RidgeRunner’s Diana 34.

This report covers:

- Disassembly

- Mainspring out

- Remove the piston

- Report 1

- Report 2

- Why so smooth?

- Why cocking was hard

- What now?

- Summary

Today we open up reader RidgeRunner’s Diana 34 (no, it is NOT an RWS 34 — RWS doesn’t make airguns!) and see what we find. My “Final observation” from Part 1 was partly correct. This is a practically new Diana 34. I doubt it has had 500 shots since new. But the “assumption” that the mainspring was broken was incorrect. The mainspring is whole.

Disassembly

I know you all want to see the disassembly so I’ll show it. First I put the barreled action into my mainspring compressor. I used a deep wall socket to press in on the trigger assembly. That takes tension off the two crosspins that hold the trigger assembly in the spring tube. The two crosspins then came out with finger pressure. Then the trigger assembly came out of the spring tube.

I’m calling this a T05 trigger because that’s what it most closely resembles. But there are small differences, such as the safety bar.

The trigger is a mystery because it differs from every Diana trigger drawing I have examined. It is closest to the T05, and that’s what I’m calling it, but the later T05 (the one on Diana drawings) has a different safety (it looks like a T02 trigger safety) and even a somewhat different trigger blade. The trigger blade in this rifle is plastic.

The two crosspins have been pressed out with the pin punch shown and I am relaxing the mainspring with the compressor.

Trigger assembly is out of the rifle. At the top is the rear spring guide. It appears to be in good condition.

Mainspring out

Once the trigger is out the mainspring slides out of the spring tube. I was surprised to see that this spring was not broken as I had conjectured. It is bent in several places and it was very dry. The rear spring guide fits the inside of the mainspring quite well.

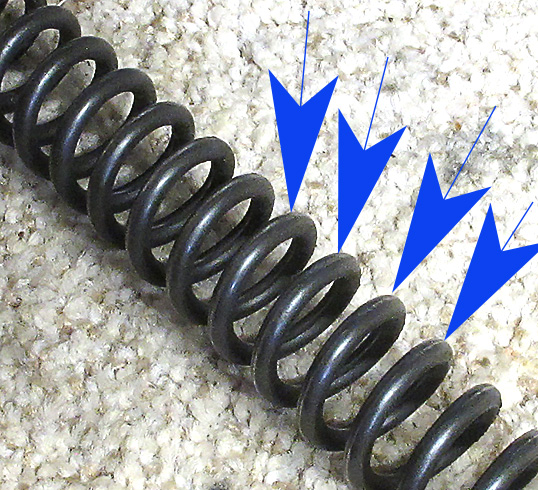

The mainspring isn’t broken as I thought, but it is bent in several places. It doesn’t look bad here, but the sides have been rubbed shiny from pressing against the inside of the piston.

If a mainspring appears straight, roll it on a flat surface and watch both ends. They will tell you how flat it is.

Remove the piston

To remove the piston the barrel has to come off so the cocking link can be disconnected from the piston. The Diana 34 has a pivot screw that comes out easily. Thanks, reader JerryC, for telling us about that marvelous Vessel screwdriver!

The piston seal is in perfect shape. However the top is coated with black ash or soot from dieseling. When I looked inside the spring tube the air transfer point is also coated with the same black soot.

The piston seal is fine, but I’ve never encountered the black soot in the center of the piston crown. That inner circle should be silver. There is also black soot coating the air transfer port.

The pivot screw was dry as a bone, but it isn’t the pivot for the barrel. There is a hollow bushing that screw passes through that serves as the pivot. It was also dry as a bone.

The pivot screw and nut and the bushing they pass through. Everything is dry.

With the pivot out the barrel slides out of the action forks. Like everything else, the contact points are dry.

As I separated the barrel and base block from the action forks it became obvious that all the parts were dry as a bone.

Report 1

RidgeRunner, as I said in Part 2, I don’t think this Diana 34 has been used much at all. As dry as it is I’m surprised by how smooth it shoots. But I think I know why. I will explain in a bit.

I think just lubricating the powerplant properly will probably reduce the cocking effort by 2 or even 3 pounds, but we’ll never find that out because I’m going to install a new mainspring that should take it down a lot more. It was cocking as easily as it did (30 pounds of effort) from the design of the powerplant and nothing else.

Report 2

The Diana mainspring is made of wire that measures 0.126-inches in diameter. There are exactly 33 coils, so the compressed length of the spring is (33 X 0.126) 4.158-inches. The spring’s outside diameter is 0.825-inches. The inside diameter is 0.565-inches.

The inside diameter of the piston is 0.950-inches, which means there is a huge amount of clearance between the inner piston wall and the outside of the spring. This rifle should have buzzed like a jar full of angry hornets! But it didn’t. Why?

Why so smooth?

The mainspring is kinked on both ends and there are shiny silver spots on the outside of the coil where the spring has been pressing against the inside of the piston wall. That’s what kept the buzzing to a minimum. If the spring had been lubricated it would have been buzzier, not smoother, because the spring would have rattled around instead of pressing tight against the inner piston wall.

The arrows point to the shiny spots rubbed on the sides of the mainspring wire.

There was an extraordinary amount of pretension on the mainspring. It came out of the spring tube at least three inches, if not more. That much is entirely unnecessary. I think Diana used the same spring in several airguns, so the fit isn’t optimum.

Why cocking was hard

Remember in Part Two I mentioned there was a hesitation during the cocking stroke? That was the end of the piston entering the rear spring guide. That would have worn in over time. I can fix it by lightly reaming the opening of the spring guide. What caused the barrel to be hard to break open I have no idea, but I will keep looking.

What now?

First I search through my assortment of mainsprings to see if anything I have will do the job. If I find nothing then I buy a mainspring. Beyond that I think the only thing is to clean all the parts, remove as much of the slop in the powerplant as possible and to lubricate properly.

Summary

RidgeRunner has a nice Diana 34 that I think I can make nicer for him. We’ll see what comes next.

BB,

In pic #1 under “Disassembly,” is the end cap aluminum, or is it the same plastic as the trigger?

“The springs outside diameter is 0.825-inches…The inside diameter of the piston is 0.950-inches…”

Holy Toledo!…an entire 1/8″ of slop? As an engineer, that offends me.

I can’t believe a high class airgun manufacturer would allow that.

I can understand, for economy’s sake, wanting to use the parts you have on hand on multiple guns…

…but only if you can do so within reasonable tolerances…I found that shocking…

…no wonder that spring was so bent up!

Well, the good thing is, RidgeRunner will get an excellent rifle back when you’re all done. 🙂

Looking forward to the rest of this journey,

Blessings to you,

dave

Dave,

The end cap is plastic.

BB

BB, I guess that’s fine, since, from the pic, it appears to be a non-structural component. 🙂

Dave,

You do need to keep in mind that the Diana 34 of this time period was the entry level, bottom of the line airgun for the company.

All airgun companies have had their ups and downs. Over the years Diana has been plagued with quite a few.

RidgeRunner, yep, I hear ya; but the good thing is she’s about to move from “entry level” to “top shelf.”

By the time BB’s done with her, I’m sure she’ll be a sweet-shooting gem.

I’m really glad you sent him this rifle; I’m enjoying this series…

…and judging by the comments, I’m not the only one. 😉

Dave,

As near as I could tell, it was a safe queen. It is not anywhere near broken in yet. With a little tuning, it should be pretty sweet. We shall see.

Is that barrel pivot pin bushing common to all springers?

I assume it is there for the action forks to really tighten down on and still leave a predetermined side space for the barrel to pivot on.

I seem to remember tightening the pivot bolt to remove barrel side play on one of my China made springers just the right amount without over tightening and then staking it.

Perhaps it was just loose on the bushing and tightening it just enough resulted in the proper clearance to pivot easily without too much play?

Bob,

The bushing isn’t that common. All I can tell you is the barrel stayed where it was put after being cocked. There is no side play.

BB

Bob M,

I had tightened and then had to loosen the pivot bolt again. It will tighten to the point that you cannot move the barrel. The bushing is too short to prevent the forks from closing tightly on the barrel block. It is a nice touch though as it prevents the block from rubbing against the bolt and helps to prevent the bolt from loosening from repeated cocking.

B.B.

I sure hope that the new spring fits the ID of the piston better. Otherwise, soda bottle sleeve?

Your comment about the sides of the spring contacting the piston walls bring up the very important, and often over looked Idea of how the spring transfers power to the piston. Top hat, heavy washers as spacers, flat spring ends, all and more very important and not enough spoken about. Should the top hat fit slightly looser that the spring guide?

-Yogi

Yogi,

I took those measurements for me as much as you readers. I hope to find a spring that fits much better.

As far as a top hat goes, I’m still ponddering.

BB

BB,

I would have said this air rifle had not seen much usage. Sadly, there was no lubrication anywhere. That may have been what the issue was with opening. With no lubrication on the lock-up ball, it may have become jammed and refused to slide back into the block, unlocking the mechanism. Merely wild speculation on my part.

The soot may have come from someone using the wrong type of oil in the chamber. Dieseling with a light petroleum based oil may have caused the soot. Fortunately, it did not seem to damage the seals.

BB

I can’t resist thinking out loud. When I do that sometimes I open myself up for getting embarrassed. Here goes anyway. As suggested already someone put the wrong kind of oil in the transfer port chamber. When shot it detonated causing the spring to get bent out of shape. Factory lubrication got burned up in the explosion leaving the soot residue. Subsequent shooting was smooth because little if any combustion took place in the piston chamber because there was nothing left to ignite.

Can’t help but wonder if proper lube of parts and a new spring would bring her back to specs.

Deck

Deck,

” proper lube of parts and a new spring would bring her back to specs.”

They sure would. But the specs aren’t what I’m after. I want a smooth-shooting 34 that’s easy to cock. It will be an air rifle RidgeRunner will delight in.

BB

BB

Lots of readers including me are enjoying this one.

Deck

Deck,

The wrong type oil in the transfer port is pure speculation, but could possibly explain the soot. The bent spring may be from so much slack between the side of the compression chamber and the spring. It also was an overly long spring which under “normal” circumstances would be quite compressed, even when at rest. This particular air rifle was built in the mid 90’s. That is a long time for a spring to be partially compressed with lots of slack around it.

So are we talking about a 9 fpe D34?

What power output do you have in mind?

If that is the case, you could cheap out and just cut 2-4 coils off the existing spring?

Sorry Ridge Runner….

-Y

Looks like a T01 era 34. Curled steel safety and black plastic spring guide is a giveaway. I am sure it’s in the works, but please replace the spring guide. Good luck-nice rifle.

I think I agree. I read that the T05 had only a single screw to adjust length of the first stage only. I wonder if the gun is not stamped T01 or T06, etc., then is it a “D”? Were there T01 guns that were not so marked?

Sorry RG- I don’t know. I have had Diana rifles prior to this date that were stamped both trigger type and date. Perhaps this one got through production without the trigger type stamp.

Arbiter, were your “Diana rifles prior to this date that were stamped both trigger type and date” Model 34s? This one is 1995. Read my comments below. I think after a certain date, Diana began marking each rifle they made as Type 1, Type 2, etc., abbreviated as “T01,” “T02,” etc. to distinguish between significant changes, with perhaps minor variations within each Type.

RR-2 were 48’s and the other was a 38 (34 variant w/fancy stock).

arbiter,

I am in no way near being expert on the Diana 34. My guess would be a T01 era, but I have been told the T05 is the one with the plastic blade. This just may have been a transition piece where Diana was experimenting with various parts. I do know this trigger is sweet and I do not care if it is plastic or not. I have a Diana 46 with a plastic trigger. It is also a trigger to die for. If I am not mistaken, the safety on this can be reset.

RR-I am not an expert either, but, both my Diana 48’s with T01 triggers have plastic trigger blades. I am with you on the trigger blade-plastic doesn’t matter in this part because the Diana trigger blade isn’t a weight bearing or part that will suffer wear.

Well, I ain’t never heard that before. T01 with plastic triggers. I always thought they were metal. Learn something new every day. Maybe that 46 I have is a T01 also. I do know it is real sweet.

How can you tell the difference?

RR-I have had 3 Diana rifles with T01 triggers, all have plastic trigger blades and steel safeties. I haven’t seen a metal trigger on modern Dianas until the T06 unit. You can tell by appearance-smooth, shiny, black, usually are plastic. T01 and T05 have plastic trigger blades, T06 has an aluminum trigger blade.

Sorry to be late to the dance. These Diana triggers are a confusing issue. I wish someone from Diana would post an authoritative comment on the Diana nomenclature…(hint, hint).

Looking back to earlier reports shows this is not a T05 or a T06. Both had plastic safety buttons and the T05 had only one adjustment screw while the T06 had three. See this series:

/blog/2011/06/comparing-the-t05-trigger-to-the-t06-part-3/

Check out part two of that series. Below are some pics from them.

OK, I think I found some definitive information.

https://www.gatewaytoairguns.org/GTA/index.php?topic=186849.0#msg156146033

So I think Ridgerunner’s Model 34 has a “T01” trigger.

Also, in my search I found that the T01, T02, etc nomenclature is essentially “Type 1, Type 2” etc., but it refers to the Rifle overall, not the trigger. So let’s say the Model 34 Type 3 was around when Diana came out with a new Model X rifle, which may be marked T01 for Model X, Type 1, but they may have the same trigger! So it is important when discussing triggers to always associate it with a Model number. My Model 24J has the same trigger as RidgeRunner’s Model 34, except the adjustment screws do not have flat heads on them. And I have been able to confirm that my Model 24J’s action and trigger are the same as a Model 24D.

Hello everyone FrankB here.

Back amongst the living….. I haven’t had the luxury of thinking about airguns for 6 months or so.

It’s nice to have my daily dose of The Godfather!

Tom I hope your sister continues to do well…… I have just now managed to read about the Giffard 8mm. I do hope you continue making progress to fully experiencing it. I’m happy to ride along vicariously.

To all my air gun friends I miss you.

Today’s blog may have emboldened me

To take a peek inside a pair of Hyscore 807s……. One of them accidentally fired with the barrel not quite shut. Now it cocks but the trigger only releases

When the barrel is broken open in the spring tension is taken off. I’m not scared of a rekord trigger unit,…. But I’ve yet to mess with Diana.

Anyway prayers and good thoughts to all

FrankB

Frank, take precautions to not lose the small ball bearings and any springs that may try to escape you into the 5th dimension. I tore down a Winchester 416 (Diana 16) last night and the main pin through the spring tube kept falling out and trying to escape without me noticing. I think it was there as a fall back safety feature because it was under no tension at all. Luckily, I was able to put all the parts back together. But I have not gotten the courage to take apart a ball bearing trigger yet.

Thank you much for the heads up!

With my track record I suspect I need to do the job inside of an inflated trash bag. I have a horrible track record with things like the spring and ball in crosman trigger unit safeties, etc…… I’m sure I will use tacky grease on reassembly. Once bitten twice shy LOL

Hey Frank!

We have indeed missed you! Welcome home!

RidgeRunner! I have missed you my friend. I see that you’re doing a good job running the home for wayward air guns. Reading the blog this morning I did feel a sense of home…… For which I am grateful to Tom and everyone. Prayers and good thoughts to all. FrankB

Frank, it’s good to see you back, man! 🙂

I have missed my wonderful Airgun friends. Not to mention enabling and being enabled LOL!

Tom,

I keep looking at photo #6. Your caption reads, “The piston seal is fine,” but to my challenged eye it looks torn. (I’ve “enhanced the photo’s contrast and attached it below.”) At about 10:00, is that an optical illusion or shadow I’m seeing?

Michael

Michael,

I had to enhance the heck out of this pic to get the soot to show and that is a huge illusion.

BB

I thought it might be. Could be a shadow.

And only The Shadow knows what lurks in the innards of malfunctioning airguns…

B.B., thanks for this series. I can’t wait to build a spring compressor and tear into some of my Dianas. So far, I have only completely torn down the guns that I can take apart without one: a Tx200 and a Diana 16.

I’m really curious about the problems that RR experienced but that you have not. I can’t wait for the next installment.

Thanks B.B., I am thoroughly enjoying this series. What did it? What is it? It reads better than a suspense novel.

In my mind, perhaps confused, with the bent spring some coil was randomly having a hard time stepping inside the piston, explaining the apparent barrel lock. The lack of lubrication is surprising, as the factories generally use oils generously. Perhaps the previous owner dried it up intentionally? Also, I second Michael’s suspicions about the seal.

Question, assuming you do not find a proper fitting spring – what would you specify to order one? Any favorite supplier?

Henry

B.B. and Readership,

Be careful when you size a spring to a tube!

Both the length as well as the inside diameter of the compression tube can bind a coil spring. “The diameter of a compression spring will increase when compressed. This increase is a function of the pitch (p).

Calculate the OD expansion and compare this to any work in tube requirements. Remember to incorporate the high side of the OD tolerance when examining the work in tube requirements.”. One of Lee Spring’s White Papers has the formula to compute how much the diameter of a coil spring increases when compressed.

https://www.leespring.com/

They have some other great resources as well as stock and custom springs of every kind.

Also: https://springipedia.com/compression-general-design.asp

shootski

PS: This is why shootski will probably stick with his two gas spring airguns, single/multi pump, CO2, and PCP’s!

Thanks Shootski! That is very useful information.

Henry

Everyone,

No, RidgeRunner’s 34 IS NOT a T 01 trigger. That one is a ball bearing trigger. This trigger is CLOSEST to a T05, but not the one shown today. Go here to see.

https://twchambers.co.uk/airgun-spares/dianaoriginalgecado/

BB

Looking good BB. I have a Diana 34 in .22 Cal. that I purchased from an estate some years back. I lubed it with Tune-in-a-Tube, a little chamber oil, and gun oil on the linkage parts. Shoots well and accurate. It’s my current go to gun for the local Red Squirrel population. They don’t seem to care for it.

Thanks for the pics of the take down. I may need to work on it some day. I will need to order a spring compressor first!

Mike