The HW 50S breakbarrel from Weihrauch.

Part 1

Part 2

Part 3

Part 4

Part 5

This report covers:

- Ground Control to Major Tom

- Where are we?

- From the last report I said this:

- Then I said:

- The deal

- After the tune

- Try, try again

- How fast?

- Stuff happens

- Call Vortek

- What have we learned?

- Blessing in disguise

Today we test the HW 50S that has received the Vortek PG4 SHO tuneup kit. For all who have wondered what it’s all about, this test may tell us.

I will test the velocity, the cocking effort and the trigger-pull. You may remember that when I installed the kit I also adjusted the trigger, so there is that to consider. And finally — is this kit worth it? Let’s get started.

Ground Control to Major Tom

I had rotated the rubber mulch pellet trap box so there were no impact holes on the face I was shooting at and I fired the first shot. Nothing. No velocity recorded and no hole in the box. Either I missed a huge box from 5 feet away or the pellet did not exit the bore. From the breech I looked down the barrel with a flashlight and saw nothing, as in no light shone through. The pellet didn’t come out.

In more than 30 years of tuning spring-piston airguns this is the first time this has happened to me. And at this point I didn’t exactly know what had happened. I got a .177 cleaning rod and pushed out 4 pellets that were all sitting at the muzzle end of the barrel. One was mashed from being hit by others behind it.

What was happening? I took my protein pills but I lost communications with Ground Control. Am I experiencing every first-time airgun tuner’s worst nightmare, as in “What do I do if…?” Cool! Because I know what to do.

Where are we?

You know how I write these reports partly for you and also partly for me? Well, this one’s for me. Because I saw this coming — sort of — and I said several things about it beforehand. Yes, I did. Let’s see.

From the last report I said this:

“I snapped the new piston seal on the end of the piston. It seemed smaller than the factory seal, so I assume the parachute will expand rapidly to seal the compression chamber. We shall see.”

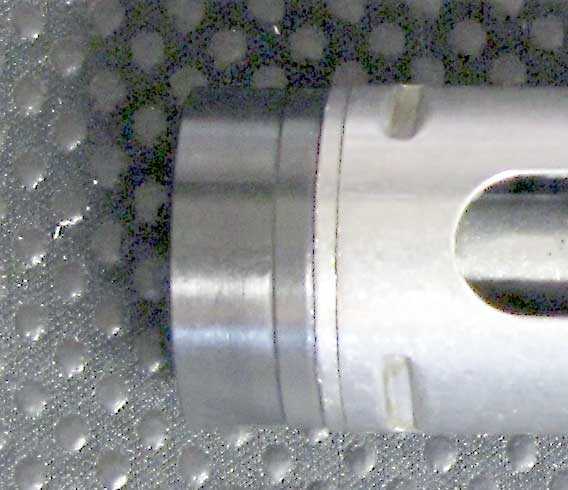

I was so surprised by the fit of that piston seal that I even showed you a picture of it.

The new piston seal is the same size as the piston. It’s smaller than the factory seal.

Then I said:

“Now slide the piston into the spring tube. You will find that with the new piston seal it slides in without any resistance.”

Well, that’s the first time that ever happened! And here is the deal.

The deal

This kit came to me from Vortek in a sealed package. The piston seal was inside the package with the PG4 SHO kit. Right or wrong, it is the seal that was sent with the kit and the seal that I installed.

After the tune

After a tuneup I always test a spring piston rifle by cocking and firing it several times. Obviously I do this with a pellet loaded in the barrel. I did this in my office into a pellet trap that’s loaded with duct seal and already has several hundred pellet holes. Now that I think about it I never did see where those pellets went in the trap, which is sort of like saying, “Other than that, Mrs. Lincoln, how did you enjoy the play?”

However, when I rodded out the bore, all those pellets came out with the one I had just tried to chronograph. Like I said before, one was smashed and three weren’t.

When I rodded the rifle barrel this is what came out.

Try, try again

I am an airgunner, which by definition means I am also slightly crazy. The definition of crazy that I’m using today is doing the same thing over and over and hoping for a different result. The third time I shot the rifle I got my result. The shot missed the second skyscreen, but let me show you the pellet on the box. Yes, I said ON the box!

The pellet penetrated the box, partially.

Okay, my cardboard chronograph tells me this pellet wasn’t going very fast. Don’t gotta know much to make that call.

And, I am an airgunner, so I shot again, and again. I was hoping the rifle would heal itself. Don’t laugh — I know some of you guys do the same thing!

Let’s see — two stuck pellets and a dent. Yep, not very fast.

How fast?

The chronograph said 103 and 139 f.p.s. Hmm. I bet the Vortek PG4 SHO is probably supposed to go faster than that. And I also bet it’s not supposed to have a big jolt when it fires. Whatever could have happened?

Stuff happens

I bet when this kit was packaged someone grabbed the 25mm piston seal for an HW 30S instead of the 26mm seal for the HW 50S. You know, I have never made a mistake myself, but I have been told that others sometimes do.

Call Vortek

So, I waited until the sun was up and put in a call to Vortek. Surprise, surprise — Tom Gore said he was about to call me. He read Part 5 of this report the evening before and saw that I had installed a 25mm seal on the piston. He wanted to tell me that this seal will probably not work at all, plus the rifle will fire with a big jolt as the piston slams into the end of the compression chamber without a cushion of air to stop it. Imagine that!

He will put the correct seal in the mail today and I will replace it as soon as I can get to it. Then I will redo today’s velocity test as I stated in the beginning.

What have we learned?

We have learned that when a piston seal slides into a spring tube with no resistance, it’s probably not the right one for that gun. We have learned that when pellets don’t even exit the muzzle after a tune, something is wrong. We have learned that accidents do happen from time to time — it is the nature of this fallen world. We have learned that BB Pelletier makes the same mistakes as everyone else. And finally, we have learned that spring piston airguns usually do not heal when something isn’t right. Call the manufacturer.

Blessing in disguise

Today’s event was a blessing in disguise. It was because in the almost 18 years this blog has run there has never been an instance where I made such a huge mistake. That fiasco with mounting the scope on the Eagle Claw rifle back in August was a biggie, but this one is bigger still.

Granted this wasn’t just my mistake; I had help making it. But this should show you guys who want to dig into a spring gun but are afraid that you don’t know what you don’t know and somehow that’s going to bite you, that everyone gets bitten, sooner or later. When stuff is supposed to work and doesn’t it may not mean that you have done anything wrong. You may have had help.

I’m glad you got to look over my shoulder today. I hope this encourages you to make some mistakes of your own.

B.B.

Dollars to donuts, I bet you did this “on purpose”, just to educate us!

I believe that you learn more from mistakes than success….

-Y

Yogi,

Thanks for your vote of confidence, but I assure you — this was my mistake. 🙂

BB

if nobody made mistakes there would not be erasers on pencils

Using the erasers included on pencils is itself a mistake. I don’t recall ever having any that worked well. A separate vinyl eraser was always the way to go.

Encourage us to make some mistakes of our own. I don’t think we need any encouraging of our own for that. 😉

B.B.

When you shot those 4 pellets, did the discharge sound sound “off”? I would think that you would of noticed the piston slam. Was the transfer port imprinted on the undersized piston seal face?

I would expect Tom to comp the entire kit for all your troubles…

-Y

PS was the spring also for an HW 30?

Yogi,

It will be interesting to see what the piston seal looks like.

BB

BB

Didn’t the HW50 come in two different tube sizes over the years ? The older ones and the newer ones different ?

tt

TT

From what I remember you are right. But my rememberer isn’t what it use to be.

GF

By the way, the freaky squeeker is looking a lot better, except for his tail. I have seen more hair on a rat’s tail. Otherwise he looks pretty good (for a tree rat).

tt

TT

I think it was Shootski that mentioned it might of had some mites or something that caused its hair loss.

Still kind of strange. At least it’s getting better. And that’s good because the cold weather is just right around the corner. Wonder if it will be staying in its nest this winter.

GF

He gets tooo stay in the hamster cage.

tt

Yes, once upon a time the HW 50 and 55 came with a 25mm Compression tube. The newer HW 50 and 99 come with a 26mm tube.

-Y

Hey B.B.

I’m running a SPECIAL on Hair Shirts this week!

Sounds like you need a few…

Also, if you put the split peas on the floor in the corner and kneel on them you will feel much better…

So you found you have made your Bed of Nails and decided to wallow on it…

WOW!

Coming clean is such a catharsis!

Great report!

You WILL get over it I hope!

shootski

BB,

I do not need any encouragement when it comes to making mistakes. I do quite well on my own, thank you. I’m the kind of guy who measures twice and still cuts wrong. It is not too bad when it is too long, but often it is too short.

I do try to learn from my mistakes, but the lessons keep falling out with everything else. I think I need ear plugs.

I tried using ‘BEANO” as ear plugs to help with the brain farts….It didn’t help!

rk,

No type of ear plugs will help with brain farts. They usually come out of the mouth, not the ears.

So true, so true

Speaking of mistakes, apparently WordPress has upgraded something and I am no longer receiving emails. Again.

BB-

I thought the dimension of the new seal looked off the other day, but I too, assumed that it would expand with air pressure. After all, ‘new and improved’, is…. Improved! Right? All those years ago, I ran faster and jumped higher with my Red Ball Jets, didn’t I? We are conditioned to assume that ‘solutions’ for a problem are correct and when they are not correct, apply more ‘solution’! Thank goodness BB stopped when he did.

I probably would have devised a testing jig to measure partial pellet penetration (PPP!) in the cardboard. A whole blog comparing pellet types, weights, etc., perhaps. Factions developed extolling one brand over another. A rising murmuring of slug users slamming slanted soliloquies. Oh, BB, it could have been grand…

BB

Thanks for being willing to tell us. Few people have enough genuine self esteem to let others in on any of their failings.

I’m wondering how many shots and hours of cleaning will be required to duplicate the previous barrel characteristics. Oh, and the piston face.

Deck

“You know, I have never made a mistake myself, but I have been told that others sometimes do.”

LOL! This must be a “Tom” thing. …And I quote a guy (Tom) that I worked with:

” I thought I made a mistake once but I was wrong.”

BB,

Do you know what the difference is between the Vortek PG3 and PG4 kits? I’m curious as my supplier only has the PG3 kits in stock.

Hank

Hank,

I’m afraid that I don’t know the difference between the 3 and the 4. I imagine both are good.

BB

Some say that the only useful part in this Vortek kit is the end cap and everything else is just fluff.

https://www.youtube.com/watch?v=yYTKxUy4gW4

It is understandable that it is difficult to build a business and charge a lot of money for only a tiny plastic part so we can expect Vortek to add even more parts to their kit as time goes on.

B.B.,

You provided many welcome chuckles this morning.

However, I disagree that it was your fault. You did nothing wrong, at least regarding the too small seal. Yes, you put too many pellets through (most of) the barrel, but that is trivial. Vortex made the mistake, and yep, they do happen occasionally.

Michael

B.B.,

Yogi’s question above is a good one. Was the spring also for an HW30? The package might have had the correct parts but an incorrect label.

Michael

Michael,

No, I don;’t thjink the spring was wrong. The rifle cocks with a lot of effort that’s too high for a 30S.

BB

Or like twotalon said above.

Weren’t there two different tube sizes made over the years for the hw50.

You saved the old seal? You could try a short stroke tune maybe. As for the fallen world, it sure would be nice to blame bad parenting, but here in Cali, it’s probably prop 13, the ever so popular property tax law from the 70’s. So, Vortek dropped the ball on this one. I had a similar issue with a product from them, sometimes it’s not a bolt on fit and you can choose to send it back, or improvise.

A wrong seal has no work around that i know of. Not sleeving the bore..

Rob

Rob

B.B., your mistake was failure to run the installation by the Seal of Approval before beginning your tests. Arf!

“We have learned that BB Pelletier makes the same mistakes as everyone else. ”

— B.B. Pelletier

“No, NO! Say it ain’t so!” — dave

B.B.,

Just kidding, I actually thought this report was great; I learn a lot from the ones where everything goes as planned; yet I think I learn more from when they don’t. Or, to put in another way, the unexpectedness of things really drives home the point you’re making.

This report made me smile, as it reminded me of many “dave disasters” of the past. 🙂

Take care & God bless,

dave

BB,

As soon as you get the correct seal your 50 is almost the same as mine. I went with the HO kit.

If you want to another awesome test with the 30 and 50 get the slip on moderator for it. It does make a world of difference.