FWB 127. It’s the same rifle as the 124 only in .22 caliber.

This report covers:

- Start

- Barrel

- Clean all parts

- Remove all burrs

- Replace the breech seal

- Assemble the rifle and lubricate the parts|

- Lube the piston

- Piston seal is perfectly sized

- Install the barrel

- Mainspring compressor

- Two concerns

- The bolt

- Restock the rifle

- The results

- Trigger pull

- Bottom line

Today I overhaul the FWB 127 and then see what kind of job I’ve done. I’ll show you the interesting stuff. Let’s get started.

Start

From the disassembly we did in Part 3 we learned that this rifle needed a new breech seal and a new mainspring. The breech seal was old and hardened flat and the mainspring wasn’t a standard FWB spring.

I discovered the new factory mainspring is longer than the one that was in the rifle when I got it. It’s also wider and fits inside the piston with very little clearance, so thick grease isn’t needed to stop the twang.

The new factory mainspring (bottom) is much longer than the spring that was in the rifle. It’s also wider.

I’m sorry but I didn’t measure the thickness of the wire in the new spring. It does have 40 coils, which is an increase of 13 over the aftermarket spring.

Barrel

You will recall that the 127’s barrel was leaded. The first job was to clean it, which only took a few minutes. I used a brass brush with some JB Non-Embedding Bore Cleaning Compound. Following that about 5 patches went through the bore with rifle bore cleaning solution on the first one. After that the bore looked clean again.

Clean all parts

After the barrel I cleaned all the other parts of the powerplant. That took some time because the black tar grease that was used by the airgunsmith who tuned the rifle last time was difficult to remove. It took a lot of cotton swabs and patience. The inside of the piston took the longest because several areas are hard to reach.

Remove all burrs

Once the parts were clean it was time to remove all the burrs. This is where I caught a break. The airgunsmith who tuned the rifle last time had done a marvelous job of smoothing all the metal surfaces and removing all the burrs. He did it better than I usually do. That job can take hours, depending on the rifle, so not having to do it really saved me time.

Replace the breech seal

I don’t know if you remember but in the last report I said I thought this rifle had been last tuned about 20 or more years ago. When I removed the old breech seal this became obvious, as the old seal was so hard that it cracked when I pried it out.

When I pried the old breech seal out of its slot it cracked in two places.

The new seal pressed right into the groove left by the old seal. That step, alone, probably restored a lot of velocity.

Assemble the rifle and lubricate the parts

Now it was time to put everything together and lubricate all the parts as I went. I used two lubes — moly grease and Tune in a Tube (TIAT).

Using a cotton swab lubricate the inside of the piston body and the piston rod. Then lightly — and I do mean lightly, lubricate the outside of the new mainspring. Then shove it into the piston body and insert the piston back into the spring tube.

Lube the first half of the mainspring with TIAT lightly, then insert it into the piston body. The TIAT grease that’s on the piston rod will take care of lubing the inside of the spring.

Lube the piston

Now I lubed the outside of the piston, prior to sliding it back into the spring tube. I used moly grease for this.

I lubed the piston seal, the front and rear of the piston body and every place where metal rubs on metal.

Piston seal is perfectly sized

When I put the piston back inside the spring tube I saw that it had been sized perfectly to fit the tube. The last owner of this rifle thought the seal was too tight and that was robbing power, but I couldn’t have sized it better. It slid in smoothly with no resistance, yet it was still tight in the tube.

The piston slid into the spring tube easily. The piston seal is sized perfectly!

With the piston now inside the spring tube it was possible to lube the back half of the mainspring with TIAT and not get anything that stuck outside the the spring tube greasy. You just place the spring tube so the spring that’s still outside doesn’t touch anything.

Install the barrel

At this point the barrel goes back on the rifle. That needs to happen so the cocking link can be connected to the piston. There is a fitted washer on the right side of the base block that holds the barrel. Put moly grease on it and the grease holds it in the place it fits in the base block.

Put moly grease on the fitted washer and on the place it fits. That will hold it in place as the base block slides into the action fork. Lube the other side of the base block as well and also the pivot hole that runs through the base block.

The cocking “shoe” that connects the cocking link to the piston goes on the end of the cocking link and fits through the widened slot and the rear of the cocking slot. I lube it with moly grease on all points of contact.

It doesn’t fit easily through the widened hole in the spring tube. That’s so it won’t pop out of the spring tube as the gun is used. Turn it slightly sideways to slip it through the slot.

Now (and ONLY now — after the cocking link is connected to the piston) you slide the base block into the action forks and align the pivot hole. I grease the pivot bolt and slide it through the pivot hole, then tighten it with a screwdriver. After it is so tight that the barrel remains in place when placed anywhere in its arc, the small screw goes into the open end of the pivot bolt. Do not tighten this screw too much. The pivot bolt is what is tightened to hold tension on the base block.

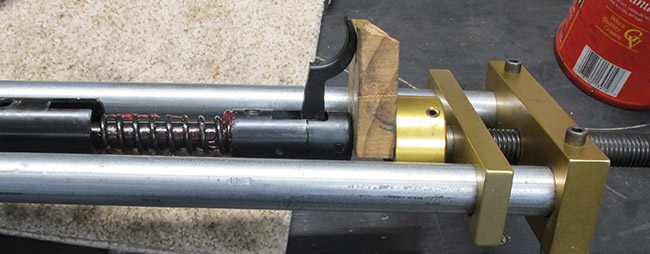

Mainspring compressor

Now the barreled action is installed in the mainspring compressor and the trigger assembly that has the rear spring guide is placed in the other end of the mainspring.

The trigger assembly with the rear spring guide is put into the mainspring and the barreled action is installed in the mainspring compressor.

Two concerns

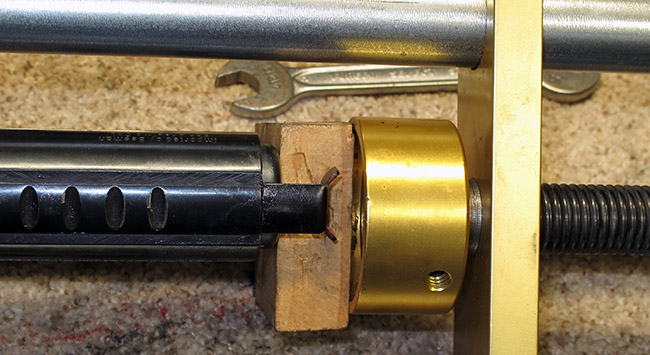

I said in Part 3 that the FWB 124/127 is on the easier side of spring-piston rifles to work on. But there are two concerns with this model during assembly. The first is when the sliding safety is installed. That happens as the trigger assembly is pushed into the spring tube. But the timing of it is critical, as is what you do as the compressor is sliding the trigger assembly into the tube. Let me show you. The next two pictures are from a 124, but the parts are identical.

A small coiled spring fits in the trigger assembly under the safety.

The sliding saefty bar fits over the trigger assembly and on the small spring like this.

Here the sliding safety has popped out of place as the compressor pushes the 127’s trigger assembly back into the spring tube. The small coiled spring is bent out of place when it looks like this. The trigger assembly must be backed out of the spring tube so the safety spring can be installed correctly and the safety slid back into the spring tube correctly.

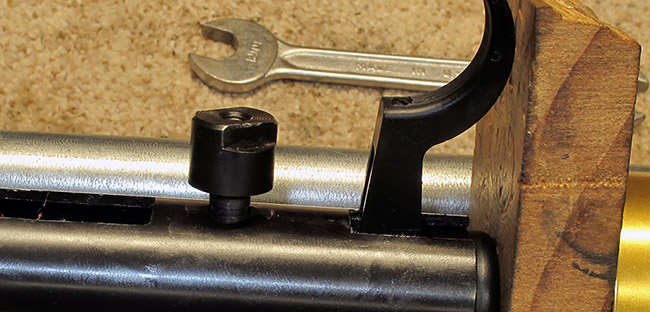

The bolt

When the trigger assembly is in the spring tube and aligned correctly, the bolt that holds it is installed. This is the second concern when assembling a 124/127. The bolt is hardened steel, but the threaded bolt hole in the body of the trigger assembly is aluminum (aluminium in the UK). It is super easy to cross-thread that bolt! You must be extra careful to align the bolt so it doesn’t cross-thread, and taking extreme care at this point is the only way I know to do it. I took a full ten minutes adjusting things just right so I wouldn’t cross-thread the bolt.

Take great care not to cross-thread this bolt.

Restock the rifle

Now that the action is together it can be put back into the stock. Once in you can cock the rifle, load a pellet and fire it. I did and the job was finished.

The results

The rifle came to me cocking with less than 20 pounds. I said in Part 3 that I thought a factory spring would put it at 24-28 pounds, though in the past I remember 124s cocking at around 20-21 pounds. They have a reputation for cocking with little force.

After my overhaul the 127 now cocks with 21 pounds of effort. I shot it and it is completely free from vibration. Now let’s see where it is for velocity. Remember — I said expected around 15 foot-pounds of muzzle energy.

Air Arms Falcons averaged 584 f.p.s. before with a 17 f.p.s. spread. They generated 10.17 foot pounds at that time. Now they average 613 f.p.s with a 15 f.p.s spread. That a 29 f.p.s. increase with a spread that’s almost the same. The energy is now 11.21 foot pounds — less than a 124 would have. This surprised me greatly.

H&N Baracuda 15s averaged 494 f.p.s. before with a 19 f.p.s. spread. They generated 8.61 foot-pounds Now they average 527 with a 25 f.p.s spread and generate 9.8 foot pounds. A slight increase of 33 f.p.s. with a slight decrease in consistency.

JTS 18.1-grain domes averaged 394 f.p.s. before the overhaul with a 29 f.p.s. spread and an energy of 6.24 foot pounds. Now they average 439 f.p.s. with a spread of 18 f.p.s. That’s a gain of 45 f.p.s. and a spread decrease of 11 f.p.s. The muzzle energy is now 7.75 foot pounds.

So I was way off on my power gain estimates. It may just be that the FWB powerplant is sized optimally for a .177 and .22-caliber is just too large. I wish I knew whether that is correct but so little has ever been written about the 127 that I have no idea.

Trigger pull

I did adjust the trigger ever-so-slightly and now I have an extremely positive second stage. The pull is now 1.4 pounds for stage one (was 1 pound 5 ounces before) and 2 pounds 5 ounces (was 2 pounds 6 ounces) for stage two. I’m not adjusting it again because stage two is now so positive.

Bottom line

The bottom line is the overhaul didn’t advance performance nearly as much as I expected. Perhaps only the breech seal needed replacing? But then again, I have zero experience with an FWB 127. The good news is I have now been inside and we know what we are dealing with.

Accuracy testing will come next.

Tom,

expect dramatic rise

If that photo at the Section Mainspring Compressor is with the spring fully inserted without compression, does that mean this rifle now has about 2 and half inches of preload? I would not expect dramatic rise in velocity shifting from .177 to .22 caliber using the same powerplant. Although I don’t recall you writing about the Whiscombe when you changed the caliber how the velocity faired. I cannot imagine a .22 would jump in velocity using the same powerplant that propels a .177 caliber handily into the transonics.

Good documentation is very hard to find. This blog is a treasure trove of documentation.

Siraniko

Siraniko,

That wood block would not have remained in place without some spring tension . So about three inches of preload.

BB

“It may just be that the FWB powerplant is sized optimally for a .177 and .22-caliber is just too large.”

BB,

Yes, it may well be just as you predicted in Part 4 of your report on the Haenel model 1:

“The Haenel Model 1 is a nice old vintage springer that would be okay in .177 but is maybe too underpowered for the .22-caliber it’s in.”

My two Haenel model 1s from Frank bear this out; the .177-caliber one spits out RSB RS 7.33-grain pellets at 560 fps for 5 fpe; but the .22-caliber version only produces 385 fps with RSB RS 13.43-grain pellets for less power than its sibling at just 4.4 fpe.

The .177 is a better penetrator on steel cans, but the slower .22 pellets really send those cans flying!

They’re both pretty accurate little plinkers, but the .22 seems to be easier to hit with, even though it has a slightly heavier trigger (that could be due to the difference in sights; the ones on the .22 are a bit easier on my eyes; they’re identical to the ones on your rifle).

In the case of your FWB 127, even though she’s not a screamer, if she’s accurate, she’ll have enough power for most needs; and if that lower power allows her to shoot more smoothly, all the better. 🙂

Blessings to you,

dave

Dave,

Thanks for what you said. I forgot the Haenels but now that you mentioned them I do remember saying that.

BB

BB, no one could possibly remember all the wisdom you’ve imparted over the years!

Thanks be to God, we have it all written down for us! 😉

BB, IMHO for accuracy this would be a great candidate for RWS Meisterkugeln Standard .22 Cal, 14.0 Grains, Wadcutter.

SSC,

I’ll try to include a .22 Meister — if I can find one in my stash!

BB

Why??

Wadcutters loose all their ballistic stability at around 30 yards. Yes for 10M work, great. Not for any distance shooting, IMHO.

-Y

You are correct Sir. IMHO the rifle in question is not designed for beyond thirty yards . The wadcutter shuttlecock design shines at lower speeds in terms of accuracy. I rarely shoot wadcutters beyond 20 yards but love the groups they make at that distance with my tamer air rifles.

B.B.

Great report! Very well documented.

Just eye balling the two springs, it seems that the wire diameter is about the same?

Very surprised that it did not pick-up more velocity. I have heard some people compare the FWB with the HW 80. You have shown that that is a false comparison.

-Yogi

Yogi,

Yes, I do think the wire diameters are very close. And I also think the factory spring is scragging inside the rifle right now — at least just a little.

BB

B.B. Pelletier is at it again:

Highly informative report, dozen super pictures and what a surprising result = another wonderful blog ! 🙂

————

I wonder whether it was to maintain easy cocking that they decided on a thin but loong wire coil and whether this would’ve performed differently with a less sticky lubricant?

3hi,

As I have pointed out below, the .22 is/was not very common in Europe, or the USA for that matter. As has been pointed out by others, the powerplant was likely optimized for .177. FWB made/makes some very fine air rifles. Almost all of them are .177 though. This particular sproinger is indeed a rarity.

You should also keep in mind that this sproinger was made in a country that has very strict power level restrictions.

My personal experience with TIAT is that is if used sparingly as BB has done, it will not really slow things down.

RidgeRunner,

thanks for your interesting comment, which makes my airgun collection an unusual one as it reflects more my preferences than this continent. 🙂

————

By the way, because the expression “sproinger” seems to be one of your favourites, I am going to ask what I have been meaning to for some time: is ‘sproinger’ a portmanteau, or a merging, of the noun ‘springer’ and the onomatopoeia ‘boing’?

If, as I suspect, this is the case then, would a ‘sproinger’ be preferable to a ‘spranger’? 🙂

No I think RR has marbles in his mouth when he says SPRINGER and that is how it sounds to him.

FWIW- RR- Speech therapists can correct your impediment.

-Y

MRMRMRRRMMM. PFFFT! Clatter, clatter, clatter. What speech impediment?

Check out the illustrations of this air rifle.

https://www.pyramydair.com/product/benjamin-trail-np-xl-air-rifle?m=2052

It was you who gave us the invasive cardboard stock! I think I will just go back to shooting my feral soda cans with one of my sproingers.

hihihi,

I have always considered it onomatopoeic, cleverly imitating the twang of poorly fitted springs in spring airguns. Think of a Warner Brothers cartoon in which an anthropomorphized coyote is struck in the head by an anvil, and we hear a “boing” sound effect.

Michael

Michael,

silly me, of course! You see, instead of an ACME anvil, I had imagined Zebedee from The Magic Roundabout.

Anyway, remembering Mr S. Jackson’s words about donkeys, or asses, in The Long Kiss Goodnight, I thought it prudent to seek confirmation… 🙂

Close.

Check out the illustrations of this air rifle.

https://www.pyramydair.com/product/benjamin-trail-np-xl-air-rifle?m=2052

3hi,

If you happen to look through the pictures of this nitro piston air rifle, you will find a “cartoon” illustrating where I acquired this term.

https://www.pyramydair.com/product/benjamin-trail-np-xl-air-rifle?m=2052

RidgeRunner,

WOW, what a surprising answer – thanks !

——

I learned a lot:

I kinda expected ‘sproinger’ to mean a poorly tuned ‘springer’, not that ‘sproing’ is literally meant to be the sound of a generic coiled-spring hunting airgun being shot.

I also thought it to be your personal invention, not something straight from a cartoon.

Though they likely exist, I actually know of no other springer airgun specific cartoons.

Finally, I would have lost the bet that says pyramydair pictures cartoons to educate their visitors and to promote gas-spring airguns for hunting. 🙂

LOL! I may be insane, but there is still a method to my madness.

BB,

LOL! As I am sure you are aware, I personally see nothing wrong with the power level of this sproinger. This is likely the reason that you do not see very many of this model though. As has been stated, the powerplant may very well be optimized for the .177. This particular caliber was never really very popular in Europe.

P.S.: Air Arms Falcons averaged 584 f.p.s. before with a 17 f.p.s. spread. They generated 10.17 foot pounds at tyhat (that) time.

RR,

Thanks. Fat fingers. 😉

BB

Thanks for another well done report. I am looking forward to the accuracy tests!

I apologize for going way off subject here, but I just cannot help myself.

I just read the HAM review of the new Crosman 3622. I am impressed. You can most definitely see the “old” Crosman influence in this PCP.

If you are a fan of the Discovery / Maximus (I sure do wish they would bring these back) you will be ecstatic about this little carbine.

FM, I hope you are paying attention.

Yes indeed, FM is paying attention; already thought that when it becomes available, hope there is an option to order one with a steel breech. Like the basic/simple characteristics of this airgun – enough there to get the job done and you can’t beat the price. This is sort of a “VW Beetle” of airguns.

A couple of days ago engaged in a bit of can-killing with the .177 red-dot sighted Max and was reminded how much fun these “Maxes” are to shoot.

Great article today BB; glad it is you tearing into this nice FWB and not FM.

FM,

I doubt very seriously it will be offered with the steel breech, but that will be very easy to install yourself. I installed a steel breech on the 2240 I have. Personally, I do not think I would bother. I would recommend using it “as is”, most especially as you have more than one Max.

Yep, see the point – once you start piling up on the extras and mods, you might want to graduate to a little higher-priced PCP that gives you even more bang for the buck. There is a good 362/3362 steel breech installation tutorial on another company’s website which seems pretty useful.

Plenty of air-tillery to play with around here in any case.

B.B.,

I agree with RidgeRunner that the 127 was probably less popular than the 124 because of the lesser power.

And I must second hihihi’s compliment on your photos. They are excellent. A quick look at your photos from 12 years ago shows a remarkable improvement today.

Elmer Fudd is not alone in eagerly anticipating the accuracy results now that the bore is clean.

For my money the Feinwerkbau 124/127 is the zenith of breakbarrel springers. Mine is essentially perfect, even superior to my Air Arms TX200 as it is so much lighter.

Michael

Michael,

I kinda gotta agree with you on the weight issue. This 127 and my 124 both seem perfect!

BB

B.B. thanks for this report. It is fascinating how this powerplant is so anemic when it comes to .22. I was thinking about Predator GTO domes, which are alloy pellets. I was also wondering if the transfer port is bigger than the .22 version, and would a bigger transfer port help. Would that be an excuse to bring out your Whiscomb with the interchangeable barrels and transfer ports? Finally, with other anemic springers, sometimes deep seating helps give the pellets a head start.

Over the weekend, someone posted a picture of using blocks of snow as targets. That’s clever. Speaking of fun targets, I was in WallyWorld yesterday and realized….

It is open season on Peeps!

There is an unwritten rule somewhere which requires you to use a peep sight when shooting Peeps, RG.

Peeps for Peeps. I like that.

B.B.,

Regarding your velocity numbers……you have a very low serial number (8390). Almost all early (under 10K serial number) FWB 124’s AND FWB 127’s had issues of out of round compression tubes, not well sealed compression tubes, etc. according to Paul Watts and Jim Maccari.

Here is JM’s response to a guy that installed JM’s new (at that time) Super Grade Spring in his FWB 127 and was averaging 578 FPS with the H & N FTT (14.66 gr) and was concerned that the power was low:

“Its too hard to answer that because the spring isn’t the biggest influence on power.

the .177 124 was factory rated when new at 760-770 fps with an 8 gr pellet.

I have seen FWB 127’s with a 14.3 gr do in these numbers 540-560-580-620 fps

Old guns have out around tubes and smaller breech seals- slower.

I have seen perfectly tuned specimens in the 40K SN range do 740 fps in .22 with that spring.

A guess would be 640-680 if its not under 10K SN

Elevation alone adds to it plus barrel tightness and so on.”

JM

Kevin,

Thank you. I remember Jim saying that.

BB

Kevin and B.B.,

Now I need to check the serial number on my FWB 124. It is an early one as it has the earliest address, the Beeman home (San Anselmo), for the retailer. It has an aluminum trigger, but I assume it originally came with a plastic one that the original owner replaced with the complimentary aluminum (or aluminium) one.

I have never chronied it. I will report back with the serial number.

Michael

Kevin and B.B.,

My 124 has a 112XX serial number. I will chrony it and post the results. I am certain it has been tuned, however. It shoots silky smooth.

Michael

Is that what a “parachute” seal is supposed to remedy?

Well B.B.

Sounds like it is time to take out the Sunnen hone and ensure that the comp tube is really really round.

Or send it to somebody who can…

You did say the the piston slipped in pretty easily. Maybe too easily?

Does ARH stock oversized piston seals for the FWB piston head?

-Yogi

Take what Kevin says to the bank. JM has told me essentially the same thing in response to questions concerning significant issues with many earlier tubes, particularly in the sub-6000 range. (For that reason I’ve always tried to stay above S# 8000 when purchasing 124’s, though I learned never to turn up my nose at a plastic trigger model. Properly adjusted, they can be every bit as excellent as a good alloy trigger model. It’s not like they wear out.)

Plus, I have a somewhat later FWB 127 S# 530XX that was tuned with, I believe, the same spring referred to above that whomps out JSB Exact 14.3’s at a consistent 700-705fps at 900ft elevation for 15.5fp. Yeah, I didn’t think that was possible either until I bought this gun from a well-known air gunner who brought the action only back from England in his checked luggage many years ago (because he couldn’t find one here in the US) and built it back up with one of JM’s custom Tyrolean stocks way back when he was still selling them. He told me it liked that pellet and ran at that level, so I ordered a couple of tins from Pyramyd along with other pellets, and when the 127 arrived, it chrono’d out right where he said it would. It’s somewhat heavier to cock (though still nothing like a Diana 34 or an R9) and it fires with more authority than a 124 with JM’s regular full power kit, but it’s not harsh. I need to measure its cocking force on some good scales sometime.

BB, you said, ” I wish I knew whether that is correct but so little has ever been written about the 127 that I have no idea.” I have read in the past that FWB 124 is best in .177 cal. The 127 works but not as well in .22 cal.

Mike

BB

I’m backing off on my request for some sort of short cut to reach maximum accuracy with a springer. The feedback so far indicates there is none. But there is a lot to do to get there and putting things in some sort of order would help.

Like spending time plinking and informal target shooting with various ammo using different holds and shooting positions to not only break in the airguns mechanicals but get to know the airguns likes and dislikes.

For instance, my first, somewhat powerful, QB25 could not hit anything with consistency. Kind of like the BB guns of my youth. Sometimes I hit what I aimed at sometimes not. Just figured I was not a sharpshooter and only lots of practice would get me there.

Never considered looking for a grouping to see if the airgun was at fault and there was not a large selection of ammo to choose from to notice any improvement. And who would make a gun that did not shoot straight? Ridiculous, it had to be me.

So I got more airguns to see if things worked out better. I now had a need for pest control. Then I found BB’s Blog !

“Check for lose stock mounting screws” The QB 25 improved significantly but I still was into hit and miss and now I know most of the reasons why. A springers accuracy is affected by a ton of things and only experience, lots of practice and trial and error, with each airgun will sort them out.

No short cut, but a list of things, steps to follow, to achieve maximum accuracy with one would help.

That QB 25 sat for years as almost useless for failure to check one thing.

All the information on getting the most out of your air gun is here in this blog, someplace. Skipping a required step, like those stock screws, may result in an unpleasant airgun shooting experience and end it there.

A check list from step one, like deciding what you want to do with the airgun, then educating yourself to all the various types available out there now, and what their intended use was designed for. From cheap plinking to extreme accuracy. Then inspecting and cleaning it right out of the box and so on.

Sub divide it into airgun types and proceed down the line to finding that pellet, or BB?, that gets the most out of your airgun and having “A Fine Air G un Day”

I imagine it would really help a new Air Gunner.

I now believe manufactures avoid tightening screws too much to avoid stripping things out during assembly. Try to use a screwdriver appropriately designed to provide the proper torque required to help avoid doing that … One that fits.

I believe that most/many accuracy issues have to do with trigger pull. That is where I would start…

Check weld would be next…

-Yogi

Yogi,

Believe I agree with you. Really became obvious when I had the rifle fixed in place on the rest, and ‘on target’. The slightest movement of my head, cheek weld, changed the position of the crosshairs seen in the scope. If I ever tried to reposition the rifle to put the cross hairs back on target, I would obviously be taking it off target. They were really locked on. My head position changed, not the rifle, so I had to move my head to line up with the crosshairs in the scope and repeat that for every shot.

Without a good trigger, you must really concentrate on the pull. There is nothing there to assist you in the way of performance without a good second stage.

Bob M,

I have one for you as a starting point.

Search to see if Tom has reviewed the airgun you want to shoot. Read the whole blog a few times. Get the same or similar pellets if BB used obsolete pellets.

When shooting find the balance point on YOUR off hand.

Rest it on a shooting bag/shooting rest since it is different for each of us.

Mark the airgun with tape that will get your hand and fingers to the same place each time. Don’t use a rear bag…your shoulder has feel – not the bag.

Use tape to mark your cheek weld point too.

TRY A FEW SHOTS.

Adjust your seat.

Move that front bag.

Make adjustments to the tape so it simply feels more natural.

TRY MORE SHOTS.

Repeat…

What you are looking for is YOUR NATURAL bench position.

You DO NOT want to muscle anything at the bench!

For if you do, you might as well shoot Off Hand the way most shooters do (with no training) they have no Built Position and no knowledge of how to find THEIR Natural Point of Aim. They do the same thing at the bench.

Oh! This might help you directly…you know there is a correct way to hold a tool for a task. If you see someone not hold a Tool correctly you feel it in your bones… don’t you! Same thing here with benched gun.

Know what your fingertips/Thumbtips doing (or not doing) your hands will follow, then arms, and body.

At the bench they should ALL do as little as is possible.

shootski

PS: That should keep you at your new bench for some time.

Shootski,

Good advice for me. Not sure how a new air gunner would even know about BB and this blog, unless he was told or happened to come across it looking for information online. And that would more than likely happen fast. The Blog pops up all the time looking for answers to airgun questions.

It would be nice if something like this “Accuracy Check List” was widely available.

A bit late to the party. Sorry, other tasks to get to. But the comments really got my attention. I bought a 124 last year in NC and discovered velocity was in the 500’s as well so I was really looking forward to this blog series. I had replaced the piston seal as well and had no improvement. When BB didn’t have any success, I thought “just like mine” but then read Kevin’s comment about out-of-round compression tubes for serial numbers under 8390. Mine is 7927 but it’s a .177 Sport model. Now I know what the issues are. By the way, many on the internet recommend using a zip tie to hold the safety slide and spring in place when installing the trigger group into the action.

Fred formerly of the Demokratik Peeples Republik of NJ now happily in GA

B.B. the link to part 3 takes me to part 2. Thanks.

Roamin,

Fixed.

BB

Thank you, sir!