by Tom Gaylord, a.k.a. B.B. Pelletier

This report is for blog reader David Enoch and for several other readers who asked for it after he did. When I did the first report on the main cause of scope problems, which is the scope being adjusted either too high or too far to the right, David asked me to explain how to correct the situation.

There are several ways to correct this situation, and today I’ll explain the easiest one, which is also the one most often attempted by shooters: Shimming.

Important fact!

The problem we’re trying to correct here is that the scope does not adjust high enough to get the pellet to hit the aim point. Here’s a very important point about that. Many times, the scope will have been adjusted beyond its upper limit, and the pellet will still be striking low. So, if the shooter shims the scope like I’m about to show you, he may discover that the problem has not been fixed. That’s because the scope was adjusted way too high in the adjustment range. Even though he’s corrected the angle a little, he hasn’t corrected it far enough.

This frustrates those who are new to this sport, and they’re often put off by the fact that the fix doesn’t work. They think either their scope is trash or their gun is trash because they do not appreciate what’s really happening. I read comments all the time from people who experience this, and it’s clear to me that no one has ever explained everything to them.

I don’t know if this report will help them, either, because these people are not the type who research their problems. But if you have a friend who tells you about something like this that happened to them, you’ll now have the information to explain what’s happening.

Shimming helps

You all should know that on a gun with open sights, the rear sight has to be moved in the direction that you want the pellet to move. The rear of the scope is like the rear sight of an open-sighted gun. And the front of the scope is like the front sight, by the same logic.

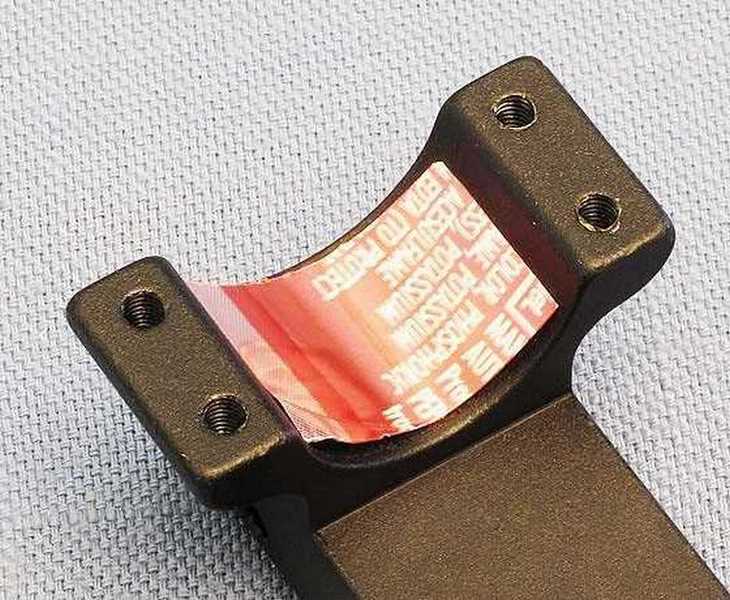

If the rifle shoots too low, we want to move the rear of the scope up, and that can be done by shimming the rear scope ring. What we’re looking for is a downward angle (slanting downward toward the muzzle) to the scope, so the shim is placed under the rear scope ring to lift up the scope tube at that point. Nothing magical about it.

What is a shim?

A shim is a piece of material that causes something to move. Carpenters use shims all the time to square-up the frames of doors and windows. In their case, the shim is a wedge-shaped piece of wood they drive into a crack until the frame they’re straightening is true. Then, they break off the part of the shim that sticks out of the crack and the job is finished.

In our case, we will make shims from flat pieces of metal or plastic. We’ll cut them to the same size as the scope ring half they’re going into…or just a little smaller. Then, we’ll put them under the scope tube when we mount the scope in the rings. The shim will raise the scope tube by fractions of an inch; and if the problem isn’t too great, that’ll solve it.

Aluminum soda cans make good shim material. I used metal shears, but good scissors (not your wife’s sewing scissors, though!) will also work well. I flatten the can in the middle to make the cut easier, and you only want one thickness of material for one shim (i.e., not both sides of the can).

When the material is cut to size, lay it in the bottom ring. Metal will conform easily to the shape of the ring. Plastic from a soda bottle will not and will have to be flattened by the scope tube when you mount it.

Once the shim is in the bottom of the ring under the scope and the cap of the ring has been tightened, it’s very difficult to see the shim. If you can see it, it either isn’t in the ring all the way — which isn’t a huge problem — or it’s too thick, which is a problem.

How many shims?

The reason people don’t shim scopes is because too many shims will dent the scope tube when the cap screws are tightened. How many shims can safely be used depends on the thickness of the shim material. If you use metal cut from aluminum soda cans, you can use as many as two shims stacked on each other. If you use the thicker plastic cut from a 2-liter soda bottle, I would stop at just one. Any more and you risk the possibility of denting the scope tube when the cap screws are tightened.

What doesn’t work

If shimming under the rear ring will cause the rifle to shoot higher with the same sight setting, what about shimming above the rear ring (under the scope cap)? Will that push the pellet down? The answer is no. The impact point will not move if you shim above the scope.

To move the impact of the pellet down, put the shim under the front ring. That lifts the front of the scope, which is the same as moving the front sight up. Moving the front sight always moves the impact point in the opposite direction.

What about shimming left and right?

Can you shim the scope on its side to move the impact left or right? Yes, but be careful. If the shim extends down to the underside of the scope, it’ll also move the scope up or down, depending on which ring you’re shimming.

Do this first — before shimming

If you can, turn the rings or one-piece mount around and try them that way. Scope rings are not made with tremendous precision, and sometimes turning one or both of them around — and swapping the front ring with the rear ring, in the case where 2-piece mounts are being used — will move the impact point the way you want. Do this before you start shimming, as it puts less stress on the scope.

Sometimes, the design of the scope rings does not permit turning them around. This is particularly true in the case of 1-piece mounts that are also asymmetric. They can be mounted only one way and have a very limited range of positions for the scope. In this case, shimming may be the only recourse.

What about…?

I’m stopping this report here because I want to bound the information. I can talk about adjustable scope mounts, optical centering and other scope-related topics in later reports. In fact, I’ll be watching your comments to this report to see what’s needed.

To avoid damaging the scope tube, I cut my shims to at least the full arc-length of the rings surface. Cut them too short, and the shim will not cover enough of the rings surface and press into the tube. You can even cut the shim a bit longer than the ring’s surface. There’s a small gap between the rings, especially when adding shims.

Victor

Dave,

This is a very useful blog. I only recently found out about using aluminum from cans for shims. I now do this for all of my air-rifles that I plan on taking out to the field, where I might shoot beyond 25 yards. Doesn’t hurt to have extra head-room for elevation, and not just when you have barrel-droop.

Good stuff! Thanks!

Victor

Properly mounting scopes on airguns is such an important topic.

Scope problems on airguns is the number one topic on most airgun forums. When you filter out posts asking for advice on specific airgun models having problems, generic questions about shooting techniques, bragging about groups or kills you’ll find that newbies and veterans post on airgun forums desparately seeking advice related to scope mounting problems.

I’m relatively new to airguns but I came from an extensive firearm background. I thought I knew a lot about scopes and mounting scopes on guns. I was wrong. Airguns humbled me. Why? Because we typically shoot at much shorter distances with airguns.

Normal for a scope to have 1/8″ or 1/4″ moa. This means for every click of adjustment for your elevation or windage adjustment your bullet/pellet strike at 100 yards is adjusted approximately 1/8″ or 1/4″.

Let’s assume you have a common scope mounted on your airgun that adjusts in 1/8″ increments. Let’s also assume that your using the best shortcut to sight in your newly mounted scope at 10 FEET.

/article/All_about_scopes_Part_3_April_2005/22

For your 1/8 moa scope, 8 clicks = approximately 1″ at 100 yards. 16 clicks = 1″ at 50 yards. 32 clicks = 1″ at 25 yards. 64 clicks = 1″ at 12.5 yards.

If your pellet strikes 1″ (one inch) off the aimpoint at 10 feet (3 yards) you need to dial in roughly 256 clicks.

Most scopes don’t have this range of adjustment. Even if you have a 1/4″ moa scope that only needs 128 moa your scope may run out of adjustment. Here’s something else to consider. When the scope specs state that the adjustment range is 100 moa that usually means that the elevation is adjustable for 50 moa and the windage is adjustable for 50 moa. It doesn’t mean that each are adjustable for 100 moa.

All this aside I would like to see airgunners avoid the frustration in mounting scopes on airguns that lead to running out of scope adjustment or worse overadjustment of the scope that causes floating erectors that are even harder to diagnose.

My best advice is to get a centered scope within 1/4″ of the proper poi at 10 FEET (see above link) using shims, adjustable mounts or if necessary barrel bending before they start adjusting the scope elevation/windage knobs. This all by itself would eliminate so much grief in the airgunning world.

kevin

Kevin,

Before we get into the math of scope clicks at different ranges, are you aware that they don’t all work out as they say? Often scopes may move the bullet one inch in 6 clicks, or 7 at 100 yards. Those numbers they give are approximations. The higher-end scopes do come closer to their numbers than the low-end scopes do, but never take those number for granted.

B.B.

B.B.,

Yes, incremental moa adjustments and total moa adjustments are approximations from the factory. Can even vary with the same make and model of scope.

My real point was to emphasize why airgunners can quickly run out of adjustment on their scopes and why shimming or adjustable mounts or barrel bending can minimize grief/potential problems (like a floating erector tube) with their scope in the future.

kevin

I put the HHA optimizer on my 22cal hatsan 125 sniper springer and I can keep my crosshairs dead on from 10 yards out to (for now 200 yards) but thats as far as I can shoot till I finds more space . I have barely turned the dial so I don’t think 400 yards is out of the question . You just shoot till you know where the pellet is going to hit and mark on the tape under the marker . once you have your distances set you can turn the speed dial and shoot at something 10 yards away and with in 1 second you can shoot at something 100 yards away or anyplace in between. Its made for a crossbow but it works great on air guns .Here is a link https://www.youtube.com/watch?v=R8qBxoj4viU.

Seems to works in the same principle as the Leatherwood ART scope but the cam has been turned 90 degrees.

It’s exactly these problems that make me wonder why the adjustment mechanics are put inside the scope, instead of the scope mounts. A scope without any internal adjustments would be a lot cheaper and can have a better otpical quality. Adjustable scope mounts are not difficult to make.

Mel,

I agree with you. In fact, I am talking to Leapers about doing just that.

B.B.

One reason…

Known “clicks” in adjustments. Most scopes are graduated in 1/4″@100yards (or 1/8″ for the more precise models).

If your external adjustable rings are a two-piece mount, the movement per click will vary depending upon the distance between the front and rear ring.

External adjustment rings also tend to be bulkier and need to be protected from impact. And how do you get enough grip to prevent recoil shifts while still allowing for shifts in the entire optical tube within the ring.

There’s a number of solutions for all of these problems. The new “Elcan” optical sight is an example of a rugged scope that solely depends on external adjustments.

Would this be the unit … ???

http://www.anacortesgunshop.com/p/7080/elcan-specteros4x-combat-optical-sight

Very useful, I am in the process of optically centering my scope and mounting it… It is quite a process to get the correct way around for the scope mounts etc, before you start shimming etc. It is even more of a process to do this with recoiling rifles… I think symmetrically clamping scope mounts are porbably the way to go with extremely precise mounting of scopes… Not just because they average out the sideways error of the rails, but because you can shim either side to correct for that error… if it is optical centering you require…

At this point if it is optically centred and takes less than half a sideways revolution at 15m/16.4 yrds I am ok with that… haven’t even thought of looking wat it does left to right at 35yds or 30 m… oh yes… only have 1 rifle, and it is at around 800fps… Advantage of 15m zero… good place on trajectory and 1mm = 1 click… I am lazy to calculate in the little spare time I get to shoot…

P.S. is it useful to have thin squishy layers as protection, in order to shim more than say 2 layers of soda can? or will that just cause variations in the scope mounting… thinking those industrial strength double sided sticky tape, or just good quality insulation tape…

I Shimmed my scope with double sided sticky tape over two years ago and have never had any problems with it since that time. Turning the scope mount around as B.B. suggested corrected some of the droop so I only had to use one layer of tape.

Pete

Shakes,

I’ve done it both ways and found no real difference. Once all the squish has been compressed out of the shims, they act like hard material.

B.B.

So what you are saying is that you are changing the centerline of the scope to a different angle in reference to the barrel centerline. It being on a level plane. And were the pellet exits the barrel on that same level plane. And hits at a given distance.

So now if you look at it this way see what you think. Hold the scope centerline straight and level with the shim in the back and tell me what happens. Now the barrel centerline is pointed up in the same angle that you shimmed the scope centerline. So now when the pellet leaves the barrel it is pointed upward.

Now the pellet shoots higher.

But here is the next thing. I guess that the above is a one type of fix in a sense. But like its stated above.

If you don’t get that shim centered side to side the scope will not adjust true when you adjust one axis.

If you adjust up so many clicks you will get a certain amount of left or right windage adjustment with your up adjustment. Depending on what side of the scope you have the shim going too.

Vise versa the up/down will be affected some amount when you adjust the left/right windage adjustment.

And obviously you also need to make sure your scope recticle is level or the same effect will happen.

Talk about chasing your scope zero around. It will drive you nuts.

So for me I don’t want that extra variable in there. And maybe shimming will work OK for the shorter range shooting but when you start stretching things out lets say to 70 to a 100 yrds or more. You will probably not be able to get enough shims under the back of a scope if you are shooting a weaker gun with a heavier pellet if you want your scope zeroed at that far out. I know that’s what scope hold over is all about when you zero at a closer range (and most people don’t shoot out that far) but when you do decide you want to shoot at a target all of a sudden at a longer range.

Here is what I do. I will always go to a taller scope mount if I (can’t) get enough elevation adjustment. But one of the things you have to watch is that you get your line of sight in an uncomfortable position. Start going to high then you will find yourself lifting your cheek off the stock. Then you start messing with other things related to accuracy.

So now (with short scope mounts) if I draw a line pointing out from the scope centerline like a fine laser beam and that beam is hitting the center of a marble at 50 yrds. and that just so happens to make the pellet hit low. And this is with the elevation adjustment all the way up.

So now I put lets say a 1/4” taller scope mount on. And I am still all the way up on my elevation adjustment. What will happen is I will need to hold the front of the barrel higher and the stock of the gun lower to achieve the correct line of sight. That Will make the gun shoot higher at that same 50 yrds. Then you adjust your elevation down closer to center to hit the marble.

I shoot at longer ranges sometimes. Target practicing and hunting. But I zero at 50 yrds. I will (not) adjust clicks on my gun when I’m finally satisfied with my scope zero at 50 yrds. If I shoot under 50yrds. I usually have to put the crosshairs under the target. If I shoot longer distances the crosshair will be above the target (hold over or hold under).

One thing I do know is the longer range away the target is that your shooting at the more precise things need to be adjusted. And just a slight amount of movement from the gun when you pull the trigger at 100 yrds. can be a miss. But if you were only shooting at 25 yrds. and moved that same amount you would still probably have a hit on your target.

Wow alot of complicated stuff these airguns can be.

And while I’m at it.I was going to ask this the other day and forgot. Does anybody still shoot C02 guns ? I got a 2240 that’s got a .177 cal. Disco barrel and breach on it. With the 1399 stock. Talk about a light gun. But this gun kind of falls into this category of gun/scope problems.

I shoot it out to 60 to 70 yrds. with the 8.3 Superdomes. And it chrony’s around 580 fps. on a 85 degree day. You won’t believe the scope I got on it. A Bushnell Banner 3×9/50mm with a 100 yrd. fixed parallax. I got the high see through scope mounts on it. I needed those to get the scope adjustments closer to zero. It is a pretty dog gone good gun.(its getting late;I can tell,the slang is starting to come out when I type) But it needed those to get my favorite 50 yrd. scope zero.

And its finally Friday 🙂

Gunfun1,

You are WAY overthinking this. For instance, please tell me how you know when a scope is level? Level with what? Nothing on a rifle is ever plumb, so there is nothing to be level to!

Level is just an illusion the shooter uses to keep from canting. You could shoot just as accurately if the scope was rotated so the reticle looked like a large X. As long as the rifle is always held in the same attitude, the scope works.

I learned this when I competed in field target. You spend so much time in pursuit of the ultimate in precision that you learn what matters and what doesn’t.

B.B.

How do you know if the floor of a garage is level before you start building the walls ? So scope levels are a novelty I guess. Well I would have to say that I would sure try to get the gun as level as possible then match the scope to it. So then what did you learn from the precision shooting that matters. Because I’m sure it goes along with getting the scope setup properly. And that would then help the people not make those mistakes.

I guess bad questions on my part but yes I do over think things at times. Cant help it. I’m still trying to figure out how to reprogram my brain. I’m working on it though. I think ?

Gunfun1,

The garage floor is leveled to the earth’s gravity. But nothing on a gun is plumb with anything else. You set up the gun to appear level to you and then you check that it is every time. Thataway, it’s always the same. Level, in this case, is a relative term, for there is nothing to use as a baseline reference.

B.B.

True. I guess what I was trying to point out is that the scope levels you can put on the scopes helps you repeat your hold which Is one more thing to help in accuracy.

And I agree it is relative to what ever way it would be determined that level would be. But you have to keep the cross hairs at that position every time you make your shot. With a level you can reproduce the hold closer to the same way each time.

Gunfun1,

Yes, that is correct. Perhaps I should address leveling the scope in a blog?

B.B.

If you’ve got a truly leveled garage floor, you’ve got a floor that won’t drain…

I’d expect a garage floor to have been sloped toward the front center, so spills and rain run-off flows out the door.

And to the middle if they made it that way. You got me again. 😉 Said jokingly though for real.

I think I just made up a new word though ?!?!

As a matter of fact I use CO2 with my Talon SS for two reasons. First, the Talon’s air tank is very large and using CO2 cuts down on trips to the dive shop even though I have two tanks (I have six PCPs to feed).

The other reason is that the 12 oz. CO2 tank gives me a much better line of sight thru my scope.

I have no idea what others experience has been with CO2 but I see absolutely no difference in accuracy with CO2 although there is a slight drop in velocity but not enough to be a negative influence on accuracy.

Hello again to all those familiar with me. I was in the hospital for the last 4 days but I’m back.

G&G

G&G,

I hope you are well.

B.B.

Thanks B.B. I just had one of my occasional bouts of diverticulitis. Not really serious but quite painful.

I’m glad to be home (on the blog I mean).

G&G

I had that back in 2007 and I know the pain you are going through. Was in the hospital 3 times within 5 months. 1st time was antibiotics and watch my diet. Came back about a month later and had to have 7″ of my colon taken out. Then had to go back and have everything reconnected. Haven’t had anymore problems since.

So I hope they get you straightened out before you have to go through anything else.

Thanks for the encouragement. I have too much diverticulosis to remove enough intestine to permanently solve the problem. Fortunately these bouts only happen very rarely.

Just pray for me that I don’t have anymore recurrences. Thanks.

G&G

I will.

Be careful tightening the mount down when shimming! I have dented a scope tube by doing that with too big of a stack before. You may just want to get a scope lapping kit from Brownells and lap the mounts correctly after figuring out how much and which way with the shims. Shimming is ok if you don’t need much correction, but for drooper correction you might just as well get an adjustable mount.

/Dave

Dave,

I prefer adjustable mounts over shims. Allows me to fine tune optical center +/- 10 clicks. Optics in $80-200 scopes are not perfect and optical quality falls when going off center. The key is staying in optical center using adjustable mounts or shims to get the job done. I’ve also discovered another issue that can impact accuracy. Eye relief. Learn to be consistent on the distance you place your eye to the eyepiece. This issue does vary with scopes, and I have found Bushnell and Hawk to be the best at avoiding it. Take 10 shots with the shortest eye relief, then 10 at the longest eye relief at your preferred shooting distance. If the results are the same, then you are good to go. Otherwise, you just uncovered another variable that impacts accuracy.

BB,

Great topic!!!

I agree with everything you just said.

Wow that just made me think of a engine trick we do when building a engine.

We take lets say .020″ off the main caps then bolt the caps on to the block then line bore the block and caps up .020″ in the block. That makes the pistons poke out the top of the deck or closer to the top off the deck for more compression. (gets the piston and rings closer to deck height or above). Well then there is more tricks that come after that step when engine building.

Referring to Daves comment about lapping.

GF1,

Engine shop I worked at in the 80’s did the same on their rebuilds. That and .060 over pistons helped a bit. A little here a little there, it all as up!

/Dave

Wow that’s when I did most of my engine building was in the 80’s. But built different vehicles through out time. Did alot of 10″ tire cars through out time.

Drove a big block 455 Olds (really a 540 ci Olds big block with solid lifters with big block Chevy screw in studs stroker motor) back and forth to work everyday 38 miles one way back in 82 .

Did the Fastest Street Car Shootout. EFI class and Easy Street (iron head and one power adder,10.0 et) with a big block 79 Camero RS with a 150 shot of nitrous. And a 72 Nova with a 12.5 comp./355 small block with a progressive 200 horse shot. And the EFI car was a 97 Z28 (11.30 @118)

Later got into the SRT4’s when they came out. (03 yellow was doing 12.8’s @118). Then got a 05 and built a stroker motor with the old school tricks and was making 500 hp with methanol injection and a .035” nitrous jet on a fogger nozzle in front of the inter cooler (stock turbo).

11.65 @127 was best run. And mph record for front wheel drive at the track I went to.

Too many cars to talk about.

That is what I wanted my career to be. But it ended up going a different way.

That WAS the good old days.

B.B.

Thanks for the blog, but there is no comedy value like there is on the other websites…..you did not give faulty information.

I would still rather fix the problem than compensate for it when practical.

twotalon

Another great scoop dope installment B.B. There are many ways to ‘skin a cat’ and probably many more ways to correct scope maladies. I know you know most of them. I’ll look forward to your revealing more as this topic continues. Thanks

I find the better the scope the easier it is to sight in

and the risers that Pyramid sells will do the trick when

the shims need to be too thick.I think the scopes that come

with the gun are the hardest to adjust,simply because that’s

where the manufactures cut corners.

Hello BB,

I have been a lurker to your blog for years, reading it daily. I find the comments section very informative with a wealth of knowledge from experienced shooters being shared in an open-minded manner without the arrogance typical in today’s world. I appreciate today’s blog because of my own past struggles with scopes and mounts. I would like to mention a product that I recently used that worked pretty well and that I don’t recall being discussed here before. I tried the Burris Posi-Align inserts when I installed a new scope an my latest springer. These plastic inserts fit into the Burris rings and have an offset thickness of .005″, .010″ or .020″. This allows you to adjust POI before you ever touch the scope adjusters. And they are spherical, so no scope tube denting. Have you tried these before? Thanks.

Zac

Zac.

Hi and welcome to the blog!

No, I haven’t tried the Burris inserts, but Conetrol did the same thing back in the 1960s. It sounds like a useful way to go.

B.B.

Zac,

I really like them. Well worth my money.

john

I recently read an article (sorry, I can’t find the cite for it), but it explained that you should replace the top of the rings the same way you took them off. It seems that the rings are manufactured as a one piece unit and then are mechanically cut in half. The cutting isn’t thousandths of an inch precise, so if you swap the ring tops (put the back halves on the front, or vice versa, or even turn them 180 degrees) the rings *may* not completely contact the scope tube evenly. So, the ring tops should be oriented exactly as they were in the package.

I don’t know if this is true all not, just putting it out there. Though it does make sense.

chasblock,

Good tip!

B.B.

chasblock,

Makes sense to me as well. Wish I had known this before. I would have marked my rings so that I could maintain the proper arrangement.

Victor

chasblock,

It requires alot of faith on my part that ring parts were accurately matched up upon packaging. Worst case, I picture Lucy Ricardo & Ethel Mertz at a conveyor belt…either in a panic or too bored to care. 😉

john

Thanks for the Blog BB. Guy’s shimming isn’t the most technical way of fixing the problem. BB isn’t claiming that. An adjustable mount or a droop corrected mount is a better option but… if you want to work with what you have, shimming is an option. I am not going to shim a $500 scope but I sure will shim a $150 scope if I need to. Another option I am still squeamish about is barrel bending.

Howdy Mr. BB, Ms. Edith & the gang, Thanx, Thanx, Thanx! First off ya need ta know, thank God I’m kinda cute, cuz I sure ain’t very bright. Last week I decided ta put my big boy pants on & adjust my trigger. Won’t bore ya with the gory, heartbreakin’ & tragic details, but after a couple hours of work I wound up with a gun that now fired when all I did was look at it, a hole in the ceiling, & a scope that was now hittin’ 8″ high. Boy, that was FUN! What else can I fix! Quick tip, if you’re gonna put one through the ceiling, use wadcutters, cleaner hole & much easier ta patch. Ok, now that I had the trigger set to not go off when I walked past it, I had to figure out how the scope wound up so far off & how ta “fix” that. Will refer back to the not real bright part. What was a simple 15 minute shim fix turned into 4 hours of itchin’ & scratchin’, cuz I didn’t understand the correlation between scope adjustment direction & which end of the scope ta shim. Bottom line, trigger has 2 stages, scope is dead nuts, my velvet Elvis tapestry does look kinda cool on the ceiling & I still can’t shoot fer squat, but I’m learnin’ !?! Thanx again ya’ll, have a great weekend & shoot/ride safe.

Beaz

Beazer,

I stopped filling holes in the walls and ceiling, ’cause when I do I just shoot another one. If I leave them showing apparently my quota is filled and I don’t shoot any more.

Hillbilly logic, but you go with what works.

B.B.

Howdy Mr. BB, thanx for the response, I’m honored. Ater reading your very useful tip, I returned my velvet Elvis to it’s rightful place in the front picture window of my dee-luxe double wide & decided my new story is: Proper attic ventilation is very important out here in the desert southwest…

Will you two please stop. Your going to give the kids reading the blog a bad example.

You are kidding right ???

Howdy GF1, Kidding? Absolutely knot! It’s right up there with huggin’ whales, savin’ trees & visualizin’ whirrled peas. Proper attic vetilation is very serious when done one pellet at a time. Shot placement is critical & should only be done by a professional!?! But yeah, ya got me I was stretchin’ the truth a little about the double wide, it’s only a single, but with the chrome wheels, velvet Elvis in the window, Camaro up on blocks & pink flamingos in the front yard, it looks just as good as any double wide…

Have a great weekend & shoot/ride safe

Beaz

A single-wide with an attic?

I’m impressed!

Les

One approach is to use Burris Signature rings and shim UNDER the rear insert to avoid scope tube damage.

I recently successfully attempted to hit a 12 oz soda can at 502 yards and 552 yards using an air gun.

I had to have the maximum adjustment that I could get from my Leupold long range scope that has 107 minutes of adjustment to begin with.

I used Burris Signature rings and inserts underneath the plastic inserts to avoid denting my scope. By doing that, I could use more than two inserts as the inserts will rotate with the scope angle as you tighten both front and rear rings.

This put me on at 100 yards with the elevation at the bottom of elevation adjustment and still not to the end of elevation adjustment at 552 yards.

When I tried to make a hit at 608 yards, I was at the maximum elevation adjustment and using the Holland’s MOA reticle, which affected accuracy. On the next attempt at 608 yards I will use more shims to get to 600+ yards without maxing out my adjustment.

The video’s of the shots can be seen on both the Yellow forum and the TalonAirGun.com.

So you were zeroed at a 100 yrds. ?

I love long range shooting. What grn. pellet did you use and what fps. was it shooting at ?

Without going to watch the video did you take more than one shot and if so was the shots consistent.

If you don’t mind me asking.

Yoshi,

We call it the Pepsi Challenge.

I did not use a pellet.

I was shooting a Haley 257 Scandalous mde by Jack Haley and tethered to 3500 PSI air regulated and the bullet was a from a NOE 100 grain mold, cast of 20-1, sized to .258 and lubed with Traxx 10 weight Silicone oil. Muzzle velocity at 5700 feet and 85 degrees is around 1000 FPS.

The 36 inch barrel is a TJ barrel with a 1-10 twist and has a AR 15 style muzzle break.

I got the can on the third shot from 502 yards, I actually shot 4 total at 552 yards, but 552 yards took several shots. The next day we tried 608 yards and in fact busted a can, but review of the video and examination of the can revealed it was hit with flying rock.

Tofazfou on the forums was the first to do this, hitting a 12 oz canat 447 yards with a modified AirForce rifle with a TJ barel and assembled by Dyotat on the forums, Dyotat repeated the feat at 447 yards with the same rifle.

My scope was zeroed at the ranges I was shooting 502 and 552 yards, I was able to get that far out as I wrote using the Burris Signature rings and shimming them.

Roachcreek

Cool stuff.

Roachcreek

Also forgot to ask.

Sorry.

But do you know the distance between the center of your scope to the center of your barrel ? You don’t have to say if you don’t want.

Either way thanks.

Burris Signature rings – way to go.

Your so right there is no reason to shin your scope since Burris came out with their system . It just amazes me how many people that shoot at all still don’t know about what the ring inserts can correct . If the guy that made this story would have just typed moa adjustable scope rings he would have seen the very first thing listed was the Burris system . I was glad to see at least one person reading this story had the correct answer to doing a scope adjustment the correct way .

izh46muser,

Welcome to the blog.

B.B.

Thanks BB . I don’t usually reply to things but when it come to shimming and doing it the way your showing is just a really bad thing to do . The only way to correctly shim is to do it the way burris is doing it or pour it with acrylic . by pouring it with acrylic your really making a custom insert. What you do is prop the back or front up with a spacer like your pop can cut to get it where you want it ,then block out the screws and spaces between the screws and the far end of the rings so when you pour your liquid acrylic into the space on the opposite side nothing will run out and it will fill to the top of the side your pouring it into . Put a thin layer of Vaseline on the scope and the ring .then mix up your acrylic and pour it in .Then once that has set up take the shims out and do the same thing you just did on the opposite . The acrylic only takes a few minutes to cure and your ready to go . you don’t want ANY space that is not touching the scope body or the back side of the ring . You want full contact from front to back and on the sides .

That should read I got 4 cans at 502 yards and one at 552 yards.

Roachcreek

What was Conetrol ?

Gunfun1,

Conetrol was a scope mount company that made scope rings with eccentric ring inserts that could be rotated to provide elevation and depression for the scope tube.

B.B.

Today me and my friend went to the woods range to zero in his new CZ-550. He’s a great shot, but doesn’t trust himself when it comes to mounting scopes. So here comes duskwight and his set of tools, bench, soft rests, etc. And LOTS of mosquito repellant 🙂

A little crowd at the range – 2 more guys, but one was truly remarkable, he wielded mil-styled long-barreled Saiga.

Now brace youself, here comes horror: quad-rail installed around its barrel and 3 (!) laser target designators installed on it, so the pattern is some sort of “Predator style”. A grip/bipod under the barrel, reflex sight above on a Warsaw-to-Picatinny mount and some sort of magnifyer slanted to the left – didn’t see it right. Custom plastic SVD-style stock. 8 mags in tac-vest pockets. He shot 3 mags into hanging plastic canister at 25 m then just packed all his stuff and drove away without saying “hi” or “bye” to anyone.

Now I wonder if there is some zombie apocalypse or WW3 scheduled that I missed.

duskwight

duskwight,

You didn’t get the memo?? WW3 is scheduled to coincide with this year’s winter solstice, with the zombies from Mars arriving well before the Vernal equinox to take advantage of the carnage and confusion…

/Dave

/Dave

Party won’t allow this to happen, comrade!

duskwight

Of course not! What was I thinking?!

Pardon? Wasn’t the VERNAL equinox three months ago?… Heck, the summer solstice is a week off…

Whoops…. First post on the new computer and it didn’t have the name/mail form data to prefill for me…

I just “experienced” am airgun that no amount of shimming or scope doping will help. It was what I call “Uncle Pappy’s Root Cellar Frankengun”. It used to be a decent airforce talon. Somebody decided to “power mod” the gun which was not a good idea. He put in some custom oddball 18 inch barrel. The bore was some odd caliber like a .257. Something you have to cast your own pellets for. Then he soldered a sleeve in the gun and added on to the frame so it looked like a Talon SS. Then he put in some massive home made valve system so that on low the gun gets around 15 shots and the tank is empty. There is no way that gun could hit the inside wall of a barn while standing in the barn 2 feet from the wall. Then to make matters worse I spent 6 hours gutting this gun and bringing the oddball barrel out the back of the gun and putting a 12 inch .22 cal barrel in the gun as my customer wanted me to do. This did not help this gun do what it is supposed to do. The pellets leave the barrel with so much air behind them that they spiral, tumble, corkscrew and never fly straight. There is absolutely nothing that can be done for this gun except to gut the thing, Order all the stock parts for it, cut the frame back down into a talon frame and hone out the sleeve soldered inside the body. In all the repairs will exceed the value of the gun. This gun is precisely the reason I never ever buy a used gun.

I have use “High Tech” material for shims. Used milk bottle plastic!

Mike

Everything has a time and a place. But is it really that hard to shoot a gun ? I guess its one thing to over think something. But its when you over do is another. But when you think about it the right way it is a success.

I believe that is true about more things then guns.

And here I go again… Nope not White Snake…just me…..

Am I the only one without a blog this morning?

We are monday right? Don’t tell me I got up early when I could have stayed in bed!

J-F

J-F, try going to top of this page and clicking on “How does rifling twist (etc) Part 8”. That should take you to Monday blog. Regards, Jim H.

Thanks Jim but I did check that and when I posted this morning it wasn’t there yet.

J-F

Hi to all, I’ve been a lurker here for several years and have learned lots from reading both the articles and the comments. I just purchased a Talon P along with the AirForce 4-16 scope and AF high rings. Yesterday when sighting in at about 30 feet, I had to bring the scope to darn near it’s max elevation to get the pellet into the x ring. this obviously is not a good situation as there is virtually no more vertical adjustment left (perhaps 5 or 6 clicks and that’s it) I would hate like heck to have to shim a brand new scope (not a Nightforce but not a cheapie either!) Can this be addressed with higher/lower mounts or by some other means?

Thanks to all, Kevin in CT

Kevin in CT,

It’s not the height of the scope. It’s the angle. You need to shim the rear scope ring. Read this report and follow it.

B.B.

Thanks tom, I was hoping to NOT have to shim the darn thing. would adjustable mounts solve the problem?

Kevin in CT,

Yes, they would. But upon reading your comment again, and reading Loren’s reply to you, I see the problem. You are trying to zero at 10 yards. That is too close and it will throw off the scope at all the other distances.

Zero the pistol at 20 yards. That should make the scope work better and you will be on from 20-30 yards. At 10 yards use a laser if you need to, or as Loren suggests, use the mil dots, if your scope has them.

But I would still shim this scope, because it will still be too high in the adjustment range — even at 20 yards.

B.B.

b.b.

All I know is , it is the height of the scope on mine.

It is what it is.

Loren

Kevin in CT

Because of the height of the scope above the barrel on the Air Force guns, you will need to use the mil dots in your scope from 10 yd’s to about 20 yd’s. You can zero at about 25 to 30 yd’s. Then use mil dots again out to your longer ranges. You can remedy this situation somewhat by using a drooper mount,although air force guns don’t have droopy barrels.

I use the Hawke adustable adapter with Weaver low mounts and the same AF scope you have.

Hope this helps.

loren

Thanks Loren, I’ll keep this in mind

Thank you all.

I’ve read this blog for about 8 months now an the more I read the more I realize how little I know ! But you are educating me well . Its nice to know there’sat least one place for sound practical advice out there.

So to recap a guy should optically center for windage but mechanically center for elevation ie clicks ?

Peter,

Yes, with qualifications. I will cover those qualifications when I do the next part of this report. The entire answer is both more complex and also simpler than that.

B.B.

Thank you Mr Pelletier

Ill treat your reply like a favorite book signed by the author.

Cryptic!

BB can you post a picture of the Conetrol shim rings ? I’m trying to visualize what the shim looked like. And I wonder if the Burris shim rings look the same.

Was there a set for the back ring and the front? Were they maybe a little over a half inch wide with the part you put to the back lets say .030” thick and the front maybe .010” thick.

Like putting the scope at a 5 to 8 degree angle to the barrel with the back higher or were they the same thickness all the way across.

Because if you put the shims in front and back or just in the back. Either way all you did was raise the scope cross-hairs . Same as putting taller mounts on.

Yes you do raise point of impact that way.

But have you tested different scope heights to see what would happen when the pellet hits the target.

Zero the scope to bullseye on the target the best you want. Don’t change power level, don’t change pellet and don’t change the range your are shooting at.

Don’t touch the clicks on the scope after you get it zeroed. Put lets say a 1/8” taller scope mount on the gun. Then mount the scope for the same eye relief. Then do some shots at the target.

Probably your windage will be off but we are talking elevation here. Tell me the results. I have done it. The pellet will strike the target higher.

You will find that both ways makes the cross-hairs go higher in relation to the barrel. And you will find that you need to hold the butt of the stock lower both ways to maintain your line of sight through the scope when your are looking at the cross-hairs. Well that tells me the barrel just got pointed upwards more in the front.

Test it or tell me if you reported on this before. If I’m wrong then its corrected and I’m sorry.

And yes I did over complicated my first post and probably this one again. :{

Gunfun1,

I will look for a picture today, but don’t you have some old Shooter’s Bibles? That’s where they are — ij the 1950s and ’60s Stoeger catalogs, in the scope ring section.

B.B.

No I don’t have a older shooters Bible but I did search it and found pictures and descriptions. And also the Burris rings.

Gunfun1,

So, you’re good?

B.B.

Yep found them both. Thanks.

I’m correcting myself to an extent. I just found out something interesting. I believe this is why I get these results all the time. Shooting higher with a taller mount.

I have 3 extra scope mounts. 1 of them is a short scope height 2 piece mount and the other 2 are a medium 1 piece mount (which is taller than the 2 piece mount).

I checked the height with a indicator and the 2 piece mount were pretty equal (.002”). The front and back mount. Then I checked the 1 piece mount front and back and the back was definatly taller by .007” or what I call the back which has the scope stop screw in it. So that will make the gun shoot higher.

I wish I would have checked that before. But really never gave it that much thought till reading this blog.

But does holding the gun in different ways affect the sighting on a scoped gun or red dot type sight ?

Gunfun1,

A gun will have different recoil characteristics with different holds. That can result in pellets/bullets going higher or lower.

B.B.

Millet Steel locking, elevation and windage adjustable scope rings…

https://www.amazon.com/Millett-Smooth-Angle-Loc-Windage-Adjustable/dp/B00162MLUI/ref=cm_rdp_product

$30-$40 on Amazon for a pair.

A must have for air gunners experiencing barrel droop or not enough vertical adjustment on the scope elevation knob… I ran into this put both a RedField Revenge and Accushot scopes on my Gamo Bone Collector .22cal air rifle. Could sight dead-center, but both scopes ran out of vertical adjustment 1″ below bullseye at 15 yds.

Anyway, clearly the optical line of the scope is tilted low – even when mounted on solid Hammers / UTG dovetail to picatinny adapter + scope rings. All normally flush and solid steel clamped down.

I guess with air rifles, some anyway, need elevation adjustable scope rings to save us from abusing internal scope adjustments and keeping them closer to their optical center and spring ranges.

Based upon the linked item description, these are only WINDAGE adjustable, not elevation.

If you want to see a really interesting set of rings — find a set that fit the Sako double-dovetail bases.

Besides a rather steep (and deep) \ / when viewed in the sight line, they also had a \/ when viewed from above — firearm recoil actually tightened the rings to the bases.

They also had adjustments for windage on one side, while the other had the larger knob for mounting/dismounting the scope.

Sorry yeah you’re right, here’s a better set of elevation adjustable rings fitting a dovetail,

https://www.amazon.com/gp/product/B002K7A2LI/ref=ox_sc_act_title_2?ie=UTF8&psc=1&smid=A30DGGRQPDAP9Y

Though I want elevation adjustment for weaver / picatinny – as I use a Hammer’s dovetail –> picatinny rail conversion. I install those on all my break barrels that don’t come with a welded weaver rail already.

I guess I will switch my UTG 1″ scope rings, front to back, see if that fixes the optical / barrel axis issues… I really don’t like ‘shims’.

Anyone have a link for a cost effective weaver / picatinny set of elevation adjustable scope rings, please post here – don’t care the vendor.

I know this blog entry is 2 1/2 years old but I can’t help but offer another solution to shimming a scope. Most of the shims addressed above talk about shimming within the curvature of one of the rings (mostly the rear one) or immediately under the ring. There is another way that will correct up to about 6″ of elevation at 20 yards without damaging the scope tube.

You will need one empty soda or beer can (rinsed and dried), tin shears, a hammer, some electrical tape and a razor blade.

Cut a 1/4″ wide by 2″ long piece of tin. Trim the edges. Start folding in 3/8″ lengths. After each fold, tap the shim with the hammer to smooth it out. Continue until you have six layers of tin. Cut off any extra tin and trim the edges. Get a piece of tape about 1 1/2″ long. Lay the shim on 1/2 of the tape and fold the tape over like a sandwich and give the shim a few more taps with the hammer. Trim the excess tape. This shim measures about .0425 inches thick. The shim is now ready to install.

The key is to place the shim between the barrel and a scope rail, not a scope ring. If your rifle doesn’t have a flat area in the scope area so that the shim doesn’t move around when installing it you may have to get an additional rail mount or use some temporary adhesive to hold it in place. Once the shim is installed between the scope base and the rail mount and tightened down, you can install your scope normally.

I have 2 RWS air rifles, a model 34 and a 460 magnum. Using a UTG droop compensation mount and this shim, I was able to correct for about 13 1/2″ up elevation at 20 yards.

I hope this gives you another option for elevation compensation.