RidgeRunner’s Diana 34.

This report covers:

- Nice one

- Old-style?

- Breech lockup

- Velocity

- Crosman Premier 10.5-grains

- JSB Exact RS

- Rear sight

- Overall condition

- Final observation

- Next

- Summary

Today we begin the project to improve the shooting characteristics of reader RidgeRunner’s Diana 34. That’s the actual rifle shown above.

There is a surprise in today’s report. It comes at the point when I tested the velocity. Until then I had one opinion and it changed at that time.

Nice one

I received this rifle last week and saw it for the first time last Saturday. I cocked it, just to see what I was up against, and I also shot it twice. In my opinion, this is a nice old-style Diana 34. The ball-bearing breech breaks open easily, the T05 trigger is adjusted perfectly and the rifle fires smoothly. I was surprised because I had never seen one shoot this smooth. That doesn’t mean there isn’t room for improvement in the firing cycle, because there always is.

Old-style?

When I say old style I mean that the Diana 34 went through a number of changes over the years and the rifle they made at the end of production wasn’t the same as the one they started with. This one has the T05 trigger that is the finest in the Diana trigger line. The T06 that everybody likes is also very nice but Diana simplified it slightly from the T05 — probably to lower production costs. This trigger is set to 1 pounds 4 ounces in stage one and the glass-crisp stage two breaks at 3 pounds 6 ounces.

This rifle was produced in December of 1995. It was made toward the end of the production run. The production date stamped into the spring tube reads 12-95.

RidgeRunner’s Diana 34 was made in December of 1995.

There are a couple keys to this rifle being an older version of the 34. For starters, it has no rubber buttpad. These early ones are just crosscut at the butt.

This wooden butt is the first style the Diana 34 used for many years.

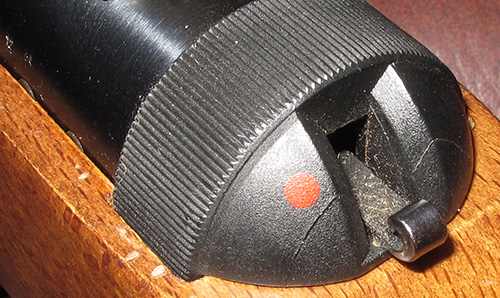

Another clue to the age is the safety. All Diana 34 safeties are located at the rear of the spring tube and above the pistol grip. They come on at cocking, but only the early ones have a flat steel release that’s curled up at the end. Later versions have an angled black plastic release.

This flat steel safety release is the first style of Diana 34 safety. The rifle is cocked in this image.

Breech lockup

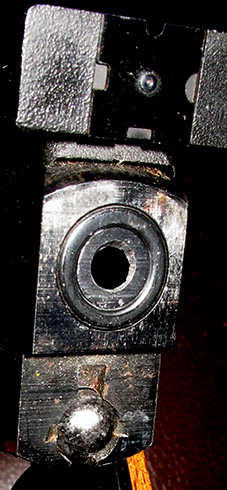

The Diana 34 has a ball bearing breech lock that rides over a steel inclined ramp, until the spring pushes the ball over the steel ramp to lock the breech. It is not a chisel detent, which means it can be lighter, yet still positive.

I found the barrel to break open easily. I bump the muzzle out of habit, but I don’t need to. That’s a good thing because the spring-loaded ball is held in place by two deep swages. I think removing the ball is a major exercise that involves machining. It won’t be anything that I tackle.

This view of the breech shows the two swaged dents (at three and nine o’clock) that hold the ball bearing breech lock in place.

Velocity

This is where my opinion about RidgeRunner’s rifle changed. When the rifle was cocked for the third shot in the velocity test the barrel stopped in mid-stroke. It feels very much like a section of mainspring has broken off and is tying up the gun. I was able to complete the cocking stroke, but from that point on I felt the same resistance with each cocking effort. Could this be what RidgeRunner experienced? If so he meant that the rifle was impossible to cock, not to break open. Or understand that when I say break open I mean just opening the breech prior to cocking.

Crosman Premier 10.5-grains

The average velocity with 10.5-grain Crosman Premiers is 709 f.p.s. The low was 704 f.p.s. and the high was 719 f.p.s. That’s a 15 f.p.s. difference. At that velocity this pellet generates 11.72 foot pounds of energy. That’s on the low side for a 34, which supports my broken mainspring theory.

JSB Exact RS

JSB Exact pellets averaged 857 f.p.s. from this 34. The low was 847 and the high was 867 f.p.s. — a 20 f.p.s. difference. At the average velocity this pellet generates 12.84 foot pounds of energy. That’s also on the low side for a 34. I expected 14+ foot pounds at least. The broken mainspring theory is fleshing out! Diana mainsprings have a well-deserved reputation for breaking. Usually it’s one inch broken on both ends, though I have seen several springs with just one end broken.

Rear sight

The rear sight is missing its elevation screw. It looks like somebody may have removed it to mount a scope or peep sight and forgot to put it back. The rear scope base has very light wear on the sides of the base, which is typical of a new rifle only. It’s an aluminum part that gets scratched and dented pretty quickly.

Overall condition

The rifle has 100 percent of its bluing and 98 percent of its stock finish. There are a couple handling nicks on the wood and that’s all. The mainspring appears dry and devoid of lubricant.

The mainspring appears pretty dry.

Final observation

After looking at this rifle and handling it for this report I have come to the conclusion that this rifle is in almost-new condition. I’ll bet the mainspring broke early and the first owner put the rifle away for a few decades. Maybe he even forgot about it. Then he dug it out, tried to cock it, found that it locked up and sold it.

The groove in the inclined plane that the breech ball bearing rides on still has most of its bluing. I saw a report on the Airgun Nation forum where the owner thought that the groove had been worn in the steel by the ball bearing, but what he actually saw was the inclined plane with no bluing remaining.

Next

What I will do next is disassemble the rifle to examine the powerplant parts. From the way it cocks and shoots I expect to find a broken mainspring and a like-new piston seal. After I see the insides I can order parts to get it going again. I need to measure that mainspring and also the space in which it fits so I can get a lighter mainspring that will fit well.

Summary

We have a neat new project open and underway. This one is a little different as we are trying to create a super-soft tune that cocks easily and works well. We are going after a smooth shooter — not a magnum breakbarrel. I am excited to see what can be done.

Tom,

So the stiff opening that Ridgerunner is describing is actually the broken mainspring binding on on the piston walls as it is being cocked? Glad you don’t have to do anything for that ball bearing detent. Opening this rifle and revealing the spring might show a damaged spring that might still be usable. Or are you planning on ordering a spring kit (from Vortek?) from the get go?

Siraniko

BB: I second the notion that the Main Spring is broken. I have gone through two on my Model 36 since ’89 and the description is perfect for what tends to happen. Also, as Charles Trepes said a couple of decades ago, “the coils of the broken spring can rotate around each other at the break and then work – after a reduced fashion.

A dry, broken spring would be my guess, and is something you can readily address. Please do the thing you do well and accompany the process with pictures.

Await with interest this series. My Model 36 is a 1989 edition made in West Germany.

T05 trigger is the finest in Diana’s trigger line? I’m certainly not an expert but I would take the T01 of my D54 any day. Adjustable to perfection, something that I couldn’t get with the T05 of the D350. And the safety is all steel with a really audible click…

B.B.,

I’m so happy that RidgeRunner decided to send you his rifle for a tune up.

He will wind up with an improved air rifle.

You will get to do some interesting reports.

And all of us readers get another learning experience.

So, it looks like its win, win, win…very cool. 🙂

Blessings to you,

dave

BB: I certainly have no desire at my advanced age (I’m just a few months older than you are) to take up being a gunsmith. Last Fall’s experience in repairing my TX200 is indelibly etched in my mind. At that time, as I was reassembling the rifle following an attempted Vortek tune, the trigger assembly exploded all over the kitchen. I ended up returning the whole thing to Air Venturi who repaired and returned it to me for a mere $75. I think they took mercy on my inexperience. My point is that the more I can learn from you, as well as this blogs membership is pure nirvana for me now. This type of blog is very much among my favorites. Thank you, Orv.

This is why FM is a firm believer in his “if it ain’t broke, don’t fix it,” minimal intervention and “first, do no harm” philosophy.

Super, wondering what spring and guides lay in this gun’s future? Maybe you could have your neighbor make some that are “Goldie Locks” perfect. Moly or Ultimox?

-Y

I’m very excited about this series because it will have a LOT of info that I can use on my growing collection of Dianas. I have a Model 35 with a suspected broken spring, but which is a smooth shooter. Can one simply take out the broken coils and use the remaining spring?

But I am confused about the trigger. The Diana numbering system does not seem to coincide with their trigger modules across their various models. For example, this website has many exploded diagrams of Diana airguns: https://www.omps2.it/en/715-diana-spare-parts.

Looking at those diagrams, it looks like the Model 34 T05 should have the angled plastic safety. I have a Model 350 T05 with the angled plastic safety.

My Model 24 J I bogged about has a “D” type trigger, but it does not look like a Model 25 D, it looks more like a Model 34 T01. It has the curled steel safety and the two adjustment screws through the plastic trigger blade. The diagram for reader Bill’s Model 54 T01 also seems identical. However the diagram for the Model 24 T01 seems like an entirely different animal.

B.B. reported that RidgeRunner’s Model 34 has a T05 trigger, and I presume that is correct because he can look at the marking on the spring tube. But the exploded parts diagrams would have led me to predict that we were looking at a Model 34 T01 based on the style of the sights, rear safety, and stock. Moreover, I have read that the T01 had two screws through the trigger blade to adjust first and second stage like my Model 24 J, but the T05 trigger only had one screw to adjust first stage length of pull only. Then Diana brought back a two-screw adjustment in the T06.

Now I’m curious about whether reader Bill’s Model 54 T01 looks like my Model 24J. Here’s a link to my guest blog for your convenience, Bill.

/blog/2023/04/roamin-grecos-wrestling-match-with-a-rws-diana-model-24-j/.

In any event, I’m super-excited to peek over B.B.’s shoulder to learn how to tune these vintage Dianas, and how to select replacement springs for them.

RG

Sorry for the delay but somehow I lost series of things… This is what the T01 trigger looks like.

Fascinating. The screw heads look bigger, but that’s the same placement as on my Model 24. I would bet that they are the same mechanism. Why Diana would name the same thing differently is beyond my comprehension, unless we are all under the false assumption that T01, T02, T03…T06 only refer to the trigger mechanism….

Now I really messed with my own brain!

Thank you for the picture.

The two adjustment screws do not protrude at all. Please excuse me for not taking off the stock for a better picture.

I send you a different picture for apology though.

My parents are going to Greece with my sister and brother. I haven’t been since 2019. I miss it! We would normally go to Chios and have a very similar view.

Perhaps next summer….

And what is going to be in that big black case by then, in order to make the view very similar? (LOL)

I guess I will have to pay my new airgun buddy a visit….

Now you’re talking

Bill,

I could smell the fresh seabreeze!

shootski

Everyone, the wood-stocked Crosman 362 seems to be available again on Crosman’s website, but at $399, it is a lot more spendy compared to the original.

BB,

My issue was I could not break the 34 open, period. I smacked the barrel at least five times and it would not open. The ball detent seemed to tight. All I can think of is I might have been hitting it at too much of an angle. I was having no trouble cocking it once it was broken open.

It is my understanding that Diana only used the plastic trigger on the T05. Is that correct? Many shooters objected to such and so Diana came out with the T06. At least that is what my rememberer says.

All you needed was to mail it to B.B. and the barrel now opens easily…. Hmmmm.

;o)

Embarrassing, to say the least.

To the contrary, RR, the coils probably started screwing themselves together under residual pressure.

When my original MS broke, it did precisely what you described. It would cock when I got it to the then Precision Airgun Sales and Service on the east side of Cleveland. It wouldn’t shoot well, of course, because the MS was shortening itself and had, obviously raw ends where the steel parted itself.

Now, when MS #3 finally lets go, I’ll just pack up the action and send it off to UMAREX.

RR, one more thing. A secret! There is NO SUCH THING AS AN INANIMATE OBJECT! Objects just sit very, very still waiting for their opportunity to “pounce” at the worst possible moment. I have known oil pan bolts to run away under a dim bottom side of an automobile and hide near the contact patch of a tire. I think they even laugh at you from their dark hide having cammo-ed themselves in the same flat black color….

RidgeRunner,

What a gorgeous air rifle you have here!

You might be right about the evolution of the Diana trigger. That is certainly the history of the Feinwerkbau 124 trigger. At first they were plastic, then owners were given a metal one, then the model started to ship with metal triggers standard.

Michael

Michael,

It is quite a looker.

B.B., those exercises must be paying dividends. Now we need an arm wresting match, B.B. vs. RidgeRunner. ;o)

From the sounds of it, he would win.

BB

Count me in the growing list of folks who call this among their favorite type reports.

For just a few minutes you had me wondering if Ridgerunner was pulling our strings. But then the cocking behavior changed all of a sudden. I’m thinking the ball bearing detente is about to change too should you choose to shoot it more because he clearly says above it was hard to open. He is not a little guy nor is he old and feeble. Happily we shall all get to see what surprises await inside this Diana 34.

Judging from other comments it seems that Diana made use of whatever trigger parts they had in inventory so long as function was not compromised. I have several Diana models and all the triggers work well for me.

Deck

with a trigger like the one in this rifle it will shoot into one hole at 30 yds cause a good trigger is all that is needed for accuracy. it dont matter if the barrel is bent rifling gouged and rotted a good trigger will overcome it all

LOL! I wish!

It may have been me. From what BB has said, I may have been hitting it at an angle. I guess the ball may have become jammed in place momentarily, but I have never heard of such.

This is a handsome air rifle and no doubt will be a very nice shooter once Tom is done with it. RR, it is a keeper but, what does FM know?

FM,

I would not get rid of it lightly.

Oh boy! I like were this report is going. I have a Diana 34 in .177 that I purchased, new, many years ago. I really like the rifle, its construction and fit, but something is not quite right. Trying to calm down the harsh cycle I installed a Vortek kit, for which I first had to build a spring compressor. The mod went well, the cycle improved some, but I feel that there is more to be done.

I will be looking attentively over BB’s shoulder in search of ideas. looking forward to the next part.

Henry

Henry_TX

TIAT on that spring would make a very noticeable difference but you may know that.

Deck

Good point Deck. I used a heavy grease – sparingly as instructed – that came with the kit but I never tried TIAT. The sad truth is that its bad behavior sent it to the back of the rack. This series will help to perk up the interest in it.

Henry

That grease should work pretty well. If you go with the TIAT idea, you can go by Lowes or some place and get Lucas Red and Tacky. Same stuff. Real cheap.

Thanks for the tip RR.

Henry

Henry, you put your Diana in time out for bad behavior? That’s what I did with my kids when they were little. ;o)

I think that when RidgeRunnet gets this Disna back from BB with a sift tune, it will earn a spot an his tevered wall of fame.

B.B.,

Forgive this Dark Sider but…

You said: “I found the barrel to break open easily. I bump the muzzle out of habit, but I don’t need to.”

But RidgeRunner once again says: “My issue was I could not break the 34 open, period. I smacked the barrel at least five times and it would not open. The ball detent seemed to tight. All I can think of is I might have been hitting it at too much of an angle. I was having no trouble cocking it once it was broken open.”

Now both of you are documented to have way more experience with Break Barrels than I do but I have questions looking for answers.

1. I believe B.B. is right handed but I don’t know RidgeRunners handedness. So would it make a difference?

2. Do the both of you hold break barrels the same way to cock them?

I ask because sometimes i use my left and sometimes my right arm/hand to cock my SSG ASP20 break barrels; the only two i own.

Could this statement of RidgeRunner’s be a clue: “All I can think of is I might have been hitting it at too much of an angle.”

3. What angle is that?

4. Why hit barrel at an angle in any case?

“Dumb” Dark Sider would like to know some more.

B.B. wrote “The Diana 34 has a ball bearing breech lock that rides over a steel inclined ramp, until the spring pushes the ball over the steel ramp to lock the breech.”

5. Could we get a detailed photograph of this steel inclined ramp on a future Part? Please.

I noticed the two deep cuts at 12 and 6 o’clock that look like a way to get leverage on the back of the ball.

6. Did dirt or other debris get in there behind the ball?

shootski

shootski,

I’ll address your concerns in the next installment.

BB

Whoops, sorry to steal your thunder, B.B.

Shootski, RidgeRunner, B.B., and readership,

I too have been puzzling over the discrepancy between RidgeRunner’s and B.B.’s experiences so far with this rifle and wanted to put out some thoughts to see if they are bourne out in future parts of this series.

First, perhaps RR got such a good deal on this rifle due to the difficulty in cocking. If fixable, so much to the better, which is why I asked if the remaining spring could be used, perhaps with a few washers to allow the spring to spin withing the cylinder.

Second, I bought a “new old stock” Walther Terrus that I needed to slap the barrel to break it open for a while, but it eventually became easier. Although it has a chisel detent, the principle is the same. So in RR’s case, being a used rifle, perhaps there was some corrosion or congealed “ugh” behind that detent ball that somehow got knocked loose. Or perhaps that detent ball and the steel ramp are in need of lubrication. Or both.

Third, B.B. surmised that the main spring may be broken because he experienced difficulty cocking the rifle. RR had difficulty breaking the action, not cocking, so I am guessing the broken spring was binding RR on the breaking which is where you have the least leverage, but now the broken piece or pieces are gradually intertwining with the rest of the spring and are binding further down the cocking stroke. If B.B. keeps cocking and uncocking, it may fully intertwine and become smooth again at a lower power, like my Diana Model 35 is.

As far as the angle, if a slap is needed to break open the action, it is usually perpendicular to the barrel and in line with the hinge. On my Walther Terrus, initially, I had to either put the hinge over a knee to increase leverage of the slap, or I would grab the gun with my other hand over the spring tube near the hinge and pull in the opposite direction of the slap, to sort of give that slap a running start. And when I mean “slap,” we are not talking patty cake here. You gotta give that barrel a good smack with the palm of your hand, with some follow through, to get it going.

Good luck, B.B.

Shootski,

By angle, I am referring to the angle of rotation. I may have been hitting it more to the side than on the very “top” of the barrel. Either that or the ball had somehow “wedged” itself in the “locked” position.

I took some velocity readings with my chrony, but I had not calculated the FPE. If I had, I would have noticed it was pretty low on the power and might have remembered the history of Diana broken springs.

RidgeRunner,

Thanks for the added information.

So when you hit that Diana with your hand

it STANG a lot…

sorry…couldn’t resist ;^)

I’m hoping to learn some about not breaking my break barrels since they are beginning to be worth some real money. Even if this airgun of yours is a coil sproinger.

Hope she gets all better and comes home to RRHFWA to stay.

shootski

shootski,

I hope so also. We will see. By the way, you can have those gas sproingers of yours. 😉

RidgeRunner,

I hope they keep shooting well for a long time.

I don’t care how much they appreciate in value.

The SIG gas springers are fun to shoot; i can’t ask for more.

shootski

B.B.,

Thank you!

shootski

All,

There has been some speculation as to the origin of this Diana 34. I bought it from a friend who was selling it for the wife of an older gentleman who had past away. As all of the money was going to the widow, I did not diddle around about the price, though I did get it at a good one.

As BB stated, it looks to be in very good condition and apparently has not seen much use. Initially, I had a lot of trouble cocking it, but I loosened the barrel block pivot screw a little and it seemed to cock fine.

I had taken to wearing a leather glove as it was taking quite a slap to open it and my palm was getting sore from it. Shootski, I am left handed but have always shot right handed. I hold the rifle with my right hand and break the barrel open with my left hand.

I doubt that the ball bearing detent was the issue. The whole hinge point structure is steel, the breech block is steel, the axel bolt is steel the ramp is pretty good steel as my ’89 M-36 ramp works perfectly all these years against a hardened ball bearing.

I think the problem is in the spring tube and the resistance there is what is causing the problems.

BB will surely find what has and is happening when the disassembly commences. The two times that I had this happen, I have the piston seal and breech seals replaced while the rifle was in disassembly.

RidgeRunner: how is your 36 different from your 34?