by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

-

- Mac’s gun

- Difference between the Talon and Talon SS

- Long barrel

- Air flow is the key

- The Condor

- The Freimarked rifle

- NRA airgun range

- However…

- For RidgeRunner

- Michael

<

It seems like you readers are hot for more information on tuning valves and adjusting power on precharged pneumatics (PCP). Very well. In response to something RidgeRunner said yesterday, I will do Part 2 of this report today.

Mac’s gun

It began many years ago with my friend, Earl MacDonald — Mac. He was of the opinion, shared by many airgunners, that a high-velocity .177 caliber pellet will be most accurate at long range because it will drop less over distance. So, he wanted the mostest-fastest .177 ever made. He talked to AirForce, where I worked at the time, and convinced them to let me build him a super-fast .177 Talon from blemished parts. In those days production was smaller than today and we didn’t have as many blemished parts around. Still I managed to find the parts I needed to assemble the gun.

Difference between the Talon and Talon SS

Many airgunners say “Talon” when they are referring to the TalonSS. They are two different air rifles. The Talon has an 18-inch barrel and no sound suppression. The TalonSS that is suppressed has a 12-inch barrel that is tucked inside the frame of the gun — in something airgunners call a shroud today. AirForce pioneered this design in 2001, when they brought the Talon SS to market, and they have been refining it ever since. They were not the first company to offer a shrouded barrel on a PCP though. That honor falls to Davis Schwesinger of the now-defunct Air Rifle Specialists, who added his own shroud to the Career 707s he sold. AirForce Airguns was the first manufacturer to design a shroud into an air rifle on purpose.

Long barrel

Mac had a 25-inch Weihrauch .177 barrel that was made for an AirForce rifle that he bought from the company, Mac I, so that became part of the rifle. I took a valve that was built for power by decreasing the return spring rate by a couple pounds so the valve would open easier. I also raised the height of the top hat considerably higher so the valve stroke would be longer — meaning the valve would stay open longer. Use it on a TalonSS with a standard 12-inch barrel and all you would get was a louder rifle with no appreciable velocity increase. But put it on a rifle with a super long barrel and you got what Mac was after — a Talon that would shoot H&N Baracudas supersonic. I believe that is the rifle that RidgeRunner now has, because he reports Baracudas going supersonic. A Talon with a standard 18-inch Lothar Walther barrel and a standard valve would be shooting the same pellet in the low 900s with the power adjuster set all the way up.

Air flow is the key

RidgeRunner was right when he said air flow is the key to velocity. However, it has to be coupled with a barrel that’s long enough to benefit from it or all you do is waste air and make noise.

The Condor

In 2004, when AirForce brought out the Condor, the world received its first supersonic .22 pellet rifle. I mean one that was purposely designed that way — not one that somebody goofed up with hairspray or oil down the transfer port. The Condor valve has a huge air passage compared to the standard AirForce valve. I was as amazed as the rest of the airgun world when I saw the performance, which I did firsthand. AirForce was so concerned that the rifles lived up to their advertising that we chronographed the first 100 and recorded their velocity by serial number — just so we had the proof. That was where my story from Mr. Condor that I mentioned last week came from. When he brought us his bag of parts we knew exactly when it had been sold and to whom. And also how fast it shot when it left the fsctory. And when I say “we” tested every one of them, I mean me. I shot each one of them through the chronograph while the numbers were recorded.

The Condor was a big lesson to me, but it turned into an even bigger lesson when we wanted to send our rifles to the NRA for inclusion on their indoor range at the NRA Annual Meetings and Exhibits. Before I tell you this tale, though, you need to know another behind-the-scenes story.

The Freimarked rifle

Germany has a law that an airgun cannot exceed 7.5 joules (5.5317 foot-pounds) of energy at the muzzle and still be considered an airgun. In Germany, airguns have traditionally been used for target shooting and this power limit is plenty of energy for that. If the gun develops more than 7.5 joules, it must be registered as a firearm, and other laws, like who is legally allowed to shoot it without supervision, come into play. Airguns that meet this requirement are stamped with the letter F inside a pentagram and are considered free (frei — hence Freimark) from legislation. There are rules that govern the use, possession, transportation of airguns, as well, but they are considered free from the more restrictive firearms legislation.

However, there is no way that a conventional AirForce rifle can meet that low power requirement. Most of them cannot even be dialed down to that low level of power, but even if they could, the fact that they have adjustable power that exceeds 7.5 joules makes them non-compliant. We wanted to sell airguns in Germany, so a special valve was designed to restrict air flow. I won’t tell you how we did it, but once it was done the rifle used only the air that was inside the valve body at the time of firing. It worked well.

NRA airgun range

Then came the opportunity to be on the NRA indoor airgun range at the annual meetings and exhibits. This is a show that’s open to the public, and in recent years over 60,000 people have visited it. But we could not be on the range with our guns because the NRA uses pellet traps that were given to them by Daisy, and AirForce rifles can shoot right through them!

So I took the valve that was developed for Germany and found a second way to restrict the airflow — making a double-restricted valve. Once it was installed on a Talon SS there was no way that rifle could be adjusted to get much over 5 foot pounds. I showed it to John McCaslin, the owner of AirForce, and he tweaked it further, then built several rifles for the NRA. As far as I know, they are still being used on the airgun range.

However…

But that’s not the end of the story. After seeing what could be done, I lobbied long and hard to make and sell this setup to the general public. With a tank containing such a valve, a shooter could take his 30+ foot-pound Talon SS and turn it into a quiet, safe indoor target rifle his whole family could enjoy. Not only was it safer and quieter — it also gave over a hundred shots per fill. We knew that from our experiences on the NRA range. The MicroMeter tank was born! I never envisioned it but owners of the more powerful Condor are also buying the MM tank. Sometimes less is more!

For RidgeRunner

In this report I have talked about airflow. But I left out something that most of you haven’t considered. Increasing or restricting the air flow is an important part of the power control equation, but there is more to it. When it comes to restricting air flow it’s not just how much you restrict the flow but also WHERE you restrict it. Restrict it in some places and the power will drop but the gun will still respond to power adjustments. Restrict it in other places and the power will drop without the possibility of ever increasing again.

I cannot tell you more than that or I give away design secrets, but let me give you an analogy. Let’s say that the city of Los Angeles needs a lot of water. And let’s say one place they get it is from the Colorado River that flows through the Grand Canyon. Let’s say this water ends up in a large man-made lake called Lake Meade that’s contained by a big dam — we’ll call it Hoover Dam.

Hover Dam can control the amount of water that’s sent to Los Angeles by controlling the output of water that gets past the dam. However, if the water level in Lake Meade falls too low, it won’t be Hoover Dam controlling the output of water. There won’t be any water at the dam because the level is too low. In that instance you can open all the dam’s floodgates and it won’t make any difference. That’s as much as I can tell you about how to control airflow.

Michael

I don’t know if you picked up on it, Michael, but I talked about power adjustment in both Part 1 and again today. But that wasn’t all I wanted to say. It was your questions about power adjustment that started this report and with power adjustment I will finish it in the next part.

So that means there has to be a place to store the built up air.

Then the air that is stored needs to be controlled that fires the pellet.

So then there is a valve to control that air to the barrel.

And multiple things take into account how the air flows from the valve.

Then that extra area or other valve if we want to call it would be a what?

Then we can also control the air to the barrel with just a valve. And be in some cases as good as a regulator at controlling the air. That would be the resivoir size along with the other things needed to make the air leave the valve to the barrel.

The only thing in that case there would be a limit at some point of how many shots at a desired velocity would be able to happen.

So the question I have is. If you have a gun with a given air valve and adjustments and transfer port size to make the air get to the barrel. And you have a given size air resivoir. What would be needed to get more shot count to distribute the air more precisely with what the gun has in place already?

Oh and forgot.

When you finnish next with power adjustment. That is a important part of the equation to get the full potential out of a regulator.

If you don’t have that then you can only change fill pressure and regulated pressure to accomplish only a bit of what would happen if you had that power adjustment.

Basically the striker spring at least. But even more so if you also had striker stroke and transfer port size adjustments.

BB,

Yes, I got that rifle from Mac. The only pellet I could shoot in it at the top of the power curve that was subsonic were the 16 grain Eunjin pellets and their grouping at 25 yards looked like a shotgun pattern.

VERY interesting. I’ve been hard at work on the upcoming 2400KT modding blog and a lot of the same basic principles — valves, valve spring modification, and air flow restriction — all come into play there too.

Hiveseeker,

I sent you a note on a older blog. Not sure if you saw it. I got a new 2240 to start playing with. At any rate, I found a place to get a fore arm, which was the main point of the post. Other stuff too. I would consider wood options or even 6 position options. A adapter of sorts would be needed for a 6 post. AR style though,.. if something like that even exist. Ideas? Stock set up is the default and would be fine.

So all in all, I am pretty good for the time being. Looking forward to your next report now that I am part of the “club”,…. almost. 😉 I will be consulting your blogs.

Chris

I just emailed you a link to the custom stocks. Make sure you click on the spot by the pictures that says “veiw all”.

The pictures of the stock will say the name of the website down on the bottom of the picture. If you click the picture it will take you to the website.

Let me know what you think.

GF1,

Very nice. Lot’s of custom stuff. Some of those puppies look like the proverbial “money pit”!

Chris

Yep tons of stuff out there for the 2240’s.

Chris

Oh and thanks for that link you emailed me. I checked it out some this morning. Will look more later.

Would you mind putting up a link to that blog? I’m interested in a conversion to HPA.

Idaho

Here is part 4 of the 2240 hpa conversion. It has the links to 1,2 and 3. So that way you have them all to read. Have fun. 🙂

/blog/2014/08/crosman-2240-conversion-to-air-part-4/

Gunfun

Thanks!

I’ll check it out.

And I do like the glider idea. Relaxing.

Idaho

Yep I had a couple 2240’s I converted to HPA after finding out about the hi-pac conversion with long barrels and the 1399 skeleton stock. Nice shooting guns on Co2 or HPA.

And yep the gliders especially with the addition of the electric motor can stay up in the gliding around for hours at a time. Especially if you keep catching thermals in the sky. Watch the hawks when they are soaring. You’ll see one wing bump up and they will turn in the direction of the bump and raise 20 or more feet up when they catch the thermal. Same thing with gliders. I had them so high before that they looked like spec in the sky. You can set in a lounge chair and fly one of those. 🙂

Gunfun

After reading through the conversion, it just does not make sense to convert my 2400 KT with its 10″ LW barrel when I can buy a single shot pcp for not much more, maybe less. It will remain a C02 powered warm weather gun. Perhaps it will go up for sale.

Idaho

Yep that’s one way to look at it. If you already got the gun then you only got to pay a little bit more for the conversion parts.

Now if I had to go buy a 2400 KT and then also the conversion parts I would probably buy a Maximus.

Now on the other hand the 2240’s are a tinker’s gun. So if you like the idea of changing your gun around to shoot it a different way then the 2240 is great for that. Shoot it a couple months one way then change it up.

I know everyone isn’t like that. But I know a few people that are crazy that way. 😉

Hi Idaho,

The scene has indeed changed since I started the 2400KT blog. I considered the gun to be almost a mini PCP, but now you can actually buy a PCP rifle for not a whole lot more than one of the higher end Custom Shop guns! There are no pistols in that category yet, and one of the remaining advantages for the 2400KT is no filling required — just pop in another CO2 cartridge. Your comment makes sense, though I would say keep it. I shoot my CO2 guns much more often than my PCPs, they’re just easier especially when you don’t have time for a fill.

Hiveseeker

I do think I’ll keep it. It has unique qualities – incredibly light for one. Very accurate. And I agree CO2 is not the worst thing. I also have a CO2 pistol that shoots well so might as well have a pair of them.

Its sure interesting seeing the PCP market evolve rapidly.

Hey Gunfun1,

Thanks for responding, you beat me to it. Your comments and experience with these guns has been helpful to me as well! There are a lot of custom mod vendors out there. One I’ve noticed that offers custom folding AR stocks for 2240/2400 is Maverick Custom Airguns, also offers grips. He has a website but I only saw the AR stocks on his Facebook page under Maverick Stone. Actually got my eye on one…

Hiveseeker,

Maverick noted. Will check. Looking forward to wherever the project takes me.

See below at the comment to Benji-Don. If you have any opinion on the options, I would appreciate any input. On the other, I can see where you may not have experience yet with stuff other than what is offered at the Crosman Custom Shop. Still, I value your opinions.

Thanks, Chris

Hiveseeker

Thanks and just trying to get the word out there how cool these guns are for a fraction of the cost compared to the high end guns. They shoot just as well for the most part. And so much you can do to them compared to other guns.

And thanks for things on the website. I will check it out.

BB,

Very interesting, but what I need is a drawing to get the feeling for what is important where.

For instance: I assume that the quality of the regulator must be quite good in order to be able to deliver a relatively low pressure airflow at a constant but high rate as the valve opens. If not you need a small reservoir behind the regulator to topple of swings in airflow. Are all those regulators that good? Are they also spring-loaded and therefore do they deteriorate over time?

As with the valve; You describe that the spring pressure is important. I can follow that, but “I also raised the height of the top hat” is Dutch for me. There were expandable top hats in the 19th century, but somehow that concept does seem to fit.

I can check it out for myself and buy a PCP in the process to dissemble and see for myself (which will give RidgeRunner home for the wayward quite a set of parts as assembling something is something quite different as we all know after our first alarm clock disassembly) but maybe there are other readers which also need a basic course.

Regards,

August

August,

Yes, I should have included a drawing. Well in the next part I can do that, since the top hat is part of the firing valve and therefore part of the power adjustment process.

B.B.

BB,

I am confused by that top hat height adjustment, also. Does that mean that you turned back the sealing surface of the top hat’s face, thereby letting the spring ( I think you called it a valve return spring) stretch out more and that would weaken the force applied by the spring to the top hat as well as causing the face seal to be further from the valve seat when it is put under compression by the striker’s hit on the stem?

I can understand what I just asked but I won’t be offended if you can’t. After all, I can’t use my hands when I communicate here. That is so crucial to my speech that during the first 3 weeks of recovery after a recent hand surgery 2 of my buddies said I stuttered and 1 still claims I have a lisp!

Halfstep,

Oh, gee! In the next report I will show how the top hat works. Don’t try to figure it out — it’s not as complex as it sounds.

B.B.

Okay, my hands are cuffed!

Hi August,

Regulators are quite simple (housing, piston/valve, springs and some O-rings) and robust. The springs’ pressure in an airgun regulator is usually provided by a stack of Belleville washers – not a coil spring.

I think that the whole trick to designing a “good” regulator would hinge on getting the correct volume at the appropriate working pressures for the application at hand. I’m speculating here from what I have read/seen as I have never designed/made a regulator myself (need to get a lathe first 🙂 )

Here is a link showing the operation of a Walther Dominator 1250 regulator…

https://www.youtube.com/watch?v=MPyTlqXc0vM

Hope this helps.

Hank

Vana2,

Good video. On a shop air compressor’s regulator, the down stream pressure will tend to go above the set pressure as the supply pressure decreases. It doesn’t look like that would happen with the valve you linked to. I wondered if that was an issue with regulated guns and now I know it’s not.

Halfstep,

Glad you liked the video!

I’m not sure if that over-pressure issue was ever present in regulated rifles as it would not be desirable to have those kind of variances.

I am just starting to research regulators in more detail. My experience with them for now is that they just quietly do their job. I did adjust the regulator and hammer spring on my .177 HW100 as it was pushing 8.44 JSBs over 1000 fps. Since I don’t hunt with that rifle I traded some velocity for increased shot-count.

Hank

Vana2,

After watching that video I don’t see how it could be an issue. Air line and hydraulic pressure reducing valves ( another term for “regulator” ) are constructed differently and I guess that’s why they behave as they do when the supply pressure gets low.

Off topic. Has anyone tried makng an air shotgun starting w/2240 with steel breech or starting with a QB 78?

wdash,

Welcome to the blog.

Yes, Dennis Quackenbush used to make tranquilizer dart guns from Crosman 160s, which the QB 78 is a copy of. If it will shoot a dart it will shoot shot.

B.B.

Wdash

Yep done it with a QB79 on a regulated HPA Air Venturi bottle. Tryed with a 1322 but not enough power.

Here is a video. Play it in slow motion. That gives the full effect I believe.

https://www.youtube.com/watch?v=qw4NuXElIfA

How this helps for what your looking for. All I can say is I was surprised with the QB79.

BB,

Error: read in second alinea: “but somehow that concept does NOT seem to fit.”

Regards,

August

B.B.,

I did indeed pick up on the power adjustment topic in the reports, and thank you.

I find histories of product development very interesting reading. And what makes these AirForce product development histories great is the emphasis on good and innovative design. Too many corporate engineering and design decisions are made in an accountant’s office using non-engineering criteria.

I can see from this report why you wanted to be at AirForce as it was in its early development. I can tell from your enthusiasm writing about it that it must have been gratifying for you.

And while the AirForce model I keep thinking about is the TalonSS, if a Condor ever fell into my lap, I would get a Micrometer Tank for it pronto. I do have speed dreams like everybody does, but the dreams of mine that are grounded in my real life have more to do with impressive shot count and conserving that precious HPA. Then again, adjustability matters for cranking it up for target shooting at a long distance, which I would love to try.

Excellent report, B.B.

Michael

B.B.,

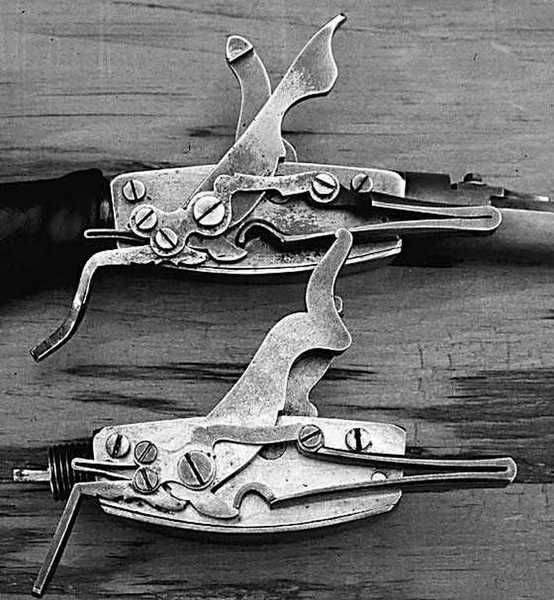

Your explanation above of the role time has in the performance of a valve reminded me of “dwell time” and your report on the outside air gun lock. For the benefit of anyone here who might not have read that, here is the link, followed by one of your photos from it to serve as a teaser. (The bottom lock is an air gun lock.)

/blog/2015/11/the-magic-of-the-outside-lock-part-1/

Michael

B.B.

A Blog request…

Think it might be of general interest so I am hoping/requesting that this series will include details on how to approach setting up a regulated PCP from scratch.

I know that most PCPs perform well right out of the box. And, with a little bit of pellet testing they perform very well. But, at some point I am not going to be able to control my urge to fix something that is not broken and want to get into fine tuning my PCPs to a specific pellet. I would appreciate some guidelines in how to approach this.

I came across an exceptional deal on a new .177 Walther Dominator 1250 so I even have a volunteer (victim ???)for this disassembly/reassemble/tuning project 🙂

I am thinking that genetically, the tuning process would be something like…

1 – chose a regulator pressure

2 – set a high hammer spring tension high

3 – test fire pellet of choice

4 – check velocity is in the desired range ( if not, go back to step 1)

4 – adjust hammer spring

5 – repeat steps 3, 4 & 5 until optimum spring setting is achieved

6 – test pellet of choice for accuracy

7 – try other pellets

8 – make notes of settings and results

9 – if all else fails, restart at step 1 🙂

Maybe this could be a blog series on its own?

Hank

Hank

Here is something to think about. You know how a Marauder rifle can be tuned to let’s say shoot a 10 grain .177 caliber pellet at 900 fps with a 3000 psi fill down to say around 2100 psi.

Then that same Marauder can also be tuned to shoot that same pellet at the same velocity on a 2400 psi fill down to say 1500 psi.

If you was going to put a regulator in that gun what fill pressure tune would you use. The high pressure tune or the low pressure tune with the added internal regulator?

Then the next question is how did you get the same pellet the same speed on both different fill pressures?

I’ll give a hint. One simple adjustment out of all that are available on a Marauder will give the velocity you want out of the gun with the regulator depending on what fill pressure you choose.

And I know what fill pressure tune I would set the regulator at. But then one step farther. What if I don’t have a gun that can be adjusted. Now what do I set the regulator at and what fill pressure do I use?

And not directed at you. I’m talking in general if anyone has their idea of what would work.

B.B.,

Details, details, details …. and all of them important. Great stuff from you and loyal posters. A few days ago I learned that, for 60 meter shots at least, the mildot hold over varies with magnification … not a lot except it is enough to be important for the hit or miss.

Here is part 2 of a how to for calibrating your scope and distances. Where I am even getting this URL has been difficult. The is a part one, of course. I searched Google for “verminhunterstv secrets of” and that brought up links right off the bat. The channel belongs to a couple of British fellows. Yes, for the moment I am fascinated with what they do with sub 12 fpe air rifles. Learning a lot, actually. I believe you have said much that parallels.

https://www.youtube.com/watch?v=DglJYVIAKnY

The first few minutes show the setup; the rest is using information in Chairgun.

I know there are fewer details for my NP rifles than for PCP, which seem to have infinite variables, but there are enough. I believe I have a chance to try some 50 or 60 yard shots. More, later.

~ken

All,….Off topic, but here is some additional info. on a A.V. air stripper and a 1 piece baffle insert that I got awhile back. Both screw directly onto the Maximus-Hunter version. Here is the products:

/search-results-ext?Ntt=PY-A-7784&sid=1375A617A415&N=0&Ntk=primary&q=PY-A-7784&cx=002970863286801882398:jlcminxfwdw&cof=FORID:11;NB:1&saSearch

/search-results-ext?Ntt=PY-A-4557&sid=1375A617A415&N=0&Ntk=primary&q=PY-A-4557&cx=002970863286801882398:jlcminxfwdw&cof=FORID:11;NB:1&saSearch

I put a regulator in the,22 Maximus recently. I did not re-sight it. The results at 50 yards from Point Of Aim, POA were:

Std. barrel,….. : 5/8″v…… 1/8″>

Baffle……………: 2″v……… 1/8″>

Str. full back….: 1 3/4″v… 0″

Str. mid post….: 2 5/8″v…

I repeated the testing indoors at 41′ today and the general movement of the groups matched what the 50 yard test showed, but on a smaller scale.

At 50, all groups were around 1″. At 41′, they were all around 1/2″. (hey, it has been about a month since I have shot) So, improved accuracy is yet to be seen. The movement at 50 yards was interesting. Oddly, the baffle insert produced the nicest looking group at 50 yards. The sound was a bit less/different then and today. The A.V. air stripper (inner cone) has 12mm fore and aft adjustability.

So,…. no definitive answers. Just passing along what my results were,…. Chris

Opps,.. something went wrong.

Str. mid. post. should read 2 5/8’v and 1/8″>

Str. full fwd. post………… is 1 1/2″v and 1/4″>

I think the computer thought I was coding or something. One more time,….

A thought,.. one which I have had before,….

There ought to be a “combobulatin” of formulas that apply to PCP’s components and adjustments as to what changes what.

I am not even sure how to express it, other than: Opening the port will do this, but then you also need to do that. Increasing the valve dwell X% will get X% increase, but do this first. This, impacts that,.. and thus will require an adjustment to this, to get X. Change the barrel from 10″ to 24″?,.. ok,.. but consider this first. Sure, the components and adjustments (externally or internally controlled) will vary,.. but I am sure that there is some basic/universal? principals that apply across the board,.. to all of the “players”.

I have yet to see anything like that. The closest thing may be like the M-rod manual. Other ones? It is ok and will give you an idea of what to expect when you do something, but not that good.

I guess that I am thinking of someone applying math and formulas to express a universal interaction of parts common to all PCP’s. From that,… it would give a person a solid (direction) in which to move. Not solid #’s, but rather solid direction. Maybe a go/no go flow chart?

Sure, anyone can do that with there individual rifle with enough shooting, adjusting, data collecting and analyzing. Still,… there ought to some commonality somewhere that is to be found, in 1 place. Simple to grasp/use as well.

Maybe,.. Daystate, FX and even Crosman have all of this “magic” well documented and can control it all like some kind of Wizard?

Maybe all of this is just a pipe dream? Something to ponder though. Enough of my rambling’s! 😉

Chris,

I would bet that the top companies with highly engineered airguns have computer models that do a good job for their guns. Probably based on both empirical data and the laws of physics. They have spent too much money on these models to let the competition get them. But if you start making a list of the variables that would go into a model that would estimate just muzzle velocity. I can be many and the coefficients for things like springs, transfer ports, and valves can be many and they need to be developed for the model to work. That means many many tests where only one variable at a time is tested. This would be as good as it gets I think. A universal model would have a hard time with the various concepts inherent in all the different PCP’s out there.

Think of the transfer port. A good model would need to know more than the diameter of the transfer port. It would need to know the entrance shape and the size difference from the opening to the orifice and the same on the exit into the barrel. It needs to know the length of the tube, the shape/angle of the tube and the entrance and exit coefficients to calculate the pressure loss from the valve to the barrel. The transfer tube is probably the easiest part to model.

Back to your request I think B.B. has given us most if not all of that information over the years; if it was compiled it would make a nice book.

The only way I see to get what you are asking would be to develop a set of graphs for a particular gun by changing one thing at a time. The problem I see is based on my experience with my Marauder in .22 caliber.

I spent a year and a half making adjustments and trying different pellets and had a folder full of data. I am sure I did not exhaust all the combinations and probably skipped across some that may have given me the accuracy I was looking for. After all that time I finally gave up and bought a new hammer forged barrel. The gun with the new barrel was no longer pellet picky and did not take much fiddling to get very close to the moa accuracy I was looking for.

The problem is every gun will be different. I do not regret the time I spent on the Marauder but I can’t say I learned that much after the first few tests. It was more frustrating than a good learning experience, Now with the new barrel I am not sure getting into the same detail I did with the first one would give a good return on the effort it is good enough now and by far my most accurate air gun. Not that I have a bunch of accurate air guns. Most of them are like yours the less costly variety that I don’t mind tearing apart and experimenting with modifications. If I ruin one of these they are not big loss.

If you want to see what is out there on the physics and equations for pneumatic guns do a search on pneumatic canon physics many grad students have done a theses on them.

Not sure why lately I have got so far off the trail, Guess I can blame B.B. with all these thought provoking reports since he took up shaving with a straight razor.

Don

Don,

Thank you for that added insight to the topic. I can say,.. that I do not disagree with anything that you said. Still,.. me,… being thick headed me, believes that something should be able to be put together.

If,.. you take just one quality maker,… I would think 100% that they have a pretty solid data base, based off of ALL of their models, past and present, just as you said at the start of your comment. That gives them a solid (direction) in which to head on future products. Yes, there is many variables,… but there is also the basics.

Yes,.. and dang that whole straight razor stuff anyways! 😉

All that aside,.. GF1 mentioned that you put a 24: barrel on a ?. I think that do I recall that as well. Question: Is there any barrel “droop” at rest or “whip” when fired? I just got a 2240 and GF1 is recommending a 24″ Maximus barrel. That is a whole lot of barrel hanging out there in space. Your thoughts?

Chris

Chris,

That was the 1322 /blog/2017/11/hatsan-bullmaster-pcp-part-4/#comment-407676

Interesting how much difference a barrel can make, guess that is where most of the accuracy of any gun is.

Mike

Mike,

Thank you. That is what I remembered. I am looking forwards to “playing” with it. I am just trying to keep myself from having 200+ wrapped up in a 59 dollar pistol. From my preliminary looking around on the net,.. many have failed before me. 😉

Chris,

It would be very easy to make a 2240 a very expensive I have one and it is only modded with the steel breach, skeleton stock and rear sight.

The pistol is accurate right out off the box, but you will want to upgrade.

Chris,

I have two Maximus barrels they are not that expensive. I have one from the Hunter version you have and another from the original Maximus. I like the Hunter version because it has less machining so it looks better on other guns.

I have the 1/2 inch threaded adapter on the hunter barrel that acts as a small weight. I have the aluminum barrel weight from the Crosman 2300s on the original Maximus barrel. I think they both do a little better??with some weight the 2300s aluminum weight is about what you want. On the Hunter barrel with the threads I tried various weights and anything more than the end adapter seemed to degrade the accuracy. Even without any weight they were about the same as with the weight. I just liked the looks better with a little doodad on the end.

I use the long meal breech on the pistols, I have not tried a Disco breech but having the screw hole behind the bolt would make loading pellets easier. Having the screw next to the transfer port sleeve will give the breech a better attachment to the pressure tube. So I see a trade off between the two. Especially for the 2240 I do not use a barrel band at all on the 2240. That gives a floating barrel from the breech and I have a scope on the gun so the scope to barrel is a little separated from the power plant. I was thinking of converting my 2240 to .177 caliber and getting a .177 Maximus barrel. I have not tried that yet.

My favorite gun with the Maximus barrel has been the Crosman 1322 multi-pump pistol. I have not tried it with out the barrel band. That is because I only have one metal barrel band and it is also the pivot pin bracket for the pump. I don’t want to mess it up. This combination is by far the most accurate gun I have with the Maximus barrel so far. It gives my Marauder a run for the money up to about 30 yards or so.

Right now I have a Leopold scope on my 2240 guess that makes it a high dollar gun the mods were the metal breach and barrel and barrel weight not too much money there. Below is a picture.

Don

Don,

Thank you for the added info. once again. I thought about .177. Still can I suppose, since I am ordering a breech and barrel. My big hands and fingers prefer the .22. Mine will end up like yours most likely + a forend. I have a CP scope that came with the Maximus. It is surprisingly good and hopefully will work nice. So thus far, investment looks to be fairly minimal.

Some mods that I see that might be worth exploring are,

– Hammer w/striker

– Hammer spring

– Hammer/striker external adjuster

– Power valve

– Transfer port

– Trigger components?

The first 5 I think would be sort of a required kit/set, as they all inter-relate. Just a valve and port might not do much without getting it knocked open harder and a way to adjust it all.

Some stuff can be home made/done, so that is an option too. There is a ton of stuff to learn. I can see where Hiveseeker got frustrated and decided that he just needed to do it on his own based on what I have seen thus far.

Like Idaho said too awhile back,… consider what you can spend on other forms of leisure and air guns a pretty good bargain. And,.. I do like to get inside and play around and this looks to be a very easy and versatile platform for that.

Thanks again for help. Chris

Chris and Benji-Don

Crosman probably already had this stuff we are talking about 70+ years ago.

Wonder how they came up with the how’s and why’s to make something work a certain way all the way back then?

GF1,

Crosman had some very clever folks back then and the company was not run by the bean counters. They probably even shot the guns they made.

It is amazing some of the stuff I have seen lately. We have a set of glass bowls that vary from about 2 gallons down to a few ounces in the set. About half of the bowls have the brand and made in raised lettering on the inside. obviously they were not tried out first or even given a quality control once over. And they are not from China.

Don

Benji-Don

I’m thinking the shooting the gun part applies the most.

Chris,

Oh and I forgot; there are more than a few thick headed and stubborn folks on the blog and that is a complement. The discussions, even the disagreements are always good natured and civil. That is one reason I read this blog. It is a tribute to Tom and Edith.

Don

Don,

Ditto that,… 100%!

Suppose to say they probably had this stuff (figured out) 70+ years ago already.

Don,

It’s funny that you would mention the straight razor. I am still getting ideas from that exercise, and I’m still learning about straight razors, as well. Not going to bore you with them any more, but they are what’s pumping energy behind the curtain.

B.B.

B.B.,

I have noticed a greater empathy for all our questions. Especially the ones I am sure you have already answered. I don’t see how you take such a complex issue and give such succinct and clear answers. I know all your experience and a great memory helps but it also takes a lot of hard work.

Thanks

Don

Din,

Thank you. That kind of comment keeps me going! 😉

B.B.

B.B.,

“behind the curtain”,…? So,.. you ARE the “Wizard” that I referred to above? 😉

Just kidding on the razor article’s. I found them fascinating and learned more about quality sharpening than I have ever learned in my life. Hey,… “pumping energy” is a good thing! I could use a bit more of that my self.

Chris