by Tom Gaylord, a.k.a. B.B. Pelletier

Announcement: Captain Steve Hardy is this week’s winner of Pyramyd Air’s Big Shot of the Week on their airgun facebook page. He’ll receive a $50 Pyramyd AIR gift card. Congratulations!

Captain Steve Hardy submitted this week’s winning photo for BSOTW.

Today, we have a guest blog written by Steve Daugherty. He submitted this piece some time ago, and it fell through the cracks. My apologies to jim for the delay.

If you’d like to write a guest post for this blog, please email us.

One more piece of the early Daisy No. 25 puzzle

by Steve Daugherty

When I bought my new Chinese Daisy No. 25, I remembered that the No. 25 I had as a kid seemed to have had a lot more power and was built much better. So, earlier this year, I began looking for an early ’60s gun and soon found one in pristine condition on Jim Manning’s website. He gave me a great deal on that gun — which was exactly like the one I got for Christmas 1963 — and he got me interested in the older No. 25 guns by selling me a Variant 3 from his personal collection. In a short time, I’d acquired some very nice wood-stocked 25s, including the subject gun.

This very early No. 25 came to light recently in a classified online St. Louis ad that had been listed for a few weeks. Though the ad photos were poor, I enlarged the image and could see that the front sight was adjustable. I didn’t have a gun made that early. It didn’t shoot and wasn’t in the greatest condition, but it was a Variant 2 “straight stock” Variation 5 that I didn’t have. (See the Daisy King website for clarification). For less than $100 with shipping, I couldn’t go wrong. When the gun arrived, I saw that all of the parts were original, though the gun had seen a lot of use.

My seemingly ordinary Variant 2 No. 25 with solder patch-style claw and adjustable front sight.

The front sight is adjustable for windage.

Someone long ago had tried to stretch the worn-out shot tube follower spring, and the tube now had a slight bend and some tool marks. When I broke down the gun, I noticed that they’d also tried and failed to remove the plunger assembly, but they didn’t get the mainspring back in place properly. Since someone had already begun to take it apart, I figured that I might as well try to disassemble the gun and check out the seals.

The plunger assembly was pretty much frozen in place. I had to dump a lot of 3-in-1 oil around it to get it to slowly budge. While working on freeing the plunger, I noticed that the 3-in-1 was seeping out of the underside of the barrel, which would have normally been weld-sealed. Finally, the plunger assembly came out — but it didn’t look as complicated as photos of other assemblies I’d seen. The simplified plunger assembly eliminates the air tube of the standard No. 25 plunger assembly, which was probably the Achilles heel of this design. Though I may never know for sure unless I reseal and shoot the gun, it was, most likely, a relatively weak shooter. Regardless, I’m not reassembling the gun for now. I’m mounting it in a display case, as-is.

The mainspring and plunger assembly of the subject gun.

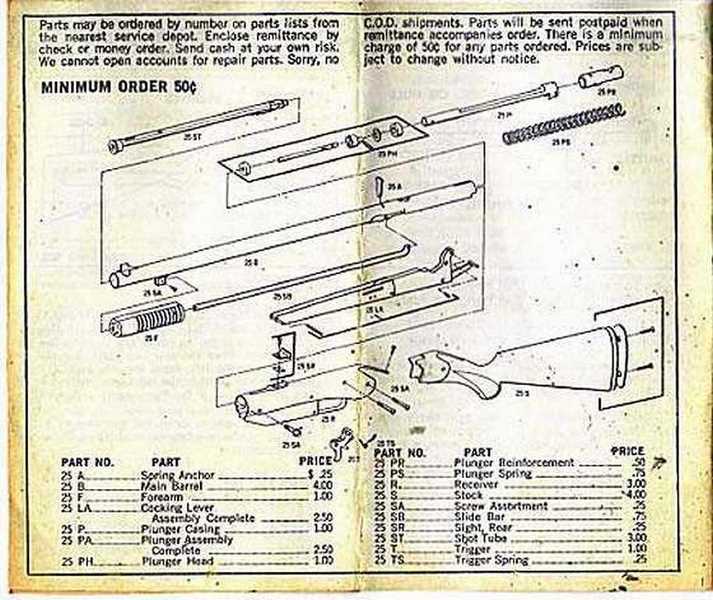

This schematic is for a production Daisy No. 25.

Compare the simple mainspring/plunger assembly of my gun to the one in the diagram of a normal No. 25. Among other parts, my plunger is missing the air tube — the “solid-rocket-booster” — of the No. 25. The lack of an air tube had to decrease the gun’s power. [Editor’s note: The air tube Steve refers to projects up from the head of the piston. When the gun fires, it pushes the BB off its seat and accelerates it to an initial 50-80 f.p.s. before the compressed-air blast from the piston shoots through the hollow air tube, boosting the velocity up over 300 f.p.s.]

Also, there appeared to be a brass sleeve that was also moving out of the barrel behind the plunger. I spent a good while carefully working it out of the barrel.

When I got the brass sleeve removed, I noticed that it has a female threaded fitting on the end that the shot tube directly screws into. This gun didn’t have a welded-barrel air chamber like every other No. 25 — it had a separate internal air chamber! The shot tube screws into the 6-inch brass air chamber’s end-fitting instead of the normal threaded abutment that’s supposed to be permanently located in the barrel. One worn-out seal was on the end of the plunger; the other was friction-fit inside the brass tube, behind the screw fitting.

The brass air chamber and plunger assembly have a notch and matching protrusion to align them during assembly.

The shot tube screws directly into the end of the brass tube.

The shot tube is attached to the brass compression chamber tube.

I was more than a little stunned by finding all of this. In addition to the abnormal inner mechanism, the gun has an oak stock that was a very unusual feature for the No. 25 airguns. They were normally stocked with black walnut. For more info on vintage Daisy No. 25 wood stocks, go here.

The oak stock of this Variant 2 No. 25 is on top. My Variant 3 is below. Both are pretty unusual, as most straight stocks were black walnut. Could the non-standard oak indicate that this gun was a special build?

Over the next few days, I wrote Dr. Robert Beeman, co-author of the Blue Book of Airguns, who remarked that it was rare, but couldn’t tell me much else. He referred me to Gary Garber, author of An Encyclopedia of Plymouth Daisy Airguns. It also stumped him, so he hooked me up with Bill Johnson, author of Bailey and Columbian Air Rifles — and the ultimate authority on No. 25 guns. He was confused at first by the photos of unfamiliar parts, but quickly realized that it was made at the Plymouth factory. He told me, “I’m pretty convinced this is a factory experimental piece.”

The obvious question at this point: Where did the original air chamber abutment go? The sleeve you see in the barrel is part of the abutment and is factory spot-welded in place. The only conclusion is that the abutment was never there! I believe it has to be factory. As I believe you said, this was an experiment to avoid the tedious butt-welding of the barrel seam.

This gun is either a prototype, an experiment or a very short-lived transition model — perhaps made between the time when Daisy quit soldering the barrel seam and started butt-welding it — which was necessary if they were to blue the barrels (bluing won’t stick to solder). They may have wanted to see if a separate air chamber would be easier and/or cheaper than welding the barrel seam, which was very difficult with such thin steel in the early days of arc welding. As seen in the photo (from the muzzle-end down the barrel), the spot-welded abutment tube is there — but the welded-in abutment itself (that the shot tube normally would thread into) is not. The edges of the brass air tube’s fitting rested on the end of the spot-welded abutment tube.

The abyss of this unusual 25’s barrel from the muzzle end — no abutment to obscure your view!

The collective parts of the brass air-chambered No. 25 — one-off trial build or short production run? Crazy-rare, either way!

Dennis Baker also saw my gun photos and replied, “I wonder if it’s a factory prototype or a ‘home brew’? It might be one of the improvements/inventions that Lewis Hough encouraged employees to bring in to him.”

Reknowned Michigan airgun expert and avid Daisy collector Wes Powers commented, too: “What an odd piece. I can’t say I have ever seen one of these. I think it was a short run production gun and not a prototype or a tool-room gun. It is a very rare variation gun. It looks like the only way to tell what this gun is from the outside is if the air chamber has no patch and also is not welded.”

If you happen to have an old No. 25 with an adjustable front sight, there’s one sure way to tell if it has the same inner mechanism as this rare gun: it won’t have an air tube. Shine a light down the barrel, and you should see the tube. It makes shot tube installation a pain at times — a situation that was corrected, by the way, on the new Chinese guns. I haven’t seen any photographic evidence that any other Daisy No. 25 like this exists. Since there are no differentiating external features from other No. 25s of that era, there may be other examples out there — perhaps in your own collection! If you know of any similar No. 25, by all means, post your info here!

I know that disassembling old guns is a collector’s mortal sin, but I’m glad that I took this one apart. As someone relatively new to collecting, I’d say that a find like this proves that one can still find his/her holy grail out there…but some disassembly may be required!

Steve,this was most enjoyable to read.I have to point out that a “collector” meticulous enough to realize the internals of this no.25 were special is equally rare.I love your enthusiasm;”for a hundred dollars,I couldn’t go wrong!” Airgunitis claims another victim……now you are contagious.LOL

Steve,

Most impressive. You are not only brave to do what you did but lucky to turn up with such a unique #25. Mounting it in a display case will make it a great conversation piece – like something you’d see in an airgun museum.

-Chuck

Nice job with both the gun and the write-up, Steve! My neighbor had one off these when I was growing up and I was surprised that it was more powerful than my 1894.. Sure was a hard gun to cock for usa little kids though!

/Dave

Tom,

Is there supposed to be a difference in the IZH-60 and the IZH-60 Pro other than the peep sight?

Edith,

Looking through the “larger image and other views” of the NON-Pro IZH-60 there is, in the 6th unexpanded picture, a picture of it without the peep sight, but, if you click on it to expand it, it is the same picture shown for the Pro with the peep sight. Was this intentional?

-Chuck

Chuck,

I’ve alerted the photographer to fix it asap. Thanks for the heads up!

Edith

Chuck,

The sights, front and rear, are the difference.

B.B.

Okay, it was revealed to me by the Jaws of the Subconscious last night. I managed to get the perfect hold with the IZH61 for a couple of shots, and the rounds went exactly where they were supposed to without deviation. Here is proof that the gun will do it’s job. It is kind of demanding with technique, but the plastic receiver will deliver. Speaking of sights, the Bug Buster scope works so well, I’ve never round a reason to change it.

Matt61

Steve,

Thanks for sharing your gun and a wonderful piece of detective work. I really love these old BB guns, even though I never had a 25, and I just can’t get enough detail; makes me feel like a kid again, which is all too rare these days! I hope your work pays off as it should by helping other identify models with similar characteristics (if it was short production run) and — no matter what the explanation — that by publishing what you know you will get valuable feedback and possibly additional information in return.

One thing to keep in mind is that manufacturing wasn’t always the same high-tech affair it is today. Even if it were a prototype, it could have been patched together and sold (better than throwing stuff away), or it could have been pulled from the assembly line for some problem earlier and sent off to the shop to be assembled however they could figure out during down times. It could even have been carried home by someone doing R&D (after its utility was exhausted) and given to his son. You may never know for sure, and that is part of the fun for me in old BB guns: Imagining the possibilities during the history of the piece.

Thanks, guys, for the kudos, I’ve had a tremendous amount of fun with the gun & its mystery…which may never be solved. I thought that I had possibly made a connection to its one-off mechanism a few weeks ago, when I read that Fred LeFever (inventor of the #25) lived in St. Louis before going to work for Daisy – which was the *same* city that the guy that I bought it from lived (could LeFever have built it himself on a visit back home??)! I contacted the seller again, but the lead ran into a dead end: his grandfather had given it to his father, then it was passed on to him – but his grandfather grew up in Vermont & Massachusetts, so that’s where it was originally bought (his dad moved to St. Louis after WW2). The former owner was thrilled to hear what I’d discovered about the gun, especially after I sent him a pic of it in the display. He said, “It’s nice to see the gun being enjoyed by someone instead of sitting in my closet for my kids to throw out someday.” THAT is the real icing on the cake for me! If there’s a vaccine against “airgunitis”, I don’t want it!

Steve, nice write up…had to go down to the basement and run a few

bb`s thru mine. Got it in the late 1930`s …1940 the latest, as a

youngster and have enjoyed thru all the 70 plus years. It still has the

power….nice air gun…fired off a few ….oiled her up and put away in the gun vault for another month or so. My model 25 was mahe in

plymouth, michigan.

George

Great comments, George, your #25 is one of my favorite variants, mid-’30s to WW2, I just picked up a similar one that shoots like new. To determine (generally) whether a #25 is pre- or post-war, look at the welds on the cocking assembly anchor on the barrel. If it has (2) very clean, circular spot welds on each side, its pre-war, if it has (1) oblong weld per side, its post-war. As always, tho’, with all Daisys “back in the day”, some features can overlap, since they used up all discontinued parts to avoid waste. What a novel idea in this age of disposable “goods” (the ultimate misnomer for stuff that isn’t at ALL good!).

Steve… thanks for the info re: spot welds… my #25 is pre-war.

I`ve been shooting “reclaimed” BB`s from my back stop….I`m going

to have to buy new “stock” …I understand they make “rounder” BB`s

now a days. I`ll have to do some target comparisions….as I recall

the #25 air rifle was quite accurate….dispatched a few water

moccasins on the aunt and uncles farm in Michigan….talk about the

good times as a youngster.

George, I’ve seen some blown-up photos of BBs from decades ago, they look like the lunar surface compared to new ones! Daisy Silver BBs are about as good as they get, & they *have* to be easier on the shot tube. I reclaim mine, too, a powerful magnet speeds up the job. The harder-shooting #25s (’30s-’40s) seem to be the most accurate, but much harder than 350 fps would have a diminishing return with a smooth bore. My old #25s seem very accurate, until I pull out my cheap new Powerline 880 & some pellets – I think I could shoot the toupee off an ant’s head at 150 feet with it!

Steve, figured out how to get the washer off the tip of the plunger. Just replaced it today. Would love to send you picks of the rifle and show you what I did. Don’t know how to attach picks to the blogs. Believe it or not it is very simple. When you remove the pin so you can separate the head from the plunger put the head in a vice so the metal washer thats behind the leather and lightly tap the end and the washer will fall off the shat. Look at the shaft it’s tapered just looks solid it comes right off replace the leather and put the head back together will have to compress the leather to get the pin back into the plunger assembly. I was really surprised the end looked like it was part of the shaft but its not Yea!

Steve, Great reading. My Father-in-law also has a n0 25 that he bought I thin in 1938 for a couple of dollars. It would only shoot the bb about 5 feet. I was told it was the seals so I spent $20 and purchased 2 leather seals. Purchased a Daisy service manual and proceeded to disassemble the rifle. This one is like yours NO AIR TUBE. I don’t have a brass sleeve like yours if there is it did not come out of the barrel. There is only one leather washer on the very end of the plunger casing. I can’t figure out how to put the new washer on the end of casing. Looks like the washer was put on first and then end cap I can’t see how it is removed.

Fred,

The gun you are referring to here is a prototype that was never produced. The air tube in your father’s BB gun is the outer tube that has been sealed to hold air.

The leather is held on by riveting it to the plunger by forming it in manufacture. You have to be a Daisy repairman to know how to fix one.

If you want you8r gun repaired, I recommend you contact this man:

Larry Behling 315-695-7133 or co2bbjlts@juno.com

B.B.

B.B.

B.B. the rifle was purchased at a hardware store in 1938 or 1939 for $5 and change. The plunger is 9 3/4″ long without the head on. The leather washer on the tip of the head is held in place with by a metal washer that if tapped lightly comes off to replace the washer. There is no air tube like the exploded drawings. The end of the plunger’s head rests against the barrel leather washer and the end of the shot tube screws into the other side of the abutment washer. I thought at first that the tube must have broken off but that’s not the case there is no distance between plunger head and end of shot tube. The plunger assembly is like the plunger assembly of Steve Dourghty 25 except thid one does not have the brass sleeve. The leather on the plunger head is not riveted into place it just looks like it is the metal washer looks like it is part of the shaft but it is not little tap and it comes off the shaft is tapered. My question to you is when did or did the 25’s all have air tubes? and if not at what variant did they start using them. Also I asked my Father-in-law if the rifle had the gold in the design that was started in I think 1936 and he said it did not. I guess maybe the rifle could have sat on the shelf for a while. Anyway the rifle is apart and I’m waiting for the leather washers. I would love to send you picts but don’t know if you can attach photos on the replys. Thank you for all your input, the gun does not appear to be your average Daisy no 25 Variant 6 Fred

Fred,

You are describing as conventional Daisy number 25 powerplant. They all look like that.

The air chamber is just the welded outer tube and it works.

What Steve shows is a prototype that hasn’t been seen elsewhere. Daisy was having difficulty welding the thin metal tube (they used to solder it shut) and Steve’s gun was an attempt at getting around welding. But they finally learned how to weld the tube and the rest of them (18-19 million) were welded.

B.B.

I went to a gun show this morning in the next town. It was the first one I’ve been to in two years.

This was not an airgun show, so very few air guns. Some used Red Ryders, a bunch of Stoeger air rifles, NIB, and a NIB Gamo Hornet. I would up buying the Hornet combination with scope.

Discovered my neighbor has a couple scoped Gamos, too. Maybe we can get out to the range together soon.

I think I did OK on the deal. Paid $130.

It was a lot of fun. Made me wish for an airgun show to go to.

Les

The family that shoots together… For the article I can only bow to the technical prowess with the gun and to its history. It makes me long for the Marlin 39A, the longest continually produced shoulder arm in the world and the rifle of Annie Oakley herself. Wow.

B.B. a scoped AKM shooting 4MOA is not too good–although even that would probably not really hold you back in a combat situation. Still, this confirms my attraction to the Arsenal AK where my loyalties have returned. While the loose tolerances of the AK were part of Kalashnikov’s original design, they may not be necessary either. Such a simple robust action could probably be turned to other purposes like greater accuracy. Hence the Arsenal line where you’ve got the decades of experience from Bulgarian gunsmiths and an American precision rebuild at a Las Vegas facility.

Nevertheless, the scope on the AKM makes me reconsider whether this rifle is still the ultimate battlefield design. Perhaps the assault rifle concept was not the best design overall but just the best for the circumstances in which it was created. Apparently the STG44 built its reputation on the Eastern Front where it was perfectly adapted to counter the Soviet infantry arms. It had greater range and power than the PPSH41 submachine gun and a higher capacity than the Mosin Nagant rifle. Similarly, the AR15, the American assault rifle, did reasonably well in its first environment, the confines of the Vietnam jungles, despite reliability problems. The modern version, the M4, does well in urban areas (except for penetrating walls) but is almost helpless in Afghanistan against long-range fire from SMLEs! While I do believe the assault rifle design is pretty close to the optimum, it may be slanted towards specific environments.

A second consideration is the advance in optics since WWII. A huge range of improved optics has been developed, and their general effect is to extend the range of rifles. So the 300 yard range of the 7.62X39mm is no longer adequate. While 5.56 and 5.45 have better ballistics, they are prey to the winds and lose energy at greater distances. I tend to doubt that the 6.5 cartridge is the answer either. I thought that caliber was found wanting as a military round by both the Swedish and the Japanese who upgraded to 7.62. So, the new ultimate rifle should be a shortened .308, handy enough for close quarters but with the range and optics to reach out. In other words, the M1A Scout Squad! Actually, I would still probably give the edge to the Arsenal with the right scope but it would be close. Naturally, my own opinion. 🙂

As for the Rogue, a difference of 10fps per shot is not great, so the velocity is not the problem. Presumably a gun incorporating a high performance computer would also have the high manufacturing standards of other pcps. Could it be the recoil? Even with a pcp design, throwing out that much weight has to produce some recoil, so maybe that’s what reduces accuracy compared to other pcps.

Thanks for the info on the exploding gas tank. You guys are incredible. So the problem is the air not the liquid. This reminds me of B.B.’s comment about how gunpowder cannot ignite properly unless it is confined within a cartridge case. By the way, forget about Tara Conner. I came across YouTube videos of Soviet women soldiers in WWII practicing their bayonet fighting. There they were in their boots, ankle length skirts, and broad leather belts charging forward with their bayoneted Mosins. This was the same outfit that American women soldiers made fun of when worn by Major Lyudmila Pavlichenko on her visit to the U.S. (which made her mad!). But the outfits didn’t slow the women up, and they looked fairly hot, I have to admit. Also very slick with the bayonets. The technique seemed to be deflecting an oncoming bayonet with a circular movement like a fencing parry followed by a forward thrust. You wouldn’t want to get in their way.

Matt61

An effective range of 300 yds/Meters for a general issue rifle is still good since beyond that range you call in air strikes, artillery/rockets, or use crew served weapons. In addition, designated marksmen will have a scoped M-14 in 7.62 NATO.

Mike

Or you’re relying on massed harassment fire rather than aimed at any particular target. (Agincourt with rifles)

{The rear turret of the HK-91 has three peeps marked 200, 300, 400 meter… and the fourth “battle sight” position is an uncalibrated V-notch for use at close range. While my father’s Sako FinnWolf lever action came with the rare peep sight that slid onto the scope base — it rotates for 100 and 200 meter/yard? positions… The FinnWolf is a .308Win, same as the HK-91}

Yes, this is definitely true. But if you don’t have all your ducks in a row, you might need to use greater firepower yourself. Besides, the line infantry only stands to gain by using the extra range possible with optics that didn’t exist in WWII when the assault rifle concept was created.

Matt61

Hm, well it turns out that I am caught by my own spring as the saying goes. There I was slicing tomatoes with my kitchen knife, honed to razor’s edge. The blade skidded slightly on the curved surface of a tomato and Yeow. The latest Conan movie says that the pain from a cut with a Cimmerian sword is close to pleasure. Well, I couldn’t help admiring how well it did cut, but that was pretty painful, and I am typing this with one hand . . .

Matt61

Smooth edge blade, huh?

There is a reason serrated blades exist.

Haven’t encountered “caught by my own spring” before… “Hoist by my own petard”, OTOH…

But given this is a blade, and not a claymore (though petards were meant to open gates, and claymores are anti-personnel, so claymore isn’t quite proper)… “A poignard in your codpiece” keeps the blade simile — but has a more sinister air…

While at the gun show yesterday, I saw a very unusual .22 rifle. This was a bolt-action, single-shot gun that had no trigger or trigger guard whatsoever. The conventional wooden stock was solid in what would be the trigger area.

Below the back end of the bolt was a small hammer, and the gun was fired by releasing the hammer with the thumb. This appeared to be a production gun.

The only other triggerless guns I can recall seeing were homemade “zip” guns. A Google Search turned up very little, no pictures. The seller did not seem to know much about it. Any comments?

Les

Les,

It sounds like a Winchester thumb trigger to me. Look up thumb trigger.

B.B.

“Thumb trigger” brought up a medical condition! I Googled “Winchester thumb trigger 22 rifle” and there it was! With pictures and a video.

Might be a nice gun for someone missing fingers (anti-beartrap device failure?).

Les

As long as they haven’t had one too many encounters with loading an M1 Garand…

Last night, I attended a “Friends of the NRA” banquet. Had a delicious prime rib dinner and bought a chance on a nice Kimber .45 automatic. Did not win, but had a good time and saw lots of nice guns and other items raffled off.

I found out that each spring, a Field Trial air gun competition is held in North Platte. Apparently, it is only a yearly event. You can use any type of air gun, scoped or not. The only rule sounds like you have to shoot offhand. It was described as a deep u-shaped outdoor path, with maximum range being 25 yards.

Organizer of this is local outdoor writer and lecturer Rick Windham. He can be reached at RWmedia@atcjet.net.

He was not familiar with this site, so I told him about it and the FT activity promoted here, and how it helped Dave Burns with his start in FT. I would encourage any readers in this area to contact him.

I would love to see this become a year-round activity.

Les

One of my friends called with pigeon problems in one of his barns. This isn’t a new problem but the solution is still the same. After all these years (44) the Sheridan C still takes care of business!

Mike

Hello

As this page appears to focus on the Daisy #25, I hope this is a good spot to ask this question.

I have an older (no not really old) #25 and after many years of non-use, found the trigger no functioning properly.

When cocking the pump, the trigger would push back and “automatically” shoot when the pump would be returned.

I tried pushing the trigger forward as the pump was pulled back, and this prevented the gun from “automatically” shooting as the pump was returned, but the trigger was not left in the forwardmost position….it was positioned well back and ready to shoot …much like a hair trigger. The slightest touch and the rifle would shoot.

I played around with this for a little while until the trigger will now no longer catch at all.

I took the stock off, and pulled the barrel assembly off, and found a very loose-positioned spring sitting sort of inside the trigger, but it is not held in to any firm position.

I have looked for a trigger diagram, but cannot find anything.

I am suspicious that there may be something missing, but cannot identify what. there are only two components in this trigger. The trigger itself (two pcs rivetted together) and spring. Of course there are the two bolts, one acting as the trigger pivot, through the body, not counting the barrel bolt.

Can anyone direct me to a parts diagram or advise what the problem may be?

Thanks

Wayne,

Number 25 Daisys are not the specialty of most of our readers. Here is a man who should be able to help you solve you trigger problem.

Larry Behling 315-695-7133 or co2bbjlts@juno.com

B.B.

Update on the old unusual No. 25: I spoke to Orin Ribar (curator of the Daisy Museum) today, Fred LeFever (inventor of the No. 25) was still at Daisy when Mr. Ribar began working there in 1953 (the year I was BORN, aka: a long time ago!). Prefaced by cautioning that NO ONE could say for certain what this gun was (as it was made almost 100 years ago & no witnesses are still living), he said that he thought it was probably made by LeFever himself very early on, before the gun was in actual production. Ribar said that LeFever was quite excentric & would come & go as he pleased; if he got annoyed about something, he’d go back home to St Louis. He guessed that LeFever probably built this gun outside of the factory, as a final prototype, & that the engineers at Daisy changed the inner mechanism to make it more cost-effective/affordable, & to suit the manufacturing limitations of the time. Mr. Ribar didn’t mention the soldering/welding issue that I thought that the non-barrel air chamber may have addressed, so I assume that he didn’t believe that that was the purpose of this design. As he said, we will never know for sure, but I say that his guess is definitely as good/better than anyone’s! He did say that the Museum would welcome the gun as a donation for their No. 25 display, which, in itself, says a lot about the gun’s rarity & it’s role in the early history of the most enduring BB gun design of all time.

I see that this question has been asked since the beginning of the No 25 daisy. How does the trigger assembly go back together. I see diagrams but they are not the same trigger I have, they seem to be from the Model 25 pump and not the No. 25 pump. Can you tell me where I can get a spring and an assembly drawing.

Regards,

Duane

Duane,

Ask this guy:

Larry Behling 315-695-7133 or co2bbjlts@juno.com

B.B.

Great ride down memory lane. My step brother had a model 25, he got it in 1968. I believe it had a plastic stock, very pretty gun and fun to shoot. Following the web site in the article, I was able to identify two other bb guns in our family. My sister had what I believe to be the model 400. Single stroke with the rotary clip. I think she got that in 1973 or so. And then there was an ancient bb gun that we always called “the crooked shooter” because, well, you could see the bb always go high and right. We used that one to chase squirrels out of our bird feeds. It looks to me like it was perhaps a model 102. Squared forearm that was just part of the barrel. I believe that one was from the 50’s. Thanks for these articles, I really enjoy them!

Eric

Eric,

Welcome to the blog! I have been writing this blog since 2005, so there is a lot of material to see. The current page is here:

/blog//

Sometimes you can do a Google search and find old titles, as there was an older blog that ended in 2010.

B.B.