by Tom Gaylord

Writing as B.B. Pelletier

Today’s report is written by reader Ian McKee, writing as 45Bravo.

The world is shifting over to precharged pneumatics (PCP) in a big way, and that means more of us are needing compressed air. 45Bravo got an Omega Supercharger air compressor that had a couple issues from just sitting around. Today he tells us what he did.

If you’d like to write a guest post for this blog, please email me.

And now, over to you, 45Bravo.

Omega Supercharger.

This report covers:

- It works-sort of

- Talk to Todd

- Bag O’ Spares

- Progress

- Photos

- Basic trouble shooting

- No lights

- The lights are on, but the compressor won’t start

- Compressor not building pressure

- Pressure gauge/auto shutoff

- Bleed valve service

- Water pump not working

- Air/water separator auto purge system

- The main piston assembly

- Maintenance

So, you bought a PCP compressor that has been sitting in a closet for 4 years, what should you do? That’s exactly where I found myself.

Even though this is about the Omega Supercharger, many of the things that need to be checked or changed will apply to other brands of PCP compressors.

It works-sort of

When I got it it ran, it pumped air, the water pump worked. But since it had been sitting without being operated for so long, what had possibly gone wrong that needed to be addressed?

Mine would not build pressure past 1700psi, so I knew I had a significant leak somewhere. After some searching and spraying some soapy water I found the air/water separator/auto purge system was not sealing completely in the closed position, and was leaking from the vent line. I will go through the rebuild of that in a moment.

Talk to Todd

After talking with Todd, the support technician for Omega, the pump system needs to be used regularly, or the o-rings will dry out and need service. So if you are not using it regularly, just run it for 5-10 minutes every couple of weeks or so.

Bag O’ Spares

When you bought the compressor, there should have been a bag with spare o-rings, a burst disk and other parts. This compressor was one of the first produced, in 2014, and it was not shipped with the parts kit.

If you have lost yours, the entire replacement spare parts kit is available for $65.

If your main piston is leaking, parts for that are in the spare parts kit, but if you don’t feel qualified to rebuild it, Omega offers a piston rebuild service for $150, and they pay shipping back to you.

Since the system has a port to lubricate the main piston and o-rings during use, the main piston o-rings in mine were well lubed and still functional. But we are airgunners; we can swap some o-rings can’t we?

Progress

After fixing the air/water separator, and the compressor was able to get above 4000 psi, I found that some other o-ring rings in the high pressure system had dried out and were leaking, so we will go through each part as to what needs to be done, how to do it and some tips on things to look out for.

Remove the 6 Phillips head screws on each side of the compressor’s side covers; the shorter screws go in the bottom of the covers.

Tip: The heads of the gold-colored Phillips screws damage easily so be careful, I replaced the screws with stainless steel Allen head cap screws from Home Depot. They are size 10-32. The shorter ones are 1/2-inch and the longer ones are 3/4-inch.

Photos

TAKE PHOTOS OF EVERYTHING before you start. Especially photograph the electrical connections to the parts, and their places where they connect to the control board.

TIP: The flexible high pressure hoses have a fixed end on one end. Tighten this end first. The other end of the hose that has a female end should to be tightened last.

The o-ring sizes are not listed in the manual, nor in the parts breakdown, the o-rings that I used to replace the ones on the ends of the flexible and fixed high-pressure lines were a size 008.

Basic trouble shooting

No lights

The lights are on, but the compressor won’t start

There is air in the flow switch. Make sure there is water in the tank, and no air in the lines. Make sure the bleed screw is tight, as the compressor builds pressure, you may have to tighten it more. We will be starting with the easiest fixes and working towards the hardest. This first one is very simple, but VERY important! This gauge is used on most of the compressors that have an auto shut-off feature, so what I’m about to tell you applies to many compressors. It only has 2 connections, one is a flexible high-pressure hose fitting with an o-ring in each end, and the other is the electrical plug that connects it to the control board. Be careful of this connection when working on the compressor, as it is easily jostled, and the high pressure shut-off will not make electrical contact to shut off the compressor when the desired max fill pressure is reached. ALWAYS check this connection last after working on anything inside the compressor. And test that the auto shutoff works before closing the case. Remove the pressure relief valve knob from the unit, then remove both Phillips screws holding the block in place, remove the 2 flexible high pressure hoses with a 14mm wrench or a crescent wrench. Remove the clear vent hose by depressing the blue collar and removing the clear hose. Clean and lube everything lightly with silicone lube, put new o-rings in the connections of the high-pressure hoses, and reassemble and test. Above the water pump is a water control flow valve. If there is air in the line, it will not let the water pump run. Make sure the electrical connection is plugged into the control board, and no air bubbles are in the line. You can rock the machine forward and backwards, to move the water into the control valve, or you can remove the hose above the control valve and let the water flow into the valve. If there is water in the control valve and the electrical connections are good and the pump still does not run, using a volt meter, see if 12v DC is going to the pump, if there is no voltage, check the wires and connections to the control board. If you do have 12v coming to the pump, replace the pump. If your cooling water is cloudy, you can drain the system. Then refill with purified drinking water, NOT DISTILLED water. Omega also says to add 1oz. (30ml.) of regular automotive coolant to the system. If you are going to be keeping the pump in the house at room temperatures, it is not necessary to add the 1/2oz. (15ml.) of the Royal Purple additive to the system. If you choose to include the Royal Purple additive, it is available from most automotive stores. TIP: when loosening the high pressure lines, use 1 wrench to hold the fitting, and the other wrench to turn the connector on the end of the high pressure line. This was where my major problem was. Take photos of the 3 wires that connect to the black solenoid at the bottom of the air/water separator, so they can go back where they came from. Using two 14mm wrenches, (2 small crescent wrenches will work also) loosen the 2 high-pressure air lines that attach to the bottom of the air/water separator. Be careful as there is a size 008 o-ring inside the connector of each line that will need to be replaced when assembling. Remove the air output hose, being careful not to damage or lose the Dowdy seal (also called a bonded washer), and remove the large nut on top that holds the assembly in the case. Then remove the small Phillips screw next to it. There is a clear vent hose that is disconnected by pressing the blue locking collar back to the plastic fitting and the vent hose easily comes out. Remove the black nut from the rear of the solenoid, and slide the solenoid off of the shaft, Using a piece of leather or rubber between your pliers to protect the shaft, loosen and unscrew the metal shaft from the unit, being careful of a plunger and spring that are inside the metal shaft. Using pure silicone oil, clean everything, and, according to Todd, stretch the spring a little. Make sure there is no debris inside the separator, then lightly lube everything with the silicone lube and assemble in reverse order. On the front of the case, are 2 small knobs that are used to set the purge timer — labeled as the Self-Draining Adjust Device on the pump. Set these to the minimums — every 30 seconds and the duration to 1 second, and test. Let the compressor run a few minutes with a test plug in place at the end of the hose, and let it purge a few times. Then shut the compressor off and set the purge times and duration to your preferred schedule. It is a very lengthy, and detail intensive job. Omega made a detailed video on YouTube that details the procedure, and you can follow that. Or you can just ship the piston and sleeve to Todd and have him rebuild it to factory specs for $150. His contact information is: toddd9803@gmail.com When you press the power button, always make sure water is flowing through the system by looking in the sight glass on top of the case. It is a stream that is very easy to see. If you have to go into the case for any reason, there is a plug on the right side of the electric motor that has a magnet on the end, it catches metal particles that are in the lubrication system of the motor. It is finger tight, if you haven’t done it before, remove the plug, wipe the magnet clean, and re tighten finger tight. The first time you do this, it will be pretty fuzzy with metal shavings, due to the initial break-in of the Chinese motor used to drive the system. [Editor’s note. This is the first time I have heard of this magnetic plug in the motor. This is good information!] After cleaning the magnet, reinstall the cap, run the compressor for a few minutes, tipping it somewhat so the oil splashes on the magnet. Then stop the motor, clean the magnet again, then reinstall the plug and close the case. The lubricant is Royal Purple full synthetic, and should be good for thousands of hours before needing replaced, according to the technician. The older models like mine have a hand-turned grease screw at the rear top of the case that should be turned 2 full turns every 4 hours of operation. Watch the hour meter to know when this is. When the screw bottoms out, remove it, add more of the supplied grease from the syringe replace the screw and turn it in until you feel some resistance. Newer models have a green grease reservoir that sticks up above the case, and has an alert system that lights up when it is time to turn the grease system. The manual says every 6 hours of operation, turn the green reservoir 1 click (1/3 turn) then push the red indication light to reset it. Refill the grease reservoir with the supplied grease when it gets low. TIP: I added a piece of tape next to mine, and wrote down the hour meter number and date it was turned. I hope this helps someone who has a compressor that is not working, or that it just gives owners a nudge on things to keep an eye out for to minimize problems. Ian

Wires from the flow switch may be loose.

More on this is covered below.Compressor not building pressure

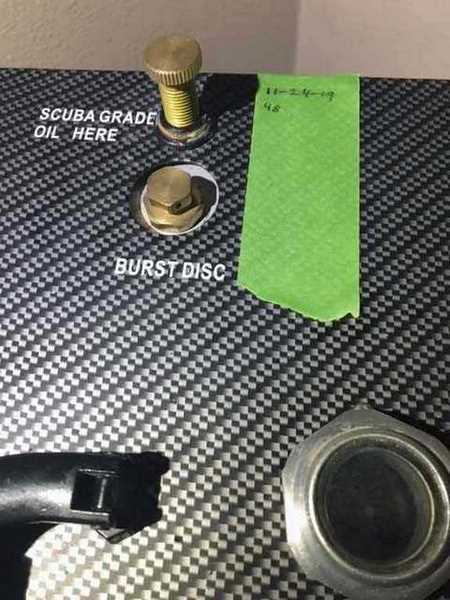

Check the burst disk for damage; (is air coming out of the tiny hole)?

A replacement disk is in the parts bag.

Tighten the fitting to a firm snug.

Check the main check valve, (use a 19mm wrench to remove the brass fitting the burst disk sits in). Look for a burnt or dirty check valve, clean the hole where the valve is located; replacement valves are in the parts bag. Place small end of spring on valve and center it, replace the brass fitting, tighten snug.

Omega Supercharger check valve.Pressure gauge/auto shutoff

The high pressure air connection is shown by the pencil, the electrical connection is right above it.Bleed valve service

Bleed valve knob in the compressor.

The bleed valve has been removed from the compressor.

O-ring in high pressure air hose.Water pump not working

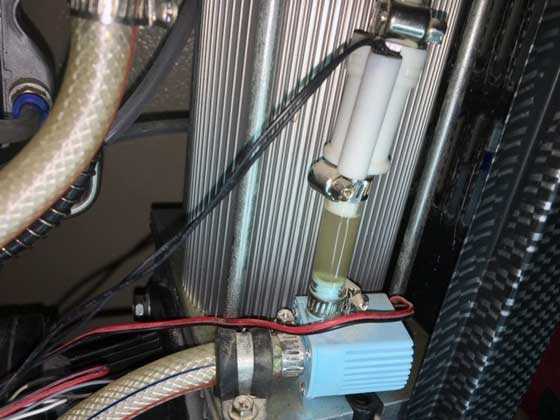

Water pump (blue) and flow valve (white thing above it).Air/water separator auto purge system

The pencil points to the 2 high pressure lines at the bottom of the air/water separator solenoid, there is an o-ring in each hose that should be replaced.

The black solenoid is off the air/water separator.

With the solenoid off the shaft, grab the shaft with padded pliers, unscrew it and pull it out from the air/water separator. See the parts that come out.

The purge timer (Self-Draining Adjust Device) allows the user to set how often the compressor automatically blasts moisture from the high pressure air line.The main piston assembly

Since I have not had to do mine (YET) I will not cover that procedure at this time.Maintenance

Magnetic plug.

This shows the location of the grease screw, and the burst disk, with the check valve located under the brass fittings the burst disk is in.

Human nature is — if a screw sticking up, it needs to be tightened. Please refrain from tightening this grease screw, except at the prescribed times, as it pushes lubrication into the compressor system.

Ian

Nice report. But I hope someone wanting to get into pcp’s doesn’t take it the wrong way. It makes it sound like these compressors are troublesome.

I have to say the ones I have and had have been very low maintenance and worked fine.

First was a Shoebox compressor that I had for about 5 years and it ran fine the whole time I had it. And my buddy has it still and has had no issues. And I even filled the Benjamin 90 cubic inch buddy bottle with it as well as guns.

And right now I have 2 of the China compressors that have been good. Got them because researched and found they fill faster than the Shoebox compressor. And they do. And like the Shoebox compressor. No issues.

And again nice report. I just figured I would state what I have seen with the 3 compressors I have owned.

Ian,

Short on time now but it looks like you did a bang up job for the report!!!! Look forwards to reading it when I get home this evening. I do remember Joe B. which I bought my air tank from said that they quit carrying Omegas due to all sorts of issues,… but that was several years ago. There seems to be lots of options out there now. I ended up with the Shoebox 10 which has been fine. Mine looks to have 30 hrs. on it from my log, which I log every time. Start fill/end fill/time. That gives me psi/minute ratio if you will and would be an indicator of performance/health.

Good Day,……. Chris

Thanks Ian, removing some of the mystery will help bring others along.

I used a hand pump for my two PCPs for several years until I bought a big bore. There was no way, so I picked up an AV compressor and a CF tank. With a little proper maintenance work, these gals should be putting out air for a long time.

45Bravo,

Thanks for shedding some light on the darkside. Sure seems more complicated than a Briggs and Stratton lawn mower engine! Who knew you needed a Masters’ Degree in Mechanical Engineering to shoot PCP’s? It is not that the Emperor has no cloths, just he/she just has old o-rings. This violates everything about, Keep it Simple!

I think I will just stick to my break-barrels….

Thanks for the report,

-Yogi

If you can work on a Briggs, you can keep a PCP, and the pump going.

Now, a television is a magic box.

How do you pull color images out of thin air?

I am a ham radio operator, and understand what it does, but the how is magic.

Ian

Ian,

Color? They have color now? 😉

B.B.

Yea, but I don’t think it’s going to last.

It’s just a fad, it will pass.

A flash in the pan if you will.

In our day we had 3 channels,

If the president was on, it was on every channel.

They played the National Anthem at midnight before sign off.

And if you woke up early, you watched the test pattern until they started broadcasting again.

Those were the days!!

Ian

I remember those days.

I appreciate the look at this as i have no experience dealing with compressors. I never liked the idea of PCP ecosystem and all the hassle, but chanced on Gauntlet .25 and while the 1900psi regulation seems to lend itself to hand pumping i am ok with that, but once i upgrade the tank and get to higher volume and 2100psi and Spring outdoor activity i can see a compressor in my future.

Likely i will end up with one of the popular Chinese models though you can never be sure what deals happen along anyhow i like having the information like has been provided in this report. I feel more comfortable with systems that are not maintenance free as they tend to be designed in a manner and with parts availability where maintenance free systems tend to be a real headache when they do fail.

Thanks for the report.

Wow, to quote Rodney Dangerfield: Tough crowd today..

This article is in no way meant to make the supercharger look bad, or turn people off of compressors for PCP guns.

No matter what pump you have, from a $40 chinese hand pump, to a $4,000 scuba compressor, they all require some maintenance, some require more than others.

And if you don’t use them regularly, like any mechanical device, things start to deteriorate.

I have a Air Venturi hand pump I keep for emergencies.

Handpumps are simple, effective, but require a lot of physical effort.

I have owned 3 different handpumps, and a shoebox before getting this compressor.

The shoebox was great, and I didn’t want to keep it in the grungy garage, but the noise level, and the support airless compressor meant using it in the house was not an option, if I wanted to stay married.

I looked at the watercooled chinese compressors, and have been following the threads on various online forums over the years about what the owners have to do to keep them running.

But like the shoebox, those compressors lend themselves to being in the garage due to the noise level, and the external bucket of water for cooling.

The Omega and the Air Venturi compressor, are very similar, in that they are both fully self contained, quality built, and capable of filling guns and large tanks.

This compressor sits in the corner, it has 1 cord that plugs into the wall outlet, it sounds like, and makes about as much noise as a dishwasher.

I was shopping for one of the new small ac/dc compressors being produced, but none of them are rated for filling tanks, when this compressor fell into my lap for a screaming deal.

With the plethora of new lower priced compressors coming to market, some of the larger older models will probably find their way to the used market at a significant discount.

This article was to give users an idea of what to expect if they buy a used compressor that has not been used in some time.

Ian

I didnt intend a disparaging response and genuinely “It’s not you its me” i absolutly despised the whole concept of PCP and needing all the stuff that ends up going with it as you worm your way into it. I didnt care if PCP was old or first you know so were steam cars. So i admit in years past i stirred the pot a few times. I am not a troll and i fully support anyone in whatever they choose to like or get into. I now have my Gauntlet and Chinese hand pump and oil and larger oil water seperator and just adjusting scope @ 50yds know it will go 75yds and perhaps a hundred and that’s with enough force to hunt small game andthat is more than i realistically expected. Easy well no but less work than i thought or viewed on Youtube so i think my $48 hand pump must be pushing a little more volume.

I say to anybody who thinks they might be ok with hand pumping you should by all means take the leap the exercise will be good for you. I know plenty of good unregulated guns are out there, but i think getting unregulated is kind of a bacvkwards step. I also know some fine guns unregulated and 2000psi are made with hand pumping in mind. What i have seen for years is people talking up not having to use a hand pump any more like it is some horrible task.

I say promote hand pumping a for instance my 1900 psi regulated GauntletGets at least 24 shots and takes less than 100 strokes to get back to 3000psi worst case 4 strokes per shot. I think that is a very fair effort to shot. I don’t know why hand pumping gets such a bad rap.

I know it might seem like i am wandering here but compressors just naturally take up different paths. PCP with hand pump kits and i am talking affordable ones need to make it into box store even at 0 profit the platform needs the public exposure. AFortitude gen 2 toned down gets hundreds of back yard shots per fill and get a few more of these in peoples hands and they are going to show friends & family.

I did not take it as such Mike don’t sweat it.

I Made every excuse in the world not to move to pcp’s.

And still love my vintage co2 guns for general enjoyment.

I used a hand pump for several years, I even tuned my Benjamin marauder down to a 2000 psi fill..

I always looked at it as 3 pumps per shot, and didn’t have a problem with that.

I grew up pumping my Benjamin 312 and other multi pumps 10 times for each shot, so as an adult I was only doing 1/3 the work!

When I moved to The AirForce platform, hand pumping a condor 500 cc tank for less than 30 shots made me look to tanks to be filled by the local fire dept.

I recently picked up a pcp match pistol, and decided to hand pump it, 55 pumps for 70 shots.

Not to bad, but I think it needs the regulator pressure set to a lower pressure as it comes off the regulator very early.

Since I have an endless supply of air again, I will fill it with my tank.

But always have the hand pump option.

I have never really been a springer guy, always multipumps, and co2.

I can shoot a springer, they are just not my personal preference.

I will never disparage anyone for what they choose to ride, drive, or shoot.

Ian.

Mike,

I just looked up the Gen II Fortitude. Pretty impressive! Mmmmm? I have a reg’ed (self done) .22 Maximus now. Me likes!

Chris

Mike,

I too use a hand pump to fill my Gamo Urban PCP. It only has a 105cc reservoir and takes about 50 pumps to go from 2000 to 3000 psi. Then I refill after two mags or 20 shots. I don’t mind using the hand pump at all but if I was shooting 100 to 200 shots in one session, the hand pump would not be fun. My hand pump is a $85 Chinese one also and it seems to be decent quality. Keep on pumpin 🙂

Geo

45Bravo ,

Good review , I am glad to hear there is someone to call on these . Condensate is the curse of any compressor.It looks like that Omega has to be used frequently , they are definitely for enthusiasts due to the maintenance and repair issues . Sort of like Harley Davidsons and old Air Cooled VW bugs !! If You don’t do some of your own maintenance be prepared to pay for repairs, this is the nature of the beast .

Gene,

Well said. The Omega Supercharger is very much like an older Harley (I had two) and a VW (I had many). They are great machines that need to be used a lot and maintained a lot. And they have been designed and upgraded to support that maintenance.

In contrast, the AV compressor sits on the floor of my garage and always is ready to go. It’s more of a Toyota of compressors — just use it.

B.B.

Yes, I agree, old technology.

This pump was made in 2014, so, 5 years old.

5 years ago there were no price point pcp’s on the market, and not many alternatives for compressors.

The number of low cost compressors coming to market in the last 3 years has exploded.

The more people that are needing fill alternatives, the more companies will figure out a way to fill that need.

At a lower and lower cost.

BB,

I have the AV set up on a garden cart with a PVC well pipe section to hold my tank when filling. I also have a large cartridge filter on my output to clean the air and remove the moisture just that much more. This is something I highly recommend. Your air cannot be too clean. PA has finally caught on and now stocks these.

/product/air-venturi-high-pressure-output-filter-fits-av-4500-psi-compressor?a=9097

RR,

I have one on the inlet side.

B.B.

BB,

Really? I guess that helps to keep the air going through the compressor a lot cleaner, but does not filter the compressed air moisture. I guess I will have to get another one now.

P.S. You can find Chinese HPA filters on line.

B.B.,

I will second the “Toyota” comment as an ’11 Rav 4 owner.

Chris

BB ,

I agree on that . I am fortunate that I have access to air . If I didn’t , I would buy a 6k nitrogen tank and adapter set and be done with it . Nothing to fix and no moisture issues. I have a 2300 psi nitrogen bottle I use in my garage that I regulate down to 90 psi for tires and airbrush use at 40 psi . I like the fact that there is no maintenance and I just bought my tank and regulator set . Also no noise !!

Excellent report Ian!

And YES – take pictures before disassembling and have an egg carton or muffin pan handy to put the bits and pieces in LOL!

Good advice. Most mechanical things benefit from regular use and routine maintenance to keep them in tip-top shape. I keep a computer spreadsheet of all the indoor & outdoor stuff that needs attention and make a point of referring to the list at the beginning of each month so that nothing gets forgotten.

I have an Air Venturi compressor and in looking at pictures of a number of “different” compressors it looks like most of them are made from common “off the shelf” parts (probably in the same Chinese factory) so your report is definitely applicable to lots of machines. ..Now I am going downstairs to looks for that magnetic bolt!

Compressors are great and so many to choose from these days! Filling a PCP from a SCUBA tank works fine and the dive shop was 10 minutes from work – did that for a couple of years. When I retired it was not practical to drive to the big city for a fill so I bought a compressor and find it to be very convenient – especially since some of my PCPs will accept a 200 to 300 bar fill.

Hank

Let us know if you find the bolt, and how it looked.

I am sure Air Venturi owners would appreciate it.

Ian

45Bravo,

That stuff on the magnetic plug can be sent to oil analysis labs since it usually catches more than just the Ferrous stuff. The manufacturers should be able to tell you what is wearing and if it is excessive…but maybe not since they don’t even seem to let the user know they use them!

Accessory oil filter?

Sounds like a report or an addendum at a minimum!

shootski

Ian,

I checked the manual and it makes no mention of the magnetic bolt. I also looked over the compressor as best I could without taking the panels off and couldn’t find one either.

Oils and water levels are good though LOL! 🙂

Hank

It’s on the right side at 3:00 location on my motor looking from the cooling fan towards the crankcase.

The silver knob in the photo below.

At least that’s the location on the Omega. Air Venturi May have chosen an other place or way to handle the issue.

Ian.

I checked again Ian, couldn’t see it but then It might be behind the cooling water reservoir.

Hank

OH!.. I have the open frame Omega and I have forgotten when I last turned it on. Maybe I should dig it out of the shed and give it some exercise.

Or dig out the Marauder pair and see if I can still hit a target..

Excellent work. thank you

Dritter

I want to know what happens.on both accounts. I say go for it. Noth’n like get’n in a little shoot’n time. 🙂

45Bravo,

You knew you were writing for a DIFFICULT GROUP, Lol! That’s why you worked so hard to make it a truly thouroughly documented report. Great picture to boot! We used to call them Hangar Queens and getting them back in an Up Status and flying always took a great deal more effort and typically a number of “exciting” Post Maintenance Check Flights (PMCF) than just keeping them flying to begin with!

You probably took heat because THE DARK SIDE brings out the worst in the Common Airgunners! Why? Because we early DARK SIDE adopters have that SECRET PACT to keep OUT the Springer/Sproinger crowd from the best stuff..MUH, HA, Ha, ha…..!

Actually if I ever found myself in a place without easy access to cheep HPA I would get the most robust compressor I could afford. I would still always fill my SCUBA and CF cylinders for the portability and immediate fill capability that they provide!

I color code all my connections/connecters with multicolor tape or paint dots and take photos just like you show. A video camera can help show steps on complicated procedures along with the sound track for verbal annotations.

I think you did a real service for your fellow Airgunners by doing this excellent guest blog!

thank you,

shootski

Shootski

Hangar queens. We called the cars trailer queens.

As it goes. Use them for how they were intended.

They were “Born to Run.” 😉

Thank you

last night I repaired my grandson’s electric pencil sharpener that for some reason suddenly just quit working.

(The plastic transmission housing came apart)

when I put it back together and everything was working I thought for probably the hundredth time I need to start recording things like this and start my own YouTube channel

I haven’t yet but I think it’s coming.

Now to figure a good name for it, since it might include more than airgun related stuff.

Ian

Ian,

I did read and fine job. I still include my original comment. You did inspire me to cycle the air compressor and the Shoebox,… which I normally do over the winter,… but I have not. That goes for shooting the PCP’s too,… even it is only a few shots, 2′ into a box/stop. I aim for 1x per month in the off season.

Chris

Thanks, Ian, for the fantastic report and instructions & pics for those of us who aren’t so mechanically gifted — excellent article. This article and all the responses are keepers — what a wealth of “inside” information & experience! I’m afraid I’m one of the ones who doesn’t use my Omega enough (2015-2016 build) and I obviously need to start running mine as you mentioned on a regular basis to keep the o-rings and seals pliable. I think I only filled my bigger tank just once last year. One question to be clear, though it might seem like a dumb question — when you say to run it for 10+ minutes on an every-few-weeks basis, you mean to run the actual compressor and not just the on switch to circulate the coolant — correct? Thanks again so much….Jeff