by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- TX2 valve for .45 and .50 caliber Texans

- Old rifle, fresh test

- “New” bullets

- The TX2 valve

- Power setting

- Seat the bullet in the rifling!

- Velocity

- One more velocity lesson

- Summary

After writing Part 2 of this report last week I went to AirForce last Friday morning and spent a couple hours with Ton Jones, talking about the Texan and the new TX2 valve and carbon fiber tank. I took my Texan that was made in the first production run, and we attached the new tank to it. That answers the first question — does the new tank fit older Texans?

|Ton Jones set up my .45 caliber Texan with the new carbon fiber tank and the TX2 valve.

The TX2 valve boosts power and currently only the .45 and .50 caliber Texans work with it. There is also a difference between the valve cap on the .45 and the .50 caliber valve, so to use the same tank on both airguns the cap needs to be exchanged.

Old rifle, fresh test

Reader Chris USA mentioned that my last report on the Texan was in August of 2015. Yes, it was. The accuracy and velocity data I have given you thus far came from those reports. Since there is a new tank and valve, I conducted new velocity testing with my same rifle and a new tank last Friday. I will cover that later in this report.

“New” bullets

Chris also suggested that I try some of the “new” lead bullets that are being made for the Texan. I hope to do a little of that, but since conical lead bullets are 160 years old, there isn’t really anything I haven’t seen. I think what Chris is really asking for are my comments about some of the bullet makers who are in the market. What I see is a lot of guys who don’t know lead bullets are responding to things the sellers are telling them.

Twist rate

Well, one thing I learned last Friday was the newer Texans come with a barrel that has a twist rate of one turn in 30 inches. They have done this to accommodate the heavier bullets people seem to use. I don’t know what the twist rate is in my barrel and AirForce asked if I wanted to change over, but my rifle is so accurate now that I want to leave it as it is.

The TX2 valve

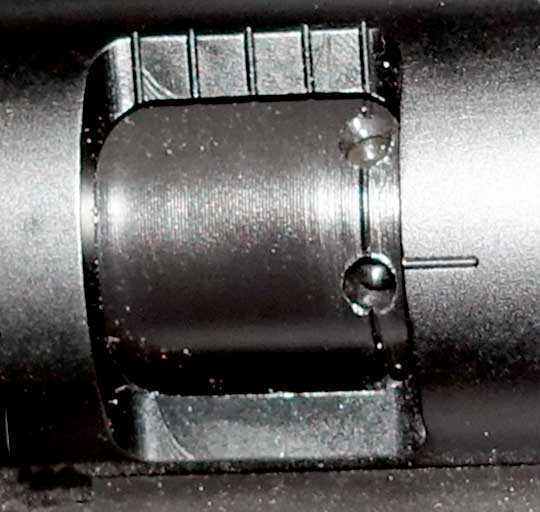

The TX2 valve is unique in that is has no spring to push it closed. It relies on air pressure alone to do that.

Power setting

In Part 2 I showed the power setting I used for my tests in 2015. Well AirForce has changed the power setting mechanism and Ton told me my rifle was set wrong for the TX2 valve. The index mark needs to be between the first and second notch on the right for heavier bullets and never past the second mark for anything. Since heavier bullets remain in the barrel longer than light ones, They maintain back pressure against the firing valve — holding it open longer.

So we set it as high as it would go. That means the most spring tension on the striker. On newer guns you may lose sight of the index mark when you reach the end of the adjustment range.

The power adjustment wheel is turned as far to the right as it will go — putting maximum tension on the striker spring. This was set for the lightest bullets we tested.

These are the power settings on the Texan power adjustment wheel. According to Ton Jones you should never go lower than the second mark that’s shown as 3/4 power in this picture when using the TX2 valve. You want to make that setting your lowest point for the standard tank, as well.

Seat the bullet in the rifling!

If there was one big mistake I made in part 2 it was showing you a bullet laying in the loading trough and telling you that the bolt would push it home. Well, it doesn’t work that way. I’ve gone back and corrected the language in Part 2 and now I have to tell you how important it is to manually seat each bullet into the rifling. I knew that from testing the TexanSS in 2018, but for some reason I reported it wrong in Part 2 of this report. And some bullets present problems, as well. For example, the semi-wadcutters that were the most accurate in my Texan want to enter the breech tipped on an angle unless they are pushed into the rifling. Their angled nose is the reason for this. Once the front band of the bullet encounters the rifling, it squares up the bullet with the bore and everything is okay. You also get more consistent velocity that way.

Ton Jones seats a bullet into the Texan rifling. If you can stand the rifle up and the bullet stays in the breech, it’s seated okay.

The slanted nose on this semi-wadcutter bullet makes it want to tip over when seated into the Texan breech.

Once the front band of the semi-wadcutter bullet was in the rifling, the bullet was square with the bore.

Ton took me outside and let me listen to a shot with a well-seated semi-wadcutter. It bellowed , which is how you know it’s seated right. And I heard the bellow through my electronic noise-suppression headphones.

Velocity

Okay, I said that the TX2 valve gives fewer shots than the standard valve. Let’s see. We’ll check the velocity with a 490-grain flat nose bullet made by Mr. Hollowpoint — Robert Vogel. There you go, Chris!

The tank was filled to 3600 psi and the gun was fired. The bullet went out at 776 f.p.s. That’s 655 foot-pounds at the muzzle. We topped it off a second time and the next bullet went out at 778 f.p.s. for 658.74 foot-pounds. This time we did not refill the tank.

Shot……Vel.

2………..763

3………..731

The tank registered 2590 psi after three shots. We then went outside and Ton fired shots 4, 5,6, and 7. On shot 7 there was a partial tank dump and on shot 8, with just 800 psi showing on the gauge before the shot, the tank dumped all its air. I would say shots 4 through 7 were good enough for finishing shots on game that was down.

One more velocity lesson

Ton filled the tank to 3,600 psi and loaded and shot a 210-grain bullet. It went out at 620 f.p.s. That left 3300 psi in the tank. He told me to watch what happened to the velocity as he shot more.

Shot……Vel.

2………..660

3………..726 3130 psi remains

4………..795 3050 psi remains

Velocity is increasing as tank pressure drops since there is no valve return spring to close the valve. Want a lot of shots from a big bore? Here they are! And, if you want to increase the velocity — reduce the pressure in the tank!

Summary

We’re just getting started with the Texan. It’s a big bore with performance you can stretch! I have a lot more to tell so don’t go away.

B.B.,

So your barrel is specifically for 210 grain semi-wadcutter bullets only? What sound does it make if the bullets are not seated properly?

Siraniko

PS: Section Seat the bullet in the rifling! Last paragraph first sentence: “Ton took me outside and let me listed (listen) to a shot with a well-seated semi-wadcutter.”

Siraniko,

Fixed it. Thanks.

B.B.

That cast semi wadcutter looks a lot like the H&G 68 (Hensley & Gibbs) 200gr I used to use in my .45 acp in 3gun competition..

Maybe a little shorter, what weight is that semi wadcutter?

I am not versed in tha big bore airgun world, but have experience in handguns, and blackpowder rifles and pistols.

And have thought some of the projectiles used in those hobbies MIGHT cross over to bigbore airguns since they are shot at similar velocities.

But the airgun companies would have to adapt the twist rate to their preferred projectile.

Ian.

Ian,

For some reason I have written and said it’s 215 grains, but it’s actually 210 grains.

B.B.

Ian,

Many of the PB lead bullets are indeed used by big bore airgunners. Many will buy Lyman, etc. molds and cast their own.

BB,

I find it interesting that you stated the twist rate of the new Texan barrels are 1:30 for those long and heavy bullets. I would have thought those projectiles would want to be spun faster. This is encouraging to me as my HM1000X supposedly has a 1:26 twist rate. I guess I am going to need to try some large lead downrange.

RR,

I was just telling you what AirForce told me.

B.B.

you are correct for PB rifles with long and heavier bullets. with an airgun can it be different? I would not think so

BB,

Thanks for considering/trying different projectiles. The 1:30 twist rate is interesting. Most opinion seems to be faster twist,.. but that could be for smaller caliber projectiles, moving much faster. Choked and not choked is also debatable,.. with most leaning towards non-choked.

The lower the pressure = more velocity and more? shots is interesting too. That makes me think of the typical partial valve lock situation. You only did 4 shots,.. but from the tank pressure and fps,.. you look to have quite a bit more left.

“I think what Chris is really asking for are my comments about some of the bullet makers who are in the market. What I see is a lot of guys who don’t know lead bullets are responding to things the sellers are telling them.”

Like I have said before,… it is hard to keep up on. I think it is a mix of both. Some slug makers also do their own testing and post results. Others do not cast,… but try many slugs in many different guns,.. or the few they have,.. if they only have a few. Results get posted by the shooter/slug maker. Trends develop, opinions get formed. As with pellets,.. your “mileage” may vary.

Like anything,.. you have to separate the experts from the arm chair engineers and good accuracy posting from the posers/BS’rs. Also, bands, no bands, how many, where, lube, no lube, what lube????? etc.. Cupped tail, flat, boat tail?

The “overall” trend is shooting more accurately,.. much further. A fellow on another site just posted 5 (10?) shots that a quarter would cover,.. at 100 yards. No shortage of pics and data from many shooters running the gamete on expertise for several years now.

Fit to bore seems critical,.. with .215″, .216″, .217″ and .218″,.. as an example. Since pellets can vary quite a bit, I am not sure slugs would vary any less in size. Sorting .25 pellets,.. I usually find at least 2 sizes, roughly a 50/50 split, using the Pelletgage.

I will say,… that semi-wad cutter slug looks quite rough. To what effect that has,.. or does not have,.. on accuracy/flight,.. I do not know. Some commonly sold slugs are quite smooth.

All in all,… very interesting and looking forwards to more Texan testing.

Chris

Edit: Just looked up that group mentioned in my post. .30 cal, 45 grain, PELLET, 1065 fps, 18 shots, slightly bigger than the quarter shown besides the group. The poster was illustrating that higher fps may not always hurt pellets.

Which is another debate for slugs. What velocity works with what?

Chris,

Good post! Lots of info!

Seems that (in addition to tolerances) the barrel manufacturers are taking a fair amount of license with the internal dimensions, hence the need for slugs of slightly different diameters and the necessity for searching for the right “fit”. A set of sizing dies could be useful.

Think that how the slug fits the leade (or doesn’t) is a big factor in accuracy. Since the seating depth is controlled by the probe (which is usually not adjustable and also subject to manufacturing tolerances) finding the best slug (length and design) is important. There’s an after market adjustable probe for the Impact, I am thinking about making something like that.

Designs aside it looks like the main difference between slugs and bullets is in the base, with airgun slugs usually having a bit of a “cup”.

Pellet guns are designed to shoot pellets, IMHO, shooting slugs out of one is a bit of a “square peg in a round hole” senerio. Given enough power, it can be done but there are lots of other considerations. Heavy pellets and light slugs (like the FX Hybrids) are doing a lot to address that. Can see dedicared “slug guns” hitting the market real soon. I do like the FX STX barrel system and the ability to change barrel liners for different twist rates inexpensively.

Exciting stuff!

Hank

Hank,

Yes, many factors. I too see dedicated slug shooters coming. X fill, X power setting, X fps X barrel/twist,.. will shoot X grain/type slug very well yielding an X FPE.

Targeting a desired FPE could also be another factor in gun/slug specific builds. While a specific build may shoot a 50 grain slug well,… I am not sure that it would also shoot a 100 grain slug well. Something like a non-adjustable hard part may also be required (new barrel/twist). In other words,..a power adjustment alone,… may not get the job done.

“,….. barrel manufacturers are taking a fair amount of license with the internal dimensions,….” Yea, that too. Not to mention all of the variation in rifling designs,… conventional, polygonal, smooth twist, X twist,.. and it keeps going.

I have seen a few people that shoot slugs a lot,.. start to come up with variation/commonality charts that are working with air guns and slugs. No doubt, FX and other’s are already doing the same.

A lot of very smart people are doing this daily and lots of successful air gun slug accuracy/performance information is already out there. The problem is that it is all over the place,.. for the most part. Progress is getting made.

Like you said,.. “Exciting stuff”.

Chris

Chris

That’s why I keep telling you that you can get more shots and velocity out of your regulated Maximus if you lower the regulated pressure and mess with the striker spring pressure. (add more spring pressure)

At lower pressure its eaiser to knock the valve open to allow a longer duration of air flow. Think about how the camshaft and valves work in a car engine. How long the valve is open (duration) and lift of the cam. How long the valve stays open to let the air into the cylinder and how far the valve opens all changes the way the engine runs.

Its basically the same in a air gun but controlled differently.

BB, I notice there is no plenum on the Airforce valve train.

Is this because the bullet weight determines how long the valve stays open, so one isn’t needed?

It seems like a simpler system than a regulated gun, more suited to the needs of a hunter than a target shooter.

But , you’re shooting wadcutters, they make an easier to measure score, but also slow down in soft tissue better

than a pointed shape, potentially delivering more energy to the game. Dual use design, I guess.

Seems like these traditional bullet forms main advantage is they are relatively easy, less expensive to make than

some of the high tech jacketed P.B. designs. which is a good thing. Loading that monster looks like a scaled down naval gun!

Rob

Rob,

Yes, the bullet weight does determine how long the TX2 valve remains open.

B.B.

B.B.,

Off today’s topic, Sorry.

I finally got around to trying (key word here is “trying”) my Sharpshooter, and like most air guns I get, it has a problem. I can’t get the gravity fed shot tube to work as there is an obstruction just before the feeding hole. It is no doubt a misshapen lead ball jammed in there. (My Sharpshooter came with a bunch of #6 lead shot.) At first I was able to force a misshapen lead ball out using a section of wire coat hanger as a ramrod, but the very next lead ball also jammed. That suggests to me that there is a narrowing in the shot tube just before the feeding hole. This newly misshapen lead ball is so wedged in there that I can’t force it out with my wire coat hanger ramrod.

I applied Ballistol to the inside of the shot tube with first with a pipe cleaner and then a couple drops of the stuff straight into the top slot. Now it is stood it up on its butt end, mocking me. My hope is the Ballistol will penetrate the spot and loosen it up, but even if I can get the mangled lead ball out, the next one will simply jam and get mangled just like the first and second one.

Any ideas?

Michael

Michael,

This happens to me with some guns. Bend a tiny hook (just a 90 mdegree bend that’s 1/8-inch long) on the end of a paper clip and get around and behind the ball to dig it out. You can also pull the trigger almost all the way and come up through the shot hole that way to pop that shot out.

BB

B.B.,

I might be wrong about what’s in there, because when I look closely at the shot hole and pull the trigger, as the “bolt” slides butt-ward, there is a short gap and then another something appears in the gap from the muzzle end. It seems to be part of the mechanism, and that seems to be what is blocking shot from loading into the carrier.

Regardless, I have tried many times to dislodge whatever is in there from each direction, and no-go.

Is there another part that sits in the shot tube ahead of the lead ball as it is supposed to drop?

Michael

Michael,

Yes. That part is the sear separating the balls into just one.

BB

B.B.,

I cleared the jam finally, TWO mangled lead round balls. Then

1. I loaded a single round ball and it shot.

2. I loaded another round ball, and it got mangled by the pistol’s action.

3. I cleared that one and loaded another, but that one got hung up somehow and wouldn’t drop. I gently prodded it from the muzzle end with my homemade ramrod, it dropped into the carrier unmangled, and then it shot.

4, I loaded yet another ball singly, and it got mangled like the others, by the pistol.

So, a lemon from yesteryear, I guess. I’ve had a lot of those. :^( Any ideas that don’t involve a peening hammer and a driveway?

Michael

Michael,

Without looking up how it is put together,.. can’t you just take it apart and file a bit here and there? Or open up a tight spot here and there.

Also, it sounds as if the shot size is varying a bit.

You can fix it! 😉

Chris

Chris,.

It is tack welded together. It is non-maintainable.

B.B.

Michael,

Just keep on shooting it. It needs the use.

BB

B.B.,

I’ve attempted to shoot it now about a dozen times, more or less, and most of the time I worked under a bright desk lamp and closely examined things as I went.

The sear is digging into the lead ball and misshaping it pretty severely, almost every time. Then the ball is too out-of-round to drop through the shot hole into the carrier. I can usually then gently nudge the mangled ball slightly and get it to drop onto the desk.

If I cock the pistol with no ammo, I can carefully place a lead round ball directly into the carrier with tweezers and shoot it that way. That is no way to shoot the pistol for fun as it takes about a minute per shot, but it demonstrates that the sear is the only issue. I did try lubricating the round ball with Ballistol to see if it might just slip beyond the sear instead of getting pinched by it. But nope, that made no difference. I suppose steel shot might work as it would be too hard to be misshapened. If that doesn’t work, then this is just a lightweight paperweight.

The smallest quantity of shotgun shells I can find in any gauge is 25 shells for $25-$35, so unless anybody here happens to have a spare shell with #6 steel shot they wouldn’t mind cutting open. . . I guess I’m leery of throwing good money after bad.

Michael

BB,

This comment made it to my mail box,.. but not on the blog or the Comment RSS scroll,

Hey Chris USA,

B.B. Pelletier replied to your comment on AirForce Texan: Part 3. Comment content:

Chris, I tested supersonic flight against accuracy for diabolo pellets in 2007. /blog/2007/03/whiscombe-rifles-and-barrel-harmonics-part-5more-accuracy-questions-plus-a-look-at-airgun-power/ BB

Reply to this comment: /blog/2020/09/airforce-texan-part-3/#comment-461493

Yes, I remember reading that one and always keep that in mind when discussing high fps and Diabolo pellets. You refer to it on occasion in blogs.

Chris

Chris,

I deleted that comment because it is wrong. I did a test with a Whiscombe in 2011 that proves that supersobnic pellets are accurate.

B.B.

https://www.amazon.com/Spardar-Insulated-Stainless-Automatic-Cigarette/dp/B06XW91Y16

with a way smaller boiler.

?

Steam,

Don’t go anywhere,… I like the way you think. 🙂

I would still go with a PVC set up, aluminum foil burst disc and hard plumbed steam fittings.

Oh yea,… maybe stand back a ways on the first test,.. or two…… 😉

(your foil burst disc would be the limiter/safety)

Chris

PVC is a good idea. Maybe just supply of feedwater to the boiler for simplicity.

B.B.,

Tantallizing dissembling on the T2X valve!

So if it is a partial Spool Valve just mumble a few incomprehensible words and I will understand they are treating that very fact as proprietary information…Lol!

Climbing MV as tank pressure goes down!

Indeed!

shootski