mount allows the removal and replacement of the scope in seconds and it theoretically returns to zero every time. I had one on that Nickl scope I mentioned above and at 100 yards the impact of the .30-06 bullet only moved by about an inch when the scope was taken off and remounted.

Such a scope mount costs $600 to $1,000 today, and that’s just the mount. Mine had the lower half of the front ring soldered to the bottom of the objective tube (the upper ring half wasn’t there), which meant disassembling the scope to do the work. That can easily double the cost. And this expensive scope did not have a reticle that stayed centered. They didn’t come to scopes until the 1960s. Having said that, I mean that they didn’t come to scopes that were adjusted internally. Obviously the externally adjusted scopes always had them.

Weaver bases

I’m mentioning Weaver bases here because I don’t want you to think I have forgotten them. They are an important development, but they will be discussed in the next report.

The 1970s

In the ’70s the Japanese gained dominance of the rifle scope marketplace and brands like Weaver and Lyman faded. They would disappear from the scope world in the 1980s.

Once the Japanese gained control of the market they standardized things and the one-inch scope tube became common. Three-quarter-inch tubes were considered toy scopes fit only for .22 rimfires. Airguns didn’t mount scopes at all. But by the end of that decade, they did. Air Rifle Headquarters and the Beeman Precision Arms company both offered scoped air rifles.

The ship hit the sand!

And that’s when the boat rammed into the sandbar. Because remember what I said about scopes being mounted to rifles by drilling and tapping scope ring screw holes? The Japanese wanted things to move faster, so more scopes could be sold. Few rifle owners wanted to pay a gunsmith to mount their scope, so rifle manufacturers began making scope rings that fit their rifles. And of course they were all proprietary, so Sako rings wouldn’t fit on a Remington and vice versa. And we still have some of that going on today.

But that wasn’t the ship that hit the sandbar. That ship was the fact that nearly all firearm rifles shoot low! Yes, they do. And, because of that, they need scope mounts (rings) that have some rear elevation to get them up on target. When gunsmiths were mounting scope rings by hand they were taking care of this in the job they did. They lapped the rings after mounting them so they put the scope on target at a specified distance that was usually 100 yards.

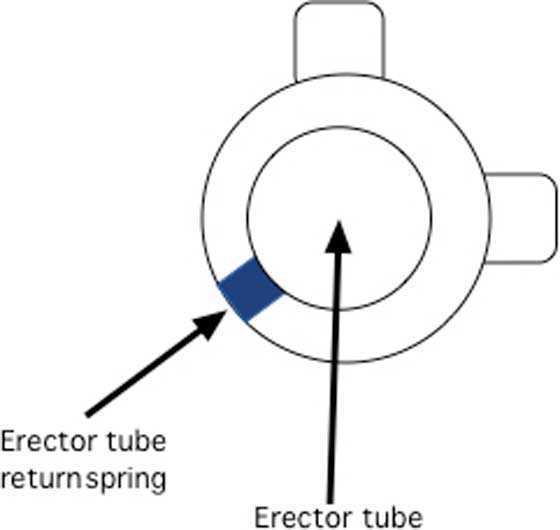

The worst firearms with a down angle are the AR-15 platforms that actually have scope rings that produce X number of minutes of down angle. They sell them for long-range shooting, but most ARs need them to keep the scope in adjustment at 100 yards. Without them the scope either has to be shimmed in the rear or it gets adjusted so high that the erector tube return spring relaxes too much and the scope won’t hold zero. Shooters blame the scope when it’s the rings that are at fault. I will say that premium scopes can be adjusted higher than cheaper scopes, so the cheap scopes get the rap for not doing the job when all along it’s the rings.

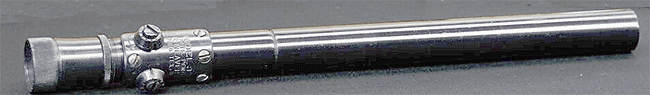

The erector tube sits inside the scope tube and is adjusted just like the externally adjustable scopes you have seen.

The erector tube spring pushes against both the vertical and horizontal scope adjustments. If it relaxes too much the erector tube will bounce around and the scope won’t hold zero.

And, if all of this is true for firearms, guess what? We airgunners call it scope droop. We have a name for it because it is so common! And we understand it much better than firearm shooters because everything we do is done up close to the muzzle.

Nowhere near finished!

I’m done with today’s report, but there is so much more we need to cover:

- Etched reticles

- Illuminated reticles

- Ring height

- Eye relief and rear scope ring placement

- Scope clearance for rifle operation

- Exit pupil size

- Parallax adjustment

And there is probably even more. Remember — this report is still about scope rings. But the design of the scope drives a lot of it.

BB,

You sure opened Pandora’s box with the report on scope rings.

Siraniko

Siraniko,

That’s true, for sure! But I am learning a lot, historically, from this set of reports, so I hope B.B. keeps on rolling with what he started…even if it means he has to write an avalanche of reports. 🙂

Blessings to you,

dave

B.B.

No Pandora’s Box. Just great info and interesting pictures.

-Y

PS you don’t know where you are going if you don’t know where you have been.

I have some friend’s who say that Japanese WW2 submariner’s binoculars are some of the best glass ever made.

They use them, on a tripod, to look at the heavens.

-Y

Yogi,

No “Reply” below so I’llanswerhere…

The distance from the rifle to the mirror should be at least half the minimum focus distance of the scope. So for most scopes that’s 5 meters or about 15 feet.

Hank

The german ‘Haken’ is indeed a hook, ‘einhaken’ = to hook on, but ‘hacken’ means to chop, do you ‘c’ the subtle difference? 🙂

BB,

I can confirm what HiHiHi said. It should be “Einhakmontage”.

Great series, by the way. The spider silk thing is crazy 🙂

Stephan

Guys,

I just saw this. Mea cupla! Yes, Hi3 I C the difference.

BB

BB

This one is shaping up to be one of the best report series you have ever done. I am enjoying getting educated. I’m a history nut too which explains my enthusiasm. As Yogi reminded us we don’t know where we are going if we don’t know where we’ve been.

Like some other readers I have many rings, adaptors and risers which are essential to my optic switching habit.

Deck

Deck,

Oh, I know the feeling! 😉

BB

>>> Like some other readers I have many rings, adaptors and risers which are essential to my optic switching habit. <<<

Deck,

I can relate, I play "musical scopes" often enough that I made a "portable plumb-line" for leveling the cross hairs 🙂

Having canted cross hairs just erkes me in the worst way – must be an OCD thing! LOL!

Hank

Hank

Now that has to be the handsomest plumb-line ever created. It actually is a work of art. I can just imagine it being in a museum with no information and people guessing what it is. Sun solstice instrument? Ship navigation device? Putting slope reader? Is the dial a bubble level, a magnetic pole reader or a wind gage?

I think I must need one.

Deck

Deck,

A museum piece? Just some scrapes cobbled together. LOL!

I was thinking I might write a guest blog about it but then who needs another article on how to level a scope eh?

The portable plumb-line is a convenient reference – works well. BTW, if you are going to make one, the three nuts are the “knobs” on the leveling legs for the base.

Hank

Yes, a guest blog would be great. You set the mirror how far away?

-Y

Deck, you said it, man! After seeing this work of art by Hank, I feel like a real cheeseball for using the rod that closes the blinds to level my scope cross hairs; since the rod is on a swivel and hangs vertically it works, but it’s hardly elegant! 😉

Dave,

I set up the plumb-bob right infront of the muzzle and use a mirror set 20 feet away so I can look through the scope and align the bore of the (leveled) rifle to the vertical cross hair to get everything trued up. Setting the parallax (focus) to see the plumb-bob and muzzle at the same time makes alignment easy.

Works well for me.

Hank

Hank,

Between this pic of your rig, and what you wrote to Deck and me, I can cobble together a “Hank Special” for my next scope mounting adventure; thank you! 🙂

Cheers,

dave

Timely topic for FM; got done zeroing in the Whisky3 on the .22 Ben Max yesterday; getting 1/2″ groups at 25 yards with Crosman Premier HP 14.3 grain pellets – amigos, this is very good shooting for FM and he is satisfied. Sadly after a dozen shots, the rifle lost power so that pellets could be seen in flight and hitting about 4″ below the outer bullring…PSI still at 1750 or so and no obvious leaks. Time to troubleshoot and maybe even learn something.

FM,

By Ben MAX I’m presuming you are talking about the Benjamin Maximus.

They aren’t regulated so it may be (well) off the power curve and the guage is telling you an untruth (could be stuck). Give the guage a light tap to see if it is mobile and try refilling the reservoir to see to the velocity drop is fixed.

The second thing I would check is to see if you have lost the o-ring (that seals the breech) off of the pellet probe. I lubricate that o-ring with a bit of silicone grease (regularly) make a point of leaving the bolt open when not using the rifle – keeps it happy and healthy.

Could be that the o-ring just may not be sealing well anymore – put a piece of tissue over the breech area and test fire a pellet to check for a leak. It the tissue blows away you need to replace that o-ring.

Hope this helps.

Hank

Thank you and shootski for these tips and suggestions; will work down the list as needed. Funny, first thing that FM’s Fawlty mind thought of could be wrong was the o-ring for the pellet probe. Examined it under a magnifier and a light, seemed ok though appearances can be deceiving; also considered the silicone grease and will definitely apply some. Per your suggestion will leave the probe out of the breech from now on.

Yesterday did FM’s Two Can-Side test; no chrony here yet so took a steel can and shot into it from 25 yards; the pellet hit at the POA and went thru both sides with authority – seems Maximus healed overnight. Nevertheless will further troubleshoot as needed.

Again, this novice appreciates all the help from the veterans. FM WILL save these tips which were nowhere else to be found.

FawltyManual,

Hank has covered most of the things to check first well.

If none of them prove to fix the problem

I’ll add a few things to check that don’t happen that often.

Is the hammer (Striker) hanging up on the sear, tube or are you getting a halfcock?

Have you lubricated the hammer?

Is the hammer spring broken?

Is the valve stem damaged in any way?

Is the transfer port obstructed?

shootski

I wonder how the externally adjustable scopes went, and silently re-entered the market as the bases for ELCAN type scopes.

The international scope adjustments need to operate in significantly smaller tolerances. Plus, they shift the lenses out of proper alignment.

Hi Folks,

It seems that Pyramyd AIR has picked up some targets that go bang, check them out here /product/firebird-65-bio-target-10pk?a=12026

Kinda cool item.

Mike

BB, the AR180 had a tapered base and socket for a QD scope or scope mount. The base slides into the tapered base and a spring loaded pin fits into a socket.

I enjoyed the post.

David Enoch