by Tom Gaylord, a.k.a. B.B. Pelletier

This is the start of a long exploration into the use of swaged bullets in both firearms and airguns. I told blog reader Robert of Arcade 2 days ago that I was about to start this one because he was talking about wanting to use the larger smallbore calibers (.22 and .25 calibers) and smaller big bore calibers (.257 and .308) to hunt larger game. But to do that, we need bullets (and pellets) that are accurate.

This report has been nearly one entire year in development, but you’re just hearing about it for the first time today. It all began with my Nelson Lewis combination gun that I have written about many times. Back in the first part of that report, I showed you some original bullet swages that came with the gun. The problem I have with these swages is their design. The bullet is swaged into the die, but then has to be tapped back out of that one-piece die, which is very inconvenient. It would be easier to get out if the die had a separate nose punch that could be taken off the die and the bullet tapped on through.

These dies came with the Nelson Lewis combination gun I acquired.

Last year at the Roanoke Airgun Expo, I saw that airgunner Mike Reames was making swages for some of his big bore CO2 guns, and people were using them with great success. I talked to Mike at some length about these swages and decided that I wanted to try a swaged bullet in my Nelson Lewis gun. But I conducted a proof of concept test with the rifle — to see if I got the bullet size correct . Unfortunately, I shot what proved to be an overload in the gun. It was a 250-grain .379-caliber bullet, where the weight of the round ball I usually shoot is just 80 grains. The pressure created by the heavy bullet blew the percussion cap nipple off the rifle, and I had to get it repaired. That shut down the experiment for a long time.

Earlier this year, I was at the range with my Thompson Center .32 muzzleloader, and it struck me that I could use this rifle as a testbed for the Nelson Lewis gun. Get the Thompson Center rifle working with swaged bullets, then transfer that experience to the Nelson Lewis gun.

I know the barrel diameter of this rifle quite well, so I again started talking to Mike about a swage set. What I was after was a bullet that would slide over the tops of the lands of the rifling and easily slip into the bore. I reckoned that the force of the exploding black powder would expand the base to both seal it against gas loss and also take the rifling. The bullet I want to make is like a Minie ball that’s swaged instead of cast. If this is of interest to you, email Mike for more info.

What is swaging?

Swaging means to form something in a die by pressure alone. It sounds high-falutin’ but it’s as simple as hammering a nail. And it doesn’t take as much force to swage a small caliber bullet as it does to hammer a small, common 6-penny nail.

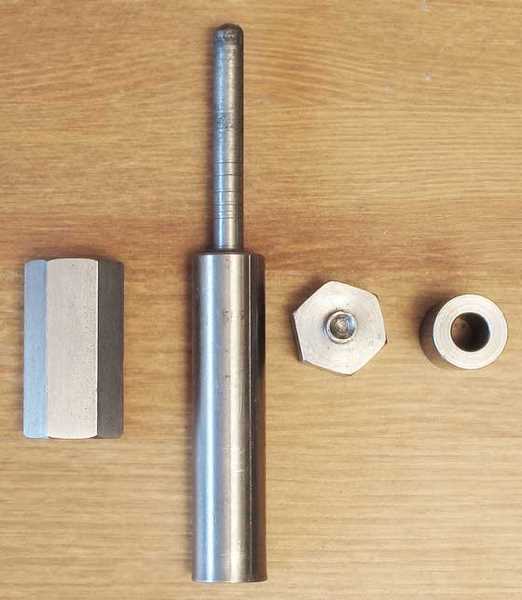

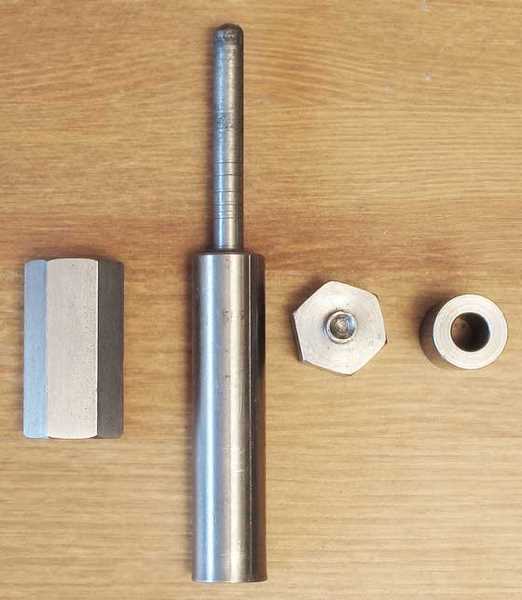

My swage set arrived and consists of 4 pieces: nose punch, die body, spacer and swage punch…which works on the other end of the bullet. I asked Mike for a swage to make bullets that measure 0.316 inches on the outside, and the two samples he sent with the swage set measure exactly that size. I was now in business to make swaged bullets!

Here are the 4 parts that came with my swage set. From the left, they are the swage die, swage punch, nose punch that goes in the small end of the swage die and the spacer.

The swage is put together as it is used. I left out the spacer because I don’t use it. I control the swage by controlling the force of the one hammer blow used to make the bullet. The results turn out very uniform that way.

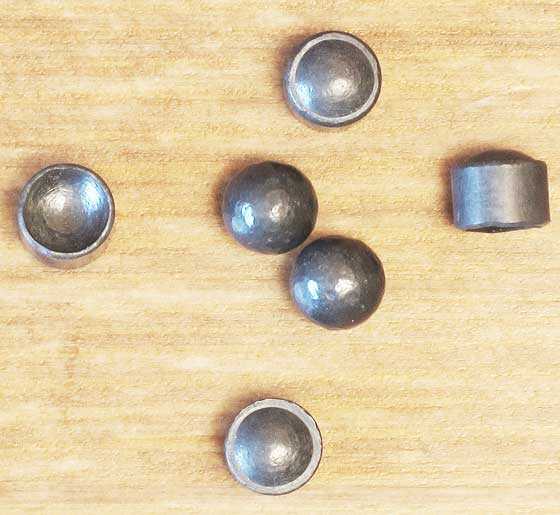

I started by swaging some of the 0.310-inch round balls I’ve been shooting as patched balls in the rifle. The rifle is .32 caliber and the lands are about 0.316 to 0.317 inches apart. The round balls weigh only 45 grains, so the bullet they make is very short. The swage puts a concave hollow into the base of the bullet, which helps the lead base expand when the black powder explodes. The nose is slightly rounded but still has a sharp shoulder to cut a nice hole on paper.

The .310 lead balls in the center were put into the swage die, which was resting on the nose punch. Then, the swage punch was inserted in the die and struck one time. The strike was not as hard as hammering a common nail, yet produced uniform bullets. At the top and bottom, they’re standing up. The right one is laying on its side, and on the left one is standing on its nose to show all parts of the finished bullet.

Because I control the weight of the bullet I make by what I put into the swage, I also swaged some .32-caliber lead bullets that weigh 88 grains. They make a much longer bullet that may be more useful for hunting game up to the size of javelina and coyote. The smaller bullets would be okay for squirrels and up to turkeys. Of course, this all comes down to how accurate these bullets are, so I’ll need a good day on the range to find that out. I’m looking for faster, easier loading than patched balls and better accuracy. That’s hoping for a lot, but that’s what this is all about.

The .32-caliber lead bullet (bottom center) was swaged into these three bullets. At the right, the bullet is laying down. On top, the bullet is standing up. On the left, the bullet is standing on its nose.

Why swage a perfectly good lead bullet?

Looking at the last picture you have to ask why I would bother to swage a perfectly good lead bullet like that. Why not just shoot it as it is? Well, the answer is that it’s not a good bullet for the rifle I’m shooting. It has a body diameter of 0.314 inches, which is too small for the bore. The swage enlarges it to 0.316 inches. The finished bullet looks just as long as the one that was unswaged. The concave base of the swaged bullet is where the lead came from to make the cylindrical bullet longer.

I actually went to the range last week for the first test, but I’d used the swage die backwards and got bullets that are far too large for the gun. The swage die is made like a funnel, where fat bullets enter the top and 0.316-inch bullets come out the bottom. That is, if you use it the right way. Since I turned the swaging die around, what I got turned out to be bullets that are far too big for the bore of the rifle.

This is what happens when you swage the bullet in the wrong end of the die. The entrance to the die is shaped like a funnel to admit slightly larger chunks of lead to be swaged into smaller bullets. So, the bullet is tapered like this and far too large to enter the bore.

I emailed Mike, telling him I got the dimensions wrong and we started planning what to do about it. That’s when I looked closer at the bullets I’d made and discovered my mistake. I quickly swaged a couple more bullets with the die in the correct direction, and they all turned out exactly 0.316 inches in diameter. Mike was glad, I was happy and I had yet another story to share of how not to do something. The good news is that I can run all the big bullets through the die a second time, and they’ll come out right.

The bullets made the right way will slide down the clean barrel of my muzzleloader in about a second. Right now that seems good to me, but it’ll take a successful range test to know if I’m right.

How difficult is it to swage a bullet?

If you can hammer a nail, you can swage a lead bullet with a die set like this. This is the way accurate rifle bullets have been made for more than 150 years, and it’s dirt-simple. There are no copper jackets to swage the lead cores into, so I’m not talking about a process that requires hundreds of dollars worth of dies and a special press. All you need is a hammer and some lead of the appropriate size. If you wanted to make a .22 pellet by swaging, for example, you could use a 15.43-grain Gamo round lead ball. The weight would be right for a .22 pellet as would the diameter of the ball. What you would be doing is changing the shape of the projectile from spherical to an elongated cylinder.

What you cannot do is use more than one piece of lead to make a bullet. If you do, the pieces will all conform to each other inside the die and fall apart the moment they are out. So, forget any ideas of adding pieces of lead to increase bullet weight.

Mike will make a set like the one seen here for $85. If you aren’t a machinist, this is well worth the price.

The best bullet

Every caliber bullet has a range of weights that will work. Too little lead, and the bullet is shorter than it is wide and subject to be unstable. Too much lead, and it becomes too long — again, subject to being unstable. The faster it’s driven (velocity), the faster it spins (rifling twist rate), which stabilizes longer bullets (to a point). Part of the test I’m doing is to determine what length bullet works best in my rifle. Since length also means weight, we talk about a certain caliber bullet by its weight more often than its length.

Of course, accuracy means a lot in what I’m doing. I’ll be looking for the most accurate bullet I can make. I may have to balance the bullet weight against the powder charge, for reasons of stability explained above.

The goal

I’m doing this to see if there’s any future to it. If there is, then I want to make an accurate bullet for the Nelson Lewis combination gun. That was always the goal. But now that I’ve listened to Robert from Arcade, I think this needs to be tried for airguns, as well. I’m thinking a very powerful airgun and a pellet/bullet that I can make myself.

BB I’m way interested in this.

You made a recommendation above for a .22 cal. airgun with the 15.43 grn.Gamo round ball.

I would love to try this for my .25 cal. Marauder.

I need to ask this question. If I was to make one of these swaging dies for my .25 cal. Marauder; If I took one of my 31 grn. Barracuda pellets and measured the big diameter of the pellet skirt. Do you think that would give me a good starting point for my die diameter? I already have in mind what size I would make the nose of the die. And does the die really need to be tapered?

I have thought about this before. And now that I think about it. I believe Sheridan made some .20 cal. pellets that resemble what you made.

But doing what you said above gives you the opportunity to be able to control the accuracy of your gun without having to only try what the pellet manufacturers are making. When you get it right of coarse.

I could make up a bunch of different weight pellets/bullets and I would be happy as can be trying them out all day long if you know what I mean.

Gunfun1,

Disassemble your Marauder to the point that you can insert a cleaning rod through the barrel from the breach end. Insert a snug fitting pellet into the breach and as gently as possible, push it through the barrel. If all goes well you will have engraved the lands and grooves on that pellet and you can get accurate measurements from it of your barrel.

Now, does the Marauder have sufficient power to utilize a swaged projectile such as BB has made? I seriously doubt it. Your projectile will need to fit your groove measurement to seal the barrel as the Marauder lacks sufficient power to deform the rear cup to seal the gases behind the projectile. It also lacks sufficient power to cut the rifling into the projectile and overcome the friction your swaged projectile will develop.

Slide over to the Talon Airgun Forum and dig around in there to see what those guys are doing.

Now, having said all this, I could be wrong.

Good info RR. But I really believe it is about the fit of the projectile to the barrel. I can make different diameter dies real quick and easy if I need to.

I just experienced this with the .177 Eun Jin pellets that I tryed in my Talon SS. They were not at all good in that gun. But were better in my Marauder(I think the Marauder with the bolt was actually able to seat the pellet better in the barrel than I could with my thumb in the Talon SS barrel).But here is the part that is kind of funny.

There is a handful of guys and a couple of girls at work that shoot air guns. There is a big variety of guns among us. But one of the guys has a springer break barrel (and I wont mention what brand it is; but it is a well respected air gun making good power) He wanted to try the Eun Jin’s. Guess what. The one he fired didn’t make it out of the barrel. And I’m not lying it really didn’t make it out.

So I definitely disagree about the Marauder’s power to shoot that type of projectile. Again I think it is all about the sizing. That is one of the things that contributes to air gun accuracy when you are trying regular shaped pellets.

Plus the last time I chronyed my .25 cal. Marauder with the 31 grn. Barracudas the gun was doing around 940 fps. That’s about 61 fpe. of energy. And here is the best part. It gets a better consistent shot count than my .177 Marauder with both set up for a 3000 psi fill. Hmm. I wonder how that is possible.

And RR I do appreciate the info about the other site. But done seen what is up on the other sites. And what I have seen here so far. BB will usually set things straight here before things go to far.

GF1,

Ridge Runner has given you some good advice. I would add that the pellet skirt is always too large for a bullet diameter. You need to slug the bore and produce a bullet that rides the lands. The driving band at the base like the old Sheridan pellet is the way to go.

B.B.

B.B.

And anyone interested…

The Sound Lock kit for .177 works great with the micro tank. The TSS will be tough on the starlings this winter.

twotalon

This is a great post, BB. I had just started experimenting with my own rough casts and had considered swaging pellets, too. If you remember, I am also experimenting with various shapes and using Computational Fluid Dynamics to calculate and compare drag.

Chris S.

BB, you know I have a TC Cherokee ML as well and a .45 cal barrel for it as well as the .32 barrel. My whole idea in suggesting that bullets that could be used in airguns with the right barrels and sufficient power came from my ML shooting.My thoughts on a .25 or .30 cal cast RB shooting MSP came from my Cherokee , as I know that provided the barrel is rifled for the ball is will be accurate at the velocity that could be generated, because it is in the ML. I have also made simple swages like Mike did for you ,but I use a arbor press ,either my hydraulic one ,or my manual one. My 10 1/2 ton hydraulic arbor press is overkill but it does have a gauge to show pressure being used, and I probably shouldn’t even mention it as it costs about $1500 to buy one,from McMaster Carr so most folks wouldn’t have one for casual tinkering , but then I’m different than most folks. The bullets you are making are like the old collar button bullets used by the turn of the century(1800’s) shooters for indoor shooting with the .45-70 trapdoor Springfield . I think that you are going to find them only good at short range. Actually I found a .457 dia swaged RB with a tuff of dacron and 8.0grs of Unique powder to be better when I played with this idea in my old man’s 1884 Trapdoor 30 years ago. Another design that I’ve used is .32 wadcutters designed originally for the .32S&W long pistol cartridge. I’ve used these in barrels ranging from .320 – .308 dia. and they were VERY accurate out to 50 yards. Would be very easy to bump up for in a to big barrel senario. If you were to squash it a bit to make it smaller it might be like the old Sheridan pellet that Gunfun mentions. That is, provided that you don’t blow out the nose for lack of material. That is an idea I haven’t tried but I will now.I still think we need to be able to shoot cast bullets in our airguns , and I think you could still get away with swagging those down, as long as you didn’t go to far. Something on the order of the Lee sizing dies would be the cheapest route to go for the average guy. They will even make you a custom one for reasonable money.The limiting factor is that the airgun has to have enough power and has to be available to the average guy in a factory product, and as you say , the money has to be there for that to happen .

Robert,

I actually own a .32 wadcutter mold for 98-grain bullets, but I need to cast them in pure lead for this. The ones on hand are too hard to swage.

Really a carpenter’s hammer is all the force needed to swage these bullets. And it only takes one stroke of the hammer.

I never though of using the as-cast wadcutters in that rifle, bit I will. And I agree that these bullets are not good for long range, though they should work out to 100 yards I would think.

But we shall see.

B.B.

BB, the .32 wadcutters I was refering to the are swagged hollow based ones ,not cast. You can do the same in .35 cal guns with the pure lead swagged wadcutters avilable for the .38 special pistol . I also believe you about the hammer part. I just mentioned what I was use ,as I want to folks to know that I’m very serious about my shooting and not blowing smoke.

Indoor shooting with a .45/70?

Better have a good exhaust fan!

Les

My take is that while it works, most of the time there are easier alternatives. Bullet molds can be had for a fair price. The cast bullets can then be sized as needed. Bullet casting is not hard. As for pellets, you can buy almost anything you need again at a fair price. Swaged bullets seem to be a last resort when other methods won’t work. My 2 cents.

Mike

Mike,

I’ve been casting bullets for 45 years and swaging is much faster and easier. Whether it produces good results remains to be seen, but it sure did in the old days.

B.B.

Mike ,the issue here is that while I agree with you that cast bullets are ultimately the way to go , you need to have a firearms barrel rifled and bored to take them. If it is undersize you will not have any accuracy from it.In my experience, best accuracy in my firearms is from cast bullets that are generally .0003 over bore size , like .311 dia sized for .308 barrels, .313 dia for .311 barrels.

True. My .45 Colt Rifle likes .454 Bullets.

Mike

Please consider commenting-on Elmer Keith’s observations with his 35-caliber design of bullets at 28 to 40-thousand PSI pressure.

35-caliber,

I don’t have Keith’s material on the .35 caliber at hand, so why don’t you take the lead on this?

I do know that out to 220 yards the .32/40 was always considered to be one of the most accurate rounds.

B.B.

It was but the .38-55 is the .35 cal one.

Robert,

I sure know about that one — don’t I? Haven’t gotten any screamer groups yet, though.

B.B.

Not anonymonus, but Keith designed his revolver bullets for long range shooting with a flat point and a wide full caliber driving band behind the crimp groove to cut a full caliber hole in whatever it hit. The driving band centered the bullet in the barrel. Thick driving bands might not be such a good idea for air guns bullets, but the idea of a band that is slightly tapered behind the point on the front of a bullet (much like the Sheridan original pellet) , tapered on the first third of the band, and a full caliber band or bands on the body of the projectile. My 2 cents …

Since reloading supplies am to be scarce now (and for who knows how long…), it might be worth buying pure lead wire and setting up a cutter to make custom weights. Cutters can be a cheap homemade guillotine type or even tin snips or dykes with an adjustable stop clamped on. Then you can sit and cut hundreds of bullet blanks while watching a movie.

/Dave

…..Just don’t eat popcorn while handling lead, please!……

/Dave,

That is one way of doing it, but since I have about half a ton of pure lead on hand, I prefer casting my starter slugs.

B.B.

BB,

An off the wall question for you.

A Ruger Air Hawk appears to be a Chinese copy of a RWS 34. Unfortunately, they did not do that great of a job of copying the trigger assembly. I was wondering though if they had done a good enough job to allow installing of a RWS trigger assembly in the Air Hawk?

RR,

To tell the truth, I don’t know. This sounds like a Vince question to me.

Vince?

B.B.

RR,

I’m not BB or Vince, but I remember that people were taking the Ruger (or the equivalent generic designation) trigger assembly and putting it into D34’s because they wanted the metal trigger, so the reverse swap must be pretty straightforward, if you want the Diana T05 trigger (the T06 requires a different piston), but I don’t see it getting you much; the TO5 clone on the Blackhawk I had was quite good, but they probably are luck of the draw from factory as far as tolerances/settings and so on. You might consider talking to Mike Melick about what you don’t like on the Ruger trigger and see if he has any suggestions, either for improving the trigger yourself or maybe sending it to him. I also think he had some triggers that were tuned, but maybe I’m mis-remembering.

BG_Farmer,

Well, the trigger on my Air Hawk is plastic and although it is better than what I expected, a T05 has to be better or the Germans should just give it up.

Actually, I am very pleased with this sproinger. It is almost new and I picked it up with a Daisy 717 at a yard sale for $90. It shoots pretty good for a sproinger and since I have so little in it, I was thinking of tinkering with it and see how much more I can wring out of it.

One of the first things I have to do is replace the 100 yard parallax scope with something like a Bug Buster so I have a scope that works at the ranges of a sproinger.

How do I get in touch with Mike Melick?

Google “flying dragon air rifles” — don’t know if a link is appropriate, although I don’t think it is directly in competition with PA in terms of product line, services, and focus; he is a good tuner from what I can gather and knows the Chinese guns very well.

My understanding is that the Hawk (xs, b25) triggers are polymer coated metal, but I could be wrong, or it could have changed. The TO6 on my D34 is just noticeably better than the T05 clone on the Blackhawk I had briefly, but the difference in use was so negligible as to be academic. When they copied the D34, they improved it in a couple of ways (e.g., articulated cocking link, sleeved mainspring). My Blackhawk failed after a short time of elation with it for other reasons (Chinese QA you know), and I thought the D34P would be a safer choice, but I actually enjoy shooting the Diana less and have been thinking about selling it and buying another Blackhawk and keeping the extra in a tuning/repair fund. I don’t know that the Blackhawk is a better rifle (obviously not finished to the same standard), but for me it was a better shooting rifle that handled better (the synthetic version of the Ruger uses a very slim stock like the older Panthers).

Howdy Mr. BB & the Gang,

Mr. Square Head, Spongy Pantz here, Nuttin’ ta add as this isn’t my deal, but find the info from those who have/do to be very interesting. Havin’ read every word on this blog, often more than once, can follow along with the ideas. Thanx ya’ll. Shoot/ride safe.

Beaz

Beaz,

Booga booga! Now you are cursed with the desire to cast and sage your own bullets too! Jk….

/Dave

…..swage…… Sigh… Some days I can’t even curse right……

Thanx alot pal, ya just gave me the “ride metric/drink martinis/get my nails done every week & wear frilly underwear” curse!!!

Not really sure makin’ my own would work for me, don’tcha hafta be able ta at least hit in the same general area you’re aimin’ at before ya worry about whether ya can make a good projectile?

beazer,

Are you tellin’ us you Don’t wear frilly underbritches? Not even sometimes? 😀

B.B.

Nasty rumor floatin’ around that if enough beer is involved & the party’s rockin’, I’ve might’ve had a pair on…my head, but they didn’t start out there & I wasn’t wearin’ ’em when I saddled up. Can’t confirm or deny. Don’t remember.

Ha! I ride metric! Now maybe I’ll be able to afford a new HD since I gave the curse to you! 😀 (not mentioning whether I have the rest of that curse….)

Careful what ya wish for there, Spanky. Karma is a woman & she always collects. If ya do go H-D, it’ll only come in one color, light red (yup, pink). Don’t blame me, you started it, wavin’ yer wand around w/out havin’ a firm grip on it!?! B.t.w., who does your nails?

B.B. , OK all this is very interesting and has me thinking and wondering. Am I reading correctly that you can take a .32 wad cutter bullet and shoot it our of a .32 cal muzzle loader rifle?

Also, when you “swagged” the .32 round balls in “bullets” (first pics) can you then shoot them without a patch or do you still need a patch? Very good blog today! Thanks, Bradly

Bradley,

I don’t shoot .32 wadcutters from my muzzleloader. Robert from Arcade said to use them as starters to swage into .32 ML bullets and I said I would try. Actually, I thought he said to shoot them as is, but I misunderstood him.

These swaged bullets will be shot without a patch. And they drop through the bore. So loading will be faster. I’m hoping the cupped base and pure lead will obturate on firing and they will take the rifling well, but that is what this test is designed to ascertain.

Imagine cutting about a minute off your loading time on every shot. I clean the bore after every shot, so this should never foul to the point it cannot work.

B.B.

B.B., yes, swagging 32 wad cutter is what I mean (not just raw .32 wad cutters). Sounds to me that it would save a step and cheaper to do in the long run than buying .32 round balls and patches. That said, I’ve shot many round ball (50 cal only) but not “bullets”. Do you really have to clean after every shot? I ask because, like I said, I’m used to round ball/patch. You can shoot all day without cleaning the barrel. And I’d think with the .32 (verses the .50) would be cleaner because of less powder. That said, I shoot Pyrodex. Never really messed with black powder. Oh and making my own “wad cutter” pellets from BBs looks fun too. I could see doing a 22, but a .177 lead bb? That would be a cute little wad cutter.

You can also shoot those .32 swagged wadcutters as is, from your .30cal. rifles like the .30-06 , .303 British , 7.65 Argentine and so on. They work well in worn military barrels. The ones I’m using are 100grs and measure .313-.314 in dia . I have never used cast ones as I only have semi-waddcutter moulds , but I would guess that cast from pure lead they’d probably would work. As BB said they are toosmall for the ML were using. I ‘ve been doing this for years for squib loads instead of using RB . They are more accurate. Just don’t go crazy and push velocity too much , like you might with a light copper jacket bullet ,ie: half jacket speer plinkers . I got the idea years ago from an article in the “American Rifleman “by CE Harris, when the (then new) Taurus brand of swagged .32 waddcutters first came on the market. The swage I made which is similar to BB’s bumps these up to .323 dia for use in my .310 Martini cadet rifle. I put a ball bearing in the base of my tool to form the skirt . I also use cone shaped inserts from my case trimmer to make the skirt thicker to stand more velocity . I made my tool to be able to make thicker base skirts. The nose is the same profile as the one BB has. it takes only 5-600lbs of pressure to form the bullet using the gauge on my press.

Bradley,

Give this a try! Swaging is much faster and easier than casting.

B.B.

BB and RR thanks. That’s why asked. I was trying to save some time by just measuring the pellet skirt.

So here is some other things that I was wondering about regarding the .25 Marauder. Do you think maybe if I loaded one of the tighter fitting Eun Jin’s or even one of my other pellets that load easier in with the bolt of the gun and then pushed it back out with a rod from the end I loaded it from. Do you think that would work to get me some kind of size to start with?

And the closest round ball that I know of is #3 buckshot. They also weigh around 25 grn. So that would keep the bullet I swage in a good weight area. But do you think that lead would work?

And twotalon I was wondering if you got to try your gun with the Sound lock kit. And I have been looking at the Micro meter tanks also. So that is nice to know. What fps was your gun shooting with your original tank and what fps is it shooting at with the Micro meter tank?

GF1

The TSS was doing lower 800s with CPH on the standard tank, and was starting at 700 with 8.4 Exacts on the micro.

twotalon

GF1

Also, with the micro, turn the power wheel all the way down. No point in beating the valve to death.

twotalon

GF1,

The pellet should go all the way through the barrel to account for any choke. No reason it can’t go from muzzle to breech, though.

B.B.

Shot isn’t pure lead as I recall — they make it fairly hard so it doesn’t deform when the shotgun is fired.

Probably not something you’d want to use in an air gun, even if you manage to swage it down….

A friend that farms gave me a call last week. Again this year, pigeons had moved into his equipment barn. So, I went over with a pair of Sheridan “C’s”. Four pumps worked well, I got three the first trip and the last one the next day. The great thing about a multi pump is that it can be pumped enough to be effective but still not go through the metal roof. I brought two so I could shoot twice without a reload.

Mike

Good idea on bringing two guns! Sent many a pigeon home with a .22 cal Crosman Medalist pistol when our old barn was around. One of us would go inside and the shotgunners in the field would get the ones that escaped.

BB, TT and Wulfraed. Ok all good info. Another question though. Does anyone know of anything available in lead that would be close to the .25 cal. diameter.

And what I’m getting from this is that I could get some type of soft lead and cut a piece from it. But I suppose the blank of lead needs to be close to the finished diameter that I want the bullet to come out at. And the heavier that I make that blank the longer the bullet will also come out.

Am I thinking right?

And TT I believe you just convinced me to get the Micro meter tank.

GF1

Keep in mind that the micro has a straight downhill curve. You can’t tune it.

You will also have a different P.O.I. than you would have with the standard tank, even if you stay with the same kind of pellet. You will need to zero the scope again when you switch tanks.

twotalon

GF1 : I think at the end of the day you’d be better off getting another barrel for your gun in .25 that would take the Lyman #257420 and cast the bullets. Or get a custom mould to fit your barrel if you have the power to launch the slug. I tried making a .22 die one time and while I did make a bullet out of Gamo ,22 RB, and it sorta looked like a Sheridan pellet, but it wasn’t accurate. I could hit an orange at 25 yards but that’s as good as it got.In .25 , a buckshot mould would be your best bet if you go there. Go to sharpshooter buckshot moulds for the mould .

GF1 , that would be Sharpshooter USA Buckshot Moulds. Man I wish this blog had an edit feature…

Robert

Thanks I will look at that also.

But my whole Idea about being able to swage is that I could make projectiles and still be able to shoot if the pellet supplies dry up like the fire arm stuff did. Although that is getting better in my area now also.

But the components of a swaging set up would be a easy thing to carry in a backpack or shooters box.

PCP gun, Hand pump, Swaging kit and you have a nice contained setup for what ever reason could arise.

Like Zombies or something you know.

And TT by the straight downhill curve. Do you mean that the fps of the pellet will drop off quickly with each shot. Am I thinking right?

GF1

What I got worked like this….

I started shooting with the Exacts with 180-190 BAR fill. Shot down until I lost 100 fps.

Took 130 shots to be sure that it was going to stay 100 fps below the initial velocity. The shot to shot velocity started to open a bit after 120 shots. I don’t remember if it took two or three shots to drop 1 fps from the time I started until I reached 100 fps down from there. You could plot a straight line on a graph from shot 1 to shot 120 . No obvious “curve”…..just a straight line downhill. Very predictable linear drop.

twotalon

TT

Ok I understand what you mean now. Fps is lower with the Micro meter tank. And as you make each shot from 1 to 120; the fps. drops gradually.

That should help to keep the shot in a kill zone for a longer amount of time then. That would be another benefit for me and my pest bird problem. And with the gun producing 700 fps. with the 8.4 grn. pellets that would be a bit over 9 fpe. That should still be enough power to take a Starling out to 40 yrds. or so.

And another positive check mark for the Micro meter tank in my opinion.

GF1…

Please note that it took about 120 shots to lose 100 fps. You will not have any fantastic shot count out at 40 yds with a micro. Maybe 30-40 at most. But they will be quiet.

I think that 40 yds is stretching it a bit with the micro, but can be done under good conditions.

twotalon

That would still be good for pest control I believe.

I probably should of said pest control of Starlings. But it think it would still be enough for a bigger bird at the right range.

This is my first post on your blog.

I have been reading your daily blogs for a few years now and it is one of the

First things I do on my way to work so thanks for that little bit of joy in the morning.

The swage topic is somthing I am very intrested in as I have an intrest in casting and making my own pellets.

I bought a .25 bullet mould some time ago and have just started to get back into making somthing I can actually use in my air rifles as I am from the Uk and dont own a firearms cert .25 air rifles are very low in fps but are still usable for close range pest control and fun for knocking over tin cans.in the uk we dont seem to have the market you have in the US so I have made my own swagers and they size the bullet down to .250 and the fit nice in the barrels I hav.

But now im trying to speed up the time it takes to size and make them into pellets so have got a lee press and .452 sizing die which im getting an insert made.

So looking forward to the other parts of this blog.

Barry,

Welcome to the blog!

There will be additional reports on the process as I go. I was actually at the range testing the swaged bullets yesterday, but I don’t want to give anything away until the report.

This should be an interesting test.

B.B.

Thanks for the welcome looking forward to it.

Very interested in this!