by Tom Gaylord, a.k.a. B.B. Pelletier

Nelson Lewis combination gun is both a rifle and a shotgun.

It’s been a while since I last wrote about this gun. Blog reader Kevin asked if I was going to write anything more and I answered yes, but what I did not tell him or any of you was that in October of last year I blew up the gun.

Blew it up?

That’s not entirely accurate. What happened is the nipple that accepts the percussion cap was blown out of the barrel and right past my face. When it went, it sheared off the hammer lug that connects the exposed hammer to the sear. I never found the nipple, but the hammer was lying on the shooting bench next to the gun. When my shooting buddy, Otho, asked me if I was okay (he was standing behind me, having a premonition that something bad was about to occur), I answered, “NO” for the first time in my life. Usually, guys will say everything is okay right after they’ve sliced off their thumbs with a circular saw, but this event was so startling that I wasn’t really sure what my condition was. “No” just popped out.

What happened?

Okay, get ready to criticize and tell me what I did wrong because I haven’t got a clue. Do you remember me telling you that airgunner Mike Reams can make swages to make conical bullets of almost any caliber? I learned that at the 2012 Roanoke airgun show. And do you remember that I wanted him to make a set for the Nelson Lewis gun? Well, what I did this day on the range was called a “proof of concept” test. I loaded a conical bullet in the rifle — partly to confirm the diameter requirements for Mike and partly just to see if the gain twist rifling really would stabilize a conical. But the only conical bullet I had was a 250-grain lead bullet for my 38-55 Ballard, which coincidently has almost the identical size bore as the Nelson Lewis rifle.

I’d been shooting a patched .375-caliber swaged round ball in the rifle up to this point. That ball weighed 80 grains. So, 250 grains would be heavier — about 3 times heavier. What I did was load a proof load into my 160-year-old gun and shoot it. Nothing wrong there, right?

When the gun fired, it recoiled more than usual (no kidding!), but that wasn’t what I noticed. I noticed a jet of fire about a foot long coming out of the nipple hole that had been so recently vacated. Then there was the verbal exchange between me and Otho, and then he cautiously walked around to my front and looked at my head — mostly to see if it was all there.

I’d been wearing shooting glasses, which I always do whenever I shoot a black powder arm (and after this event, when I shoot anything else, too), so my eyes were fine; but above my right eye was a large patch of black powder that embedded itself in my skin. I looked like the “murdering coward Tom Chaney” from the movie True Grit, who coincidentally had a black powder Henry rifle blow up on him. The powder had to be picked out of the skin with tweezers over the next few weeks and there is still some of it in there today, more than 4 months later. But I was okay.

My Nelson Lewis gun, on the other hand, was broken. And, as far as I know, Nelson Lewis doesn’t work on his guns anymore, having been deceased for the past 135 years or so. What was I going to do?

Otho to the rescue

Now you need to know something about my buddy, Otho. He’s a retired Airframe and Powerplant (A&P) mechanic who has worked on turbine engines and airframes since Vietnam. One of his skills (he has skills — and people like me need to know other people with skills) is welding. And I don’t mean trailer-hitch welding, either. I mean the ability to — well, let me tell you what he once did. His father stored a Gen-1 Colt Single Action Army revolver improperly, and it rusted badly. Rusted as in deep pits all over one side of the gun. So, over the course of a year, Otho spot-welded each and every pit, then worked it down with a file until it was flush with the rest of the metal. When it was perfect, and by perfect I mean perfect, he had the gun re-case-hardened so that today it looks new. All the factory lettering was preserved so you cannot tell that any work was ever done. Or at least I cannot tell, and I know Gen-1 Colt SAAs.

Both these Colt revolvers were stored together and rusted equally. Otho welded every rust pit and refinished the Single Action Army on top. This is a master at work!

So, Otho looked at the sheared hammer lug on the Nelson Lewis gun and says he thinks he can fix it. He thinks he can weld the hammer lug back up and file it to fit the hammer. This news sounds wonderful, coming as it does on the heels of the gun’s destruction. Let me show you what is involved.

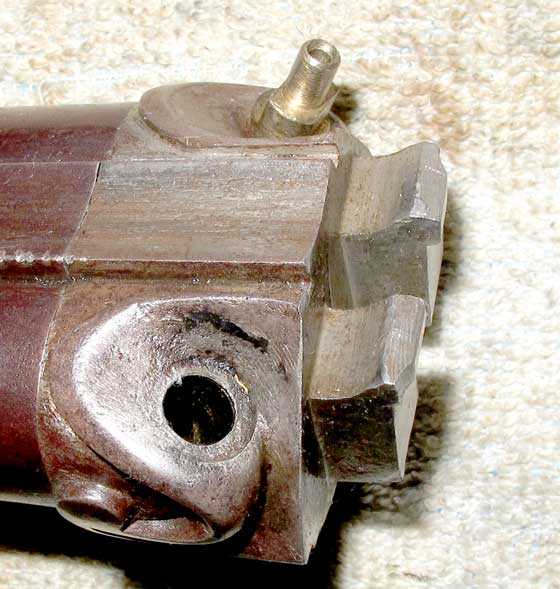

The nipple is gone. All the threads are, too.

The hammer was sheared off at the lock plate. The other end of that square lug is the rifle’s sear.

The hammer was sheared off the lock as neatly as if it had been properly removed.

The flip side of the hammer shows the lug that was sheared.

See the part with the leg sticking out? That’s the sear. It also has the lug that the hammer used to be connected to — or at least it is supposed to.

I disassembled the lock and looked at the sear carefully. Surely, it was made in two pieces because how did Lewis put a square lug on a complex sear otherwise? You know what? He cast the part in one piece. Out of steel. In 1850! They wouldn’t have automobiles for half a century and here was this gunsmith in upstate New York making complex parts from cast steel! I thought Bill Ruger invented the casting of gun parts. (Just kidding. Please don’t hit me with comments. I am aware that the lost wax casting process is very ancient.) But seriously, did you know that gunsmiths in 1850 were casting parts from steel? That’s not the paradigm I’ve been given to believe.

And one thing was certain because of how the part was initially produced. It would either have to be welded or made entirely new. Otho’s plan now sounded very good.

In November, I gave him the lock pieces and he began to study them. His task wasn’t just to weld the lug, but also to maintain the correct orientation so the hammer would fire a percussion cap again. And that brought up the other thing — there was no nipple for the cap. It was blown off the gun and never found. And the threads in the hole where it was were completely stripped. Otho had an idea about that. Use a Heli-Coil. When I balked, he told me that a Heli-Coil is approved by the FAA for threading stripped holes. And the FAA is about as anal as they can be when it comes to parts’ integrity and safety. So, I guessed it was okay.

He began welding small amounts at a time. Welding and welding, and then filing when he got close to the right dimensions. Then it was weld and file, weld and file. This went on until January. I think he finished the job while I was at the SHOT Show. Then he told me about his worry. He had been worried that the sear metal might vaporize as he welded, but that hadn’t happened. So the steel was good. Now he was concerned that all the heat from welding had taken all the hardness out of the part.

He took the part to a knife-maker friend of ours to have it Rockwell tested. But the part was too odd-shaped and small to fit in this guy’s tester. So, he drew a file across it and made a guess what kind of steel it was based on the date of manufacture and how it took the file. Then, he hardened it in his kiln until it was hard as glass. Next, Otho did a complex series of tempering heats that drew the hardness down to approximately Rockwell 38, which the knife-maker guessed was the hardness of the original part. Do you think this is too much guesswork? How do you think Nelson Lewis did it in 1850? He heated it on his forge until it glowed brightly enough, then quenched it in whatever oil he had (possibly sperm whale?), then he drew the temper the same way.

The hammer lug (the square projection standing up in this picture) has been restored to the sear. No, the lug isn’t perfectly square. It’s shaped exactly like the hole in the hammer. The hole for the hammer screw was even drilled off-center and threaded exactly like the original.

The proof of the pudding

Otho installed the Heli-Coil and a new nipple I gave him, then the both of us reassembled the rifle. He was very concerned about the hammer, so I test-fired just a percussion cap in my garage and everything was fine.

I went to the range to test the rifle with a full charge of powder and a correct bullet. First, I shot off another cap, to clear the path in the nipple. Then, I loaded about 20 grains of powder and tamped just a wad on top. That was fired okay, so now it was time to load the rifle for real.

I loaded the rifle the same way I’d loaded it before — with a patched round ball ahead of about 20 grains of 3F black powder. I tied a 10-foot cord to the trigger and carefully cocked the hammer. I pulled the trigger with the rifle sitting in the rest and it fired without incident.

This shot was posed. I was 3 feet farther back when I fired the gun for real.

Once I knew the gun was safe, I shot it like I had before the accident.

Once the gun passed the test and I knew it was safe to shoot again, I settled down and shot a quick 5-shot group at 50 yards. It shot to the same point as before the accident and grouped about the same.

Five shots at 50 yards made this group. It’s in the same place and the same size as before.

How does the gun look now?

I’m sure you’re curious how the gun looks after this trauma. The fact is, apart from a small dent in the top of the pistol grip where the hammer spur hit the wood, you can’t tell anything ever happened. I thank the Lord for my safety, and I thank Otho for being so skilled. I’m so fortunate to have my gun back and whole again.

No moral

There is no moral to this story. And I hope you readers are all smart enough to not need to learn anything from my misfortune.

I will continue to shoot the rifle, but not a lot. I think, given the circumstances, this rifle has done enough for me. It deserves a rest and, except for an occasional day or two, that’s what I intend to give it.

Too much pressure from the conical. Pressure kills. Glad you are OK, and the gun was restored. Also, you never know what a barrel has been through before (including the nipples being stripped), so this is one more reason not to shoot very old guns (although I got carried away with the excitement also): Nipple failure was probably a best case scenario.

Just a nitpick, but technically, the sear and the hammer must be separate. The hammer is attached to a squared shaft on the _tumbler_, which is roundish with little notches for the sear to engage.

Tom,

Yadah.

Thankful that you’re ok. Guess that little episode put an end to your male modeling career.

I don’t know enough about shooting older black powder guns to understand what caused this. Certainly not the fact that the conical was 3 times heavier??

The more I learn about Otho the more impressed I am. His skills are impressive but his patience is what I envy.

As to the future of your relationship with the Nelson Lewis gun……I remember several women in my distant past that I was initially very enamored with but as time went on and our relationship become explosive………

kevin

Kevin,

Otho is incredibly creative and insightful. He can look at most things & figure out how they work and how to make them better.

Last year, Otho gave Tom a huge vintage drill press. It needed wheels to move it around our garage, and they had to be lockable so the cats couldn’t use it as skateboard. We thought & thought & thought about it but couldn’t figure out how to get the wheels attached (the footplate had wheel holes, but they were made for specific wheels that we couldn’t get…nothing in the store worked). So, Tom told Otho about the problem because we knew he could figure it out.

That afternoon, Tom went for a walk. By the time he came home, I’d figured out the perfect solution…and was so excited to tell him the minute he returned. When he walked in the door, he was talking on the phone with Otho, who was giving him the solution. It was the exact same solution I had come up with! I was so surprised that I’d come up with a fix exactly like Otho had. Ever since that time, I refer to sparks of brilliance as “an Otho” or I give myself “an Otho award” for having a unique insight into how something can be fixed or improved.

To know Otho is to be amazed by his ability to see things others cannot see.

Edith

Edith,

I envy gifted people like Otho and Vince since they not only have the vision but also the ability to fix complex problems. I’m an unevolved ape like creature in comparison.

While proofing and editing this blog I’m actually surprised you didn’t change the title to “GO AHEAD, CRUCIFY ME.”

kevin

What’s wrong with cats using the tool as a skateboard? 🙂

Matt61

I’m not familiar with any organs with a 10′ pipe — I think the common standards are 16′, 8′, 4′, etc. with 8′ considered the base. Either way, I hope the chord sounded good…

(Not to make light of your incident)

Wulfraed,

You’re catching a lot of these lately. Either I am getting worse (probably) or you are getting better. 😉

B.B.

Mostly the ones with the humorous overtones (no pun intended).

Just more evidence that one should not rely upon spell-checkers (now if the book publishers would take that lesson — I’m certain I never saw that many typos in published books back in the 70s. Though the most blatant error isn’t quite a typo.

Roger Zelazny, “The Hand of Oberon”. ALL paperbacks (including the omnibus volumes) have paragraph 4 starting out as:

I’d originally read a library hard-cover of this book, and new that sentence wasn’t right… Consider (emphasis mine):

A rather significant flaw, which has made it through at least four paperback editions (not just printings).

Blast, the emphasis was lost — italicizing something that gets shown in italics didn’t work… Ah well, just read it closely.

Wulfraed,

I fixed it. These oversights are usually a consequence of not paying attention because I’m doing several other things instead of paying attention when I proof the blog. Last night, I proofed it while I was watching TV because I didn’t have the time to do it during the daytime.

I appreciate it when our blog readers let us know there’s something we need to correct.

Thanks,

Edith

That is quite an amazing story, B.B. You have the initial disaster with the rifle, then, a good friend who has the technical knowledge and patience to make things good again. Like Kevin, I’m not familiar with the ins and outs of a black powder rifle, so I have nothing to offer as to what went wrong. As for there being a moral to this story, I believe it tell us how careful we must be in every aspect of our shooting experience, and in daily life. We must accept things like this just happen. From reading your daily blogs, I believe you to be a safe, methodical shooter. You carry a lifetime of experience with all aspects of the shooting sport. You minimize the possibility of an accident happening because of your vast experience and respect of all guns. In your case, you received a powder burn above your eye. We all know it could have been a lot worse. We do what we do, because we love to shoot. The tricky part is to be able to assess possible risk, against our love of the sport. Being secure in knowing we have done all we can to minimize danger.

Caio Titus

Titus,

Thank you for your kind words. Naturally I blamed myself for this, and I still do. The conical bullet I selected was just too heavy.

However, no one knows how many nipples have been replaced in this gun in its life, and to tell the truth, the threads in the barrel were probably not in the best condition. I may have just accelerated an existing problem by a few decades.

The new Heli-Coil threads seem to be working very well, indeed. And the new Hot-Shot nipple I installed seems to be ideal for the gun.

I was initially afraid to shoot the rifle again, but after three shots I stopped worrying and settled down to have some fun. I will keep the loads where I know they are not dangerous and just enjoy the experience from now on.

B.B.

A properly installed heli-coil is frequently stronger than the original thread.

I believe the moral of the story is, “it isn’t what you know, it’s who you know.”

You could have traveled the world in an effort to have the hammer/lug restored, only to be told you were SOL, or to have it done poorly and or improperly. And at great cost. But people of high character tend to find each other, and so you have a friend in Otho, who can work miracles by the looks of it.

A second moral of the story might be, “it’s a damned lucky thing BB doesn’t have a nipple embedded in his skull.” Be more careful, don’t give Edith a heart attack.

SL,

Yeah, it took me about an hour after the explosion before the reality of what you said sunk in. I am indeed fortunate that the “accident” (stupident) was as harmless as it was.

B.B.

BB,

I think I know what happened. I gather from what you said in this article you loaded a 250 gr conical on top of 20 grains of 3f black powder. Is that correct?

Because if it is, what you experienced is called “detonation”. Three F black powder is way to fine for heavy bullets in light loads. So when you touched it off, the resistance was way to much and instead of the powder burning progressively as it should, the pressure built so rapidly it simply exploded!

You have to be aware of this with reduced loads using fast burning smokeless powder also. The exact same thing can and has happened with light loads of fast burning smokeless powder. And the results are equally as disastrous.

I would have chosen 2F or even F for that weight bullet, and went with around 30 – 35 grains.

But I am very happy you were not seriously hurt!

And the feat your friend performed was what I would call miraculous. I am sure there are not many people in the whole world who could do what he did! And far less who would do it even for a friend. You need to buy a lottery ticket. Your luck seems to run off the scale.

Once upon a time, 1974 in fact, I bought a repro Navy 1851. I knew nothing about black powder and typically filled the cylinder with powder and crammed the ball down. I now realize I was fortunate it did not act like a grenade in my hand instead of a pistol. One day I had multiple chambers ignite at the same time. The little wedge that locks the barrel to the action was shall we say, slightly deformed and because of that the head space is about 1/8″. Other than that, I could find no damage but I decided to retire it. I cleaned it good and crammed two lead balls down each cylinder and made a nice wall plaque for it.

RR,

But you know — you were loading that revolver the right way? The only black powder revolver that you have to worry about when loaded as you describe is the Colt Walker. It can accept 60 grains of powder, which is a rifle charge. Most of the original Walkers blew up because of overloading. That’s why the Dragoon cylinders were made much shorter.

But the trick to stopping chain-fires is to spread Crisco on top of all the balls, after they are seated. It prevents the hot gasses from getting past the balls in each chamber. It also turns the gun into an oily mess, but you’ll never have a chain-fire.

B.B.

Yes, I have since learned I should have been lubricating the balls and probably been using a little lighter loads. Oh well, I survived.

B.B.

GOD was watching over you.

We had an accident down here a few years ago. This guy tried to convert an airgun (springer ) to a firearm and it blew up in his face. He did not survive.

Next time use a twenty foot cord and stand behind a brick wall.

Thank GOD you are ok. Without this blog I would have had to resort to smoking Ganga to get my daily fix.

Pete

Pete,

You know, I believe I did thank the Lord that I wasn’t harmed! I know Who watches over me.

B.B.

BB,

Glad to read that you survived!

Excellent tale and one I will share with my children the first time they ever get to shoot my blackpowder guns.

Chris S.,

Well, after that happened, Otho and I had a long discussion about black powder. Turns out Otho was not aware that you dare not load black powder cartridges with an air gap in them! When I told him that would blow his guns up, he was shocked.

So, some good came from this incident, after all.

B.B.

B.B.

A bit too much lead there ? You should hear about what too many deer hunters around here do during muzzleloading season. Then again maybe you should not.

Some times too much pressure manifests its visible sighns in the hammer being blown back to half cock. But another thing that can do it is having the nipple vent hole burned out too badly.

I like a nipple to have plenty of thread, and I like it to fit without a lot of slop. If the thread is just too sloppy, there will not really be very much holding it in.

twotalon

TT,

Yes, I found that out.

B.B.

Because of the way taps work, you really need 5 threads to get 3 full strength ones. It works pretty well if you have that much room, because even with a bottom tap (unless you grind one off further), the hole gets tight near full engagement and seals. I know a some that go to the trouble of making a “seat” for the bottom of the threaded section of the nipple (or vent liner) to seal against, also, and that further minimizes gas cutting the threads. Nipples are always a problem because they take a beating, plus they either are liable to corrosion if not removed regularly or wear and/or cross-threading if they are removed regularly. It is even more exciting when a drum pops off. We have seen this at shoots (thankfully rarely) when people wanted to remove the drum every cleaning, and either wore out the threads or stripped them.

BG_F

Yeah, having someone blow a drum next to you could be a lot worse than standing too close to the wrong side of a flinter.

twotalon

BB, I am glad I wasn’t shooting it (I am left handed). I think I might have had a bit more of an injury with my face in front of the nipple.

David Enoch

David,

This time it was the right-handed shooter who was in danger. The rifle barrel on the Nelson Lewis gun is on the left side!

B.B.

BB: Stuff happens. Even Elmer Keith blew up guns learning about them . As BG said , probably too much pressure and it was just time for that part. The old gunsmith who ‘s shop was next door to us while I was growing up, said that while proofing guns shows that they didn’t fail THAT time it doesn’t mean that they won’t ever. As he put it “once don’t mean nothin” Be careful with that one. If you ever want to sling some .54 cal conicals down range over humungus powder charges , you are welcome to borrow my Kodiak double anytime.

Robert,

Thanks for the invite, but no, thanks. I don’t like overpowering guns.

That old gunsmith was a smart man, too.

B.B.

BB,

that’s enough close calls for you! Last year at one of my target shooting meets (25 yd bullseye), someone remarked, “there’s no such thing as too much safety”. Something we all should take to heart whether we are firing BB guns, air guns or powder burners. And now, bring on the snow. I’m in the office in NYC and fully 80% of my co-workers didn’t bother to come in, probably “working from home”. Ha! Candy butts.

Fred DPRoNJ

Fred,

Yes, it’s been bad weather here, too. It only got up to 73 yesterday, and in the morning it was down in the 50s! Brrr!

Today is a real cold morning. It was in the low 40s, though I think it’s going up to 66 this afternoon.

B.B.

I guess the moral is be sure to ware your eye protection when shooting. Always.

Mike

What a great story and great reminder for all of us to be careful. How often do we shoot our BB guns without our safety glasses only to hear a BB pass close to our head while coming back from a ricochet we hadn’t anticipated? Not that I would know anything about that personaly of course.

Glad you’re OK. I would have liked to see a picture of the glasses to see the damage done to them. The powder in your forehead could have been nice too and would have added some drama to the blog.

See Edith, Tom doesn’t even need a motorcycle to try and badly injure or kill himself.

J-F

J-F,

The shooting glasses don’t have a scratch on them. I debated on showing them, but they look like new, so there isn’t much to see.

B.B.

J-F,

I was grateful he wasn’t blinded when I saw him come home on that day.

Edith

Glad your O.K. Mr. Gaylord!

Wonderful work Otho!

Thanks, Otho, for giving us A&P’s an even better reputation! (we’re not all quite as talented….) Great job on that Nelson Lewis!

That being the left barrel, BB, you were really lucky! Could’ve turned out much worse even with safety glasses.

/Dave

Sounds like user error here but this demonstrates why I dislike old guns. As the metal ages it is prone to fatigue so if something goes wrong things will be destroyed and you are likely to not be able to find repair parts. So you need to know somebody special that can put humpty dumpty back together again or you end up throwing the ruined gun away.

Historical note: Yes, there actually was a real Humpty Dumpty. It was the name of an English siege cannon that sat on the wall of an English fort. It was destroyed by the french in a direct hit which knocked it off the wall. The English troops tried to put it together and get it back on the wall to repel the French but it was too badly broken and too heavy for the available horses to hoist it back onto the wall. After the battle The loss of the cannon was noted in the fortress commander’s logs as the rhyme we all know today. So when you teach the humpty Dumpty rhyme to your kids you now know the historical details and it now makes sense, more than an egg creature sitting on a wall and falling off.

Fascinating. And the story rings a very faint bell. How in the world did they come up with the name Humpty Dumpty for the gun? It seems perfect for the egg creature.

Matt61

I have no idea how they came up with the name for that cannon. I imagine it comes from the same Brits that penned the song “Yankee doodle dandy” Which was originally an insult to us during the Revolutionary war as a British drinking song. After we won the war we threw it in the British faces by setting the song to our own music and calling it a patriotic song. It’s still played by the army marching band in Washington D.C. for dignitaries except for Great Britain dignitaries who still view it as an insult today. Incidentally, the part where “Yankee Doodle stuck a feather in his hat and called it macaroni” never made sense to me until many years later when I learned what it was. A Macron is a rather foppish fashion. so they were pretty much calling us a bunch of foppish fashionistas.

Just a little bit more U.S. history for you. Who knew dry dusty old history could be so interesting?

Thanks for that John.I will no longer get hungry when I think of the “great fall”…..but I will be sad about a unique piece of history being shattered!Oh well……gotta break eggs.

There’s plenty of creepy things in nursery rhymes believe it or not and they usually have some foundation in history. That’s one thing I like about history. If you look hard enough you see some really interesting things. I’m still trying to figure out the history behind one artifact i have here. It’s a set of whiskey toasting cups from the first class section of the HMS. Titanic. I’m still trying to figure out why one of the survivors thought enough of them to bring them with when they boarded the lifeboats. They are still in pristine condition after all these years.

Perhaps theft??? You know you really can’t take some folks anywhere! I too have a few really interesting objects from history.I have 2 photographs from the failed Endurance Antarctic expedition…taken by Frank Hurley,that show Ernest Shackleton and five others leaving in the lifeboat to get help,as well as one showing help on the horizon.Both are signed & captioned by Shackleton himself,as well as a half sheet of the very first stamps from Antarctica.All were used to “purchase” safe passage for Shackleton aboard the USS Heredia in April,1918.Oddly enough,Sir Ernest Shackleton was flat broke at the time! The USS Heredia was a United Fruit co. Banana boat captained by W.F.Steveson.It was renamed the USS General Pershing and was sunk by a U boat in WW2.

Could be, but by the time they were getting on those lifeboats it was pretty clear the titanic wasn’t going to be above water very much longer. I suspect people were grabbing whatever belongings they could and trying to get in those lifeboats in short order. Somehow somebody scooped up that beautiful box with those silver lined cups in it and held on to it and kept it until I got it at an estate auction. Now it sits on my fireplace mantle and I toast the new year in them every year.

Hold on to those pictures and that history. It may be worth a fortune someday. Especially if you know the history of that item and can pass that knowledge on with that item.

I recently found something else that has quite a history too. It’s a hat made from old brazilian truck tarps. The tarps spent their lives being beat up covering cargo moving through the Amazon. Eventually the tarps are thrown away. A village in Brazil collects the tarps and spent truck tires and make some really cool hats out of them. They were featured in Zombieland and The Losers. Woody Harrelson saw a cameraman wearing one of these before the shoot and decided his character wanted one of these. So The property manager was sent on a quest to find out where these came from. He had to track the hat all the way to brazil. Since then everybody has to have a cool hat like that. Check them out at realdealbrazil.com. These things are the coolest bit of history i have ever seen. Totally recycled and awesome.

Already worth quite a bit of money.An identical print with three words difference in the caption sold in 2011 at Bonhams Auction for 21,600 pounds,or around $33,000! That one was the lifeboat launch.Imagine how much that person would give for the return of help 4 1/2 months later……after the men had given up all hope.I can feel the elation of the men,who were stranded for over 400 days in a very difficult surrounding,when I look at the image.It is a powerful image! (it was shot with a Kodak vest pocket camera)

That picture could possibly get you a down payment on a very nice house or a very nice car.

i have no idea what my Titanic cups are worth.

I need to sell it to pay the hospital & surgeon who saved my very nice left leg! I had a blocked artery that nearly cost me the leg from the knee down.(I guess “down is implied….LOL)

We’re at the nesting depth so I had to “reply” one person higher

Only since you are the one writing… After all (to be morbid), maybe the lower would be saved as a transplant (if the French are transplanting faces, what other body parts could they work with, Herr Doktor Frankenstein)

If you would like seeing the pictures or the stamps John,you can mail me by adding “pc@aol.com” to my user name.(no spaces) I also have a well preserved military pike head that was unearthed in a Tennesee farm field! Since they hadn’t been used after the 17th century……it also is a curious find!

BB,

Otho does nice work, do you know what type of welding he used? On another front I used to work with a man who had prothesis where his left hand should be. It was the result of mixing black powder and alcohol while shooting a muzzle loader. He had one of those here hold my beer and watch this moments.

shaky,

I just asked him and he said oxy-acetelene.

B.B.

BB …

Would you please ask him what he used for a filler rod? And, I sure would love to know which torch he used and what size tip.

Thanks very much.

NRS

NRS,

He’s out of touch right now. I’ll ask him when I get the chance.

B.B.

B.B., you have shown a photo of a revolver or two the past couple of days. This leads me to write a brief note. My Crosman 3576 is not being shot as much as the Gamo PT-85. It is not because one is a true semi-automatic DA/SA, although that is noteworthy; it is because the PT-85 feels so good in the hand while the revolver feels not so good (less ergonomic). I will continue to bring it out and shoot it but it is not comfortable like the Gamo. ~Ken

Ken,

I have two general rules about the guns I shoot. First and foremost , they must be accurate. Only accurate guns are interesting.

Second, and only applying to the accurate guns, is I want them to feel good in the hand. Let me give you a short illustration of how this works.

I used to believe the M1911A1 pistol was horribly inaccurate. Then I met an officer who had qualified to shoot in the Olympics. At 25 yards he shot 50 rounds into a 2-inch group. Okay, so the pistol was not inaccurate — I just didn’t know how to shoot it.

But even though it was accurate, now that I knew for sure that it was — it was still very uncomfortable to shoot. The line of the bore is so high above the wrist that the gun bounces when it goes off. Feels like a lot of recoil, even though it isn’t.

Then I read Patrick Sweeney’s two books on the 1911 and I learned to hook my thumb over the safety switch when shooting. Now the gun did not bounce and was, in fact, comfortable to shoot. And I already knew it was accurate, so my opinion of the pistol turned around completely.

That Colt revolver (Colt Army Special) that I showed a couple days ago is an example of the gun that is accurate but doesn’t feel very good in the hand. I have a Ruger Security Six that feels much better and is equally accurate, so that’s the gun I like to shoot the most.

B.B.

B.B., thank you for your response; I appreciate it. Not only do I appreciate what you say about a gun not feeling good in the hand, but also what you say about learning more about holding one. I just applied the same three finger hand shape to the 3576 that I do to the PT-85 and it feels seriously different from what I have been doing. The only catch is that the trigger starts far enough forward that the only way I can shoot it is in single action. This is not a great problems since I have been shooting single action 95% of the time, but I had thought to start in the same position. This will take some real world trials. Thanks much for your help. ~Ken

B.B., I have been doing some shooting with the 3576 since I responded to your illustration. Sure enough, by giving up on expecting to shoot double action my hold is so much more comfortable and the revolver is a joy to shoot. With respect to a defensive firearm this would be unacceptable, but for this CO2 revolver it is quite welcome. I just had to think about it differently, and you helped me do just that (and it was so simple when said and done). Thanks! ~Ken

Oops! I said that the inability to shoot a defensive firearm in only single action mode is not acceptable. Well, maybe not the most desirable but I won’t turn down a single action western revolver. In fact, I plan to look at some black powder revolver’s this weekend (and they are all single action, of course). Has anyone seen a black power Rhino revolver? Just kidding. ~Ken

A “Black Power” revolver? What, you gonna join a leftover group of 60’s radicals?

A “Black Power” revolver? What, you gonna join a leftover group of 60’s radicals?

Nah. I have long wanted one. I haven’t checked to see if there has been a run on black powder, though. I guess I’ll find out soon.

~Ken

Hold on, B.B. I’ve been wondering about this story. I recall you saying that this Olympic shooter could shoot those fabulous groups with any pistol from the armory. But is it not true that the GI 1911’s do not have the large manual safety for resting the thumb? It doesn’t look big enough from the pictures; I thought that was a sporting modification developed later. >:-) So how did this guy shoot the pistol accurately without that safety?

On a related note, I have dry-fired endless times with the 1911 using the WWII instinct shooting methods. (And it saves money on ammo.) The method as developed by W.E. Fairbairn and the OSS involves holding the pistol with one hand, arm extended at 45 degrees below the horizontal. To shoot, you swing up your arm like a pump handle until the gun breaks your line of sight with the target, then you convulsively squeeze with your whole hand. Can’t argue with the pedigree of this method since it survived kung fu gangs in Shanghai and the Nazis. It felt fine except every so often, the gun would fail to go off. Unacceptable. I finally realized that putting my thumb on the manual safety moved my hand just far enough off the grip safety so that I didn’t always engage it. No amount of concentration or altering of the position quite eliminated that occasional failure to fire. I finally solved the problem by taking my thumb off the manual safety, and the pistol has worked flawlessly.

I was reading about the banana wars in the interwar years, and one Marine said that the .45 pistol was used a lot and up close. (By the way, I have a better understanding of how the Marines did so well in the Pacific War after reading about their exploits in the banana wars. That was some seriously gruesome stuff. The bandits who the Marines were fighting were operating outside of the laws of war or any other kind of laws. However, they were outgunned by the Marines who preferred the Tommy gun, the BAR and the 1911 in the heavy jungle.) Also, I understand that the 1911 was originally designed to stop charging drugged out Moro tribesmen in the Spanish-American War, another close-range situation. And the 1911’s fine record in WWI was made in the trenches at close-range. So, this all makes me think that the gun was designed for blasting up close, and the accuracy was just an offshoot of its overall good design, not one of the original parameters. That would explain how once the thumb safety was added, the 1911 could start to realize its target potential. But it doesn’t explain how Lt. Col. Bonsall could shoot so well without it…

By the way CowBoyStar Dad, I neglected to send my recommendation for your 1911. No one can argue with a Wilson pistol, but you’re going to pay for it. As for the Colt name, my understanding is that the management has undergone quite a few changes with accompanying changes in quality control. I believe they are doing well now, but I don’t know that the Colt you are getting now has any more connection to the original GI issue .45s or to the SAA revolvers any more than anything sold with a Beeman name is connected to Robert Beeman. B.B. would obviously know more if this is a fair analogy or not. But in any case, I want to plug the SW 1911. What you’ve got is a company that is older than Colt, but has not had the same quality ups and downs. True their expertise is in revolvers. But John Browning did the hard part with his genius design. All you need now is manufacturing expertise that Smith and Wesson has in spades. You also have their unsurpassed customer service which is at the opposite end of the universe from the lunatic woman who is (hopefully) selling me my Mauser (although as a caveat I don’t know how easily you can access them from Canada). So what you get is an almost custom-quality 1911 at mid-level prices. Mine has been great, and as soon as I apply Victor’s shooting techniques to it, it will do even better.

Don’t forget to keep after your M1 Garand and Enfield No.4.

Matt61

Matt,

You can hook your thumb over the military safety switch — it just isn’t too convenient. But that shooter didn’t do it. He held the gun like most people would, only he used the special hold that I have mentioned several times in the past.

The thumb thing is something I picked up from modern shooters and all it does is make the 1911 easier to shoot. It doesn’t make it shoot more accurately.

B.B.

Tom, this isn’t related to the current airgun review, but I was reading in this blog about the Beeman RX2 and I watched Paul’s video review of this gun, and in both reviews it was emphasized that the RX2 is very difficult to cock. I’m wondering why it wasn’t mentioned that the pressure in the gas cylinder can be changed to vary the power of the gun, and also alter the necessary cocking force. I would have thought that this info would’ve been discussed, as it is an important feature of this gun.

I’m trying to decide between the R1/HW80 and the RX2/HW90, which is why I’m asking about this. It would seem that it would be easy to make the RX2/HW90 more docile than the R1/HW80 with just a pressure change. I’ve read that you keep your R1 at approximately 16FPE for a more pleasant shooting experience, but your gun had to have parts changed to get to that. I would think that this type of change could be an “at home” procedure with the RX2/HW90, provided that I purchased the necessary pump and fittings.

Thanks for a GREAT blog!

What say ye?

harleyflhxi,

The gas pressure cannot be changed in the gas piston of a Beeman RX2/HW90 without some very expensive equipment. You are thinking of the Theoben gas springs that do allow adjustment of the internal pressure. Most gas springs do not offer this feature.

B.B.

I’m full of morals for this story. 1) Do not attempt Sauron-like tinkering or face the fiery consequences. 2) Resume my search for a ballistic helmet. I believe they can be had for under $200. 3) Be grateful for friends like Otho who can do magic with metalwork. His uncommon name makes me wonder if he is one of the Maia, the same order of being in Tolkien’s universe as Gandalf and Sauron, or perhaps an elvish craftsman…

I don’t have all of staunchpatriot’s information about burn rates (which is persuasive), but my general conclusion is the same. Did you, B.B., not tell me yourself that the bigger the bullet for a given load, the bigger the recoil? That seems to be the case here (with an extra factor for the conical shape). More force was generated backwards for the 3X heavier projectile that went shooting out of the nipple hole instead of down the barrel. On the other hand, luck was with you with a muzzle loader as I believe they are much safer than a breech-loader. The gun is solid back there, so the force can only go out of small holes in the lockwork rather than tearing apart a breech-loading receiver. I have made up my mind that stories about the Mosin Nagant bolt being blown back out of the gun and through the head of the shooter are apocryphal, but it could get ugly. Glad you are fine. I can see why you waited to tell us to avoid severe chastisement!

So, how did Otho fill up the pits on the rusted gun with spot-welding? Did he just fill up the holes with solder?

Victor, by all means at least make sure your brother-in-law knows of your interest in the M1. Nothing offensive about that. Glad to hear that you’ve had experience with this marvelous gun. What kind of accuracy were you getting out of what I assume were service-grade rifles?

Well, I was spectacularly wrong in my belief that California’s cannon had been defused by their already restrictive gun laws and that they wouldn’t increase them as part of the latest movement. Quite the contrary. Numerous political figures have gone on record to say that they were proud of having had the most restrictive gun laws, and after New York’s legislation, they feel moved to reestablish themselves and regain their title! The proposed legislation is going after all semi-autos which will have to be modified to fire one shot at a time. The bullet button mag lock will be outlawed. Nothing will be grandfathered in, and gun owners will be required to comply. Background checks will be required for ammunition as well as for guns. I presume that internet ammo sales will be out the window. And with the democratic supermajority in the state legislature, it looks like the laws will be passed pretty easily. It looks like my reloading career will go glimmering.

In view of the renegade ex-cop in Southern California now, I’m led to wonder if we have more crazy people now than before? I actually lose count of all the incidents from this guy, the man in the bunker in Alabama, school shootings, mall shootings, movie theater shootings, firefighter shootings? Or is it that the crazy people are just expressing themselves now. This capital murder of the ex-cop is taking things to a new level. In Hawaii, there was a guy who shot and killed a police officer, and he was sentenced to 7 consecutive life terms.

With my new shooting technique, my dreams of competition have gotten a little more vivid, but they are running up against the kneeling position. My right ACL was destroyed in a martial arts accident, and even after surgery, it hurts to put any pressure on the knee. So what good is a kneeling position anyway? 🙁 Why not sitting instead? In hunting you would either find a rest or use what Jeff Cooper called “jackass prone” positions to get as stable as possible. My only guess is that this is some kind of holdover from military tactics of the past although many military situations would prefer the sitting. When the Marines were shooting at the Japanese who tried to flee from the Tenaru River by swimming out to sea, the Marines used the sling in the sitting position. Perhaps the kneeling position does allow you to get up and down faster than sitting although for fit soldiers, the difference would be negligible. I can only conclude that this is some kind of historical artifact from when soldiers would load and fire in ranks.

Matt61

Matt,

Yes, Otho filled up all the holes — but not with solder, which is lead and very soft. He filled them with steel that is very tough and can be hardened.

And I’m pretty sure he is an elvish craftsman.

B.B.

Matt61,

This is just for myself but on our training live fire course the time the targets stayed up was determined by their range. For the middle distances there wasn’t really a lot of time to get into a sitting position and standing was not steady enough. Between shots you had to keep walking forward and watching for the next target to pop up , it could be anywhere from 50 to 350 yards. Also in tall grass or brush you have to be able to see over it. Sitting or prone are to low ,standing to unsteady.

A friend recommended a book to me that I found interesting ,it sounded like one you might like . If you have not already read it ” Incognito” by David Eagleman it is about the workings of the brain.

shaky,

I’m going to buy “Incognito” by Eagleman. Looks very interesting. I have read 3 of the 4 books by Malcolm Gladwell. Brilliant observations. I still have to finish the 4th book, “Outliers.” I have recommended all 4 books to everyone the marketing department at Pyramyd AIR.

How we think, what we think, why we think & what makes people select the things and do the actions they do give us a window into how we should present products to prospective customers. I think Eagleman’s books will be just as beneficial. Thanks for the heads up!

Edith

Edith,

I hope you like it, I thought Matt61 might because it deals a lot with the subconscious. Another book I found interesting was ” The Invisible Gorilla” I can’t remember the authors (there were two) I borrowed it from the library about a year ago. Once you read it you will lose a lot of faith in eyewitness accounts . What people see and what they think they see are often very different.

shaky,

I looked at The Invisible Gorilla: How Our Intuitions Deceive Us on Amazon (by Christopher Chabris and Daniel Simons). Looks very good and right up my alley. Because I’m just $4 away from free shipping (for the 2 books you’ve recommended), I looked for similar books that got good reviews. I decided to order Mistakes Were Made (but not by me) by Carol Tavris and Elliot Aronson. Thanks for the recommendations!

Edith

I was going to go out and buy pellgun oil today but realized I already have “gamo air gun oil” can I use this to seal off the co2 capsule instead? And can I use this in the compression chamber of my TR77?

On a CO2, almost anything is probably viable (no brake fluid though). The pressures are lower (~750PSI), and CO2 is not an oxidizer.

For use in a spring gun? No idea… RWS (don’t know who packages the kit now) used to sell airgun kits with two oils: a spring oil, and a chamber oil. The chamber oil being a silicone based fluid that should not combust under the heat and pressure of firing (using oxygen in the air); the spring oil is more of a light petroleum-based lubricating/machine oil. So what is the Gamo product — could be meant for either purpose.

Calling all experts,

About how many pumps does it take, using a brand new Hill MK 3 pump with dry attachment, to fill a Marauder to 2500 psi from EMPTY?

Thanks very much in advance,

Michael

Michael,

Somewhere between 250 and 400 pump strokes, depending on many things.

B.B.

B.B.

It came out to 250 strokes for me, not counting the stroke I think I had! (LOL!)

The saving grace is that I plan never again to have to pump it from 0 to 2000 psi, although the last 500 psi were the toughest.

I let the pump and myself rest between every 33 strokes. That left a final session of 25 or so.

I’m in Midwest farm country, so the closest location to fill a large SCBA to 4500psi is a 230 miles round trip. Add the time, gasoline, wear and tear on the car, the fill fee, and the cost of a one-hour SCBA that will have to be replaced in 14 years (“New” ones seem to be already a year old), and I guess I need to start saving for an SCBA compressor.

Michael

Presuming that pump has about the same volume as my AirForce labeled pump…

My Marauder takes about 10 strokes per 100PSI, so about 250 strokes total from ambient pressure to 2500.

My Condor reservoirs take about 15 strokes per 100PSI. My Crosman Silhouette pistol takes about 5 strokes per 100PSI.

Thankfully you survived,and with both eyes & no third nipple! I’m glad the Lewis gun is intact Tom,but more relieved you’re safe.THAT was a close call!

Maybe Otto could make you some Elven body armor?

Forgot to mention,I blew a drum off a percussion Kentucky pistol……a “not so gentle laxative” moment

to be sure.This was from corroded threads (gun was a used gift) and I was learning by trial.NOT a good mix!

Good thing the Lewis didn’t have a gold-wash finish or I’d be doing BONDage jokes about now.

A forehead nipple would look out of place,unless you’re Joan Rivers after one more facelift.

…..but you could walk around saying “my eyes are down here buddy!”