by B.B. Pelletier

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

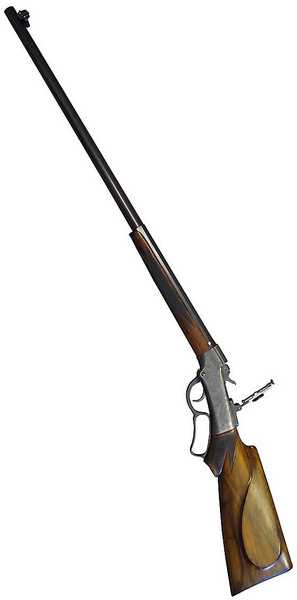

My Ballard is a factory-made special-order rifle made in 1886. It looks almost new and the bore is pristine.

Today, I’ll report on my progress in getting the Marlin Ballard to shoot. I’ll tie that back to airgunning, because the same principles that drive the accurate firearm rifle will work there, as well.

In fact, today’s something of a shocker and a screamer. The shock comes from how badly I prepared the ammunition, and the screaming came when I saw the last two targets for the first time.

Preparation

To prepare to shoot the Ballard, two things must happen. First, the rifle was cleaned as soon as it returned from the range the last time it was shot. Because the barrel is so glass-smooth, it takes only a few minutes to clean. Then, it sits on display, proudly awaiting its next outing.

The second thing that must be done is the ammo must be prepared. I have not resized the cases before reloading them. Because they are always fired in the same rifle and in the same chamber, I have filed a notch in their base so each case is always oriented in the chamber the same way. They are loaded straight into the breech with the notch at 12 o’clock.

The cases were deprimed, the primer pockets were then cleaned and Federal large rifle primers were inserted into each case. Then, I ran a belling tool into the case to open the throat to receive the new bullet. Next, all 40 cases received a fresh charge of H4198 powder. I’m using an RCBS Uniflow powder measure, and it was easy to set it at the 17 grains of powder I determined last session would be the optimum charge.

I’m still using the original Winchester cases that I determined were slightly too short for the rifle’s chamber. But, they’re all I have and they’re on their third loading right now.

The key to today’s test was to see if I could detect a difference in accuracy between the sized bullet that measures 0.379″ and the as-cast bullet that measures 0.381 inches. With everything else being the same, I figured a 10-shot group would show the difference, if there is any.

Trouble, trouble, mega trouble!

Never have I had so many difficulties loading a few straight-wall rifle cartridges. The 20 sized and lubricated bullets went together with their cartridges pretty quick and without any problems; but, when it came time for the as-cast and finger-lubed bullets, it was like juggling flasks of nitroglycerin. Some of the finger-lubed bullets got stuck in the seating die from the excess lubricant around the bullet. I had to disassemble the dies several times and drive out the stuck bullet out. I assembled the die again, and that caused variations in the overall cartridge length.

Another problem I had was that the nose punch in the seating die has the incorrect taper for the bullet I’m using. It cut a ring on every one of the 40 lead bullets I loaded. This was the worst lot of ammo I’ve ever made, and it showed.

Each of these problems has to be addressed and fixed in the future. Right now, they’re causing me to make ammo that isn’t too pretty.

Those cartridges should all be the same overall length. Having to constantly disassemble the dies to remove stuck bullets caused this. This is sloppy ammo that shouldn’t shoot well. Notice the file marks in the base of each case that are used to index the case to the chamber.

The ring below the flat nose of the bullet shouldn’t be there. It was caused by an improperly shaped nose punch in the bullet-seating die. The fix is to send several bullets to RCBS, the die maker so they can cut a nose punch that’s matched to the shape of this bullet. This is one more problem that detracts from the accuracy of this reloaded round.

Excuses, excuses!

With all of these excuses, I’m sure you expect another mediocre report. Don’t! The gun did very well in spite of all I did to derail it. The day was perfect, without a breath of air, so 100-yard shooting was very easy.

As always, the rifle was rested on an MTM rifle rest on my MTM shooting bench. The bulls are 3-7/8 inches in diameter and perfect for these sights at 100 yards. My front sight element is an aperture, so the trick is to center the bull inside it and level the bubble in the spirit level to cancel any cant.

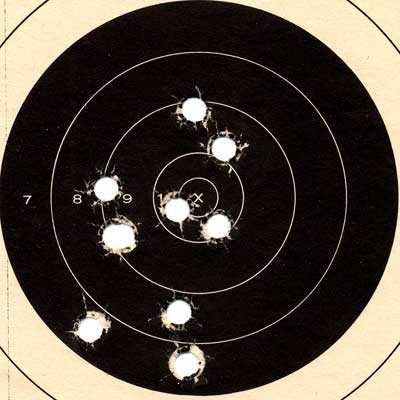

The sized bullets were in the first group of 10. They gave me an average target.

Well, at least they’re all in the black. Ten sized bullets made this mediocre group at 100 yards.

Then, I switched to the unsized bullets. I expected a thorough trouncing of the sized bullets, but it didn’t happen. In fact, the two targets look very similar. And, I threw one shot out of the black!

The unsized bullets were slightly worse than the sized bullets.

So, what gives?

I’m sitting there wondering what I could do to improve this rather mundane performance, when it hit me. I wasn’t close enough to the rear aperture! I would have to hold my eye up close so the most light possible comes through the tiny peep hole.

Also, I could pay more attention to the bubble in the spirit level with my eye closer to the peep hole, because I could now see the bubble better. You would be surprised to see how much cant you normally put on a rifle if you haven’t got a bubble to check yourself. I found that it felt like the rifle was tilted to the left when the bubble was actually leveled. My natural inclination to hold the rifle resulted in it being tilted far to the right.

Second targets

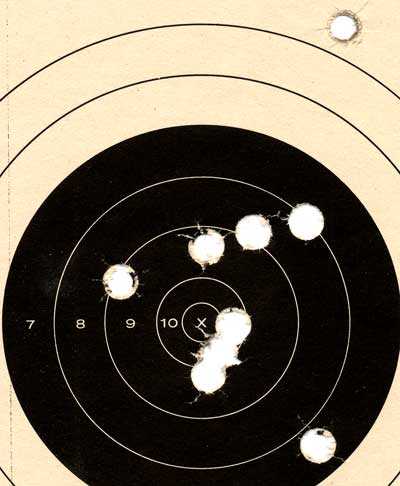

Now that I sorted out how to shoot, it was time to shoot the second set of targets. This is where the surprise was.

Eight sized bullets went through the group in the bull. This is real progress!

Seven bullets went through the center of the bullseye! These are the unsized bullets.

Analyzing the targets

I’ll cut to the chase. I don’t think I can really tell whether the unsized bullet is more accurate or not. Seven out of the 10 bullets made a group that measures 0.835 inches between centers. However, the actual group size of that target is 2.609 inches.

The best sized bullet group measures 1.437 inches for 8 shots and 2.55 inches for all 10 shots. That’s too close to call. But since the unsized group is not that much larger than the sized group, and because my sloppy reloading can easily explain the difference, I think the larger bullet is the better one. My lubrication process has to change, because I can’t keep disassembling the bullet-seating die all the time. I need to find a way to lube the bullets so it leaves the grease in the grooves instead of all over the side of the bullet. I guess I’ll break down and try the classic “cake cutter” method, where the bullets are stood in a flat pan and melted grease is poured in the pan until it reaches the top groove. The grease is allowed to re-harden, then an old cartridge with the end cut off is used to cut each bullet out of the hardened lubricant.

Also, I need to remember to begin my sighting procedure the right way next time, with my eye close to the rear aperture. I have to remember to level the bubble for every shot.

Mac suggested that leaving the powder loose in the case might have been a contributor to fliers. The next time I reload, every case will get a Dacron wad over the powder. I use one in my .43 Spanish, and it works well.

Lasting impressions

I’d forgotten to take a spotting scope to the range on this day, so I was unaware of what the final two groups looked like until I walked up on them. Seeing a large hole in the center of the bull on a 100-yard target is thrilling, to say the least. I refer to good shots as “screamers,” and I’m darned if I didn’t do a lot of screaming when I saw those two targets.

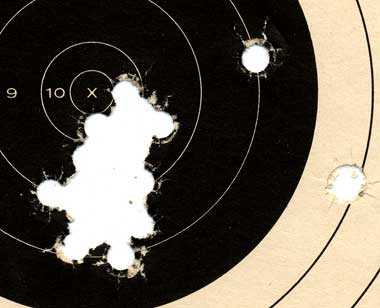

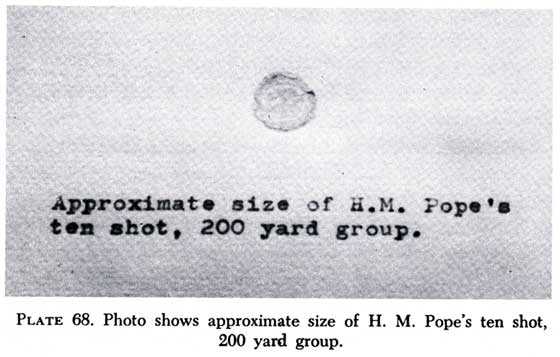

All my life, I’ve read articles about the great marksmen of the late 19th century, and I’ve looked at the targets that accompanied their articles. To put my shooting into perspective, Harry Pope, the great barrelmaker and world champion rifle shot, once put 10 rounds into a 0.20-inch group at 200 yards. Talk about a screamer!

This group is a representation because the original was lost. This was scanned from the book, The Story of Pope’s Barrels, by Ray M. Smith, copyrighted 1960 and published by The Stackpole Company. Revised edition 1993 printed by R&R Books.

Pope shot this group with his .33-47 rifle, which was a breechloader that was also a muzzleloader. The loaded cartridge was first loaded into the breech in the normal way, then a bullet was loaded from the muzzle and rammed down to the top of the cartridge. That way the “fins” of lead resulting from the rifling were not on the base of the bullet when it exited the muzzle, and that has proven to increase accuracy. Should we be muzzle-loading pellets? I think not.

Pope shot the famous group and walked down to the 200-yard target to retrieve it. He set it on the ground and measured it with the calipers he always carried; but, since the wind had picked up, he held the target down with his knee. After measuring it, he stood up, but before he could grab the target, the wind caught it and dropped it in the nearby river.

Unlike Elmer Keith’s famous 400-yard elk kill with a .44 Magnum revolver, nobody doubts the truth of this story. Harry Pope had the reputation of being scrupulously honest in all his dealings; and, if anyone was ever going to shoot a group like that, he was the one most likely to do it.

I never expect to come close to this kind of accuracy, but it would be pleasing some day to shoot 10 shots into an inch at 200 yards. I know benchrest shooters do it all the time, but I would feel more fulfilled doing it with this 125-year-old rifle. It was good enough for target shooters in 1886, and that makes it good enough for me today.

How does this relate to airguns?

I think that’s a good question that deserves an answer. In airgunning, there are certain air rifles with a reputation for extreme accuracy. Some, like the underlever TX200, require technique to shoot this well, while others are more forgiving.

Some of these accurate airguns are even vintage and no longer made. The FWB 124 would fall into that category, as would an Air Arms Shamal PCP. We’ve discussed subjects like extreme accuracy, and many of us seem to be in pursuit of the smallest groups possible. It’s my hope that by sharing what I’ve had to go through to obtain good accuracy from my old Ballard, that you’ll be able to apply some of these same things to your airguns.

I haven’t even mentioned sorting my bullets by weight to this point, but that’s coming. Now that I have a good load (equate that to finding a good pellet and the right power setting) and have learned the importance of good shooting technique like sighting and cant reduction (equate that to the artillery hold and also using a bubble level on your airgun), I’m ready to take this quest to a whole new level.

I admit that I do enjoy shooting this firearm a lot, which is the main reason I do it. Kevin has just shown that my rifle might be worth over $12,000, but I’m darned if that will make me get rid of it. Sure, it’s beautiful to look at, but seeing those tight 10-shot groups at 100 yards is more beautiful to me. Townsend Whelen said it all when he said, “Only accurate rifles are interesting.” Well, this one fascinates me. But it is just as easy to be fascinated by a Weihrauch HW50S that cannot seem to shoot multiple pellets anywhere but to the same place.

B.B.,

Great article! What amazing accuracy! I always used a spirit Level on my front sights. I was taught that a consistent cant was critical. I must say, that group shot at 200 yards by Harry Pope is hard to be believe. I wonder if anyone else had gotten even close to that kind of performance. Do you know if that very rifle is still available somewhere? I wonder what was so special about that rifle, that it could produce such an unbelievably tight group? That’s got to be humbling to just about every shooter that’s tried to master marksmanship.

In the end, performance is relative to whatever type of gun you’re comparing. This group by Pope has got to be in a class all by itself.

Victor

Victor,

Yes, others did get close to that performance. But never challenged it. In fact, the same day Pope shot a second group that was under one inch at 200 yards.

Yes that very rifle still exists in a collection, I believe. In fact there are still several hundred Pope barreled actions in existence. But few are ever shot, because they mostly belong to collectors now.

B.B.

Also, shooting without a spotting scope may have helped a bit. What were the weather conditions when you shot those last two groups? (Any wind?)

Victor,

The wind remained still for all four groups. The day was as perfect as a day gets for this. Just by changing how I used the sights this dramatic change was realized. That is an object lesson to every airgunner, because sometimes the problem is you.

B.B.

Oh, no! The problem CANT be me! 😉

Wouldn’t a spotting scope tend to help accuracy? That seemed to be the case the first time I took my spotting scope out to shoot my M1.

Matt61

Matt61,

Spotting scopes are essential, but mostly to help you verify that your rifle is sighted in, or to help you re-sight in because of wind. Remember, we should use our sights, and not us Kentucky windage. If your scope is sighted in, then in theory, you need not constantly check. One of the benefits of a spotting scope, assuming you are sighted in, is that it might give a hint that you’re holding the gun wrong, or inconsistently, or that your trigger squeeze needs extra attention.

In the case of what B.B. is doing, I don’t think he is doing much in the way of sight adjustments, as he is shooting groups. I wasn’t suggesting that he, or anyone else, NOT use a spotting scope, I’m just saying that if you don’t plan on changing the sights, then shooting without a spotting scope is the most objective way to shoot for groups.

A great exercise that we use to do was to have the shooter not use a spotting scope, but instead have a coach or teammate use one, and ask the shooter to call your shots. Again, if your shooting for groups, and your gun is reasonably sighted in (relative to the bulls-eye, then there’s nothing wrong with not using a spotting scope. A spotting scope, under those circumstances can play with our psychology and possibly influence our execution between shots.

Victor

Victor, yes there is a certain purity in sticking with the sights, and I can recall occasions when the spotting scope was a distraction.

Matt61

Matt61,

Anytime we find ourselves rubber necking (vibrating) between our sights and spotting scope, there is something wrong. This is a symptom that we should all be cognizant of. It indicates that our mind is not in the correct state. As we follow through, we should try to call our shots. After a pause that coincides with our shot call analysis, we should look through the spotting scope to see how accurate we were in our analysis.

Victor

About all I have used a spotting scope for is for helping me walk in a set of iron sights so I don’t have to keep walking down to the target to see what the poi is doing with the adjustments.

I don’t find the spotter to be very useful when using a scope unless the magnification is low enough that I can’t see the holes.

I always take along a small 3′ tape measure when I bench rest to help me figure out how many clicks to move when using a scope after I get it very close. The tape is very handy for target analysis in the field while you already have the bench set up.

I will always take along a laser range finder or a 100′ steel tape when setting up targets. Not much point in making permanent range markers because I usually try to orient my shooting direction and location that gives me the least crosswind. However , there are times that I deliberately set up to shoot in a crosswind, but the sights have to be set up for calm air first.

twotalon

Matt,

Victor answered perfectly for me. Once I knew I was on target withe forst two groups, I didn’t need the distraction of a shot-by-shot report. My friend did have his spotting scope and he gave me a report on each shot in the first two groups. I think from now on I will dispense with that kind of information.

B.B.

B.B.

That is some darned good shooting considering your ammo problems.

This would be something like mixing up a dozen different kinds of .22LR and shooting rounds from the pile at random.

twotalon

“The Art of Collecting Airguns”?

I’m pretty much done with this blog.

Lighten up… Sometimes cross discipline learning teaches you more about your hobby. I know air gunning has made me a better firearm shooter. I expect this article to do the same for those that cannot own or will never own a firearm.

JC: Too bad you have that attitude. You are missing the point of this series. It’s not just about how to aquire more stuff. If it weren’t for folks who collect airguns and firearms from the past and shoot them ,work on them and record the information,the collective knowlege of those days would be lost to all of us. We wouldn’t have a baseline to evaluate all that “new” stuff we get now, or how we got here, Robert.

JC,

Too bad. We will miss you. Good luck anywhere else.

ka

JC,

You really shouldn’t be so adverse to learning something new or different. I didn’t come from an air-gun background, but I believe that what I’ve learned here has enriched my overall experience with guns. Before delving into the world of “springers”, I took way too much for granted. I am now more critical about how I handle and shoot all guns. That B.B., and others, spend time talking about firearms is very important to me, and I’m sure others. Having this kind of variety of discussion provides real world perspective and consideration to fine details. To me, B.B.’s vast hands on experience with all types of guns gives him credibility. I’m now an air-gunner and a fire-am marksman who is better able to appreciate and understand both.

Victor

I personally do not own any firearm and don’t really plan on owning one as it would mean too much trouble to get not to mention use, shooting range are few and far between around here. Airguns allow me to shot when I want for as long or as little as I want.

But I still really like the today’s blog as I find this rifle gorgeous. I know this is an airgun blog but once in a while seeing something else gives us a wider perspective and allows us a look in the author “backyard” and helps establish the credibility of said author.

It’s easy to dismiss a writer a writer and call someone a fake but when you see what has been tried and done by someone it’s becomes harder to say that what is written here is bogus.

I hold this blog and it’s author in very esteem and will accept a blogs like the one we have today anytime Tom fells like doing one.

I think JC is what is often referred as a troll : a troll is someone who posts inflammatory messages with the primary intent of provoking other users into a desired emotional response. These persons are often unknown to the community where they post.

J-F

J-F,

With some people everything is their way, or the highway. They are too conTROLLing. 😉

Victor

JC I believe this blog is all about the love of guns in general. It doesn’t matter what type of gun it is as long as it is a gun. BB covers a vast variety of guns, air or powder powered, it is all interesting to a real gun enthusiast and both types share similarities. Don’t give up on this blog. The people here have helped me with questions on both airguns and firearms. It is a friendly place. Toby

JC,

Here is a whole different perspective, totally separate from the actual content of BB’s article:

This “airgun blog” is, first and foremost, the property of PA. It is a combination of “our community”, information sharing, education, entertainment, and advertising. Josh has done a wonderful thing with it, but make no mistake – it’s purpose is to support his business, and that business is selling airguns and related items. It is not here to be only for what any one of us want it to be.

Even if the article BB wrote had nothing to do with airguns (which I do not believe), it is a wonderful piece on an antique firearm, and it will no doubt attract firearm enthusiasts that have no interest in air guns, mostly because they think the are all like a “Red Ryder” (I know many of these people). Some of them will read other articles, and may come to join us in our passion. That brings more business to the airgun world, and also to PA, which is extremely important for this blog.

That increased business benefits all of us, because more interest means more sales, which means more investment by more companies. So this “firearm” article is clearly “airgun related” in the most important way, as measured by the purpose of this blog.

P.S. Even if you did not find anything “airgun related” in the article, it sure exists in the comments!

Alan in MI

Will you guys stop feeding the troll???

You are doing exactly what he wants you to do.

twotalon

You’re right, we got out of conTROLL.

That rifle is SEXY (if a rifle can be).

Yesterday Lloyd asked me if I knew what rifle was used in the high speed shots vid I posted yesterday. I little digging seems to indicate he’s a Russian made EDgun Matador bullpup rifle http://edgun.ru/en/cat/guns.php

these guns look pretty good, I’m not a big bullpup fan but these look pretty good.

J-F

J-F,

Thanks for identifying the gun in the video. I’ll have to read about it. 100 yd shooting there, too.

Lloyd

No problem Lloyd always a pleasure to give a fellow airgunner a hand.

If you look around a little bit on his youtube page he shows his camera setup which I find quite nice.

When using the camera he aims using the image given by the cam which should probably be good to eliminate all paralax errors (right?). He’s basically taking himself out of the shooting equation, only pulling the trigger.

J-F

BB: By your photo , it looks like your applying a slight crimp to your finished rounds, Are you backing off the bullet seating die enough when you seat your bullets? Also I agree with Mac on the filler, never had a problem with dacron.Take care,Robert.

Robert,

Yes, there is a slight crimp on the bullet. It is intentional. I may experiment to see if it isn’t needed. Maybe with the Dacron I will have all that is needed for good ignition. Mac said the same thing.

Of course back in the day with black powder no crimp was required. I have been toying with loading some black powder cartridges, as well, because I know that black powder obturates the bases of the bullets better than smokeless, which burns too progressivly.

B.B.

Another benefit of separately loading the bullet from the muzzle was that the black power fouling was scraped from the barrel as the bullet was pushed down. It was common at the time to have to clean the barrel every 10 to 15 rounds during a match when the bullet was seated in the case and not separately loaded. Muzzle loading the bullet reduced the need for frequent cleanings.

Paul in Liberty County

Paul,

Thank you for reminding me why I don’t load with black powder. I was hoping with SPG lube and blowing through the barrel after every shot I could maybe get 40 round without cleaning. No?

Looks like I may have to experiment.

B.B.

BB: Also , you’ve just got to try black powder in the Ballard. It will fill the case better, and with a grease cookie or just a wax paper wad cut from a milk carton under the bullet’s base, you just may get better accuracy. Don’t under estimate the “bump” black gives to a undersized bullets base when it is ignited, to help fill the grooves, that you don’t get with smoke-less powder. That Ballard was designed for black powder and the gun will clean up easily. Recoil with a 41 gr charge of FF or a 46 grain charge of FFF , will be mild. You should get about 1250-60 fps from the load. Also ,consider the aquistion of a custom nose pour mould that is made specifically for just your barrel. I know of Hoch moulds that in .45 cal that were available of this type. Your gun is so valuable, that the cost of a custom mould, and fussing with black powder, would be worth it , to obtain 200 yard MOA . Just a thought,Robert.

Robert,

I have given all that you say considerable thought. Especially the nose-pour mold. I’m looking at a Hoch design, so I can specify the base thickness and the bullet weight.

As for black powder, when I disassembled the rifle I found traces of old black powder residue in a few places. I left it, as it reminds me of the history this rifle has been through.

A grease cookie wad is a great idea!

B.B.

BB,

100 yd groups like that with open sights. It’s nice to have a collectible that doesn’t just hang on the wall or stay parked in the garage.

Very nice!

Lloyd

BB,

Who cares if you tie this report in with airguns?! It’s Friday. I learned volumes reading this, as I am just starting to reload ammo. Not sure if I am going to have the same probs with the .308 stuff, but I can see the .45 auto similarities. While I have no intentions of casting bullets, the lubing is interesting.

ka

Fridays could be open blog days? The blog version of casual fridays?

J-F

J-F,

I always try to give readers something to chew on over the weekend, and I guess today was a good one.

Casual, yes, but still focused and relevant.

B.B.

“The best sized bullet group measures 1.437 inches for 8 shots and 2.55 inches for all 10 shots.” That’s a 1.74 moa. Not too bad in my book. You’re half way there.

ka

Good article BB. Information I’ll never be able to get anywhere else.

My air-rifle and rim-fire shooting really do seem to cross over a lot. Somehow I have acquired a mentor at the range who is teaching me the techniques of Sport rifle shooting. What he’s teaching me is really air-rifle field target 🙂 but with a rim-fire, except I get to use a sling which he’s going to show me how to do next week. Are slings allowed in FT?

As pertaining to your cross over articles, I read a comment a while back that reminded me of a common question asked by those 16 year-olds, who know everything, during my high school days: “Why do I have to take Algebra, Geometry, Trig? I’ll never use it when I get out of here. I’m not planning to be a rocket scientist.” Then, when they grow up, they try to lay tile in their kitchen and can’t even calculate how many tiles they need.

-Chuck

Chuck,

Slings used to be allowed for FT. I don’t know if they still are. The one thing you cannot do is have a rest that connects your gun with the groups. Shooting sticks and bipods are illegal. But I used to use a res that connected my rifle to my lower leg and that was legal.

B.B.

Chuck, check out Field Target Sling on Google images and you will see what many of the shooters are using. It’s more of a brace that locks your legs and lower torso in the sitting position. Not sure if there is any connection to the gun.

Brian,

Thanks for that sling link. I checked it out as you suggested and as a result ended up doing an awful lot of lusting. There’s some pretty good equipment out there. Also, like many of us more mature shooters, I think I’m going to need a sitting sling to protect my back.

-Chuck

Chuck, ya, I resemble that remark. This old age thing ain’t all it’s cracked up to be is it!?

It’s amazing to me what relevance this article and this series of articles has to buying and shooting airguns.

I’m sure the occasional, novice airgunner will see the picture of a black powder gun that has a history of legendary for accuracy that dates back to the civil war and wonder how it relates to buying and shooting airguns in his backyard. Those with a little experience understand the wealth of information that relates to airguns in this article.

Don’t have a lot of money but want to expand your airgun horizons by being able to own vintage airguns that are historically accurate? Read this series of articles. Then, re-read them.

Is there an airgun that you’ve always wanted to own but you’ve closed your mind to owning it because financially you never thought it was possible? It is possible. Read this series and find out how. Expand your mind to make this possible.

Want to know how to shoot your airguns as accurately as possible? Read todays article and others in this series. The gems of information about wringing accuracy out of your airguns in today’s article are numerous. Among others, here’s what I read in today’s article that will help me with achieving the best accuracy in my airguns:

1-I must realize how cunning a slight bit of cant can be in destroying your shooting accuracy. Consider installing an anti-cant device on your guns if you want to shoot well.

2-Assume that your gun is accurate. If it isn’t shooting great groups believe the gun is accurate and search for issues. Too many people give up on a gun before it has been allowed to achieve its potential. In todays article we’re encouraged to keep trying different ammo, experiment with proper cheek weld, clean the barrel, etc.

3-Get to know your gun. This is only the 3rd time the new owner of this gun has shot his vintage gun. He’s still discovering it’s secrets to shooting well. This is also only the 3rd experimental load and many other variables are in play as well. It’s fascinating to me to come along for the ride vicariously since I know how relevant sorting these pieces out is to shooting my airguns accurately.

Yes, it’s important to me that I learn to shoot accurately. Yes, these articles are teaching me and reminding me how to do that well. This free and critical information is greatly appreciated.

kevin

Amen Kevin, I keep a little article from a British airgun mag taped up on my shooting bench, it was titled “Why CANT you shoot straight?” with the obvious emphasis on cant of the gun/barrel etc.

Cant is one of the most subtle and not easily remedied problems in the quest for accuracy, with most of it being memory (or lack of!) Much like a great golf swing, there are always those 4 or 5 positional and grip characteristics that make any shot work. Forget one of them and it’s OB city!

Brian in Idaho,

Couldn’t agree more. Cant is rarely talked about. Elevation changes/slope also affects accuracy.

Since I’m an idiot with few skills I like aids. A Swing Trainer for golf and an anti-cant device for shooting.

I like the Horus Vision device for shooting since it helps me adjust for cant and address slope in shooting all in one neat package. It also has mounts for 1″ tube scopes and 30mm scopes that come in the same package.

http://www.horusvision.com/calibration.php

kevin

Oh great Kevin, thanks $o Much! $!$!$!

That is a sweet little device and the clamp direct to the tube is exactly what I would expect for precision.

I’ll be back in awhile, you know what I’m doing next!

An effective anti-cant device can be as simple and cheap as buying the bubble level insert at your local hardware store and mounting it on the rear of your stock with a dab of silicone. Works. B-Square and BKL make bubble levels/anti-cant devices that attach to scopes and/or mounts. I also experimented with the U. S. Optics anti-cant device that mounted in a similar fashion to the Horus Vision and the bubble level had a protective cap when not in use on a swing arm that could be moved along side of the scope for additional protection when the gun is stored or traveling.

The electronic micro level that mounts to the ocular end of your scope is probably the most advanced anti-cant device that is also user friendly. Unfortunately it appears these are only available used since the manufacturing has stopped (temporarily??). Don’t know.

The key for a useful anti-cant device, for me, is being able to see it while maintaining a cheek weld.

kevin

kevin,

Great link. Thanks. The Horus ASLI is on order. I was considering another unit a while back that is calibrated just for each bullet, more expensive and requires one for each different cartridge, which was the reason I didn’t purchase. I watched the video too, awesome stuff. I think Leopold has a scope for about $900 that has software driven compensation in it. It almost seems as though in the near future batteries will be a field commodity as valuable as the ammo itself!

ka

Nice rifle BB.

Why would people doubt Elmer Keith’s skill with a sixgun? From everything I’ve read about him, he lived by them. Sixguns by Keith is an amazing book.

Al,

I didn’t say that I was among them. Back in my salad days, before I became old enough to “know better” I believed everything that Keith wrote. As a result, I eventually hit tire-sized boulders at 300 yards with an 1860 Colt Army and football-sized dirt clods at 80 yards with a snub-nosed Colt Detective Special.

But of course I didn’t know those things were impossible.

B.B.

I hope I didn’t come across as saying you did. If it came out that way, then I apologize.

A very kind gentleman sent me Sixguns as a gift recently and I’ve been taken with it.

Thank you for sharing all your information, it’s very appreciated.

Al,

No, I didn’t think you were saying anything. I just wanted to say how much credit I give Elmer Keith for what I know about shooting a handgun.

B.B.

I gotta ask – when you talk about hitting these targets, do you mean 50% of the time, 90% of the time, 99% of the time?

I think that B.B. addressed this question for me and said that once he found the range, he pretty much stayed on target. My Ruger Single Six is rapidly becoming one of my favorites of the collection. I’ve even started to cast my eyes at the Ruger Mark III Competition rimfire, which I think Kevin has. Is there a Camp Perry contest for this kind of gun?

Matt61

We have the Elmer Keith exhibit at Cabelas in Boise where an anima-tronic Keith narrates his exploits. He mentions the 400 yard Elk shot and people’s disbelief and then adds in his gravely voice…”all I know is, that dammed Elk died from a .44 pistol shot, mine.”

I think the average reader or shooter who reads Keith’s exploits and musings finds it too much for one man to have accomplished? And, while he was still alive, he ruffled a lot of feathers of fellow gun writers and pistoleros. Sometimes color commentary over shadows the facts.

I hope that one day I can take my wife, daughter and son on a pilgrimage to that museum.

B.B.,

A big leap forward. Congratulations.

Your hunt for accuracy in the Marlin Ballard is progressing very quickly. Those groups are a giant leap in the right direction. You’re better at this than I was since many times in reloading I would take a step backwards.

17 grains of H4198 seems a sweet spot. Robert has an interesting suggestion about powder. Others have gotten very good results with H4227 and SR-4759 when they load for muzzle velocities of 1200 to 1300 fps with a cast bullet weighing between 260 and 290 grains in the Marlin Ballard .38-55.

Since paper patched loads were the darling of the day in the Marlin Ballards I like Mac’s idea of a dacron wad. The correct nose punch and longer cases that allow a better fit in the breech certainly should help in consistent OAL of assembled loads. I hope you’ll share what affect it has on accuracy.

I thought that my reloading days were over but this is a project that would be very exciting for me. Got a spare bedroom for a few weeks?

After experimenting with your head placement, did your sight picture have any light around the 3 7/8″ target bull when looking through the front aperture? In other words, was there a width of sunlight surrounding the bull so your sight picture was a ring in a ring?

I hope you are not dismayed and will continue sharing the secrets you uncover on your road to supreme accuracy in this gun. It’s very relevant for those of us that shoot.

kevin

Kevin,

I know in my heart that this series is right for all airgunners and nothing will dissuade me from it. Of course there are crossovers! I have used a bubble level to shoot my best groups at 50 yards with a Condor, so I knew how important that was in this case.

And, yes, I can see sunlight around the bull inside the front aperture. With my eye close to the rear aperture everything became so much brighter, sharper and in focus, that I knew I had found an important secret. You can bet that the next time I shoot an airgun with a peep sight my eyeball will now be on top of the hole.

B.B.

Please forgive this greymuzzle omega, but it reads as if your experience with peep sights is new…

My understanding of how to use them had always involved getting as close to the aperture as possible (unfortunately, of three rifles, only that hybridized NRA/Daisy 953 has a peep that extends behind the receiver sufficiently to permit that — the HK91 and M-1 carbine both are about three inches too far forward).

With the eye as close as possible (without risking a black-eye from recoil), one essentially removes one sighting factor — if one can see the front sight one’s eye is centered on the aperture. Whereas, moving back removes the “centering action”. Explanation would be better in numbers but I’m too lazy to dig up the calculator and do some trig so just some fictitious numbers instead.

Assume a 1/16″ mis-alignment of the eye position. From a few inches back, the angular mismatch is so narrow as to permit seeing the front sight through the aperture. From right up against the aperture, that same 1/16″ would result in either just seeing the aperture disk itself, or the angle will be such that all one sees is sky (ground, barrel… anything but the front sight).

Instead of aligning targetfrontreareye, one is left with just targetfronteye; the peep sight is no longer a factor in aiming.

Blast… the software stripped my less-than, greater-than markers, leaving concatenated words…

target-front-rear-eye (hmmm, do escapes work: target<>front<>rear<>eye)

and

target-front-eye

Thanks Wulfraed. I never thought about using escapes to put in the < and > symbols, among others.

– Orin

B.B.,

You know, what struck me immediately from your interesting blog, was the reinforcement of a lesson I learned very early on: “there’s nothing like the right tool for the job.” Sure, innovation and ingenuity in the face of adversity are a great American hallmark, but ultimately, nothing will produce results like the right tool for the job!

AlanL

B.B. –

Harry Pope was a true pioneer in the area of precision manufacturing. I was actually doing an architectural photo shoot at a CNC machining school on Sunday While visiting with the director, I was using Harry as an example of the “best of the old school” of precision machining.

Harry used to shoot fantastic groups by using the techniques that you describe, including the use of a false muzzle to ease the bullet into the bore, protecting the heel. He felt that the heel of the bullet was more critical to accuracy than the nose. I agree with that, and feel that it is one of the chief reasons that nose pour bullet molds are preferred when chasing this kind of accuracy. I read an interesting article years ago, where the author shot a test comparing 100 yd. accuracy of match .308 ammo to the same rounds where the bullet noses had been deformed with a file or a pair of bullet pulling pliers. The difference was so small that it could hardly be measured.

Another secret of Pope’s incredible accuracy was the use of gain twist barrels. FX has recently taken a step toward that style of barrel with their smooth twist barrels. Not exactly the same, but similar in concept. I agree with you that much of the thought behind making the old black powder target rifles shoot to their top capability can be applied to airguns. Gain twist or smooth twist barrels could really help pellets get up to speed with less deformation due to pressure. That just has to aid accuracy, doesn’t it?

From what I can tell, there was one last good reason for Harry’s accuracy with a rifle. He was a phenomenal marksman. It wasn’t often that someone could beat him, even with one of his own barrels.

Regards from the flatlands,

– Jim in KS

Jim,

Question from a still (and forever) novice, despite my time on this blog: What’s the difference between ‘gain’ and ‘smooth’ twist rifling in barrels?

Thanks,

AlanL

Alan,

A gain twist starts out with a slow (one turn in 30 inches of barrel) twist at the breech and increases in twist rate until at the muzzle the bullet is turing one turn in ten inches of barrel. It is thought to decrease the tendency for a soft lead bullet to “slip” in the rifling.

A smooth twist barrel is one in which the rifling is ironed (pressed) in from the outside. It is a manufacturing technique that makes a barrel less costly to rifle. It can also improve the inner smoothness of the barrel if the right preparations are done before ironing in the rifling.

B.B.

B.B.,

Thanks- I though as much. It makes intuitive sense to accelerate the twist rate from a slow start rather than try to impose the max rate on the bullet right from the get go. After all, a piece of lead has considerable mass and hence inertia to overcome. Same principle as the fluid drive clutches on larger electric motors.

AlanL

“though” = “thought”. Aaarrrrgh!

B.B. –

The feature of the new smooth twist barrels that I was comparing to gain twist rifling is the fact that the smooth twist barrel is smoothbore until the last few centimeters, where the rifling engages the pellet and imparts a spin. SInce it requires less energy to move the pellet down a smooth bore than a rifled one, more velocity is achieved with the same pressure. The super accuracy is also appreciated, but may actually be more attributable to the high quality of manufacturing at FX than the smooth twist concept.

– Jim in KS

Jim,

And my concern is that hitting the rifling at speed allows for pellet deformation.

B.B.

B.B. –

Rightly so. I would be concerned, too, if the accuracy from the smooth twist barrels was less than it seems to be. I guess that, in a perfect world, the rifling in smooth twist barrels would start out parallel to the bore, and progressively increase in pitch to the muzzle, with just a pinch of choke for good measure. Works in theory, anyway.

Regards,

– Jim in KS

In my limited experience the ST (Smooth Twist) barrels work in practice too.

I’ve now got a Royale in .22 caliber with the ST barrel at my place and the accuracy is amazing out to 50 yards. Haven’t shot it beyond that yet.

kevin

Everyone,

Well! JC’s departure this morning and our little discussion of cant has spurred me to do some thinking. First, while JC has left, I think he missed the point of today’s blog. The point was accuracy and how we obtain it.

And the subject of cant is one I thought I had addressed pretty well in this blog, but now I see I have not.

Back in the days of “The Airgun Letter” I did an extended cant test, introducing cant of known amounts into the equation to show how much a pellet’s impact would move at 50 yards. By using 10 degrees of positive to negative cant, I moved the POI six inches laterally. So if you hold the rifle differently each time, you could be adding inches to your groups.

It’s time for me to resurrect the cant issue, because I see there are airgunners who don’t comprehend its importance.

Back in the day I invited my readers to participate, and that’s just what I’ll do this time, too. I need to re-read those test articles and then I will get back with you on what we will do. Everyone will be invited to participate in this test, irrespective of where you live. I think we had 12-14 testers in that first cant test. Let’s see if we can get a few more this time,

Oh, and by the way, the cant test was one of those times in which ten-shot groups were used. All the way back in the 1990s!

B.B.

BB, I will be more than happy to participate in this cant test. In fact, I’m going to go out this weekend and look for a level small enough to fit on the back of my air rifles. It will be interesting to see how I have been holding them.

Oh, and JC’s comments don’t bother me – sometimes folks just like to participate in a discussion and aren’t really serious about what they say or it comes out wrong. JC, remember you can always navigate away from this Blog if the topic of the day doesn’t hold your interest. You can always come back, too.

Fred PRoNJ

Fred,

Don’t bother looking for a level. Pyramyd AIR has the best one:

/product/b-square-scope-level?a=307

B.B.

Be sure to read all the review comments on that B-Square level at PA and caveat-emptor.

Brian,

Like anything else, the tool must be used correctly. This level works perfectly as long as the installer knows what he’s doing.

I own several of these and I haven’t had a moment’s trouble from any of them.

Some shooters seem to think their guns are somehow “level,” so they will fuss for hours to get the bubble to level when the vertical crosshair on their scope is aligned vertically. That is not how it’s done.

It doesn’t matter if the level is installed five degrees off plumb. As long as you level the bubble with every shot, your sights will always be in the same place, and that is all that matters.

B.B.

Got that part, that’s what I assumed was important, repeatability, not necessarily plumb to the earth. My comment to Fred was regarding the various reviewers noting “level fell out of housing” , “too large for dovetails” etc. More than one reviewer noted those issues.

Lesson learned, no PA product comments here.

Brian,

Unfortunately, I will have to attest to the loose mounting problem of the B-Square level on my Talon SS scope rail. I could not get it tight enough so I filed down the side where the adjustment is and it now works fine. The one 4 star review by Charles was mine. I mentioned the loose mount. I don’t know why they didn’t go ahead and fix it after they read my review. 🙂 I mean, with it adjusted as tight as it would go, it is too loose on an 11mm rail! What’s up with that?

-Chuck

I have one on each Talon.

One of them fit fine, but the other did not lay down flat on the rail. I had to file on the clamp a little to get it to lay flat.

Checking with a level, both indicate level with the rifles both horizontal and vertical.

twotalon

Chuck,

Thank you for clarifying this. It is not a problem. It’s a design flaw. You see, there are no 11 mm rails. They range in width from 9.5 mm to 13.5 mm. I worked with B-Square founder, Dan Bechtel to measure as many “11 mm” dovetails as we could find about 15 years ago. And we found a lot.

Somehow the manufacturing tolerances have slipped in China where the level is made and it’s now too wide for the width of the AirForce dovetail.

Your solution was easy and simple and the right thing to do. I suspect you will have to continue doing it, because China takes years to listen to problems like this and resolve them.

B.B.

BB

I had the same problem (and applied the same fix) with my level on my Marauder. It fit the Quest fine, but not the Marauder. I would think the Marauder rail size would be the “right” size, so the level clearly needs to change. All it needs is to be a 1mm tighter.

Also, mine is not level. I know what is (bubble just to the left of the center mark), but it would be nice if it could be calibrated somehow.

And the use of a side wheel pretty much makes it unusable real time. Back on the Quest without the side wheel, I could check it with my left eye without moving, but now need to take my head off the stock rendering it fairly useless in real time. I am intrigued by the Horus link Kevin provided.

Alan in MI

Alan,

Can you not stick it out to the right instead of the left?

B.B.

Alan in MI and others, re the B Sq Level;

So the scope-level product problems are valid after all?

Guess I’ll remain humbly vindicated.

Fred? Are you reading?

Alan,

At last I get a left-handed benefit. As being left-handed I can sight with my left eye, see the level with my right eye, and use a side wheel with out obstructing the level, all without moving my head.

-Chuck

BB,

Thanks for the suggestion. It didn’t really work, as it still requires that I break my cheekweld and rotate my head, but trying it lead to a better use: I had been looking over the top of the side wheel, but now see that if I rotate my head down just a bit I can see it under the scope wheel. I still have to reestablish the cheekweld, but at least the gun doesn’t move much this way. So thanks!

Also, the act of “complaining” caused me to go and take a much close work, and I found an interference with the Marauder. I little grinding of relief with my Dremel (on the level, not the Marauder!) made all the difference. I can recommend it with confidence now, but it would be better if it didn’t need two different kinds of rework to fit on something as fundamental as a Marauder.

Now that it is working well, I can help in the test.

Alan in MI

JC, don’t let the door hit ya where the Good Lord split ya.

BB, I have often wondered about the effects of cant on my own shooting. I had considered getting a scope with a built in level, but if the B Square level gets your thumbs up I will give it a try.

OOoo, now I have a new excuse! Cant must be off!

Ha ha. Slinging Lead, you crack me up.

Matt61

B.B.,

This is incredible. Before you wrote this, I was wondering if you had done such a cant test. Canting gun is something that I was programmed NOT to do, so I can’t say that I know first hand what it’s effects actually are. I just don’t do it, and if I do, I use a spirit level to be consistent. In the end, I never argued with success.

Victor

Victor,

The beauty of my cant test is that nobody has to buy a scope level to do it. You’ll see.

B.B.

My rifle instructor was a Marine drill-instructor.

I said CAN’T once (and only once), and he jumped all over me, saying (yelling),

“Don’t you EVER let me hear you say the word CAN’T again! Can’t never did anything for anyone!”

lol

But sir a size 12 can’t fit in there. 😉

Too funny! =))

Victor,

I said the same and all hell broke loose! ” I…, I… Is there something in your eye, you miserable piece of $%*^&&! (breath and spit in face from the two inch distance… finger in eye…)

“Sir the private meant the rifles’ can’t” (two inches from face again) “… If I ever hear you say the word CAN’T again, you’re going to find a size 12 up … so fast …”

Ha! Ha! Memories of midnights in the “garden”.

Thanks for jolting loose those memories!

ka

I don’t want to steal B.B.’s thunder on any upcoming blogs, but here is a very well written reference on cant from the Microlevel website.

You can see how he set up for the cant tests using a common protractor and plum bob. Maybe that will give somebody ideas for their own tests. I like that his test results show both airgun (.177 Allen Z. Anschutz) and firearm (.22 Feinwerkbau) results for comparison.

It looks like the cant tests were never finished, as the highpower tests were never posted. I’d be very interested to see airgun cant test results out to 100 yards (these tests only went to 55 yards) and at smaller angles (like 3 or 5 degrees, which I think is more realistic “accidental” cant). I do realize that it would be much more difficult to quantify the results at a longer range and lower cant angles, and a very accurate gun would be needed. Anyone up for the challenge? 🙂

– Orin

Orin,

My cant test includes the small angles, as well.

Believe me, 50 yards is all it takes. The effect of cant is linear, so the angular relationship extends to all ranges.

Look at my first two targets to see what a couple shots half a bubble off plumb look like.

B.B.

Ah, yes… it would be linear. Thanks.

– Orin

BB,

Count me in on the cant test.

You introduced me to the solution at the last Phoenix NRA show when we looked at that soon to be disappointing scope with the internal level. I have some of those and I also bought a level that mounts externally on the scope rail for comparison testing.

I have the external level mounted on my Talon SS and I can attest to it’s usefulness. It’s easy, with the external level, after a minimal amount of practice, to be able to look through a scope with one eye and check on the level with the other. It’s amazing how I feel the rifle is level then check the external level and it’s not level at all.

Does the POI change with cant? Yup, Dude! What do you want me to do to prove it? I’ll wait for your blog article on that.

-Chuck

All,

Here is a great demo of the effect of cant – it really taught me a lot:

http://www.arld1.com/images/swfs/impactpointvscantangle.swf

BB and Edith – if the link is not appropriate, please delete the post.

Alan in MI

Alan,

Not only is that link appropriate, it is also the finest representation of what happens when a gun is canted that I have ever seen. I believe I will link to it in the cant test reports.

B.B.

BB,

I knew it was a great resource, but it does come from a a site that has several PA competitor links. Interestingly, it has Airgun Express, which now leads to PA :). I grabbed the link in a way that eliminates the adds tied to it and shows only the animation, but anyone that backs up the URL a step or two will get to all the links selling stuff – here is what I mean: http://www.arld1.com/

Be sure to check it out before you link it in a blog, but do note all the wonderful animations that are there. Although it can direct people to places other than PA, it is a great educational resource.

Alan in MI

That was the link I was looking for.

The animations this guy makes are incredible I spend WAY too much time playing errr researching with his animations and the guy like sharing

“I’m just getting this page going so I’d appreciate it if you would post it to any forum where it has yet to be posted.”

He also has very nice macro pics tutorial.

J-F

Crosman got the international catalog out yesterday.

https://www.crosman.com/pdf/Crosman-2011-International-Catalog.pdf

Good news for the UK with a detuned Discovery and Marauder (and a few other rifles) but sadly still nothing special for Canada… Good thing Hatsan Is there for us and agreed to detuned a few rifles for us.

JF

J-F, so, other than surfing here and on the PA site, do you have any big-box sporting goods stores in Canada that you can frequent? May seem a dumb question but, my impression of Canada (western anyway) is one of the great-white-north and rugged outdoors-men toting .30 /.30 Marlin rifles across their backpacks! Those guys must be yank tourists in for the trophy hunt, not Canucks?

We have online store like PA and lots of smaller importers who sell more at gun shows and on the CanadianAirgunForum, that’s where I got my Webley Alecto will probably soon get my first PCP a Hatsan detuned rifle. Since they are smaller importers and probably don’t do this as a living but as a sideline they don’t have a warehouse, employees and everything that comes with it, so they can take a smaller profit so I actually paid less then the PA advertised price for my Zoraki HP-01 and the Hatsan PCP’s a few bucks cheaper than PA’s price on the same rifles (Hammerli Pneuma and AirVenturi Halestorm) but then again I won’t be getting PA’s free shipping, vast choice of accessories and expertise either.

I think we have one or two Cabela’s here and there’s always Canadian Tire, it’s kinda of a Wal-Mart that used to be guy oriented (LOTS of tools, car parts and accessories, sporting goods etc) but a few years ago they started changing the store policies and try to get more girls in a take a hit at Wal-Mart and stores like that and stoped selling firearms and only have a few Crosman and chinese Beemans guns for sale by young unknowing, pimple faced, sales rep.

That’s pretty much it.

Handguns are a PAIN to buy AND use here. It’s basically long guns for hunters and that’s pretty much it.

J-F

B.B.,

Honestly, I’m not going to call Pope a liar, but if those 200 yard groups are true, then I’ve just learned something entirely new about how accurate a gun can really be. THAT made this article very valuable to me.

Thanks,

Victor

B.B.,

You shot these groups on a day that was entirely calm. Pope supposedly shot this 10-in-1 group on a day when a gust of wind picked up his target and carried it off into the river. Sure, the wind can suddenly pick up in the time it takes you to walk the 200 yards after you’ve stopped shooting, but… do you truly buy it? Has anybody ever duplicated a group like that again in the last 120 years?

-AlanL

Alan,

Yes, this group has now been bettered, but it took a century to do it.

Yes, I believe the group, because I have read so many other times where Pope would report worse performance about himself than others would.

B.B.

Accurate shooters in American history have always fascinated me. The late 1800’s and on into the early 1900’s were a time that all men were expected to be proficient with firearms. Shooting clubs flourished and it took a crack shot just to belong to some of the more prestigious clubs.

Harry M. Pope was known for his legendary accuracy in shooting competitions and gunsmithing prowess in his day primarily with single shot target rifles. Marlin Ballards being among his favorites not only for shooting but for improving their shooting performance.

Another one of my favorite shooters from that era was W. Milton Farrow. I believe he still holds shooting records to this day. W. Milton Farrow traveled the world for shooting competitions and shot Marlin Ballards in those competitions. W. Milton Farrow was also a paid shooting representative for the Marlin Ballard company.

These “shooting records” were usually witnessed by many. Not unusual for Royalty to be in the gallery at the more prestigious rifle matches. Shooting accurately in that era was a very popular spectator sport. It’s not like lone shooters bench shooting today that post pictures of groups that make you smirk with a little doubt.

kevin

“that make you smirk with a little doubt”

Saw a video on You-tube awhile back that cracked me up, a shooter had planted a friend about 20 yards off to the side of the makeshift range and 20 yards from the target. He was sniping the 200 yard target with dead center hits with HIS rifle while the so-called marksman was at the bench rest 200 yards away with HIS rifle! The guy at the rest would take great pains to sight in and then let one rip and their camera man would pan to the paper target. Looked real cause the target was virgin until the first shot followed by another etc.

This was all caught by another shooter on a cell-phone camera and the cell-phone guy’s commentary was hilarious. Went something like a golf announcer in a hushed voice…”and now, Mr. Marksman takes careful aim and…”

Some folks will try anything to impress!?

B.B.

When I see this beauty it makes me drool… People really knew how to make proper things those days and I love the concept of a mechanism made for single purpose – precise shooting.

I wonder about “ringed” bullets – did they whistle?

A couple of years ago me and my friend went to the range, he was with his Saiga .410 “plinker”, shells loaded with cast-and-pressed bullets he made himself, quite similar in shape to bullets you use in your Ballard.

They had a distinctive technological mark – a shallow ring on somewhhat 1/3 of their length from the top. We were much surprised to hear them in flight as they produced a distinctive (and quite loud) whistle. I supposed the reason was that ring mark, that acted as a sort of siren so we named them “stukas” after WW2 dive bomber. Later he reworked his press form and got rid of that ring mark (and whistle as well), that measure also increased accuracy.

duskwight

duskwight,

No, these bullets made no sound, but big bore airgun maker Gary Barnes makes a dumbell-shaped bullet I think he calls the Hornet, and it does whistle all the way downrange.

B.B.

B.B.

A short research on the web and I stumbled onto a funny thing – in 30’s bullets with ring grooves were proposed to signal a machinegun’s magazine’s end. It was refused, because that would also mean a signal for enemy troops “Gentlemen, you can go while I’m reloading” 🙂

I made some calculations and mockups from playdough, trying to model a wood for my project’s mechanism. Well, it seems I’m going to fail making it one piece.

I’ve seen video of JW60’s disassembly, but I’m afraid to break the wood this way.

Does your JW have the same stock removal procedure, how safe do you feel it, spreading forend?

I wonder what is the wood on your JW stock as I feel I could use ashtree, ’cause it is very elastic and strong. For the same reason it’s a sure hell to work with, but otherwise I’ll be forced to abandon all-wood design, thing that I wouldn’t like to do.

duskwight

duskwight,

Yes, by JW75 requires the forearm pieces to be separated to disassemble the rifle. While that may be fine for now, there will come a day for every Whiscombe when the old stock will be too brittle for that and the wood will split.

Not a very good design.

B.B.

B.B.

So my “2-piece chassis” stock project seems to get closer and closer to life. Ok, then some more time with playdough.

duskwight

B.B.,

A beautiful thing that came to mind, when you explained how you went about figuring out what was wrong with your testing, is the human element to shooting. Sure, we talk about the finer points of guns, sights, ammo, etc., but the most important element is the shooter, and the mental processes that he/she goes through. I’ve talked about maturity in my discussions with Matt61, but it’s more than just maturity, it’s a mindset, and probably a personality type as well.

If you’re the kind of person who gets easily frustrated, then shooting very well won’t easily happen (if at all) for you. I don’t easily get blown away because something isn’t working out as well as I had hoped. When things don’t seem to be working out, I’m willing to do whatever it takes to resolve the problem. At a minimum, I’ll make sure that my final assessment is as accurate as humanly possible (to my abilities). It takes patience, an open mind, and tenacity to truly know, or learn, something about any gun that you are testing.

I recently purchased a Ruger 10/22 Target model. I took it out to the range and had a less than stellar experience with it. It was brand new, so I expected that there might be some issues with the scope mount and rings, so I checked them before shooting. Things went from not great to poor. I checked and re-tightened the scope and rings, but not the mount that attaches directly to the rifle. In any case, the mount seemed tight enough when I played with the scope and rings. Trouble was, at 50 yards I was getting groups within a couple of inches, and it was very windy, so I wasn’t sure about what I should have expected. In any case, I was forming the opinion that the rifle just wasn’t that accurate. But then, towards the end of the session, I found that the scope mount was loose. Having solved this problem, I realized that there were others (I’ll spare you the details). One thing that I learned is that I didn’t know how to shoot off of a rest. I’d never done that with a fire-am. So, since that first session, I’ve been having to learn how to shoot, again. Springers required that I learn how to shoot again, and now this. What’s important is that I don’t make snap judgements about things, and always have a positive, hopeful, attitude about what I do. I don’t get discouraged, and I don’t give up (even when feeling doubt).

Shooting is a problem solving activity, and you have to have a problem solving attitude to do it well. This is a lesson that I hope everyone learns. You provide excellent examples of this.

Victor

Victor,

I pretty much hate shooting off a bench rest, but it can teach valuable lessons. I go sometimes just to practice one thing, usually my trigger pull. The bench is good for stuff like that, because you can isolate things to a greater degree than offhand.

BAG_Farmer,

Yeah, I’m not particularly crazy about shooting from a rest, although I now appreciate it. I’d much prefer to shoot in prone, using a sling. That’s why I’m considering buying a Bell & Carlson Anschutz stock with utility rail, for my 10/22 Target. That will allow me to practice as I would an Anschutz, which I was good at, and add weights to the rail, as I used to. With this setup, I think I’ll know how accurate the rifle really is. BTW, towards the end of my last outing, I was getting 50 yard groups where the bullet holes were touching. This was just after I had figured out a few things about shooting from a rest. Unfortunately, it was closing time, so those final shots were kind of rushed.

Also, I really don’t have much of a rest, just some bags that I got from Dicks Sporting Goods. They slide too easily, allowing the gun to jump. That was one lesson that I had to learn. I need to better shoulder the rifle so that it doesn’t slide. Last week I installed a bipod with rubber feet. Hopefully that will help. Still learning.

Victor

The rest like BB has (MTM Predator?) works pretty well and is reasonably priced. There is one loaner at my range, which I didn’t like until I took the time to figure it out (DOH!). It does work well after that and is easier to stay consistent than with bags for most rifles. I’ve had my eye on a Lead Sled for a while, but since I haven’t shot c/f rested in 8 months or so, I really can’t justify the cost or get excited about it, and my .22 Savage is easy to shoot off bags or any rest when needed.

While the Lead Sled works, the real cost of the unit is buying bags of lead shot for weight. Most places sell 25 lb. bags of lead shot for $40.00 to $50.00 dollars per bag!

Mike

Lones Wigger talks about how important intelligence is in shooting. As he says, only the shooter is in a position to solve his/her own problems (some of them, at least).

Victor,

That’s pretty much how it goes for me, every time I get out to the range. Oh, I remember a lot, but I also forget quite a bit, too. I think writing these things in this blog will help me stay focused on what counts the next time I go out.

B.B.

B.B.,

I’m sure you’ve forgotten a lot more than I’ll ever know.

Victor

Victor,

Well, one thing’s for certain. I have forgotten a lot. 🙂

B.B.

A sign of the intelligence of grizzly bears is their patience with a problem…. B.B.’s rest and table look like an awesome set-up.

Matt61

Victor, right you are about maturity and shooting. David Tubb implies that shooting is the sport for a decisive person. For myself, my first encounter with shooting as a teenager revealed a certain nervous anxiety that I was not aware of. Performance was all over the place. It’s been the story of my life to get that under control, and shooting is marking the progress all the way. Could it be that shooting produces your more highly developed character….?

Matt61

Matt61,

I have told many people that I believe that my intense involvement in competitive marksmanship helped me to become goal oriented, competitive, focused, and tenacious. I kind of treat life as a series of competitive matches. Life really is competitive, sometimes it’s not fair, and sometimes it’s harsh, but we can always come out ahead if we do our best. To be competitive is to do your best. But doing your best is not just something that you do in a match. Doing your best also means that you learn from your mistakes, try to break through plateaus, and that you do not allow yourself to become vulnerable to your competitors.

Victor

Also, failure is a part of life. But you should NEVER define yourself by your failures. You should define yourself by your success, because they are proof of your potential. When we believe in ourselves, and follow through with our intentions and goals, we learn to see the transients for what they are, namely, temporary. While we sometimes need faith, experience sometimes takes us past faith, and allows us to KNOW.

BB,

You’re getting closer to the goal — I’ll have to ask Edith to go with you to the range, so we don’t get any stories about lost groups :). Cant makes a big difference — needs to be consistent; the Schuetzen I pointed you to the other day had cant built in to the stock; no guess as to what the net resulting cant was, but it probably helped with consistency for the shooter it fit.

I’m guessing that to get under an inch (your stated goal) at 200 yards, you need to be shooting .25″ groups or so at 100, which is good in itself. What are you going to call your jumping off point? If I got to under 1/2″ at 100, I would probably just shift to 200.

BG_Farmer,

Once I can get sub-inch groups at 100, I’m ready to go out to 200. But as you can see, I have a ways to go.

B.B.

B.B.

Shooting sticks, monopods & bipods are legal in F.T.hunter class along with max. 12 power scopes & stools.

Loren

Loren,

Thanks for that. A lot has changed since I competed. In those days, they tried to make the hunters shoot offhand for every shot. In one club you were penalized in points even if you took a legal AAFTA seat to shoot.

B.B.

Steve Cummings Says:

February 26, 2011 at 11:27 am

BB,

I have in my collection a Gallery dart gun like the one in your article written 12/27/2010.

The gun that I have has engraving all over the spring chamber and trigger guard. The only markings that I have found on it with out taking it apart are the letters LV engraved on the top of the spring chamber. I am missing the crank at this time but the original owner is sure that he has it some place…….. I called the contact number for pyramyd Air and left contact info with Pat Berry ext 225. Any information on this dart gun, including value would be greatly appreciated. I would be glad to send pictures if you would send me an address.

Thank you for your time!

Reply

Steve,

Pyramyd Air’s technical support department is extension 244. However, they won’t have any info for you since this is a vintage gun.

Edith

Steve,

I answered a request for information like this about a week ago. It was sent to me from Pyramyd AIR, so I assume it was you who sent it.

Of course you have now discovered the right way to contact me is through this blog. Pyramyd AIR knows nothing about these antique airguns (nor does any other airgun dealer, I’d bet) and they will always defer to me for answers.

As I said in my answer, Dennis Quackenbush can make you a crank for your gun for $60. He needs the gun to do it. Visit his website at:

http://www.quackenbushairguns.com

BUT, You DO NOT intend to shoot your gun, do you? Because if you break one of the volute springs that serve as the mainspring, where will you find another?

I have looked but find no reference to an LV maker. Maybe he was the original owner of the gun. Engraving was much cheaper in the day when you gun was made and people often personalized their possessions. Sort of like those fools who scratch their driver’s license number into the metal of fine collectible firearms today, only with class.

As far as value goes, I don’t even know what kind of gun you have. So the value ranges from $200 to $10,000. There’s no way to tell unless the gun is examined, and that includes the condition, which with these guns, is almost everything.

So you establish a http://picasaweb.com account and post a bunch of photos and we’ll have a look. Then I can tell you a lot more about your gun.

B.B.

Well… I somehow doubt it was made by https://en.wikipedia.org/wiki/Louis_Vuitton

Well alright. I just finished up with my Remington Vantage build-up. Cocking is smooth and firing is more predictable. It doesn’t seem to shoot any slower but I didn’t expect it to. This was my first dis-assembly so I’m happy with the outcome. No more do I hear the grinding sound when cocking or firing. Eventually I will give it a proper de-tune but until then I will enjoy my Remington will a smile glued to the stock.

Thanks for everyone’s feedback on getting me started with my project. Next one on the list is my game hunter sport. This is pretty fun.

gamo hunter sport, I think it’s bed time. haha.

Mac was telling his neighbor, ‘I just bought a new hearing aid. It cost me four thousand dollars, but it’s state of the art.. It’s perfect.’

‘Really,’ answered the neighbor . ‘What kind is it?’

‘Twelve thirty..’

Forgive me Mac.

B.B. / Edith,

Does PA carry replacement parts for the Evanix Rainstorm? I’d like to purchase a replacement factory hammer spring, hammer, valve assy, and trigger sear to experiment on. Are parts like this even normally available for purchase? I sent Evanix customer service an e-mail, but haven’t heard back from them.

Thanks.

– Orin

Orin,

You need to contact the Pyramyd AIR technical department to get the answer. And call on the phone, don’t email.

B.B.

Orin,

I’ve emailed PA’s tech department for the availability, cost and who to contact to place the order. I’ll let you know what they say.

Edith

Thanks guys!

– Orin

Awesome. Thank you so much!

– Orin

Orin,

I just heard back from Pyramyd Air’s tech depart. manager (Gene Salvino), and they don’t have the parts you want. The only parts they can sell are o-rings, because that’s all Evanix has sent them.

Edith

Ok, thanks for looking into that for me, Edith.

– Orin

Couple of comments on cant. A lot of the top 10 meter AR shooters cant their rifles (the cover picture of the splendid German-published book “Air Rifle Shooting” shows canting). Since my neck is mostly made up of a titanium frame screwed into the vertebrae it is, shall we say, tough to bend it, so to get a good cheek weld, I have no choice but to tilt the cheek piece into the cheek. But no matter, the question is getting absolute consistency shot to shot in the position. I’m getting a MEC gadget that screws into the front globe sight with little bars on it so I can pick up the horizon.

While *of course* you can use a spirit level on a free rifle (you can do almost anything in free rifle), it’s not permitted in 10 m AP competition under international rules, and I’m almost certain that NRA rules mirror the ISSF ones.

Even at 10 meters the effect of cant is spectacular. If you ever see an arc of 4-5 shots sagging off to one side or another of the 10 ring, that’s the effect of cant — canting differently for each shot.

Pete,

For target shooting at fixed ranges, a cant is OK and sometimes preferable for ergonomics as long as it is consistent, as in the example you cite. It can cause problems on a rifle that is to be used at a variety of random distances, though. If your rifle is not level , for example, it will cause your elevation adjustment to move the shot in windage to some degree as well, or vice versa. For another example, a shot that is spot on at 100 yards may be low and to the left at 150 yards if only the required elevation change is made on a canted rifle. I think it is is the source of a lot of problems on hunting rifles (and probably FT, which is probably one of the few respect in which FT resembles actual hunting anymore) due to its effects, since you have to record not only elevation changes with range, but also windage. For target shooters, simply noting sight adjustments at each range at which they shoot is sufficient, so cant is not an issue if they prefer it.

Sure. I wasn’t thinking of FT or any other discipline where the range could vary much shot-to-shot (largely because I have a range with only one reasonable distance, 10m, that I can use). In the simplest analysis, what’s happened is that the horizontal and vertical movements of the sight are tilted by the cant angle w/resp to the horizontal and vertical movements of the projectile. If you have to cant your gun, it’s possible to learn how to handle this correction fairly instinctively. You just have to know about how far away the target is.

And I’ll bet that inattention to that detail is responsible for a lot of missed shots.

I believe that David Tubb advocates consistent canting.

Matt61

B.B., fine article. No idea why it would upset anyone. Nice to see you at the range. Some of the reloading discussion made sense to me although much was over my head. Regarding resizing, I thought this was due to expansion of the case caused from firing, so that you need to resize regardless of what chamber you are shooting with.

The Harry Pope target was quite something. Was he using a real gun or one that was set into concrete or a vise?

Brian in Idaho, those are great descriptions of Idaho, especially with all the trees. Sounds ideal. By airgun metal, I meant all the metalwork in airguns. I don’t know much about metalworking but I’m curious about the process of shaping metal cold like with a cold hammer forged barrel which is supposed to be an accurate type. Why wouldn’t you forge something hot which seems like it would be much easier?