bullets

AirForce Texan: Part 5

by Tom GaylordWriting as B.B. Pelletier AirForce Texan big bore. Part 1Part 2Part 3Part 4 This report covers: Upgrade to the TX2 valve? Mr Hollowpoint The day Mr. Hollowpoint 333-grain bullet Stretching the air Cold! First two bullets Time to refill Summary The .458 Texan from AirForce Airguns I’m testing has been with me for … Read more

Big Bore Calibers

This report covers: Most shooters are familiar with the smallbore air gun calibers of .177, .20, .22 and .25. Even shooters who don’t consider themselves to be airgunners know at least the .177 and .22 calibers. But in recent years there has been an explosion of big bore calibers, and I am seeing that many … Read more

AirForce Texan: Part 3

by Tom GaylordWriting as B.B. Pelletier AirForce Texan big bore. Part 1Part 2 This report covers: TX2 valve for .45 and .50 caliber Texans Old rifle, fresh test “New” bullets The TX2 valve Power setting Seat the bullet in the rifling! Velocity One more velocity lesson Summary After writing Part 2 of this report last … Read more

What’s wrong with solid “pellets”?

by Tom GaylordWriting as B.B. Pelletier This report covers: Diabolo pellet The couch coach solution Tradeoffs Summary Today’s report was engendered by yesterday’s report about the AirForce Texan big bore air rifle. Many of you have been discussing the advantages of solid pellets over diabolos Today I’d like to look at this question a little … Read more

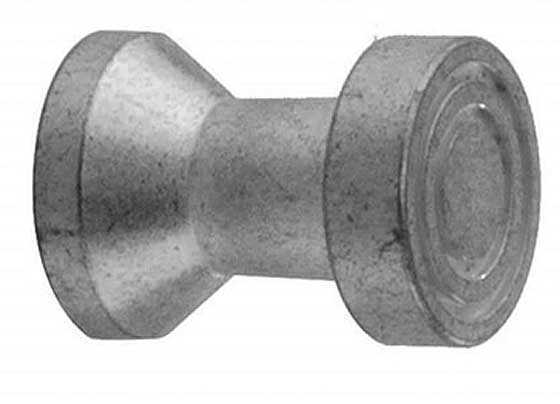

Ballistic coefficient: What is it? 2nd Half

by Tom Gaylord Writing as B.B. Pelletier Part 1 This report covers: Review Today’s discussion Round balls Conical bullets Smokeless powder A big point Shape Round balls — again The bottom line I’ve taken 11 months to return to this subject of ballistic coefficients (BC). That was in spite of some tremendous interest in Part … Read more

Ballistic coefficient: What is it? 1st Half

by Tom Gaylord, a.k.a. B.B. Pelletier This report addresses: • Definition of ballistic coefficient (BC). • How are BCs determined? • Bullets and pellets have an additional factor. • BCs are not constants. • BC is an expression of how much velocity is lost in flight. • How to cheat the BC numbers. If ever … Read more