by Tom Gaylord, a.k.a. B.B. Pelletier

The art of collecting airguns: Part 2

The art of collecting airguns: Part 6

The art of collecting airguns: Part 7

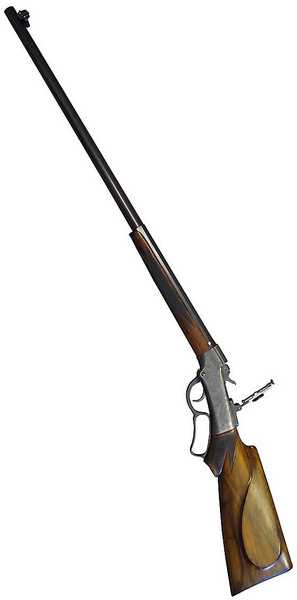

My Marlin Ballard was made in 1886 and still looks almost new.

Today is for blog readers Kevin, Robert of Arcade and for all airgunners who love more than just airguns. You love the shooting sports, and everything that goes with them.

This is an airgun blog and believe me, today’s report actually does relate to them. This is the ongoing report of a Marlin Ballard rifle I acquired right after I got out of the hospital in 2010. As you can see in the photo above, the rifle is beautiful; but more than that, it touches the lives of all my friends — my late friend Mac, my shooting buddy Otho and Kevin, who often comments on this blog! In fact, Kevin is the one regular blog reader who has actually seen this rifle in person.

Kevin was so taken with this rifle when I originally reported on it that he sent me a gift of the book Ballard — The Great American Single Shot Rifle by John T. Dutcher. But he went way beyond just sending the book. He went to Mr. Dutcher personally with prints of the photos I showed in the first report and spent two hours with the author, examining the rifle through the photos. I was asked to take the rifle apart and photograph all the serial numbers plus various details inside the gun, which I did. From what he sees, Dutcher thinks this is a special-order, factory-made rifle, which is a specific category of Ballard made for high-volume retailers like John Lower of Denver.

I started shooting the rifle almost immediately after getting it, though I’ve always been very careful not to load it too heavy. As well-made as the Ballard action is, the metallurgy is not up to modern standards. So, it gets only reduced loads that develop low pressure and only lead bullets alloyed with a small amount of tin. The way I’m loading the gun, it should hold up for 100,000 rounds or more, only a few of which will be fired by me.

I wrote a couple reports on my early progress, which are in the links listed above. But I stalled out and stopped reporting on the rifle several years ago. Today, I will bring you up to speed with what’s been happening; and, no, I haven’t had a breakthrough in accuracy — yet.

I continued shooting the Ballard with commercial cast bullets, then I purchased a Lee mold and cast some bullets of my own. My bullets did as good as the commercial ones, even though they’re not perfectly round. It’s not uncommon for cast bullets to be out of round by a thousandth of an inch or sometimes more, but it would be better if they weren’t.

Lee bullet molds are inexpensive, but they do make fine bullets.

Schützen shooting

One thing I tried with the Ballard was loading it like a schuetzen rifle. Schützens are extremely accurate target rifles that held most of the world’s records for groups out to 200 meters until recently. They’re single-shot rifles whose cartridges are loaded one at a time at the range. A schützen shooter sets up his reloading equipment right on the rifle range. His powder measure is set to throw a single charge of powder. If he wants to shoot more than one rifle, he has a powder dropper for each of them, and only a single powder charge is used.

The bullets he has cast and kept in order as they fell from the mold. He doesn’t worry about weighing the bullets because he uses a mold that is so perfect it never varies by more that one-tenth of a grain in weight, as long as he keeps the lead alloy the same. But to guard against any variation, he shoots the bullets as they dropped from the mold…so the alloy will not be that different. And you thought airgunners were anal! Schützen shooters make benchrest shooters look like weasles on caffeine.

They use a single cartridge case that gets fired and reloaded hundreds of times. They file a notch into the edge of the rim of the case, and that cartridge is always loaded into the chamber with the notch pointing straight up so there’s never any variation. The case is never resized because it doesn’t hold the bullet. It’s just filled with powder and a wad and then loaded without a bullet. Because the brass isn’t worked and is always fired in the same chamber, it lasts a very long time!

This simple tool is all you need to load cartridges at the range: A Pope capper-decapper.

The bullet gets loaded into the bore and positioned 1/16 of an inch ahead of the cartridge case, which is loaded after the bullet. A special mechanical bullet seater is used to do this because it’s difficult to push a solid lead bullet into rifling. Airgunners know this because loading solid pellets into a barrel is a nightmare! Only AirForce Airguns designed their barrels to accept solid pellets, and even then, they’re still hard to load.

This is a simple bullet seater. The bullet fits into the mock cartridge on the end of the seater. The seater is then pushed into the breech, and the bullet is pressed directly into the rifling. Higher grade seaters are mechanical with good leverage.

I tried loading my Ballard the schützen way, and I can report the following. Doing it this way, where you reload the cartridge after each shot, slows down your shooting to one shot every five minutes, or so. I suppose you could do it faster, but that’s one of the real benefits of doing it this way. You don’t have to be fast. I can shoot a 10-shot group in the same time another shooter arrives at the range, sets up, goes downrange to put up his targets, shoots several boxes of commercial ammo, retrieves his targets, knocks down, packs up and leaves. It takes us both about an hour; but at the end of it, my heart is beating 55 times a minute and I feel like I’ve been sitting on the veranda drinking a mint julep!

Schützen shooting is relaxing! I enjoy it very much, so I figuratively bit the bullet and bought a top-quality handmade bullet mold from Hoch so I could seat the bullets properly and do it right. That mold was not cheap, and it took about 6 months to be made to my specifications.

A breech-seated bullet has two different sizes to its body. The forward part is sized to ride on top of the rifling lands, and the rear part is exactly as wide as the grooves. When I measured my rifle, I found the lands measured 0.376 inches across (one side of the bore to the other) and the grooves were 0.384 inches across. Those two measurements were what I gave to the mold maker, along with the lead alloy I intended using (40 parts lead to 1 part tin). The mold he sent to me throws a bullet that measures exactly those dimensions, plus it’s uniformly round. Those of you who worry about pellet head sizes know what I’m talking about!

This custom bullet mold from Hoch is a nose-pour design, like Harry Pope used to make. This breech-seated bullet has two base bands that are 0.384″ wide and three nose bands that are 0.376″ wide. The nose bands are supposed to ride on top of the rifling — not be engraved. That makes the bullet easy to seat into the rifling.

Oh-oh!

But when I went to the range to try my new bullet — IT DIDN’T FIT! The nose was too fat and was being engraved by the rifling, which prevented me from seating the bullet in the barrel with anything short of a hammer. Obviously, I wasn’t going to do that! I pouted instead. I lost interest in the rifle for several months. But I always come back, and this time I remembered what the black powder shooters say: Black powder is better than smokeless when accuracy is on the line.

The bullet from my Lee mold is a little too small for the barrel, but black powder upsets the base. So, I reckoned that might work. I loaded some cartridges with black powder and the Lee bullet and went back to the range. With black powder, I had to clean the bore after every shot, but working with the Nelson Lewis combination gun trained me to do that, so it wasn’t a problem. Alas, these cartridges were no more accurate than the smokeless rounds I’d been shooting. I probably didn’t spend enough time perfecting my loading technique and was getting frustrated. And a frustrated B.B. doesn’t make good decisions.

Over the past 2 years, I’ve shot many targets like these with the Ballard. All have groups around 3 inches at 100 yards.

Over two years have passed since I acquired the rifle, and I was still stuck in the same place. I couldn’t shoot even one of my new bullets from my expensive new mold, and the best I was able to do wasn’t as good as I’ve done with other more mundane rifles shooting lead bullets. If I was a golfer, this would be where I wrap my expensive drivers around trees and take up drinking.

A strange encounter

Then something happened. Just a few months ago I was out at the range for another round of humiliation, and I happened to meet a real schützen shooter. I’d met him there before, but never when I had the Ballard with me. He was putzing around with one of his exotic thundersticks, and we got into a discussion of my frustrations. Well, maybe not a real discussion. Actually it was more like I went over and started sobbing on his shoulder about all my woes. But you get the picture.

He told me about another mold maker — the guy I should have gone to in the first place. Long story short, he sold me on trying another new mold. This one will be ready in 3 weeks, plus he told me all the schützen shooters go to this guy for their molds. I was straight on everything else. I was making my loads with the same equipment and in the same way he was. So, the mold must be the answer. Right? Please tell me I’m right because I’ve spent even more on this new mold than on the last one!

Oh, maybe I should also tell you this. I slugged the bore of the rifle again, to find those critical dimensions for the new mold. And this time I asked my shooting buddy Otho to check my measurements. I’d been two-thousandths off on the first mold, so it was engraving the rifling where it shouldn’t. We not only confirmed that fact, we measured the slug with several different measurement devices this time.

The internal dimensions of the bore are determined by upsetting a lead slug in it so it completely fills all space. Then drive it out and measure it. The grooves measure 0.385″ across and the lands measure 0.374″ across. Two people used different measuring devices to arrive at the same dimensions, so they should be correct.

The moral of the story

I like giving you guys good news. Who doesn’t? But not everything turns out the way we want it to, and there can be a lot of value in reporting the failures, too. I don’t mean so we can go spray-paint the names of the evil airgun manufacturers on overpasses, but so we can better understand this shooting thing we all do.

So, for Kevin and Robert and everyone who’s interested in the rest of the story, that’s what’s been going on with my Ballard. I’ve had visions of showing you impossible half-inch 10-shot groups at 100 yards from this rifle, all the while realizing with bitter irony that my AR-15 — a rifle I’ve publicly criticized for over 40 years — can actually do it. I’m not there yet (with the Ballard). Maybe I never will be, but the pursuit of excellence is what keeps me going. And the days spent with air rifles like the Walther LGV are what keep me sane.

Big Shot of the Month

Pyramyd Air’s Big Shot of the Month is Chris Ennis. He’ll receive a $100 gift card. Congratulations! If you’d like a chance to be the next Big Shot, you can enter on Pyramyd Air’s Facebook page.

Chris Ennis is the Big Shot of the Month on Pyramyd Air’s facebook page.

Guilty.

The Marlin Ballard that B.B. acquired was from the period of production that produced rifles that shot groups that took almost 100 years to replicate. They were the Rolls Royce of schutzen guns and demanded prices that were significant yet justified.

Unlocking all the doors to rekindle the accuracy that has been dormant in this fine speciman is fascinating to me. The similarities to airguns is uncanny. Too many folks give up before discovering the ultimate accuracy.

Yes, I was fortunate to see and shoulder this Marlin Ballard. A moment I’ll never forget. I’ve been around guns for over half a century. I was an ffl. For almost 30 years I had tables at 1-3 gunshows each month. I’ve owned and seen lots of guns. We have an annual show in Colorado where you will see many Ballards. I’ve paid attention to and coveted these guns for many years. Condition is paramount in these older guns. I can tell you that B.B.’s Marlin Ballard is exceptional.

It’s easy to admire a well built, tightly fitted gun from an era that was known to have great barrels on these models.

What’s more admirable in my view is an owner that refuses to be discouraged while traveling the long and lengthy path that is necessary to rediscover the right combination of a proper load and bullet to rekindle and extract the accuracy in this legendary gun.

I’ve waited a long time for this follow up report and am greatly encouraged by what I’ve read since I suspect that another door will be unlocked on the journey to discovering the ultimate accuracy of this fine speciman of a Marlin Ballard.

Wonderful article for any and all shooters. Thanks.

kevin

Kevin,

It is wisely said that obstacles are what you see when you take your eyes off of the goal. People who have a passion for something are not easily distracted or discouraged. We have a passion to pursue, which is said to be the secret of success.

Victor

Victor,

Well stated.

kevin

Wow, your shooting background goes on and on the more I see of it.

Matt61

Matt61,

Don’t be too impressed.

Back then having an ffl wasn’t hard and the record keeping was reasonable. Let me ffl expire long ago but still have to keep the records. Still have a C & R license (just renewed it).

The real reason to attend gun shows for me was to be able to see what was on the tables before the doors were open to the public. Never pulled off the multi layer gun trades that B.B. has. Kinda regret not trying harder since B.B. has acquired some great stuff by being clever and bundling.

I’m ashamed to admit that I was great at acquiring but poor at letting go. The last 5 years I’ve been selling. Mostly on auction sites since I don’t have the time or patience to sit at a show table for two days. Most of what I have/had is niche anyway. Very few folks appreciate my old stuff and it looks funny surrounded by all the black guns at shows these days. Guess I’ve sat still too long and time (demand) has left my stuff behind.

kevin

“look like weasles on caffeine.”.

I’ve resembled that remark. Too funny!

Off topic. I was wondering how gun powder is made. I’m not interested in making it, but was curious if it is even possible. So I did some research and found that modern gunpowder cannot be made by just anyone, and in fact, there is only one company in the entire US that makes a base chemical. In fact, according to my findings there is only one US company that makes black-powder. I won’t go into any details of what I found, but this did make me realize how valuable airguns might/would be if something really catastrophic happened and all ammo was eventually depleted.

Victor

Victor , there is one thing that makes me sad about today’s topic on BB”s wonderful Ballard and it is that there is little available in component’s like primers and powder to enjoy loading for it. The depletion of ammo is a reality that is here to stay, and I for one do not believe it is about hoarding. There will never again be the freedom to purchase like we had in the past. In my state there will be no mail ordering of handloading supplies or ammo allowed here ever again as of next year, and even major retailers like my local Walmarts have no .22 RF until maybe 2014. Yesterday when I was there ,the shotgun shells were very nearly depleted. There were only 4 boxes of 20 ga trap loads for instance. I didn’t see any long line of folks buying ammo either.Why is there little to no ammo being imported from outside into the U.S.A. right now? You are right about airguns. That is why I still believe that a $ 200-300 repeating .25 or .32 cal RB MSP would be a wonderful thing . At least anyone could scrounge lead and cast RB cheaply . I have a Lee RB mould for my .32 ML and I have been chided for having it as the swaged Hornady RB is so uniform and until lately recently available. Well ,I’m glad it’s there because the comet has hit.

Robert,

In my area all Walmarts have .270 Win. Some have plenty of .38 Special, and most have 30-06. I can’t find .22 caliber, but I still have dozens of boxes of that. I buy match ammo, and that is sold by lot number, so I always bought everything on the self.

Ask your local Walmarts when they restock. Most of the ones that I’ve spoken with do it on a particular day (or days), and at a particular time. One Walmart told me that they use to shelf their ammo at night, but later found that it was all gone by morning. The person who told me seem to imply that it was the employees who were taking the ammo. I’m guessing that employees are hording the ammo, and probably selling it themselves. I’ve seen this done with Weaver rings. For awhile I couldn’t find certain Weaver rings, and one Walmart employee told me that there was a guy who was buying up all of Walmarts inventory and selling them at a mark-up at gun stores. You see, Walmart prices for these rings was almost half of what other retailers had them for.

Also, in my area several ammo only stores have recently opened up. I would imagine that these stores are buying enough of an inventory that they could effect availability elsewhere. Until very recently, I had never seen ammo only stores, and now they are sprouting up randomly. We also have a bunch of new shooting ranges. So business is booming like never before.

Victor

Good points, Robert. I always thought it would be a real comet, leaving a massive trail off destruction. Come to find out it’s the figurative one, just the internal decay, the same as that which took down the Roman empire… We are led by people who think we are exempt from the rule of “Those who don’t remember history as condemned to repeat it.” And so we are now transitioning into extinction as a nation or transforming into something I don’t want to imagine. Eventually, being able to make your own ammo may be what saves you from starvation or violence.

/Dave

I don’t know how it would work but Canadian retailers seem to be well stocked. The closest range is even having a sale right now.

Maybe it could be worth it ?

J-F

Flintlocks and air rifles are the way forward :)!

BG_Farmer,

And hunting bows, when you have to take down large game.

Victor

Wow, I sympathize. No mail ordering of ammo and handloading supplies is my ultimate nightmare. It hasn’t happened in California, yet.

Matt61

For thousands of years alchemists have been trying to turn lead into gold. Obama finally succeeded this year.

This is such a beautiful rifle, I think I’d be happy just to hang it on a wall and take it off once in a while and “play” with it.

I, like Kevin and Victor admire the perseverance exibited here. I’m not sure I would be mature enough to have such patience and perseverance but then again I’m quite hard headed so if I knew it was possible maybe I’d keep going?

J-F

J-F,

It isn’t really patience that’s driving what I’m doing. It’s frustration. I read all these vintage reports of what these fine rifles could do, and yet find myself incapable of doing them. I don’t mean I should be able to shoot groups like Harry Pope did, but any well-made Ballard from this period (and this one is certainly well-made) should at least be capable of average accuracy. Not average by today’s terms, but average for the late 19th century, when the standard for accuracy was much higher.

I would be delighted to put 10 bullets into one inch at 100 yards. By today’s standards, that would be good. But by 19th century standards, the gun should do even better than that.

Currently I am fighting a 7+-pound trigger pull on this rifle, which is a liability. And the bubble level in the front sight is infinitely more sensitive than a bubble level we see today. That doesn’t make it any easier to shoot, either, for the bubble takes its own sweet time to finally settle in the center.

But if I can shoot a group that’s as good as I believe it should be, then I’m prepared to drive the gun to Montana, to have a double-set trigger installed (without changing anything on the existing parts). With that, I believe I could settle in and shoot repeated good groups (by my definition) with this rifle. And its next owner would get not only an historically correct original rifle, but also one whose secrets have been ferreted out, and whose kit of support equipment would accompany the gun.

B.B.

Well if this isn’t patience I don’t know what is.

Frustration can do both, lots of people would have just put it on a wall or worst sell it at a lost just to get rid of it and never see it again.

You didn’t give up on the rifle and keep on pushing it because you think it can do better. In my book it’s called patience.

J-F

B.B.,

It’s a form of patience that comes from as many decades of experience that you have. We do eventually learn that it’s best to walk away from a problem (especially when it gets frustrating), and revisit it when we have a clearer or different perspective, even if it means years later. Some things are just worth it.

Victor

Seven pound trigger? That’s almost as much as the double-action pull on my SW686. How can you expect to shoot any kind of group with that? Can’t you go in and lighten the trigger?

Matt61

Matt,

A double-action pull is vastly different than a single action pull. Seven pounds is too heavy, but the Ballard trigger is far more precise than a S&W trigger shooting double action.

Can I change it? Sure. A Rolls Royce can also be changed. But you want to take council before doing so.

B.B.

BB: I’ve been waiting for a follow up, glad you’re sticking with this one. I thought your gun was a special order one, too many things about it cross over to the other models of Ballard rifles. The articles you write for this blog like yesterdays , and the ones on the Air Force PCP guns and long range shooting with them are what the future is for airguns. The article I read by you in the latest Shotgun News Treasury edition on Dennis Quakenbush and long range shooting with airguns of the big bore type ,and casting bullets for them, tie into firearms like your Ballard. It is not about what propellent you use to launch a projectile, it’s what happens and how you got there that’s the interesting part.

B.B.,

Just curious.

” Grooves of 0.385″ and Lands of 0.374″ “. Were the tolerances on these two dimentions +-0.0000??

Pete

Pete,

This is cut rifling, where each groove is cut separately by a cutter passing down the bore many times. So these bores vary widely from gun to gun. Is that what you are asking about when you mention the tolerances, or are you asking me what the variation is between the largest and smallest dimension for each of the measurements — from one end of the bore to the other?

It doesn’t matter, though, because I don’t know either answer. All I can say is these barrel are very uniform, but how they would compare to a modern button or broached barrel, I really would not know.

B.B.

B.B.,

Sorry, I must have been having a senior moment.LOL! What I really wanted to know is what tolerances you gave to the mold maker when you supplied him with those dimentions.

Pete

Pete,

No tolerance is allowed. That’s why it is important that he knows the alloy (lead to tin ratio) you intend using, because it affects the size of the bullet after it drops from the mold. And I am telling you that this bullet drops free at exactly the dimensions I requested. Whether that extends down to the ten-thousandth, I can’t say. I only measured it with a caliper that registers in thousandths.

B.B.

BB,

Can it be sized in another, 2 dimension die? Kind of like a reloading press in that the bullet doesn’t get pushed all the way through, but gets knocked back out the same way it went in, thereby allowing for the narrower nose. Or would knocking it back the way it came damage it? I haven’t tried casting and sizing yet myself, but it’s coming. Just trying to think of a way to save your investment in the Hoch mold…

/Dave

/Dave,

Pope designed a 2-dimension sizer that some are making today, but sized bullets are always suspect, and schuetzen shooters don’t like to use them. If the mold is made right, it will drop a perfect bullet that needs no sizing. I lubricate with my fingers, so this presents no problem to apply the grease to the grooves.

B.B.

B.B.

Since the O.D. of the cast bullet is recipe-dependent, any chance of the tweaking that recipe such that bullet cools to a smaller diameter? Or how about casting in a heated mold? Yes, I know nothing about these matters!

john

John,

Changing the alloy of the metal does change the size of the finished bullet that drops from the mold. But my custom bullets are too large in front and too small in the rear. No good way to change that.

As you cast bullets the mold heats up on its own. It gets to around 450-500 degrees F. The molten metal runs around 650-700 degrees F. In fact, you have to pace yourself to keep from overheating the mold.

B.B.

BB: A thought on your bullet problem. Have you explored the idea of using a lube wad under your bullet? Also, although I personally have not fooled with this yet , but intend to in my modern Ruger SS #1 in .458, is to explore paper patching your bullets? Gas cutting maybe opening the groups up ?

Robert,

I agree about the bullets being too small. That is why I bought the first custom mold, and why I’m now buying the second one.

As for a grease wad, if I was going to stick with black powder I would use a grease wad, but loading the schuetzen way it isn’t needed, though some of the older shooters did still use them with smokeless.

Lots of experimenting still to come.

B.B.

Putting something frustrating down for awhile and picking it up later is something I can relate to. I can only take so much frustration at one time. I have had many projects over the years that were started and stopped many times. It has been funny to me that out of nowhere I will get an idea of how to fix the problem and I am engaged again. Sometimes it works and sometimes not. The one piece of advice I can give you is to try a lot of different things, even things that don’t make sense to you. You may not find the answer in a history book but you might find it in your garage.

I enjoyed the blog today and appreciate you writing it. It is the pursuit that is fun and challenging. If the Ballard shot 1/2″ groups at 100 yards every time you took it out it would be collecting dust in a closet.

David Enoch

I understand frustration, but I will respectfully differ on the response. In fact, stopping could be the very worst thing to do by locking in the problem and letting it eat at you. When I visited Vladimir the Russian commando (as I might have mentioned before) he doubled me over with a sucker punch to the abdomen which washed out all my interest in life. But right away, he said, stand up straight. Hunching over in a fetal position, he said, actually locks in the impact and the damage whereas by standing up, the body’s natural elasticity dissipates it away. So, it proved to be. And then he told me to take a “cleansing breath” through the nostrils. This moved around the internal organs for more dissipation and poof, there was no pain at all. I was as good as new. I was flabbergasted. Never in my life have I experienced anything like this. You can even try this experiment for yourselves. 🙂

So, the stopping from frustration could be locking in the damage in the same way. You want to keep going. Of course, don’t keep doing the same thing. Try something, try anything. Or even try the same thing on the chance that you will get insight into what went wrong. When I’m working on a truly difficult problem, the answer usually appears upon prolonged application when I least expect it. So, you just keep applying pressure. Never never never never never never never quit. Never quit!

On the other hand, if you’re so frustrated that you can’t think straight, you want to back off. It’s all about intelligent management of the problem.

Matt61

Edith,

I have appointed myself the guardian of the “Big Shot” photo description. The photo subject winner appears to be a lady so you might want to revise the last line from “he’ll receive….” to “she’ll receive ….”. On the other hand, perhaps the actual person who submitted the photo is looking for the gift card and not the subject who indeed, may not be Chris?

My Friday morning missive to get everyone’s juices flowing 🙂

Fred DPRoNJ

Fred DPRoNJ,

The photographer gets the gift card, not the subject of the photograph. When the winner has a unisex name, I do a facebook search to see if I can come up with the exact person to determine the gender. In this case, I was unable to make that determination. However, most airgunners (and most shooters) are men, so I feel secure using a masculine pronoun to refer to him.

Edith

Heh… That type of search sure wouldn’t find me… Not only am I not on Facebook, I’m not on LinkedIn (even though I spent last year filing internet job applications and some sites had “quick fill” modes using LinkedIn… After reading two books on using LinkedIn I still concluded it wasn’t usable — all my former work colleagues are SF Bay area but I’d moved to Furniture City [GR, MI]…).

At least neither the name on my birth certificate, nor my 20+ year online persona are gender neutral. And a search on Wulfraed should find lots of references that would eventually coalesce onto my reality.

If you sent a picture of your wife would put her or your name for the reception of the gift card?

hehehe I’d sure put mine. What would my wife do with a PA gift card? Well technicaly she could buy me something but it’s much easier to just order it for myself 😉

Speaking of PA order, I saw that PA can now ship some airguns to Canada! Edith do you know if these guns are already in Canada or leaving from your US location and if they’re leaving from your US location do we have a choice over the carrier choosen?

Because UPS charges horrible (often matching the price of the item getting shipped) brokerage fees and talking about it on the Canadian Airgun Forum everyone is waiting for someone to buy something and see how much it costs before ordering…

J-F

J-F,

I sent your question to Pyramyd AIR and got this reply:

Edith

Awesome, thank you for the quick reply Edith.

I think a Steel Force may be coming my way sooner than later.

J-F

B.B., folks might think that what you are teaching in this blog are the attributes of airguns and firearms, but they would be wrong. You are really teaching the principles of dedication, persistence and commitment. Thanks for this wonderful report.

That’s right. Martial arts, to name just one thing, are condensed into shooting.

Matt61

BB,

I’m also happy that you’re sticking with it. I have many hobbies and with each one of them I experience the same process of frustration, walk away, come back later to start fresh (rinse, repeat), and more often than not that is what eventually gets me the success I’m seeking. That’s what keeps me going. Keep up the good fight!

/Dave

Great report, B.B. I’d love to be able to take a Ballard and an 1874 Sharps out for a day of rest and recreation. ~Ken

B.B.,

You talk about the slow rate of fire when shooting the schützen way. Instead of having the barrel heat up gradually, you’re letting it cool down some to possibly some normalized temperature. Wouldn’t that be better for accuracy?

Victor

Victor,

That is certainly a happy byproduct of the process. As is the fact that schuetzen loads are the lowest possible to stabilize the bullet out to the range of the target. You don’t burn much powder, so your gun doesn’t heat up as much, and you take longer between shots, which also keeps the barrel cool. And you shoot nearly pure lead bullets that slip through the barrel easily. No wonder these barrels last so long!

B.B.

B.B.,

Well there you go! It’s a win-win all around. Long barrel life, and a relaxing experience. I’m sure that this also helps you keep your form from shot to shot. I know that when I shoot an auto-loader, I have to consciously tell myself to slow down. If I allow myself to get anxious, I start to make fundamental errors.

Victor

BB,

The sights and the level lead one to believe it was intended for accuracy work. I could also believe the non-hooked buttplate was intended for bench rested shooting (as opposed to offhand). BUT none of that makes sense with the “7 lb.” trigger! I know it sounds unlikely, but any chance you have a single set trigger :). Or is some part internally maybe worn, maybe too soft from the beginning? A friend of mine had an old T/C where sear bar from the lock had worn a groove in the trigger bar — that caused the sear bar to catch in the trigger bar and the pull was ridiculously high! 7 lbs. may be correct, but I tend to doubt it — most old guns were built before lawyers made triggers so hard to pull, and even simple triggers are usually quite usable! That said, if everything else is perfect, a 7 lb. trigger pull shouldn’t be insurmountable.

I’m suspicious of the groups, however, as they are not round. Even big groups should be round under perfect conditions. Try a different target that allows more precise sight placement, perhaps? Also, make sure you are resting the barrel and/or fore arm at exactly the same place every time. Assuming you always wait for good wind conditions and are compensating for the trigger, there must be something else going on.

Anyway, don’t take any of this as dismissive of you skills (you can even shoot an AR-15 :)!); its just my perspective. Sometimes they shoot perfectly without any effort and sometimes it takes years of study! Maybe this one is hard to shoot and that explains how it ended up in your hands in such excellent conditions.

BG_Farmer,

Remember that this is likely a special-order factory-made rifle. So the presence of the sights and the shape of the buttplate may not bear as much correlation to the intent of the rifle as we might think. However, it also has a 30-inch heavy barrel, and whether the customer wanted it as a hunting rifle or not, Ballard did not make a bad barrel.

When I disassembled the rifle for Dutcher, as shown in Part 6, I looked at every internal part. They are in pristine condition. Aside from some black powder residue that I cleaned off, those parts look exactly like they just left the factory.

/blog/2011/01/the-art-of-collecting-airguns-part-6/

Here is a strange thing. The bore is admittedly one of the largest ones ever seen, yet the chamber is cut so tight that a proper bullet cannot be inserted into a cartridge that can then be chambered. So breech-seating seems to be the only way to load the rifle, if there is to be any hope for accuracy. Breech-seating implies a target rifle. So you would think the customer would have specified a good trigger. But they didn’t.

Then look at where the cheekpiece is, in relation to the peep sight. Dutcher spotted it immediately. The butt isn’t a Ballard butt, though Dutcher believe the stock work might have been done by a former Ballard employee, because it looks so rifle. But the cheekpiece serves no function, given those sights. Yet there are no scope blocks on the barrel and no holes to indicated there ever were any.

It is a puzzlement. But if I can get it to shoot like I think it should, then I hope to treat myself to a new double set trigger, so I can keep on doing it.

B.B.

Tom,

The more you share about this historic piece of functional art the more fascinating it becomes.

Understand the frustration. Treasure hunting for anything, including accuracy, is laden with disappointment and frustration.

Can’t help but think of all the ballard owners that spent years trying to reconnect their matching serial number parts. All of yours match except the stock.

J.P. Lower was a distributor and could custom order a gun for you or me or himself. His 1886 catalogue that John shared showed multiple custom order guns for sale. Maybe J.P. Lower received your gun as one of his custom orders rather than a customers. Maybe J.P. Lower’s fear was that a double set trigger announced to his clientele that this is a true target gun and few of his customers were target shooters in Denver during that time and thus weren’t willing to pay the price for triggers but the 30″ barrel and implied accuracy was something they would pay for? I don’t know. Speculation.

I am fairly certain that J.P. Lower didn’t commission the elegant buttstock. I suspect the buyer had a plan to scope the gun and the first step was a new, high quality buttstock. Time passes, the buyer’s plans change and the project doesn’t get finished. Again, pure speculation on my part but it’s happened to me with many gun projects.

Your bore is huge vs. the tight chamber. Do you think with the old black powder of the day that a PURE LEAD .38-55 bullet seated in a cartridge could obturate to fill this bore?

kevin

Kevin,

Weren’t set triggers popular out West, or did they fall off with the cartridge rifles (more likely the repeaters)? Most if not all Hawken rifles I’ve seen have had really nice double set triggers, and the rifles that preceded them also seemed often to have had double-sets.

Pure lead + black powder might be an idea.

BG_Farmer,

Must assume that dst triggers were popular out west even in the distant day we’re talking about.

My point was that if a “discounter” like J.P. Lower did a special order where would he cut corners first on a high end marlin ballard? The trigger? DST’s were 10% of the cost of the special order rifles. Again, I’m just speculating.

The target shooting back then was primarily on the east coast and in the late 1800’s denver was more concerned about survival and hunting. It’s not to say that a well healed businessman in denver didn’t buy Tom’s special order marlin ballard from J.P. Lower with a desire to further customize it but again pure speculation.

For the initial cost and assumed quick stock change (since I’m convinced that a Ballard stock maker or a stock maker closely associated with Ballard created that wonderful fit and appropriate period walnut piece that had lines so closely associated with Ballard stocks of the period) my gut tells me that the buyer was a well healed gentleman that wanted a scoped target shooting gun since during this period there was a transition from target sights to scopes and never finished the project.

The cat’s meow would be to find the original buttstock for this gun. Tough, Yes. But because it’s serial numbered not impossible.

kevin

Kevin,

I have come to the same conclusions. And, no, I don’t think a black powder loaded cartridge can expand the bullet enough to fill the bore. That is why I am so puzzled.

B.B.

Interesting. It sounds like you have a plan/way forward and some expert advisors. Looking forward to progress reports. You may be right about the large bore and relatively tight chamber being intended for bench loading if it is intentional, but the trigger is still a mystery… Is the trigger pull typical for other Ballards with that type of trigger, acc. to the experts?

BG_Farmer,

I wouldn’t have thought that any Ballards had triggers as heavy as my rifle has. It can as a complete shock. And, no, to the gentleman who asked if it is a single-set trigger. It absolutely isn’t. Believe me, I have tried!

But I have next to no experience with other Ballards, so I can’t say whether my trigger is typical or not.

B.B.

BB,

Off topic, but I did like the article:

I just received my Air Venturi Bronco yesterday and absolutely love it, but I have an issue that you may be able to help me with. The gun was dieseling like most new pellet guns do quite a lot yesterday, but just a few moments ago the oil that came in the gun exploded when firing, twice in a row. I actually saw flames spit out the muzzle, and the report (shooting inside at a pellet trap) was incredibly loud. Yes, it was pretty awesome, but I’m pretty sure airguns are not supposed to fire like that, and I know it can’t be good for the brand new piston seal. I’m shooting JSB Match Diabolo Exact 8.4 grain pellets.

I have not oiled the gun, in fact the only thing I did to the gun was run a clean patch through the barrel before shooting because the barrel looked dirty out of the box. After firing a few times with the (excellent) iron sights, I took off the front post sight and installed a red dot sight, but I don’t see how that would make the gun send flames out the barrel.

I also have one more question: When removing the iron sights on a Bronco, I feel like I should put the screws back into the holes where the sights go, but I’m worried that they will go too deep into the barrel and muck up accuracy or something. I know you were worried about the same thing in your review of the peep sight for the Bronco. Do I need to find a shorter screw to cover the hole, or what?

Thanks so much, I love the blog and have read just about every post in the past several years within the past few weeks to fuel my need for information on pellet guns.

Just looked at my Bronco, I don’t believe those are thru-holes on the sights. In any case, you could use little o-rings or tubing as a form of lock washer when you put the screws back in.

Thanks! I’ll do that! I take it you’ve never had a combustion in your Bronco?

I haven’t gotten a chance to fire mine much yet. Gotta figure out how to dampen the noise.

Kev50027

I have had two Broncos and neither of them detonated, much less threw flames. I can only guess that your gun is way over lubricated. Even so, it is surprising to me that the gun would behave that way given the lower power of the gun.

Regarding the sights, I scoped my Bronco but left both sights in place. They don’t interfere with the sight picture from the scope, and I won’t have to go looking for the parts should I decide to revert to iron sights.

BTW, my Bronco seems to prefer Crosman Premier Lights (7.9 gr) from the brown box. So give those a try if you have some at hand. On the other hand, heavier pellets will often mitigate the dieseling and detonation of over lubricated guns. So maybe wait until the gun is broken in to try the lights.

Welcome to the blog, and welcome to the hobby. You have come to the right place.

I was also surprised about the detonation considering the power of the gun. I’ve had more powerful guns diesel, but never detonate.

I was hoping I could leave the iron sights on, but my red dot sight has no magnification, so the front post sight interferes with the view, and I can see the rear open sights. Perhaps giving myself a bit more eye relief by moving the red dot forward would help, but the front post is in the way.

Thanks for the pellet recommendation! I also have the lighter version of the JSB Match Diabolo Exacts, but the next time I pick up pellets I’ll take a look at the Crosman Premier Lights.

Thank you for welcoming me! I played with BB guns as a kid, but now that I’m 25 I’m getting serious about punching holes in soda cans and popping water balloons with pellets (if that’s possible).

Kev,

In the first season of “American Airgunner” (a TV show about airguns) Paul Capello and I broke balloons filled with talcum powder from 100 yards offhand. It is entirely possible.

B.B.

That’s astounding! I enjoy making slow motion videos of water balloons bursting from a pellet, but I never thought of putting other things in the balloon like talcum powder. I’ll have to try that!

Flour works too.

twotalon

B.B.,

Funny that you would mention popping balloons with an airgun. I was just telling my wife that this is something that I want to try. Balloons are great because you can inflate them up to various sizes. While I like to punch paper, most non-hobbyist prefer reactive targets.

What exactly is the effect of adding powder to the balloon? Does it disperse well?

Victor

Victor,

It is quite dramatic. If there is any breeze, you get a huge puff of white smoke, because the pressure in the balloon disperses the talcum powder when it breaks.

B.B.

I took the iron sigths off (and put them in a ziploc bag with my airgun stuff in case I want to return it to it’s original state).

I took everything off at the front but left part of the rear one on with the screws in so it wouldn’t look bad and wouldn’t interfer with my scope.

J-F

Kev50027

You might as well leave the open sights on it and not worry about it.

As far as the dieseling and detonations go, it’s overlube from the factory. Do not oil pellets either.

You can just get some cheap pellets like CPHP and shoot it until the lube problem clears up.

I have gotten rifles that were dripping with oil, full of thick grease, and bone dry. Each is a problem that can be worked out one way or another, but you need to shoot it enough that you are sure that there is nothing else wrong with it before you do any teardown and do any work on it that would screw the warranty.

twotalon

And I can visualize that all being the /same/ rifle… (bone dry bore, oil-soaked piston, and covered in cosmoline on the outside)

Some company can probably top that…

Sweepings from the floor of a body shop (powdered metal, bondo, welding splatter, and paint). Then some shavings from a machine shop. Mix it all together with the lubes, and mash the rifles down in it to preserve them before shipping. Would the Chinese do that ??? The barrel of fish oil is bad enough.

twotalon

Thanks for the reply and help! I’ll follow your advice about shooting it more. This gun may turn out to be too accurate for the red dot sight to do it justice, but I like how it gives me a more clear picture of the target.

Kev,

Mendoza does tent to over-oil their guns during assembly. That’s why they put the oil hole on the spring tubes of all their guns and it’s also why we had them take it off the Bronco. They are of the mindset that everyone wants the maximum velocity they can get from their airguns, and detonation is the only way to do that.

The detonations don’t hurt the gun as much as you might think. I have had the same problem with Dianas and Weihrauchs. The solution is to shoot light pellets to promote the oil burning off. If the condition persists after a couple hundred shots you can contact Pyramyd AIR about it. They can disassemble your rifle and dry it off, if it is that bad. But a few hundred detonations isn’t normally so bad, though it is nerve-wracking.

B.B.

Thanks for responding B.B.! I’ll try lighter pellets. When I got the gun out of the box, it was coated with oil on the outside, so the inside probably is as well.

Perhaps I’ll try storing it vertically on the muzzle on top of a paper towel or something as some gun owners do after cleaning their guns to try to get the oil to drop out the muzzle. I’m not sure if that would get the oil that’s in the chamber through the air transfer port and out of the gun though.

Thanks again for the reply, I read all of your articles on the Bronco, and those plus the reviews on PA were what convinced me to purchase the gun. I like how unique the stock and wood is, as well as the easy cocking and look and feel of the gun.

B.B.,

If a lot of oil is burned off, would that require cleaning?

Victor

Victor,

Not at all.

B.B.

BB it looks like the case is pretty big on that round. What grn. is the bullet and what kind of fps does it make ? Or I should really ask what grn. bullet did your old casting make verses what grn. the new casting will make. Like you said above head size makes a difference in pellets and so does weight among other variables also.

I just wonder if back in the day when those rifles were made new. How consistent their loads were ? And did they need to have groups smaller than 3 inch’s. Wasn’t that the type of rifle that lets say Lt. Dunbar would of used in the movie ” Dances with Wolfe “. I’m guessing maybe that a Buffalo would of been a fair sized target at 200 yrds. and a soldier at 100. So I bet the gun during that time period maybe didn’t need to do better than 3 inch’s at 100.

And on the other hand maybe I missed it somewhere ; but what range are you trying for on the rifle ? 100,200 yrds. ? And are you looking for 1” groups.

And also it looks like a very fine rifle. Almost would make me want to ( not ) shoot it; but…..just like the old muscle cars. They were meant to be driven. And believe me I put way too much money into the muscle cars I have had. But as far as guns are concerned. I shoot them for enjoyment. Mostly airguns anymore. And although they do get frustrating at times. But you got to love the challenge. Right ?

Gunfun1,

The bullet I am using now weighs 255 grains. The new custom bullet that I cannot use weighs 275 grains. The new bullet I will be getting weighs 300 grains.

Muzzle velocity ranges between 1,150 and 1,300 f.p.s. The black powder loads these rifle used to shoot shot with far greater shot-to-shot consistency than today’s factory ammunition, but not greater than the smokeless rounds I load for the gun. Max variation is 30-40 f.p.s.

In the day when this Ballard was new it was common for a good shot to put 10 rounds inside a half-inch at 110 yards (20 rods) when they shot that close. The usual distance they shot at was 40 rods or 220 yards. At that distance one inch was considered good and a half-inch was considered great for 10 shots.

B.B.

So the fps is pretty consistent then. I guess the biggest problem in making the gun accurate is the sizing of the bullet. I know this gun isn’t black powder. And I haven’t done black powder so I dont know much about them; but they seem to be a little similar.

That is amazing that they shot that good at that range. Do you think that the slower fps and the heavier grn bullet will be the trick if the sizing comes out correct. I have tryed experimenting with the slower fps and heavier pellets with my airguns out to about 110 yrds. And it seems like the gun just kind of lobs the pellet out there. The pellet guns to me are more accurate that way from what I have done. The faster lighter pellets seem to get moved around alot more in flight. When will you have the new mold ?

Gunfun1,

The manufacturer said it would be ready in about 3 weeks, so I think I will have it before July. Then I’ll cast some bullets and give it a try.

I never thought about the weight of the billet being an accuracy factor, but it just might have been at that. Maybe I will try an experiments to see what is possible.

B.B.

Hi BB,

interesting article, as always. It showcases your interest in the details. Just wondering when you are going to break out vintage pellet molds (I remember Beeman used to sell them back in the day… .22 & .25 cal) and cast a few.. Should give the readers concerned with the ammo shortage a small breath, and they could develop another hobby…. Probably equates to $1.00 per round (if time is considered), but it’s not the product but the process that brings the reward. Like tying flies, you can get them made cheaper (maybe better) – but making them yourself (and being able to catch something on it) is much more satisfying.

westernPA,

I have seen those molds. They are brass and made in England. The make solid pellets which, as far as I know, are not very accurate.

But I might have a sort of similar tale in the works.

B.B.

Just wondering you said Schützen guns are some of the most accurate guns out there at 200 yards so what size groups can a top notch shooter get with these guns?

Cole,

A great group would be 10 shots in 3/4-inch. Harry Pope put 10 in 0.2″. That’s two-tenths of an inch for 10 shots at 200 yards.

The group size is shown in Part 7 of “The art of collecting airguns”. The link is at the top of this article.

B.B.

Wow that is insane! I wish I was that good

Gun fever hit me again. I’m sniffing around for a half way decent target pistol. I’m not really a pistol guy but since I have to get any half way decent pistol I have to do it as a used gun. I’m thinking a P-3 or Izh-53M. I can’t seem to locate any IZH-46M. But no matter this won’t be for match shooting. Just for some indoor fun shooting when I’m watching a storm roll in and going to my range is not going to happen.

Anybody want to advise on this? Sometimes I am up for a bit of a different challenge.

B.B., That looks like my Ballard #9 Union Hill rifle,except for the buttplate. I went down the same path about 12 years ago. I was looking for accuracy like the rest of the Shuetzen guys get. The rifle has been parked in the safe for about 10 years now. I guess I don’t have the drive to keep it up like you do.

Roger,

You own a No. 9 Union Hill Ballard? That is what I thought mine was at first. Until Dutcher and Kevin told me about the special order factory made guns, I was unaware they ever existed.

What caliber is your Ballard? Please say it’s a .32-40. Mine is a .38-55.

What condition is your rifle in? It must have double set triggers, if it’s a No. 9. Does it have a tang sight? What is the condition of the bore?

As you can tell, I am fascinated by these rifles, and I’m so glad you commented and told us about your rifle.

B.B.

BB we were talking about weight of the bullet. I remember in one of the blogs you mentioned something about when you were in the military that you had experienced the grenade launchers and also told some interesting things about tanks.

Do you think that somehow that the trajectory of artillery rounds from tanks could be a scaled down version of what you are doing with the Ballard and what I’m trying to do with the longer range air gun shots.

I don’t know what the tank rounds weigh or what fps that they shoot at but I bet they resemble the type of shots we are trying to make verses what the higher power missiles from the fighter jets make and even the 30mm rounds the A10’s shoot.

And from the looks of the rear sight on the gun it looks like you could stretch the shot out to a pretty good distance.

I use to shoot my Dads M1 with open sites at ground hogs when I was a kid. It seems to me if I remember right from back then that the sights to me look similar. The M1 that he had was I’m pretty sure was a 30-06. And I know today from the rifles I have that is a pretty hot round (didn’t even think about that back then when I was a kid ).

I guess what I’m getting at is that the Ballard had alot of technology and quality built into them way back then. Do you think maybe they did things different back then when they loaded rounds and made the bullets. And for some reason the secrets didn’t get passed on through time. I don’t reload basically because I just don’t shoot my bigger guns that much anymore. But I remember my Dad would get mad when he said that these rounds he made came out with too much wax on the bullet. And I do remember loading the rounds and I could sometimes dig my finger nail into the yellowish colored coating.

Am I crazy or what. Have you heard of this before?

It sounds like your dad was talking about bullet lubricant, not wax. If the bullet sizer is set with too much pressure on the lube reservoir, it will over lube the bullet. Also, you are correct, M-1 Rifles are in 30-06 caliber.

Mike

Gunfun1,

I am a reloader and have been doing it for over 40 years. When you shoot an older gun like this Ballard it is next to impossible to over-lubricate the bullets. I lubricate with by hand, just smearing the grease into the grooves with my finger. Since I load at the range, the bullet is lubed and then put straight into the rifle. It never touches the cartridge case.

As for a tank, the ones I shot put out their 9-pound long-rod penetrator and just over a mile a second. They were accurate out to beyond 6000 yards. That is Armor Piercing Discarding Sabot (APDS) ammunition I’m describing. The High Explosive Anti Tank (HEAT) rounds went slower and the High Explosive Plasticized (HEP) rounds were the slowest of all. They only went about the same speed as a 30-06 bullet and the max range was much less. In the tanks I fought, the M60A1, we had a electrical/mechanical ballistic calculator that was even programmed with the wear of the bore in the tank it was in.

We bore-sighted HEAT rounds at 1,200 yards and had to shoot groups through a 24-inch circle before we were ready for tank gunnery. We were not allows to shoot APDS rounds on any range save one, where the backstop was high enough to stop the round. Every time one of those rounds was fired the range Officer In Charge had to get down into the tanks and verify the elevation of the gun with an M1 gunner’s quadrant, because if we shot over the backstop the round went into Czechoslovakia.

B.B.

I’m sure that rounds landing in Czechoslovakia was never for the best! 🙂

Mike

Mike,

I never heard of it happening. Of course the OIC would have been court-martialled if it had.

B.B.

Okay, this sounds like a labor of love. Glad you enjoy it, B.B. So, what does one get out of reloading at the range? Can’t you do all that and keep your bullets in order at home and then bring them out? I would think all the noise at the range would be a distraction to reloading. Also what is the difference between loading a bullet onto a case and loading a case onto a bullet that is already positioned in the breech? The bullet will have to seat in the case and in doing so it will work the brass somewhat won’t it?

Well, to cheer things up, I have a little triumph to report. This morning I changed out my issue SW686 grips which wiggled with Uncle Mike’s grips that are rock solid. And despite my trepidation, it didn’t take any time at all. About a minute as a matter of fact. With this I have rolled back the one problem of buying a used gun and it is in perfect shape. Uncle Mike is my favorite uncle.

Also, as my map class winds up, I am storming to the fore. To quote the emperor of Star Wars: All is coming about as I have foreseen. And you will never believe what has made the difference. Statistics! After our discussions of statistics in relation to ballistics, what goes on in the map class is childishly simple. I knew that the intellectual work of airgunning would make itself felt. So, thanks to everyone who participated.

And an unfortunate note which is just a part of reality. The latest news is that the elephants and rhinos in Africa are getting blown away at an unprecedented rate. How do we know that this is really bad? The Kenyan government is actually starting to take the problem seriously and hand out steeper penalties for poachers–although not the shoot-on-sight order that I would probably give if I had my way. If the Kenyans are starting to react you know it must hopeless. This is beyond sorrow.

Matt61

Matt,

It’d just the opposite. There can be a war going on around you, but loading a cartridge with a single purpose in mind filters out all the distractions.

My powder measure it set up to only meter the exact amount of powder I want. There is no guessing, weighing or fiddling.

And the procedure of loading each round is always the same, so you don’t forget anything, or do something twice. Harry Pope once allowed himself to be distracted while loading at the range and forgot to load a bullet. Others have shot their ramrods downrange. You work to overcome all distractions.

B.B.

B.B.

I’m relatively sure that mine is a #9 as is described on page 273 of Dutcher’s book. “The Union Hill #9 rifle is the same as the No. 8 except it was made to conform …. with a single three pound trigger..” The trigger is very nice but I never measured the pull weight. It is a 38-55 cal., same as yours. The condition of mine is similar to yours but I don’t think its all original. The forearm has checkering, but not the buttstock. It also has a carved horn tip on the forearm. I was told by the guy I got mine from that they didn’t do things like that at the factory, checkering one part and not the other. That was Bob Carow. He is mentioned as having contributed to Dutcher’s book so I suppose he was or is in contact with Dutcher and would know, but that forearm fits like the proverbial glove. I mean within thousandths. Maybe the buttstock is a replacement but it has the shuetzen-type butt plate. The bore is beautiful but it has no ladder sight. I’ve got a Litschert Spot Shot 16X scope on it.

I fooled with casting bullets for a while but it’s not compatible with my life style. I’m a paraplegic since a 1984 hunting accident and it’s hard to get out of the way if you spill a drop of hot lead. I’ve always had trouble getting nice square corners on the bullet base. I thought a Hoch mold would cure that and almost bought one but had a little scare trying to escape from molten lead and I gave up. After investing in a bullet seater and a de- and re- primer, another powder measure and on and on, it sure gets expensive. Just the rifle was expensive

Roger,

Thank you for your description. I looked at the internet instead of Dutcher’s book when I answered you last time, so of course I thought that No. 9 Union Hills had double set triggers. That’ll teach me!

Boy, would I like to have a 3 pound trigger. And if my rifle had scope blocks on it when I got it, I would prefer to look through a scope. But I can’t bring myself to drill and tap a rifle this old that is in this condition.

I know what you mean about square bases on lead bullets. I have a hard time getting them, as well. And you are also right that the Hoch mold is one good answer. I just wish mine was the right size for my rifle.

I suspect you have something like the same problem I do — a tight chamber and a big bore. You probably need to breech-seat bullets, as well. But nobody I know of sells two-diameter lead bullets for breech seating.

My late friend, Mac, taught me to always cast bullets while standing, for exactly the reason you mention. I haven’t had an accident yet, thank goodness!

You can find out if your butt and forearm are original or not. According to Dutcher they should be numbered if they are factory. I took my rifle apart in Part 6 listed above and photographed all the parts so Dutcher could see them. That was when I discovered that my butt is not factory.

/blog/2011/01/the-art-of-collecting-airguns-part-6/

You are right that a setup for this rifle is expensive. I acquired the rifle in a trade, so although a lot of expensive cats and dogs changed hands, not a lot of money did. But I have certainly shelled out some cash since getting it. Of course the belief is once you find all the parts of the kit, the shooting will be almost free from then on. I think I’m up to needing to shoot about 50,000 times to hit the break-even point. 😉

It’s a shame that you can’t enjoy shooting your rifle, but I do understand your reasons. I hope I will be able to share some good news with you about this one in the future.

Thanks again,

B.B.

Mike about the wax thing. And the M1( don’t know where that gun is now ) I was young then and probably ain’t remembering the facts real clearly. And it was probably some kind of slang my Dad was using when he was referring to the lubricant knowing him. Well at least I ain’t totally crazy.

And BB love hearing the story’s about when you were in the military. I know war is stupid. But my Dad use to tell me some interesting story’s of the technology that they had back then.

And how the heck did they calculate the bore wear?

Oh and also. Czechoslovakia ? What time period did you serve if you don’t mind me asking?

Gunfun1,

Bore was and still is calculated with precision gauges, ground to the exact dimensions. They stop when they touch the rifling and the bore wear can be read on their side, like a micrometer. Do a web search and you’ll see photos of it with the gauges sticking out of the muzzle.

Oh, you may have meant the wear in 105mm cannon barrels. That is calculated by a gauge that’s pulled through the bore. It’s called a pullover gauge, and as it is pulled over it stops compressing at the size of the bore. A borescope is also run the full length of the barrel to look at the condition of the metal.

Each round has an Equivalent Full Charge (EFC) rating, and the gun has a logbook with every round fired by type, so you always have a sense of where things are.

I was in Germany from 1974 through 1977.

B.B.

So basically like I do at work related to your first comment about the precision ground gages. We usually have a plug gage that is to the upper size of the hole tolerance and another plug gage to the lower size of the hole tolerance. A go gage and no-go gage.

As far as what you said above about the 105mm rounds. That was more like what was coming to my mind with the pullover gauge. So couldn’t something like that be made and used on the Ballard to help with bore sizing ?

And to me sounds like the EFC logs is similar to SPC (Statistical Process Control). And again referring to the Ballard. Do you think maybe any kind of info was logged back then for the barrels and rounds they made and shot back then. If so I bet those documents for the Ballard would be a great collector item to go with the gun.

74 to 77 . I graduated high school in 78. I didn’t serve but one of my friends since like 2nd. grade enlisted in 79 in the Air force. He retired from the Air force. Lot of interesting stories that he shared with me.

And I’m sure the Ballard bullet casting and shooting will be another interesting story also. And you know I will be waiting for the results. And thanks for the info again.

Gunfun1,

Ballard shooters (scheutzen shooters, really) did keep logbooks. There are documented examples of Harry Pope barrels being shot 40,000 times and still measuring within 1/100,000 th of an inch of brand new. But that is extreme.

As for the tank cannon logbooks, back in the days before computers, that was the only way to track things like wear accurately. A 105mm tank cannon barrel has 400 EFC shots on it when it is new, so tracking the number of EFC rounds is critical.

B.B.

I have always been one for writing info down.

When I experiment with different guns or ammo, scopes or whatever. I will write the info down on the target when I’m finished shooting at it. Wind speed, direction the wind is coming from, even humidity and temperature where I’m shooting at. I will put the targets on the shelf in a box. Then I can go back and reference them if needed for some reason.

I have gone back and got a target that I shot at maybe a month or so ago and compare it with the results I got on the gun today. Wind conditions maybe different and temperature and so on. But its kind of fun to see the difference of the shot group.

And I’m talking about airguns above. And I don’t get that critical all the time but the logged info helps. I found that if I do log it some kind of way.That when I thought that I remembered some combination one way it was actually different when I went back and looked at the target and info.

I do just like to go out and plink also. But I do know that the experimenting in my case always happens before the plinking. And that way I’m being just a little bit better plinker….I think. 🙂

Head on over to assra forum for advice on the ballard. These old guns WILL shoot.

Bought an old winchester 1885 this spring and was shooting 1 1/2 inch groups with it for my first shots with the help of one of the gentlemen there. They know their stuff, that wa the first “guess” at a load, and it was at 200 yards! That rifle is a real treasure don’t give up on it.

I have one too in 22lr, and have shot many others. Possibly the greatest american rifle ever made. Good luck!

John

John,

Thanks for your comments. I have since put 9 of 10 in an inch at 100 yards. I have been playing with this rifle for 4 years now and I’m still discovering what it likes.

B.B.

Great to hear B.B.

They are a real pleasure to shoot, especially if you can keep people at the range from askin you questions about it every few minutes! Lol they tend to draw a crowd!

Good shooting pardner, I hope to see you around!

John

John,

I have experimented with a Hudson-designed Hoch nose-pour bullet and several vintage bullets (from vintage molds). The best so far is an unsized finger-lubed 250-grain (that weighs 235 grains) Lee bullet forced into the rifling with a separately loaded cartridge with H4198 powder. I have tried all sorts of black powder to no avail.

The slower twist of the Ballard barrel forces me to use shorter bullets. And my chamber is small but the groove diameter is 0.383-inches.

I’m still learning.

B.B.

Are you still using a 40-1 alloy?

I tend for smokeless to use 20-25/1.

And for Black 30-1.

Which 38 is the rifle?

John,

Yes, I still cast at 40:1. I don’t understand your question — “Which 38 is the rifle?”

B.B.

As in which particular cartridge is the rifle chambered for?

38-40, 38-55, 38-56, 38-72? Or other?

Also what is the twist? Makes sense the lighter bullets shoot better, most have slower twists. Heavy bullets are nice if they work well but they’re not the be all end all.

John

John,

The Ballard is a 38-55. The twist is 1:20″, which is slower than most for this caliber.

B.B.

BB Pelletier …

Sir I am curious about your Ballard rifle as I have an identical gun with this unusual cheekpiece design in 38-55. Thx Dusty