Beeman 800.

This report covers:

- Before accuracy testing

- Why?

- Painted

- 45Bravo to the rescue!

- How to evaluate

- There is more

- What I don’t know

- The plan

- Testing

- The pistol failed!!!

- Summary

Today we look at something very different. It’s not an airgun — it’s a set of sight elements for an airgun. But they were not made by the company that made the airgun, yet they may be even better than the sight elements that were made by them.

Before accuracy testing

I wanted to test the accuracy of the Beeman 800 (Diana model 6G) air pistol, but as I noted in Part 1:

“You expect it to have target sights and it does — sort of. The front sight is a globe that accepts inserts, so that part is normal. But the inserts do not go up to the center of the globe, so that part is not normal.”

Why?

Why don’t the front sight elements rise up to the center of the front sight globe? It’s a simple explanation. The Diana 6G front sight globe was made intentionally large to fit into the palm of a shooter’s hand. It’s also slightly rounded to make the cocking more comfortable. The globe is so large that the top of the sight element does not reach the center of the globe.

The front sight element does not rise to the center of the globe. And it has been painted!

Painted

It wasn’t until I photographed the front sight for this report that I noticed that the element has been PAINTED white! No wonder this sight looked so strange to me. I have never seen this done before and wasn’t expecting to see it on a 10-meter target pistol sight element.

I will say that the paint does not show when the target is lit brightly, so it doesn’t detract from my ability to establish a sight picture. But who would paint a target pistol sight element — ever?

The other side of this insert is not painted, but the differing sized wings on either side of the sight insert make it impossible to turn the element around, so my only hope was to scrape off the paint. It turned out to be easy because it was probably WhiteOut.

45Bravo to the rescue!

Fortunately for you and me, reader Ian McKee, whose blog handle is 45 Bravo, noted my comment about the height of the front sight element and 3D-printed a batch of elements with differing heights and widths for me to evaluate. Read that as test!

45Bravo printed these 18 front sight inserts for me. That’s a lot to choose from!

How to evaluate

There is far too much to do to just install an insert and start shooting — hence this report. Will the wider inserts still work with the rear sight’s notch? That needs to be determined first.

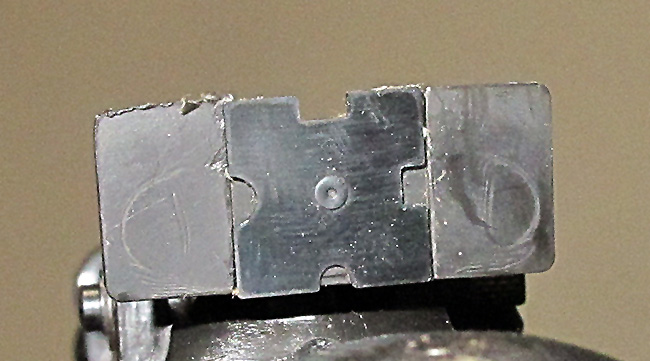

The 6G has four rear sight notches to choose from, but two are U-shaped and inappropriate for 10-meter target shooting. The other two are square notches with one slightly wider than the other. I like wide sight elements so I chose that one.

I selected the widest rear sight notch to use.

Now — which front sight element should I choose? There are several things to consider. First, will I be able to see light on both sides of the front element? That’s the only way to know that the front element is centered in the rear notch. I like a tight fit, so a wider front element is what I want, but not one that’s too wide.

When Ian printed the elements he measured in millimeters, so that is how I will report them. He made them even sizes wide, but shrinkage of the print material after cooling gives me odd sizes. The very widest post is 4.47mm wide, and it’s the only one of that width. I think the goal was a post that’s 4.5mm wide, and I also have to comment that when I measure these posts it’s easy to be off just a bit.

I installed it to see if I could see light on both sides. I didn’t think I would be able to, but I could. However, the light slivers are very thin, so I switched to the next-widest post that measures 3.937mm (probably 4mm) wide.

There is more

As I am doing this I’m also looking at the pistol’s rear sight. It seems to be adjusted almost as high as it will go. Perhaps a front post that rises to the middle of the front globe will be too high and the rear sight won’t be able to compensate for it. As the front post rises the strike of the pellet will drop, so let’s see where the rear sight is adjusted now.

The rear sight is adjusted for the lower sight that came with the pistol. If a taller post is installed will this sight be able to adjust high enough to compensate?

The height of the front post also affects the height of the rear sight. As you can see in the picture it may be very difficult to adjust it any higher.

What I don’t know

I have no idea where this pistol shoots right now. So installing sight elements without a plan is a never-ending and futile exercise. I need a plan.

The plan

I’ll keep the wide rear notch and install the factory sight element that came with the pistol. First I will shoot a group of five shots. I’ll choose a pellet I have a lot of, because this is not an accuracy test. If I see that a taller front sight element is possible, I’ll install one and shoot again. I need to be able to adjust the pellet impact higher than the center of the bull so other pellets have some room for adjustment when I get to the accuracy test. Do you see how involved this is?

Testing

Okay, I will shoot the pistol with the factory sight insert installed to see what’s what, but this report is already getting too long. What I think I will do is break this one into two reports — one today and another one on Monday. I don’t want to let this go too long and forget something.

I chose Sig Match Ballistic Alloy pellets because they were the most accurate in the previous Diana model 6 I tested. That one was a Hy Score model 816.

The pistol failed!!!

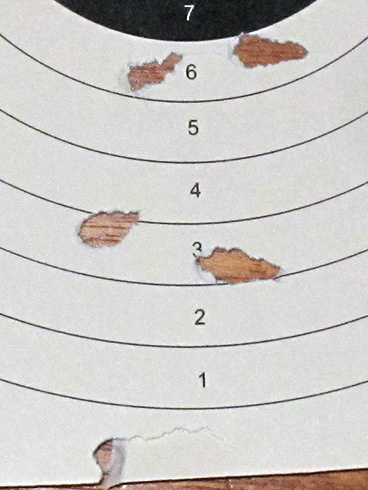

This won’t take long. I rested the pistol and shot with a two-hand hold at 10 meters. Five Sig Match Ballistic Alloy pellets grouped in 2.227-inches at 10 meters. That is WAY out of profile for me.

At ten meters the Beeman 800 put five Sig Match Ballistic Alloy pellets into a group that measures 2.227-inches between the centers of the two holes farthest apart.

I thought perhaps this pistol just doesn’t like these alloy pellets, so next I shot five JTS Simply wadcutters at a fresh target. They are lead pellets and should do okay. Five grouped in 2.179-inches between centers at the same 10-meter distance. I may not be a nationally-ranked 10-meter pistol shooter anymore, but I’m surely not that bad!

The Beeman 800 put five JTS Simply pellets into this 1.179-inch group.

Notice than many of the holes are torn and not punched clean. The pistol looks like it is loosing velocity.

Summary

That’s all she wrote for this pistol, folks. Until I can figure out what is wrong, this one is a failure. There will be no followup report for this pistol on Monday.

Tom,

The seal might be OK but something else seems to wrong with the velocities you were getting in Part 2. Is there such a thing as a timing issue with this recoilless system? It seems to be consistently shooting low so it seems the front sight that it came with is the proper height.

Siraniko

Well, that stinks.

I guess after the Pyramyd Cup we have two GISS guns to reseal.

We are leaving in like 15 days.

The time is getting so short I can sky dive off a piece of paper.

And I Just recently received the new rifle, and am still setting it up for the Gunslynger event.

Sorry to hear the 800 needs a transplant or two..

Ian

SIraniko, the gearing system uses a relatively coarse gearing, so the timing would be really noticeably off if only one tooth off.

If its “a little off” there is a bump during the shot cycle where one piston bottoms out just a smidgen before the other.

This timing is controlled by spacers

45Bravo,

Thanks for explaining how it works Ian. Since Tom did not mention anything then it is “safe to assume” that there is no timing issue with the pistol. Although it might have modern seals it hasn’t been properly inspected inside so there might be something contributing to the erratic velocity.

Siraniko

Thanks for the great report on a beautiful pistol. This will be interesting to see what the issue is with the accuracy/velocity.

Regarding the sights, if my thinking is correct, the higher front sight posts on the 3D printed inserts aren’t likely to work well due to the rear sight’s already high adjustment. A possible suggestion would be to see if Ian can print an insert with a smaller (more normal sized) circular inner opening that is eccentric so that it is near the bottom of the larger outer circle. That would place the top of a shorter post at the center of the smaller inner opening so that what the shooter sees through that opening might look a little more normal. Just a thought…

EF: Here’s a thought…..

I had a similar problem on my Diana 34 Panther (the plastic stock version). I overcame the rear sight problem by removing the rear sight, tracing its profile on plastic stock (from emptied heavy walled plastic bottles). I then cut out the outline pieces and established where the screw holes are. I drilled them out (not having a small enough leather hole punch on my multi leather tool).

I simply stacked the plastic layers until the rear sight began working with the front sight. I had some bicycle fasteners (in metric) and used two of them from the cycle spare part box to have the needed longer screws. Everything then lined up and came to “zero,” as much as my sometimes nystagmus-driven shooting would allow; meaning its ‘me’ not the rifle that misses.

In the end, of course, all the successful effort was rendered moot by the application of a UTG scope and the removal and storing of the original sights. But, I can reinstall the Diana rear sight and spacers and be back in business if the scope has a problem sometime in the future – which is VERY unlikely given the durability of the UTG Leapers unit. (NOTE: on my RWS/Diana 350 carbine in .177, even the UTG Leapers was rendered rubble by the exceedingly violent double-recoil! Fortunately, the M-36 is a kitten compared to that tiger!)

The only negative, here, was esthetic! The laundry detergent bottle utilized, in the end, was white in color. It sticks out somewhat negatively in the black and dark greenish M-36 presentation. No biggie, of course for anything but the esthetics and purists.

BB,

To my way of thinking, a taller front sight would mean you would shoot lower with the rear sight not adjusted.

Now as for the scattering and tearing of the holes, I really have no idea why such is occurring unless the pellets are just too small for the barrel and they are not flying straight. Just a thought from someone who really has no idea.

The seals on this air pistol are supposed to be brand new. Are they? I do not know this.

*** OFF TOPIC ***

I stumbled a cross an interesting (high level) read on the design considerations for the airflow in a PCP…

https://www.airgunnation.com/threads/mass-flow-rate.1317951/post-1800006

The explanations give a good idea of the kinda things that happen in an airflow. While I’ll give a “nerd alert” for the content it’s well worth reading over.

Guess that the takeaway for the typical airgunner is that simple PCPs are anything but simple and to think before you take a dremel to the plumbing that an engineer carefully designed.

Happy Friday all!

Vana2,

I read the piece…it was FREE information found on the Internet!

This is a hair better: https://www.sciencedirect.com/topics/chemistry/discharge-coefficient#:~:text=The discharge coefficient CD,typical for gases and vapors.

Poker Time:

I’ll see your Coefficient of Discharge (Reynolds Number) and raise you Afree, an Aeff, an Aeq and double down with the much better orifice discharge coefficient (Cd0) !

For those other Readership members that got this far here is a link: https://www.designingbuildings.co.uk/wiki/Discharge_coefficients,_free,_effective_and_equivalent_areas#:~:text=Effective area (Aeff) is the,as one of its factors.

to a very practical application of the above discussion on Coefficient of Discharge to your next house window selection. ;^)

Seriously i’m happy folks are trying to understand this scientific stuff but i don’t think the world of airguns has the Capital to hire the level of engineering needed to get a real handle on this. It will need to be done by über trained/educated hobbyists that do it purely out of love of PCPs!

shootski

PS: Computational Fluid Dynamics (CFD) is a very interesting area for us Dark Siders…i’m certain Rocket Jane would agree.

CFD can be a very useful tool in the right hands, and the output graphics are very persuasive and seductive. However results are highly dependent on the knowledge of the person setting up the model and interpreting the results. This is an increasing concern as CFD software becomes more straight-forward to use and so is more easily operated by people with little understanding of the mathematical model that underpins it.

If the input information is wrong, the output information will be as well. CFD is no substitute for common sense.

BB,

That off center front sight would throw me for a loop as my eyes would use the center of the globe for reference and ignore the front sight.

Yeah – my bad, being hunting oriented I focus on the target and not the front sight.

If sight geometries are working against you, I’d try making a mask to create an aperture centered around the existing front sight.

Oh, as far as painting the front sight – been doing that on my hunting rifles since I was a kid. At low light levels, it’s hard to see a dark sight against a rabbit hiding in the brush. So, no paint on my 10 meter sights but I admit to recently painting a set of Weihrauch inserts fluorescent orange. 🙂

Hank

I just had my model 6 resealed etc….took it out and resting my hand on the mill was able to do less than1/2 inch at ten…somethin’ ain’t right with yours, no clue as to what it is…

BB

Off subject but nobody is commenting plus it’s the weekend.

Could you please find a reason to shoot your fabulous 70 year old Olympia LGV Olympia again? Maybe it was among some oldies you rediscovered during the room arrangement. I reread your part 3 on August 16, 2019. The RWS R10 Match Pistol pellets put 5 pellets in .10 inches at 10 meters. Back in 2013 this same rifle placed 10 JSB Exact Heavy 10.34 grain pellets in .35 inches at 25 yards. In 2013 you used an artillery hold. In 2019 she was directly on a bag. I always look forward to my Olympia coming up in shooting rotation. She is so smooth and has that wonderful barrel locking latch.

I hope she deserves some more attention.

Deck

Deck,

I’ll consider it. The new premium pellets might be a reason to look at it again.

BB

Glad to see someone picked up the Diana 36 on Gunbroker for $189. Hope it was one of you readers out there.

https://www.gunbroker.com/item/1063083468

BB,

I am a big fan of any of the Giss system guns.

Have you considered resealing this yourself, or letting someone else do it? (I know that your schedule is probably overflowing)

Here’s hoping that your schedule allows you to continue with this test at some time in the future.

All the best.

Bill

I believe he is waiting for me to write a blog about how to reseal a GISS gun.

After the Pyramyd Cup I will have time to.

Then he will probably tackle it.

Unless we spend a day and do it together.

And that’s a possibility as well.

Ian.

I gotta ask this:

I was gifted a Model 6 with one globe insert. Any chance of getting a few of the inserts of different heights from you? I was hoping for cross-hair or other than post, but I’m desperate!

It shoots great except for the sights.

help?

John

Sure, just let me know what you want.

Like height of the top of the post in relationship to the center of the circle.

i.e. above center or below center.

Te width of the post helps too so you can get the correct amount of light gap between the rear sight and the post.

Cross hairs, the same. Center, above or below.

If you want the circle inserts, I would like to know the outer diameter you want it to be, and what the inner diameter you will see the bull through.

Contact me through 45bravoairguns@gmail.com.

Ian