Marksman model 70 breakbarrel rifle.

This report covers:

- What BB doesn’t know…

- Today

- Cocked the rifle for the first time

- RWS Hobby

- Replacing the breech seal

- Now for the Hobby string

- Firing behavior

- Crosman Premier pellets

- H&N Baracuda Match with 5.50 mm heads

- Cocking effort

- Trigger pull

- Discharge sound

- Summary

Today we look at the velocity of my new/old Marksman model 70 pellet rifle. Remember — this is a .22

What BB doesn’t know…

… could fill a blog. And sometimes it does. As I mentioned in Part 1, this model 70 is the first Weihrauch/Marksman/BSF air rifle I have ever physically examined. Years ago when I first read about Weihrauch buying BSF and then Marksman brought out the Weihrauch-produced models 55 and 70, I felt certain they were just putting their name on BSF models 55 and 70 with a few Weihrauch parts thrown in. I even said that in print more than once. But I wasn’t even close!

As I stated in Part 1, this model 70 is an 8-pound rifle. My BSF model 70 weighs 7 lbs. So, right there the differences begin. Read Parts 1 and 2 of this report to see more.

Here is the deal. When this was happening (Weihrauch making the models 55 and 70 for Marksman) they were also making their own model HW 55 — a target rifle. Why wasn’t the Marksman model 55 a copy of that HW 55 rifle by another name? BB just didn’t think it through, plus now that he has his hands on the real deal, he can examine it closely. I have been making this same mistake for a long time and I have to be more careful-er!

Today

Today we look at the velocity of the rifle I’m testing. Once again, it is a .22, and according to the manual that came with it the velocity should be about 740 to 780 f.p.s. We will see how close that is today. I will shoot a lightweight pellet, a medium weight pellet and a heavyweight. And I will measure the cocking effort and trigger pull as it is currently set. Remember, too, that this rifle has a Rekord trigger than I can adjust to whatever I want, as long as it’s safely within the limits of the trigger’s design. Let’s get started.

Before I begin recording the velocities I will shoot 5 shots to wake up the powerplant. As far as I know the last person to shoot this rifle worked at the Weihrauch factory in the 1980s.

Cocked the rifle for the first time

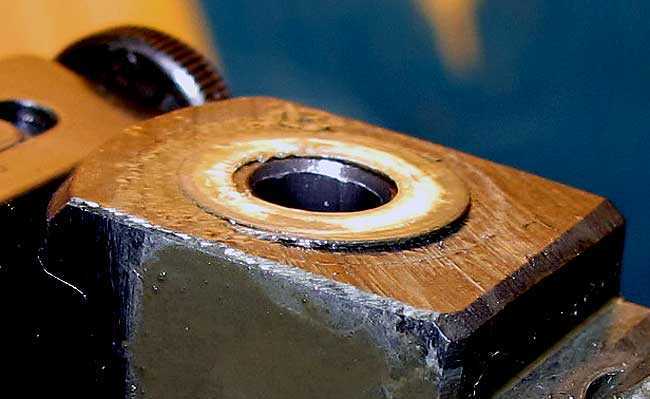

When I first cocked the rifle I noticed that the breech seal was dead flat. Well, this rifle was made before some of you were born, so that’s to be expected. Fortunately I had some Weihrauch breech seals on hand, so I replaced it.

Yes, the breech seal is flat.

RWS Hobby

First two shots of RWS Hobby pellets were 703 and 711 f.p.s. That old breech seal had to be replaced.

Replacing the breech seal

When I pried it out, the old seal crumbled into waxy pieces that had to be pried from the hole individually. The new seal went in and I resumed testing.

The old breech seal came out in pieces. The new one slipped right in place.

Now for the Hobby string

Ten RWS Hobbys averaged 715 f.p.s. with the new breech seal in place. The low was 709 and the high was 724 f.p.s. — a difference of 15 f.p.s. At the average velocity the Hobby pellet generates 13.51 foot-pounds of energy. And the old breech seal was apparently doing fine.

Firing behavior

The rifle groans when it is cocked. That sounds like the mainspring interacting with the rear spring guide.

I don’t need to slap the muzzle to start breaking the barrel. That is a relief!

The rifle has a slow buzz after the shot. It isn’t objectionable, but I want to deal with it.

The barrel does not remain in place when the rifle has been cocked. That has to be dealt with when I strip the action. I want to takethe rifle apart just to see the insides, and of course to see how this safety interacts with the Rekord trigger.

The trigger is set a little heavy, but it is very crisp. I’ll leave it where it is for now.

I like the lever safety over the standard Rekord button. It comes on positively and there is no increase in cocking force when it sets. It’s also very easy to take off with my trigger finger when I shoulder the rifle.

Crosman Premier pellets

Next up were some 14.3-grain Crosman Premiers. They averaged 627 f.p.s. with a spread from 614 to 634 f.p.s. That’s a difference of 20 f.p.s. At the average velocity Premiers developed 12.49 foot-pounds of energy.

H&N Baracuda Match with 5.50 mm heads

For the heavyweight pellet I selected H&N Baracuda Match with 5.50 mm heads. Ten of them averaged 559 f.p.s. The spread was tight — from 557 to 561 — a difference of only 4 f.p.s. At the average velocity this pellet developed 14.67 foot-pounds, which was the highest in the test.

Cocking effort

The rifle cocks with 28 pounds of effort, with a spike to 35 pounds at the end of the stroke when the Rekord trigger is cocked.

Trigger pull

The 2-stage trigger has a 14-ounce stage one, followed by a crisp 2-pound release in stage 2. Well shut my mouth about it being heavy! It is ideal!

Is the rifle breaking in?

Of course this rifle is breaking in, but what I’m asking is the velocity going to increase as I shoot? To test this I shot three more Hobby pellets with these results.

710

712

709

It doesn’t seem to be gaining any velocity. I do think I need to look inside the powerplant to see how things look. The mainspring could be kinked, just from setting all those years.

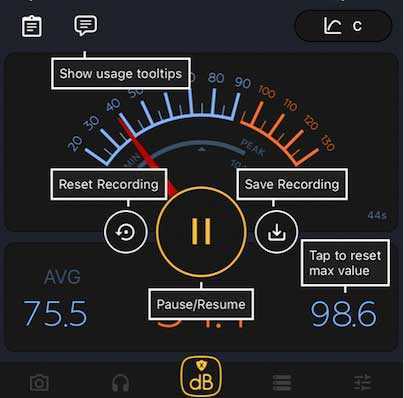

Discharge sound

Using the sound meter app on my iPhone, the rifle discharged with 98.6 dB of sound. It’s not backyard-friendly!

Summary

I learned a lot from this test and plan to use it as a baseline for future tests. But first I will shoot for accuracy with the open sights.

B.B.,

I’m fascinated by your blogs on your Marksman model 70 for so many reasons, I.e., I’ve never owned one, it was produced during a hurricane of major airgun companies acquisitions and manufacturing consolidations and the model 70 was marketed as a magnum springer. Thanks for your commitment to shed more light on this critical era in airgun history and your willingness to go inside this old power plant to discover what’s happening. The cocking effort vs velocity seems off.

ps-allow me to play siranko for a day and say that the caption under the photo should be a model 70 not a model 72

Kevin,

Fixed it. Thanks,

BB

B.B.

A .22 pellet going 740-780 fps, would that not be a magnum springer? In .177 it would surely break 800 fps. Sounds like the manual is modern advertising…

-Y

BB,

Since the breech seal was waxy and crumbly, what kind of shape is the piston seal in? I know we will find out soon and it seems to be doing its job, but it may be something to keep in mind. As for the spring, I would be surprised if it did not have a little kink in it after all these years.

The trigger. I myself would really like this Rekord over the new ones. The only reason I can think of moving the safety is it would simplify the trigger assembly, which may have had issues with the safety located within. I cannot remember off the top of my head, is the Air Arms TX200 safety located within the trigger assembly?

RR,

The automatic safety (yuk) on the TX200 is a (left/right) sliding pin on the back of the spring tube.

Hank

Eewwwh! That is the one thing I hate about the Weihrauch.

Which Weihrauch RR? Mine have a manual safety.

The Walther Dominator 1250 had (past tense – it has been “fixed”) an automatic safety with a safety on that (go figure eh?). You had to press a button on the safety in order to be able to release the safety.

Guess that is what happens if you let lawyers design guns. LOL!

Hank

Hank,

My grandson’s HW30S. It has a little button on the left top rear of the tube you push to the right. It is automatic. If it was mine, it would disappear.

Hank,

Well, either yours are older ones or have been tinkered with.

RR

I have a pair of HW 100 PCPs (.177 & .22) with a manual lever safety.

I am used to the auto safety on the TX200 and the FWB 124 and don’t think about them, still it would be nice if the manufacturers would have left them as manual.

Hank

Hank,

OK, I remember now. The safety on their sproingers works like the TX200.

There used to be an after market safety lever that also made the safety resettable, but I can no longer find it.

If I end up with another Weihrauch sproinger, that safety is going away.

An interesting window into the past. Looking forward to the following chapters.

On a related airgun note- one more week until the Flag City Toys That Shoot show in Findlay, Ohio. This is the fifteenth edition and is greatly enlarged over previous years. One hundred plus tables in twice the space. I have learned a lot over the years by attending this show. Looking forward to a great turnout!

Oooh! Right now, so close to Findlay and yet so far away in a week’s time! That’s the way the Fickle Finger of Fate works for FM.

BB

I’m thinking you are saying the barrel is loose in the lock up position. We are about to find out how much this affects accuracy before and after you fix it.

Deck

Deck-

I guess I read ‘barrel does not remain in place’ to mean the barrel, at the end of the down cocking stroke, is not retained down and is free to swing back up? This, as opposed to a wiggle when the barrel is latched in the up position.

PAC

So the sear isn’t engaged?

Enjoy the Findlay event. Wish it were near me.

Deck

Paco,

Yes, that is what I meant. When the barrel is lifted after cocking, it does not stay in place. The barrel is tight in lockup.

BB

BB, I remember the Marksman adds suddenly started to appear in the mid eighties in the Airgun magazine I would get, mostly because of the American celebrity who was the face of the domed pellets and line of Marksman air rifles that went with them. (Glen Cambell?) I suppose they were rebranded HN pellets, I thought they were nicly accurate in my buzzy R10. I am still trying to find an example of a spring piston gun where the transfer port exits verticly into the barrel. TheFWB 124/127 tp is off center with the bore, but seems to exit in a conventional manner.

I see that balancing the weight of the piston, the stroke, and spring force and tp size is a big part of all the tuning. Seems like there’s allot of math..so I just hope the manufactrers get it right ’cause I wont be able to.

Rob

Rob

How do we know if they got it right from the factory.

The only way to know is if you make changes and see if the gun gets better or worse.

GF1,

As a kid, I used to chamfer and polish (the piston side) of the transfer port as part of the “power tune up” on my springers. Large springs and/or preloads were also part of that work.

Hank

Hank,

I like the idea of chamfering and polishing the transfer port, but I want to shorten the spring and calm it down a good bit. My Tomahawk has a very solid “THUK” right now. I would like to start trimming the spring down until it calms down a bit and hopefully improve the accuracy and lessen the hold sensitivity.

Hank

I like the chamfering idea but polishing tends to cause heat.

We found that our when we was kids hopping up our dirt bikes and RC airplanes and when we was building the muscle car engines.

Hmm maybe your polishing might of had the gun running right on the edge of detonating. Maybe it was giving you more power.

Just a maybe but something to think about.

GF1,

The polishing was done with a (manual) hand drill, a wooden dowel and some polishing compound. The idea was to round off the “sharp” corners of the chamfering and smooth out any tooling marks. Essentially making the TP a bit of a venturi. The TP was not deliberately enlarged but it always ended up a bit bigger.

There was no danger of detonation, the springs were (unfortunately) not that strong LOL!

We didn’t have a chronograph but in our “shoot vertically and time to the pellet splash down in the river” test a power tune would gain me 20-25%. Guessing at 425-450 fps after the tune.

Hank

Hank

Right probably not close to detonation.

But we would have engines over heating after we would polish the runners on a intake manifold. We stopped polishing the exhaust runners too in the heads.

Port matching was the trick and tear dropping the valve stem guides was the big trick.

Polishing always caused more heat. But in a airgun I imagine it doesn’t do much to make that happen when polishing. But then again you never know. And what effect would it really make. Just stuff to think about.

Maybe the pumping heat affects pump guns too. Maybe that is what gives inconsistent shots sometimes

All I know is a lot of experimenting needs to happen to7reallyknow the end results.

Folks,

Here is an update from June 2, 2021, on my endeavor for a low pressure airgun. My goal is a backyard plinker, using a typical garage or shop air compressor. As it evolved I set myself up to get 500 fps using 100 psi air pressure with an available light pellet. The Air Arms Falcon .22 Cal, 5.52mm, 13.43 Grains, Domed pellet was selected and that is the only pellet I remember testing so far. On my first attempts with different valves I found in my junk bins I came up with around 400 fps with the best of the bunch, a typical garden hose nozzle with a handle to open the valve. After that test I decided to build a valve that would have extra volume and a seal that would open quickly and stay open all the while the pellet is in the barrel. From my recent testing I believe both of those goals were achieved.

Early in the tests I said getting 500 fps with 100 psi should be easy. Well maybe not. So far I have been stuck at just under 440 fps with my various tests on my valve. I tried holding the valve wide open with a latch; it made no difference in the pellet velocity. Next I removed the return spring from the valve to allow it to open faster, also no change in pellet velocity. That does not mean a valve that opens faster would not help but I think it would be minimal. I may still try a stronger hammer spring in the future if I have no luck with my next tests. Removing the valve return spring did allow the seal to slam against my valve stem guide and destroy my seal. So I had to make new seal along with shaping and tuning. I won’t try that again.

I have set myself up to get the 500 fps at 100 psi using the Falcon pellet. Obviously a lighter pellet or more psi would make the task easier. I see two ways to increase the velocity:

1. A longer barrel (I don’t have one longer than the Maximus barrel)

STOP:

I went to measure the barrel I have been using and it is a Crosman 2260 barrel. And I am out of .22 caliber Maximus barrels. Now I need to decide which gun to rob a barrel off of. It looks like I will be taking the barrel off of my Crosman 101 rifle even though I spent good money to have it machined to fit the 101. It was selected because it only needed one screw loosened to get the barrel off and no disassembly. Hope I do not damage the barrel.

June 4, 2021, I have learned a few things. First my valve has not been the same since I used it without the return spring. I have polished the seat and tried different seals but so far they all leak. I need to lap the new seal with some polishing compound to get a good seal. That will require disassembling the gun and the valve so I can clean the inside of the valve and not get the polishing compound in the barrel. I have not done that because taking the gun apart is easy but getting it back with all the parts in alignment is hard. The valve leak tends to push the pellet down the barrel some unknown distance before I can trigger the valve. In general not enough to matter I think.

2nd I tested the new seal in the valve with the 2260 24 inch barrel and the Maximus 26 inch barrel using 100 psi and 10 shots.

For the 24 inch barrel I got an average of 434 fps and a spread of 5 fps sd dev 1.58.

For the 26 inch barrel I got an average of 433 fps and a spread of 12 fps sd dev 4.93.

The valve was acting up more with the 26 inch Maximus barrel. Any increase in velocity was insignificant.

The following tests are all with the 26 inch Maximus barrel.

Next I tried a heavier and longer hammer spring. 5 shots gave me an average velocity of 437 fps with a spread of 2 fps. Again not significant.

Next I decided to try different weight pellets to get a feel for what is going on.

34 gr pellet 234 fps

25 gr pellet 311 fps

18 gr pellet 372 fps

13 gr pellet 435 fps

9.6 gr pellet 438 fps non lead

1.0 gr Beeman cleaning pellet 527 fps (guess at weight)

The 25 and 34 gr pellets required seating deeper than my 0.42 inch probe to even shoot.

So now back to point 2.

I started to make this point above when I realized I had a shorter barrel than I thought. I probably knew when I selected the barrel but forgot right after. That means some of my previous calculations such as pellet barrel time are using the wrong barrel length.

2. The only thing left that I can figure in my quest for 500 fps with 100 psi using a 13.43 gr lead pellet is to make the air transfer conduit from the valve to the barrel shorter, smoother, and with a larger diameter. Shootski has mentioned this a few times already. I have not done this earlier because I did not want to destroy a Maximus barrel. The 2260 barrels work basically the same and I have a few of them so I can cut the barrel in front of the transfer port in the side of the barrel and then make a short leade. Now I can eliminate my hollow probe, which must have a smaller diameter than the barrel. That was my original design. Below is the diagram again.

Will the new air transfer conduit make that much difference? I don’t think so but it is my last chance. Based on enlarging the transfer ports on other air guns it will help but not make a 65 fps difference.

Based on my testing it would take about 135 to 140 psi for 500 fps using the Falcon pellets. I no longer think 500 fps is easily attainable, maybe with a machine shop and laboratory.

In hindsight I could have been happy with 435 fps and focused on tuning for accuracy. But it has been an adventure. I will follow up with the barrel and air port modifications down the road.

Don

Well I finally achieved part of my goal I just tested some Crosman SSP lead free pointed pellets. At 100 psi `10 shots gave an average of 509 fps with a spread of 7 fps and std dev of 2.17. These pellets fit a little loose.

It was not with lead pellets or even ones that are still available though. This is with the Crosman 2260 barrel back on the gun. I think it may be a little larger bore than the Maximus barrel so less pellet to barrel friction. And I cleaned up some of the rough transition I still had from the valve into the probe.

So can I squeeze 500 fps with 11.9 gr RWS Hobby pellets? I don’t have any right now but that may be my only chance with a lead pellet.

Don

Don,

This is really an awesome experiment. I am certain that it has been done many times in the past, but I can well imagine this is most fun for you, as long as you do not allow yourself to become frustrated by the results.

Is it achievable? I believe it is. You may need a longer barrel. Maybe a little more study of the air flow through the valve/transfer port. The old timey PCPs were shooting some pretty hefty projectiles using 600-800 PSI. It can be done.

Benji-Don,

So KOOL!

shootski

Don

Have you thought about using a smooth bore barrel from like a 760.

I know you want accuracy too but that may speed your gun up. And also I have shot lead wad cutter pellets out of 760’s with good luck out to 30 yards.

Also maybe try steel bb’s like the Daisy Avanti precision bb’s or Dust Devils bb’s in the 760 smooth bore. Just a thought.

GF1,

From my testing I think you are correct. At low pressures the barrel to projectile friction makes a significant difference. I may test a smooth bore to compare the results. For now I will be sticking with the rifled 2260 barrel.

I have tried BBs before they were not the way I wanted to go.

Don

Don

Yep I thought I remember you tried bb’s before. I just figured I would mention it with the smooth bore barrel.

And I was hoping you would get your low pressure air gun working with (lead) pellets.

And yep with the rifled 2260 barrel. But at some point in time I think you should at least give the smooth bore a try.

Either way I still think you accomplished a lot. The velocity and fps spread is fine in my opinion. If it’s accurate out to 25 yards or so it will be a great gun to have. So in my opinion I like where your at with it right now.

Now you should see if you could convert a Maximus or something over to low pressure air and see what happens. Probably the valve and springs could be a bit of a challenge but I bet it could be done.

Interesting stuff Don!

Really, 435 fps in .22 caliber is pretty decent performance from 100 psi! Quite an accomplishment!

Watched a video recently where there was a discussion about tuning a PCP. They were saying that for a specific energy level (pellet weight and velocity being the same) it was more efficient to have a short, small pulse of higher pressure air rather than a long, larger pulse of lower pressure air. …The larger difference in potential being more important than the volume of air. Makes sense to me, kinda like a higher preload on a spring.

So in real terms, as much as I like the 125-plus shot-count (18 g JSBs @ 950 fps) from 250 bar down to the 75 bar reg pressure setting, I might be better off tuning to a higher reg pressure- say 125 – 130 bar. Something I plan to test later – slugs come first.

Just something else that may have a bearing on your project.

Cheers!

Hank

Hank,

Yep you are correct on the high pressure pulse to get the most out of a fixed volume of high pressure air from what I have read.

I am trying to do just the opposite. A low pressure pellet gun will never be a gun to walk the woods with. It wastes too much air. The shop compressor provides a basically infinite supply. I just want to have the smooth action of a pcp without the overhead of high pressure air.

Once I test a new transfer port to see if the pellet gains more velocity I am going back to tuning for accuracy and all that entails. It has be come my ultimate tinkering gun. The trigger has already become about average for a pellet gun. Not a good trigger but very usable.

I should have joined you in getting a lathe a while back.

Don

BD,

The volume of your air chamber, have you tried various sizes? just say you doubled the volume, what do you think that would do? and that radius/neck looks a lot like a choke point for air flow. The vent is not opening up as much as you might think. and if you were really worried about laminar flow… the flat valve back is going to cause eddies in the air flow and a major depression. Think tear drop shaped valve, and straight sides on the vent walls. Imho. Wind tunnel testing? What about a huge valve? Ideas! : – ) Robert.

RobertA,

You are killing me. Great questions. Every time I think I have hit the limit on 100 psi I make a small gain with another test. We are both working with a drill press and Dremel tool. As I improve one feature of the design then another feature that made little difference starts to make a difference.

I do think there could be a shape of the transfer port that would create an impulse increasing the pellet acceleration from the dynamics of the air flow. I remember 2 cycle motorcycle exhaust systems that created negative exhaust pressures in the 1960’s or early 1970’s. Gunfun1 has mentioned the venturi effect.

Are you sure your not the Robert A physics professor? Thanks,

Don

BD,

No, I am not a physics professor. Not even. Your valve is opening at a low rate, the more trumpet like the valve throat the slower it takes to open. Two strokes can have a tuned exhaust that scavenges the exhaust port due to an exhaust wave front reflecting off the expansion chamber but this is all to do with the speed of sound and reciprocating systems coming into “tune”, the “power band”. your rifle is not going to be doing that. My yamaha R5 350cc two stroke twin had a piston port system ( before reed induction ) that let it do 1/4 mile standing start in 11 seconds ( not my actual one but the track one ) , it was essentially an on/off switch… nuts. and drum brakes…. and very bad suspension.

A venturi system would be interesting. It’s essentially how you spit for distance. no idea how you wrap a barrel round that.

What about a choke at the breech end…. very short, that holds the pellet back till full pressure has built up behind it as it slides along the choke. ….

and you never know you might invent something new. Keep at it! : – ) Robert.

PS. The diagram is just to show what I think is happening with your throated inlet over valve travel vs non throated. Phew….

You diagram is correct. Luckily my valve made from brass fittings came out much better. I will try to get a picture or a new diagram.

My analogy to a two stroke was not good. I do think there may be some pressure waves as the valve opens that could add to the initial pellet acceleration. I have no way to test it though.

From my testing I have not gained significant pellet velocity by opening the valve faster or holding it full open.

Don

Don,

Dittos to RobertA, most especially his diagram of the valve. This is what I was thinking but much better explained than my good ol’ country boy brain could have managed.

Shorten up the transfer port also if possible.

RR,

I think that is the only way to possibly get more velocity. Shorten the transfer port and eliminate the probe and use a seal like on a break barrel.

Don

Benji-Don,

I have an image of a DAQ Poppet valve that you may want to take a close look at. Dennis is all about maximum FLOW getting impressive KE without going all the way to 300 BAR; as matter of fact he talks of detuning his .458 LA because through shots are not smart for hunters. He was talking through shots on Bison

Shootski,

At this point I don’t think my valve is a limiting factor. If I can improve the transfer port, then the valve may come back into play.

I think a larger caliber would be easier to get performance out of with low pressure air. Even .25 caliber would make a difference. I may try .177 with my valve if I have a barrel that is the same length 24 inches. I can drill out the leade to fit my probe.

Don

Don

Why do you think a bigger caliber will be better?

The resistance before the pellet moves?

Good question, more of a gut feeling based on the air friction. For two barrels the same length the air pressure is the square of the radius x 3.14 and the air friction is 2 times the radius x 3.14. I need to think about that some more.

Don

Don

Prove me wrong but I don’t think there will be less friction with the bigger caliber. Plus more weight from the bigger pellet.

That’s why I suggested a smooth bore.

But thinking more maybe a rifled barrel with a lead ball would have less contact area. That could be the velocity your after. Plus I have had accuraccy from round balks and steel bb’s from a rifled barrel.

Always so much to try. Maybe the perfect combination could happen some day.

Whatever way I’m rooting for ya. 🙂

The engineer in me noticed that he created a needle valve, with the flow velocity a nearly linear function of valve position. Your goal would be to create a valve that would be full open with very little travel. The modification proposed by RobertA (below) would help but a small radius would minimize the pressure drop at the valve opening point. The other point is the majority of the air volume is on the other side of the rod guide. To minimize the pressure drop across the guide when the valve opens, the holes / orifices should have a small radius. Just remember you are working with a compressible fluid and flow velocity matters when approaching sonic velocity, Mach numbers greater than 0.8.

Smiley,

Thanks for the reply. I think my actual valve came out much better than my diagram. I was focused on the transfer port and not the valve when I made the diagram. Luckily the materials in my junk drawer resulted in a better valve configuration.

Don

Also based on my memory which is not something anyone including me should rely on I tried to exceed certain features by a factor of at least 10. So the valve volume of at least 10 times the barrel volume and the 4 ports in the valve guide are over 10 times the area of the barrel.

I also tested velocities with the valve tethered with 1/8 inch tubing (how I plan on using it) and with the valve connected directly to my air hose. My thought is that would simulate more valve volume. There was no significant difference in velocity.

Good discussion, I think the controlling factor at this point is the transfer port. All the other ones will come back into play if I can improve the transfer port.

Thanks

Don

Don,

I read that port velocity is important. Mr. Smiley mentioned making the rod bushing holes smaller, to affect pressure differential.I like the example of the back cut poppets Shootski. I would test for when the valve is wasting air, if you havn’t already. But , I will let you conduct your own very interesting exploration. Thanks,

Rob

GRAB THE GRIPS.

Attention readers in the U.S. :

I have won some grips from Steve Corcran, they are Crosman 22xx 13xx style.

For them I have no need, and I do not live in the U.S. so…… who wants them?

Don’t be shy. They are free.

Steve wishes to only post in U.S. so if you live elsewhere you are out of luck.

They look pretty darn nice.

I wish them to go to a good home and be used, not onsold for profit. Please bear this in mind. : – ) Robert.

Robert,

Those are beauties, would love to have them, but I suggest maybe a drawing so more folks get a chance. You can put my name in the hat.

Don

Don: Name added to hat. : – ) Robert.

Robert,

They sure look nice, even nicer on my 2240.

Don has a good idea, drop my name in the hat too.

Mike

Mike: You’re in the hat.

RobertA,

Ah, what the hey, I’m game. Put me in.

RR, you’re in the hat too.

Shame they don’t fit an Izzy. They are pretty though. They would make a nice outfit for one of the ladies here at RRHFWA.

RobertA,

What a grand thing to do!

That grip would look fabulous on any of my Quackenbush Pistols!

Please dump a shootski slip into your hat.

Thank you!

shootski

Shootski,

Name in the hat!

Please: this was all started by Steve Corcran so blame him! I am merely the middle person. :- ) Robert.

RobertA,

I have looked at his stocks a number of times for my DAQs…I NEED the carbine stock for my .575 Pistol.

He does some really beautiful stocks!

Need to pinch my Portemonnaie harder!

shootski

Shootski,

I have to stop looking. It’s getting vexing to say the least. Do not pinch бумажник too hard! No no look away. I sproing, therefore I am…. thou shalt not C02/HPA/Pump. Sproings good, no sproings bad. But, soft! what sproing through yonder window breaks? I have a sproing…. etc. : – ) Robert.

RobertA

I really don’t shoot pistols so not interested. But nice grips.

GF1,

Name not in the hat! Robert.

RobertA

Thank you.

😉

Hi Robert,

This is a very generous offer. As you said, “don’t be shy” – I thought I would offer my name for the hat.

I don’t post often, but tune in daily and have enjoyed keeping up with your projects. Your abilities and motivation are admirable. Thanks for sharing and keep up the good work.

-Airman

AotB,

Name in the hat! Thank you : – ) Robert.

Robert,

Toss my name in. I have a barely shot 2240 pistol. When is the drawing? 🙂

Great progress on your gun by the way. I would have commented more (at all) but the internet has been giving me fits. Finally went to a hot spot device. Works great.

Century Link can take a flying leap off a high dive into a pool with no water. (that is the G rated version of actual thoughts). Had rural DSL/land line.

Thanks,… Chris

Chris USA,

Name in the hat!

Will draw tomorrow ( Today is Monday in NZ 09:20 hrs )

Attention:

I see a potential issue: How to get contact details. an email address would be optimal, then the winner and I can take it from there. Yes this is a thing…. we can’t do Personal Messages so I think we need BB to help start the ball rolling. I will ask him now. So the winner of the draw needs to be willing to share an email address with me and a postal address. I would suggest use your secondary email ( if you have one ) and a post office drop ( if they do that ) so you are minimizing exposure to any nonsense! Robert.

Robert,

BB don’t usually get in the mix. I have put mine out a few times here,… but broke it up so it should not come upon a search.

At any rate, best wishes to all!

Chris

Chris USA,

Roger that. If I put my stunt email up here…. how do I know the person emailing me is the winner? Anyone could contact me saying they won. This is a tricky puzzle. Oh well, I guess I will just have to trust the internet…. ( most people would say “do not!” ) Robert.

RobertA,

Like Chris says the winner will give you their email addres by breaking it up in code. Like “at” instead of @. Then send them a question to answer on the blog using their handle. No one else can use their handle.

Don

BD,

Ah ha! and a call and response test. Simple. The Godfather will be happy.

PHEW! I am glad you sorted that out. I have never used an internet thing without a PM system. New tricks! Right, so tomorrow I will do the draw and someone will offer their contact detailos. Great! ( Imagine trying to do all this by carrier pigeon… ) Robert.

Please enter my name for the drawing. Thank you.

PiO,

Name in the hat! Robert.

Hello. Entries are closed.

Drawing will be in 10 minutes. and winner announced in the latest blog. Good luck! Robert.

RobertA

I have a couple of each caliber and one even has a cracked panel, so I could find a home for sure. Very nice gesture, by the way. Hat, please, kind sir.

Half

I snoozed. Very kind gesture on your part though.

Halfstep,

Sorry to see you missed the party, you never know, something might come up again that needs a lottery! Good luck for next time! Robert.

BB and all.

The Mossberg S331 rear sight arrived in the mail today. Wow it’s small. I was captivated by their design and then, I wasn’t… , let me explain.

If you happen to look at Williams peep/aperture/dioptre sights you will notice a round cupwasher and screw next to the vertical dovetail slide. The Mossberg sight does not have that…. and I discovered why that set up is a good idea.

So I mounted the sight on my F.E.G Telly Relum indoor 5m rifle.

And… the vertical dovetail slide is very lose, what the… ah… I see, the fit is lose, it’s never going to tighten up. ( curious thing is I had a very keen sense of “deja vu”, I had been here before, many years ago. )

So how to fix? And the answer is with a shim: I used some paper folded over to slide into the dovetail edge, you can see the white paper sticking out, lubricated it with TIAT ( it’s multiversal…) and carefully slid the slide back together. Works, no slop/lash, back in business. Cost? $0. The paper absorbs the grease and is now impregnated so it’s slippery and weather proof ( I tried some feral can shim but it was too thick and grabby, the paper is way better. )

Next point: the vertical slide is on the left side where my nose is, I like to shoot looking straight ahead and not canted or yawed and I like to get up close and personal with the aperture. Guess what? I have a big nose.. heck. So what I would prefer is to be able to fit the sight pretty much in as close as possible. no dice there, so I have to keep the sight close to the bridge of my nose. Seems ok so far. My anschutz sight is not so bulky on the side and I can get in quite close without having to angle my head. I know the sight is designed for a bolt action with due respect to the action of the action. If it was mounted on the right side and had no bulk on the left side it would be awesome. So far it’s very good. : – ) Robert.

I do find it strange you had to shim the sight.

I can see the headlines now. “Sproinger Dude Takes The Gold!”

RR,

The vertical dovetail slide was not a good fit. The part that bolts onto the rifle was bigger than the part that slides up and down. There is a square spring washer but that did very little. The paper shim made all the difference. Must be about .5 mm or so, which means the whole thing was very wobbly. Not anymore! It’s really good. This little rifle can shoot. It’s like the sights disappear when I take the shot and the pellet just follows my line of sight. It’s weird. At 5m I am making tiny groups, off hand, no rest. It’s just a dream to shoot. The hold I am using is like this: I rest the foregrip on my left upward palm, pulling rifle slightly into the shoulder. Elbow hard into my waist. Right hand is resting on the grip, very light, elbow low down, the most my hand is doing is resting there. If I take my right hand off the grip nothing changes as the gun is balancing on the left hand. Squeeze trigger slowly. Wobble in the right direction when the rifle fires. Rinse and repeat. I miss shots when I pull to one side as I trigger, I think that is just some kind of tic. Once I get my game on it goes away. I am shooting at red dots about 10mm. Only one shot per dot. The aperture even shows up the shotholes, if I look outside of the aperture I can hardly see them. This is way cool. this rifle is the same age as I am and going strong! Hungarian steel! Robert.

“Today, the gold medal for 10 meter air rifle was taken by a gentleman using a home customized antique sproinger!”

RR,

I would try for that! Better get some practice in. I have had my action in and out of the stock so many times it has no bluing anymore! Looks good with bright steel. I’m thinking of parkerising it. Can do it at home. or even paint. some kind of target rifle paint job. mmm… Robert.

RR,

If you look carefully at the bottom left hand picture of the S331 you can see the gap on the left side where the paper shim is. See picture! It was pretty darn wobbly. Robert.

I put my Marksman Model 70 on the same level as my FWB 124. It’s that good by any measure…accuracy, trigger, power, workmanship. Mine is .177 caliber. Testing it over my Competition Electronics ProChrono chronography, I recorded the following based on ten shots using RWS Hobby pellets (7.0 gr.):

High: 989

ACH! Electronics!

Low: 971 FPS

Ave: 980 FPS

Ext. Spread: 18

Std. Deviation: 5

I will note that my chrono seems to consistently yield higher numbers than y’all seem to get from the same guns. I don’t think that’s attributable to my superior tuning skills (they don’t exist!). I’m guessing that my chrono is about 20 FPS fast, but that doesn’t diminish the remarkable Standard Deviation of 5 FPS.

Thumb tacked to my office bulletin board are three targets shot standing, but supported, at 33′. Two are 1/4′ groups and one is 7/16″ center-to-center. These were shot with an older 6-18X40 Bushnell scope and using RWS Meisterkuglen pellets by a 70-year-old. No doubt these could be improved upon with a bench rest and a younger, more competent shooter. Point being that accuracy is excellent.

I bought my Marksman 70 used around 1990. I’ve never had it apart. The cream colored breach seal seems to still be functioning fine. The above chronograph numbers were done about 12 to 18 months ago, so still fairly recent.

Hope this helps your evaluation of the Marksman Model 70!

Motorman

St. Louis, MO

Motorman,

That is some great shooting. Sound like you definitely have a winner. My springer skills are bad.

When Shootski got out his pom poms when talking about his Sig ASP20 I grabbed one while they still were available. I did shoot better with it off hand than rested but neither of the groups were worth telling about.

Don

Motorman,

Thanks for thisw. Monday I show accuracy.

BB

Motorman

I live abot 10 o rso miles east of St. Louis. My chrony readings are always faster too than others.

I figured I better post while the subject was at hand. But thanks for bringing that up.

I figure that it’s the arch messing with the earth’s magnetic field and that’s why our chrono’s are fast in the SLT area! LOL!!

Motorman

Right in front of us all the time and we never even knew it.

🙂

Here is a picture of my low pressure pellet gun valve. I took the valve seat off and set the distance of the valve seat and seal to the length I measured that the valve opened. I set a piece of angle iron behind the valve to the point the valve stem just hit the angle iron when shot. It looks like the valve seal is plenty far out of the way in obstructing the air flow once it gets partially open. how quick that first bit of valve opening is could make a difference. I tried a stronger and longer hammer spring and it made no difference though.

Don

BD,

I seriously think that the valve issue is moot. Once you get the valve to open fast and full then the rest is bore diameter, bore length, pellet dimensions/friction etc. and pressure chamber size. A large pressure vessel, large bore, long bore, light pellet, low pellet friction etc. or variations of this. The only other thing would be some kind of hydrodynamic feature that is missing/unutilised. Once the pellet is out of the bore it’s all over, but does the extra size make things better? All you have up your sleeve is volume ( keeping the pressure at 100 psi ) to use this is the key. Possibly there is just no way past a point that things will get better. Optimization might bring marginal gains in efficiency, it’s the overall problem that needs solving. Turn low pressure high volume into high speed tiny volume.

It’s turtles all the way down! Robert.

I also took a picture looking down the transfer port. I have tried a few different valve seals to date with no significant change in pellet velocity. Right now I have a flat seal on the stem but have also used the tapered seal sitting below the seat/transfer port.

I think the transfer port will be my next mod. That will take a while as I need to find some junk parts to use to make it. Wish I had a brass rod the diameter of 1/2 inch pipe. PVC might also work. Maybe pour some brass into a short piece of brass nipple?

Don

Don

I think you accomplished alot.

I wonder if a .25 caliber Marauder valve with some spring modifications would flow enough air to make the low pressure air work.

That would be the bigger caliber your talking about too.

Maybe its right in front of us and we don’t even know it.

BD,

Blow darts: low pressure, large volume, really long bore, low friction, low weight ammunition.

In fact this: constant pressure. When you blow a dart you are keeping the pressure in the bore at a constant pressure with your lungs.

This may sound weird but: if you had a spring powered piston that compresses the chamber volume as you push the pellet down the bore keeping the pressure UP the entire time the pellet is in the bore. Constant pressure bore. So the chamber is 100 psi, the spring is compressed ( valve and spring sear are fired together ) when you trip the system the 100psi air is “regulated” to a constant as the pellet moves down the bore. Is this too crazy? It would not be considered HPA as the pressure never exceeds n pressure. Hybrid? Fun ! Robert.

Words of wisdom from a sproinger man. Unfortunately, I do not think it works that way. Forgetting about a whole bunch of other factors, let us think of pressure. It is that sudden pulse of “high” pressure that gets the projectile going. That pulse is the volume of air being released suddenly. In an ideal world, the faster that air volume can get to the pellet, the faster it will go.

OK fine. You know all of this. I am also fairly certain you know that as the pellet goes down the barrel, the volume behind it increases and the air filling that volume is going to decrease in pressure. Your thoughts are to keep that air pressure up.

Basically, that is how the Webley Paradigm worked. It was a single stroke pneumatic with a small section of sproinger that would give the air reservoir a little boost up. It worked. It was also very complicated and was too late to save Webley.

In an ideal world, the volume of air behind the projectile will be at exactly one atmosphere as the projectile exits the “barrel”. That way no air is wasted.

Where am I going with this? I have no idea. I have not been up very long and I hear my second cup of coffee calling me. I will have to think on this some other time and get back to you guys on this.

RobertA

The next question is how much psi is a spring gun working at the barrel where it hits the pellet?

Maybe spring gun operates at 100 psi or so. If somebody has tested that I would like to know.

GF1,

A spring gun is a very efficient system taking the springs potential energy and converting it into pressure and the kinetic energy of the piston mass. At about the time the springs force matches the resisting force of the air pressure against the piston the piston is now traveling fast and ready to take over compressing the last little bit of piston travel even more. Based on the short barrel length I would say at least 800 psi is typical. That is my guess for what it is worth. I am sure someone on the blog knows.

Don

Don

I would like to know.

Maybe the valve parts from a presta valve could also be tried. Just needs a little valve spring! Those seal at least up to 150psi.

Rob

Rob,

Thanks for your comments. My testing and the evolution of my valve has gone on a long time. It has not been very systematic. My plan from the beginning was to build a valve to acheive moderate velocity using a shop compressor. I think some of my original goals have become muddled over the last year. I will try to list them. Hopefully that will be even easier in hindsight.

1. I wanted my valve to maximize velocity. That means maintaining the 100 psi pressure at the transfer port until the pellet is out of the barrel. Wasting air was desired for each shot. Using a shop compressor, a puff of air wasted for each shot is insignificant. This gun will always be tethered to an air source for an unlimited supply of air.

2. I wanted the valve reservoir large enough that it would still be at full pressure when the pellet leaves the barrel. My goal was a valve volume at least 10 times the barrel volume.

3. I wanted the valve to still be open when the pellet leaves the barrel. Thus maintaining maximum force on the pellet. I actually wanted to waste some air on each shot. I have basically an infinite volume of air to play with from the shop compressor.

I think I accomplished those goals with the first attempt. Changing the valve dwell or opening speed does not make a significant difference. As it is now configured only changing the pressure or the pellet makes a difference in the pellet velocity.

My next effort will be to construct a better transfer port from the valve to the barrel, more like in a break barrel gun. Then I will start the testing again.

Thanks for helping me organize my thoughts. I hope this clears up a little bit what I am trying to accomplish.

Don

H

Benji-Don,

Almost everything you set out to do has been realized and so far I think you have and will continue to enjoy your experiment with LPA! I think a bunch of us have been enjoying right along with you…I know I have.

Changing the caliber to a larger size will work for a number of reasons but onlyup to a point. The increase in base size is probably the biggest to get that maximum initial push. The larger pipe will increase flow volume and reduce the laminar drag that flow experiences. The issue(s) of a longer barrel is the friction increase over time/distance and the elephant in the “roomie bore” is the increase in Mass! That air in the bore that gets compressed as the projectile pushes it (the air) out of the bore is part of the projectiles Mass while in the barrel. Given your near Infinite mount of low pressure air it creates limiters “just” because you have so much available. That near static volume of air that builds inside the bore behind the pellet also becomes a good portion of the projectile’s absolute Mass. It seems that the original/early airgunsmiths were far more learned through experience or study than we give them credit for.

Keep thinking and working on the concept of getting the projectile up to speed as quickly you can just like a spring piston does and then just think of the remaining air as backfilling the vacuum that the springers have no way of doing.

You may want to give barrel porting some thought given that the air you push out of the bore is a big negative. I know you are using up barrels so maybe some reading up on the benefits of porting is in order. Not that anyone else has probably studied barrel porting for 100psi. I’ll do some digging and see if there is anything on the Internet.

Keep having fun.

shootski

Don,

Yea, Potato Canon:

https://www.semanticscholar.org/paper/Internal-ballistics-of-a-pneumatic-potato-cannon-Mungan/e729a366be835af59b3023f762da004305558b25

I found this PDF that has some stiff Math but some of the graphs and discussion are too the point.

Porting barrels is all firearm so not of much value. Lots of maximum Transfer Port discussion but not very scientific.

shootski

shootski

Is there really any way to make the LPA system any better?

“tsunami”… The LPA vessel vents into a narrow vessel, then a second valve vents the high speed wave front into the bore. There maybe some hydrodynamic system that can be applied here. Think Teslas liquid valve. Possibly preflowing the bore with air before letting the pellet go…. which could be done with bypass tubes and mechanical timed valves. Fun ! Robert.

Shootski,

I made a couple of potato cannons in the past and studied some of the barrel length, diameter and reservoir size equations. They were in the back of my mind when sizing my valve.

You are correct other than my arbitrary goal of 500 fps with the falcon pellet my gun actually works better than I expected. I can get 500 fps if I want to up the pressure.

And as I said earlier the gun is fun to shoot.

Thanks for your input.

Don

Benji-Don, I know this is not the latest blog, but I was just re-reading about the Marksman 70 and had an idea to share with you, and this seemed as good a place as any. Your project reminds me a little of a carnival game they had at an amusement park near here. You had to shoot out the star with a fully auto BB gun. It was hooked up to an air hose and a compressor, I believe. Perhaps you can find a patent filing or information or parts on those that would help you. Very interesting project. Best of luck!

Roaming,

From what I remember the carnival shooting star guns used about 100 psi. They were shooting lead shot at 300 fps. The patent would be interesting to study. I will check into it.

Hmm, regarding lead BBs: My recollection is that they had a trap that funneled the used BBs back to the operator of the game. He would scoop them into a metal straw (tube) and reload them in the guns. If my rememberer is correct, that would mean steel BBs and the projectiles would be very light. This makes me think of non-lead pellets or maybe airsoft BBs, but perhaps those options are outside of the parameters of your experiment. I hope my ideas are helpful.

Don,

To me,… not that I know anything,….. it would seem that a plenum,… built up to 150 or so,.. (compressor shuts off),… and a quick dump electronic valve,… would supply the desired continued psi push down the barrel.

At any rate,… you have done a lot. Well done.

Chris

ChrisU,

You got it, I would bet your 150 psi and a quick dump valve will work. If I bring my little pancake compressor home rom the cabin next week I will let you know.

Don

BB

The edit option is still not working today.

Can you please talk to IT again and see if they can get this issue straightened out.

Thanks, Gunfun1

GF!,

They have checked it two times and it seems to be working. Is it perhaps your cookies?

BB

Test: Everything thing gets blamed on cookies. You got ’em,… you eat them. Problem solved! 🙂

Yup,…no edit option here either. And heck,… I do not even buy cookies!!!!!! 😉

Chris

Chris USA,

COOKIES!

B.B.’s Readers who practice the King’s English will have issues with that! LOL!

I wonder why we weren’t sensitive enough to that name in the early days of the Internet to call them Biscuits?

shootski

BB

Still no luck even after clearing cookies. And this is on my phone.

B.B.,

IT giveth and taketh away.

From the New Revised IT bible: Book of Bits and Bites, Chap. IV, Verse 3.

If I was a student of Conspiracies…

It does seem strange, however, that it appears to coincide with increased Blog traffic days

shootski

BB, I think the AA heavy might do well. The best groups my R10 ever got were with a broken mainspring. Those were flying at about 660 fps. At my 45 yard.spot I had to go out and check the paper, I couldn’t believe it. I still think the R1 is the cats meow.

R

Rob,

It will be a while before I get to shooting for accuracy again. I don’t know what I’m going to find inside the powerplant. But I will keep the Air Arms domes in mind. Thanks,

BB

BB,

Isn’t it unusual for the heavier pellets to provide the most energy in a spring piston gun? I think I’ve seen that written here.

Half

Half,

It used to be the lightest pellets were the most efficient. But in recent tests I see that has changed.

BB

Everyone,

The Feltman “Shoot Out The Star” carnival guns are now owned by AirForce. I asembled and shipped most of the final 50 that werre made. John McCaslin has severa more.

I can test them for you.

BB

BB,

AirForce eh? Well they need to get the line backup and running!

Test one?,….. for us????? What a total bummer that would be! LOL! 😉

Chris

BB,

I will add,…….. I do not care what you have to do,.. or who you have to get,…. but a video bit is a 100% requirement,… if you do!

Chris

B.B.,

I found a parts diagram on line for the Feltman shoot out the star. They look very complex with a hundred small parts. The assembly could be a blog all on it’s own. A test would be great, especially with a look inside.

Don