This report covers:

- Air Venturi Rail Lock Spring Compressor

- Make my own mainspring compressor

- What a spring compressor does

- Sun Optics

- Low demand

- Making a mainspring compressor

- Kitchen table

- Summary

Today we look at mainspring compressors.

Today’s report is in response to a comment posted by reader Orv a week ago. He said,

“Could you do a step by step blog on making a spring compresser? Unfortunatelly, I don’t have a work bench and will have to make do with a temporary set up on our picnic table out in the gazebo. I’m able to service my TX200 without using a compresser. However, should my HW97K require putting a Vortek kit in it, or doing the necessary work on the HW50s that I’m recieving in pieces, a spring compresser will be required.”

I thought about it and saw that I haven’t done much on maintaining spring-piston airguns for a very long time. Sure, I’ve fixed several, like the BAM B15, but I only mentioned the mainspring compressor in passing. It’s like Orv asked me what a screwdriver was and all I did was show him pictures of screwdrivers.

Orv asked for a step-by-step report on how to build a compressor. Instead of that I will show several different compressors and you will see how they are made. That will give you the details of what you need to make one your way. I’ll also provide a great starting tool that costs very little and gets you 90 percent of the way there.

Air Venturi Rail Lock Spring Compressor

I’ll start with a compressor you can buy. There is nothing to make. The Air Venturi Rail Lock Spring Compressor comes ready to go. That’s its biggest plus.

The Air Venturi Rail Lock spring compressor is compact.

The biggest negative is it requires a scope mounting dovetail, Weaver or Picatinny scope base on the spring tube of the airgun to attach to. No problem if the airgun has one but if not then this compressor doesn’t work. Vintage spring rifles and almost no spring-air pistols have dovetail grooves. If you have used this compressor on an airgun that didn’t have a scope mount dovetail/Weaver/Picatinny base please tell us.

I did a two-part report on this compressor back in 2017, so that’s one to read. Orv, that compressor works very well on an HW97K or on most Weihrauch spring rifles.

Make my own mainspring compressor

I had to make my own mainspring compressor to safely disassemble the Beeman R1 rifle that was the subject of my first book. Having very little building skill, I overbuilt that one many times. It’s mentioned and shown in the report titled Spring gun tuning: Part 2 – Building a mainspring compressor.

What a spring compressor does

Spring-piston airguns rely on a coiled steel mainspring pushing a piston that compresses air in front of it as it slides forward. That spring is usually under tension, even when the parts that restrain it are removed. To keep it from launching them out of the spring tube unsafely a mainspring compressor is used to slowly reduce the spring tension until it’s gone.

Sun Optics

Sun Optics used to sell a mainspring compressor. They took the design from the B-Square compressor that B-Square owner Dan Bechtel and I worked out in the 1990s. Dan designed 90 percent of the tool and I did about 10 percent. B-Square sold it for several years. That’s the compressor I own and use. I reported on it in 2016.

The B-Square mainspring compressor that Dan Bechtel and I designed. It was the basis for the Sun Optics ST1700 compressor.

Sun Optics made some improvements to this design before they brought out their ST1700 Mainspring Compressor. They turn up occasionally on auction websites.

Low demand

There is little demand for a mainspring compressor, so companies don’t want to invest the time needed to design and fabricate one. When commercial compressors are available the internet is clogged with plans for making them at home. When none are available, those who need them are in a bind.

I’ll assume you read the report I linked to above about building my own spring compressor and have seen the features that are needed. Now—are there any good generic compressors on the market today? I couldn’t find any in a quick internet search, but I did find an inexpensive solution I’ll show now.

Making a mainspring compressor

In the U.S. the store called Harbor Freight sells a 60-inch bar clamp for twenty dollars. It’s called a 60-inch Aluminum F-Style Bar Clamp. Airgunners in other countries may have to buy one from different stores and the measurements will be metric but the item will be substantially the same. Sixty inches is 152.4 cm, so a clamp somewhere close to that size should fit all your needs.

A 60-inch clamp sold by Harbor Freight makes a great mainspring compressor.

The additional thing you will need with this clamp is a way to keep the airgun action from squirming sideways when the action comes apart and the mainspring is free to move. This is the part I called the bridge in the article I linked to above. No doubt our readers can suggest a good way to do this.

Kitchen table

Orv and others—you mention working on a picnic table. I used to do all my spring gun work at the kitchen table. I padded the table with blankets to keep the compressor bolts from scratching the wood. The spring compressor makes it easy to hold the parts where they are required for assembly.

Here is a photo taken at my kitchen table of a Diana model 27S assembly in which the spring compressor held the mainspring and trigger parts as I worked.

This photo shows the trigger cage spring being compressed as both the inner ball bearing cage and the outer cage are pressed into the spring tube by the mainspring compressor. You can see the absolute necessity of a mainspring compressor!

Summary

I was glad to write this report for Orv because I know there are many others who also needed it. I hope the information has been of some help.

B.B.

I have the AV Rail Lock Spring Compressor. Yes, you need a dovetail groove. Sadly, the AV Rail Lock SC’s jaws, on the two that I have used, are pretty flat and thus compress/flatten the edge of the dovetail. NOT GOOD!!

For all the other designs, my question is how do you support the barrel? If you remove it, how do support the barrel forks? Of course this only applies to break barrels….

Have a nice weekend everybody!

-Yogi

Yogi,

I always put the muzzle of the barrel against a soft wood surface. The Sun Optics compressor uses an aluminum plate that has a small protrusion in the center that’s supposed to interface with the muzzle and stop the barrel from moving. In my experience it doesn’t work as well as soft wood.

BB

Doesn’t that damage the barrel crown?

Even with soft wood…

-Y

Yogi,

Not a bit. Even the aluminum plate does no damage to the crown.

BB

Doesn’t that squash the breach seal?

-Y

Yogi,

If the barrel remains on the spring tube no additional pressure is put on the breech seal. The barrel holds it in place even with the muzzle being under pressure.

But even if the seal was put under pressure It wouldn’t be for long.

BB

Yogi

I think that the breach seal is squashed as much as it can be just by moving the barrel to battery. To keep from squashing the breach seal you should store your break barrel with it broken but not cocked. Makes sense?

Mike

Yogi,

I always remove the barrel if I can. One less thing I have to worry about.

So what pushed against the front end of the compressor?

-Y

What’s left? The forks of the compression tube.

BB: Thank you for the quick and detailed response. I’ll pull-up the related past Blogs and digest them tonight and tomorrow. I’m a bit embarrassed that I didn’t show enough gumption to properly research your previous answers to my questions. I tryed a quick search, but clearly didn’t attempt the proper keywords. Knowing me, I’ll no doubt have more questions as the time goes on. Thanks again, Orv.

Doc,

Don’t feel bad. Sometimes I can’t find them, either. It sometimes helps to just search the whole internet because this blog is rated so high that the answers often turn up as the first one or two hits.

BB

Orv, FM is embarrassed by the fear of ever having to tear into one of his “sproingers,” spring-compressor at hand or not. Hopefully those springs will outlive him. If push gets to shove, FM will research the subject and procedure to exhaustion before attempting to repair/rebuild a springer, starting with the nuggets of knowledge available in this blog. Plenty of YouTube “training” videos will be watched as well.

Search for Google Advanced Search then bookmark that. Use the word search boxes and then scroll down and limit the search to the website of this blog:

Pyramydair.com/blog

The beauty of this tool is that it searches the comments as well as B.B.’s blogs.

Of course Tomek did many mainspring swaps, of course he knew about the existence of the mainspring compressor. He could build one for this purpose years ago… and? He put in all these high power mainsprings on the kitchen table. Few times almost got killed during the process…

tomek,

Yep! I know about almost getting killed.

BB

B.B.

I think that when we are talking about a springer below 12J, there is a relatively small risk of something really bad happening. In my experience, a springer above 20J will try to kill you every time without a compressor. I don’t even want to think about changing the main spring of a Diana350 Magnum for maximum power without a compressor… (if I had one, I would probably try…anyway)

Tom,

I’d probably use a couple of scrap 2×2 on each side of the bar of the sash clamp and wrap around the action using (cord, elastics?) to secure it.

Siraniko

PS Section Low demand 2nd paragraph 1st sentence: “I’ll assume you read the report I linked to above about building myb (my) own spring compressor and have seen the features that are needed.”

Thanks for the well done report BB. With woodworking as one of my hobbies, I will likely see about getting one of those Harbor Freight clamps. I have a similar one by Bessey. But there isn’t very much distance that the clamp travels when tightened/loosened. The Harbor Freight clamp appears to have significantly more travel available. I seem to remember reading in one of your earlier articles how much travel is needed. But I don’t remember the amount. Does anyone know the distance needed?

Elmer,

Ten inches is not too much.

BB

Thanks, the Bessey clamp I have only has about an inch. The threaded screw part of the Harbor Freight clamp looks to have a little over 2-inches (my estimate from the photo).

I have one of the Sun Optics spring compressors. It is a real gem, but is still not perfect. If I worked on more sproingers, I would build something better from it.

I did not buy the AV compressor as most of the “old gals” around here do not even have any way to mount a scope. From what Yogi is saying it sounds as if AV could improve on the design.

Every blue moon I see one offered by an airgun company. It is usually very similar to the one at Harbor Freight. With the addition of a frame of some sort this could be an excellent spring compressor.

Another Oops

Low demand – Second paragraph – Second sentence

Now—are there and (any) good generic compressors on the market today?

RR,

Got it. Thanks again,

BB

A mainspring compressor is easy to make from odds and sods with the only “special” hardware needed is a lenght of ridgid (1/2″ or larger) threaded rod.

The two design requirements are a way of restraining the airgun so it can’t move out of alignment and some sort of track or guide that keeps control of the parts under tension.

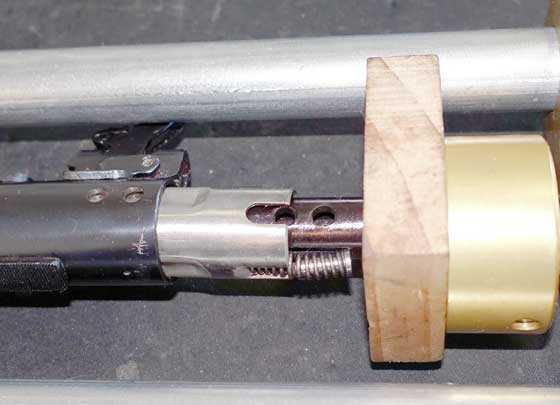

I used a 2×4 as the backbone of the compressor I made for my FWB 124. The airgun is held by the barrel clamped with a couple of blocks of wood (at the right in the picture). A block of wood shaped to fit the receiver is attached to a thin plywood guide which is constrained by a track system made from a spacer with a “cap”. The threaded rod runs through a “coupling nut” that’s mounted in block of wood attached to the backbone (shown at the left).

The compressor took an hour or so to make and cost a couple of dollars for the threaded rod and nuts. It’s easily modified to suit different airguns.

Happy Friday all!

Vana2,

Thanks for your picture. I hoped folks would post their designs like you did!

BB

The only thing you need is a “bridge,” or something to restrain the middle of the gun to keep the breakbarrel from “breaking.” Nice work.

Roamin,

The bridge is a good idea.

The force is in-line and with the breach lock-up on the FWB 124, I didn’t notice any tendency to want to break during compression.

I’ll be using the spirng-compressor to install a Vortec kit on my HW50. Better safe than sorry – it’s a simple mod/improvement, I’ll be adding a strap or bridge.

Thanks for the suggestion!

Hank

B.B.,

Enjoyable read and informative as always.

I have seen your blogs using the spring compressor but it is always with “real”springs.

Have you done a gas spring?

Is there something different in the process steps or cautions to doing a gas spring.

I figure if i ask these questions it will inoculate my SIG ASP20s from ever needing one ;^)

I did read that the Air Venturi Rail Lock spring compressor you discussed above was actually designed by Tom Gore of Vortek.

You went on in your reply to write: “… (he) needed a compressor that would work on gas piston and gas spring rifles as well as airguns with conventional coiled steel springs. Gas spring airguns may only need a fraction of an inch of compression to get them together, but because the gas pressure is so high they are very difficult to assemble. So Tom created this unit, which he says makes assembly of a gas spring easy. I guess I need to try it that way.”

So assembly is covered in the above but what about disassembly?

How high is the risk of blasting parts all over the place (getting killed) if the gas spring is still partially or fully charged?

shootski

shootski,

Yes I have disassembled rifles with gas springs using a compressor. Not much danger because of the short travel that you mentioned.

BB

I built a compressor to install a Vortek kit on my Diana 34. Since then I used four or five times in different rifles and once with a pistol using spacers. I used a section of a C clamp for the compression itself, and some straps to hold the tube fixed to the frame for safety.

My idea was to always remove the barrel first, as it would be required anyway to remove the piston. I am sure there are exceptions, but that has been the case with my stuff.

In hindsight it is overbuilt, but it was fast to do and cheap. When your other hobby is woodworking normally there is scrap wood from another project.

I am inspired to build one. I will share what I come up with. Then I’ll get to work on using it. I have an FWB 124 with a bad piston seal waiting patiently for some TLC (for Tomek: “tender loving care”)

Henry,

Thanks for your picture!

BB

I tried to show a picture of the clamp but the site blocked me. Twice.

Oh well.

Henry

Henry_TX,

Your clamp is now visible ;^)

shootski

B.B. and Readership,

Just a thought…

Orv and other readers could build their own, buy one, or they could ask to see if some other reader would rent them one.

Happy Father’s Day to all the Dad readers!

shootski

This has all been great fun for me, opening up new horizons of being able to service my own springers. I opened up my TX200 4 years ago, or so anyway, which became a true disaster. I shared that mess here on the Blog and won’t relate the debacle unnecessarily again. I believe that I’ll look into the Harbor Freight model or perhaps the one by Henry_ Tx, or perhaps something inbetween. I’ve got a couple of old “lost cause” springers out in my work shed that I believe it might be wise to try on before testing my skills on something such as my HW97K. Tom, you’ll either be my savior savant here, or the name that I’ll be cursing if I make my usual mess. Thanks Tom, and all my fellow readers for coming to my call for assistance. Orv.

BB.

People who like to use and work on their springers eventually will need a spring compressor. This one here is eleven years old and has been working fine for many jobs. The body is a length of pine 4×4, with a hard maple strip that firmly holds the scope rings, that hold the gun. The compressor bolt assy can move up and down to push just where it’s needed.

Regards,

Will

Will,

Thanks for sharing your picture!

BB