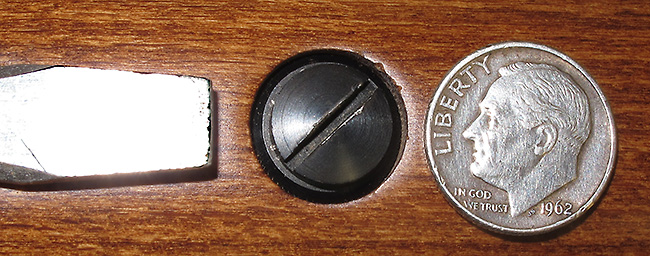

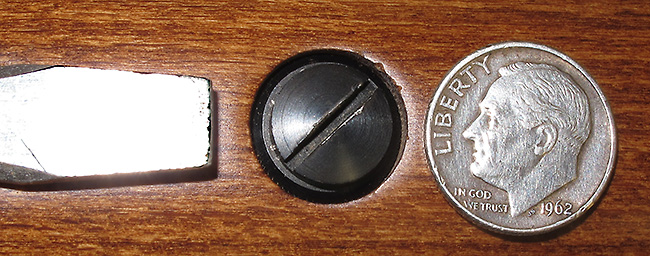

My largest flat screwdriver blades are too small for the stock screw on this HW-50S.

This report covers:

- Screwdrivers

- Phillips

- Pin punches

- Figured it out!

Yes, this is an airgun blog and yes, I want to talk about airguns, but as I worked on the HW 50S yesterday something came up that has bugged me off and on for years — the need for good tools. Specifically, I’m referring to my tools and I’m wondering why most of them aren’t the right ones that I need when I need them. Please allow me to show you.

Screwdrivers

I’m going to ask you to do some online research today, or this weekend — your preference. Try to find a good source for large flat-bladed screwdrivers for large screws. Flat-bladed screwdrivers do exist for small things. I talked with Denny about this and he immediately went online and found me a set of micro-flat-blade screwdrivers. What he didn’t realize is they were for eyeglasses and watches — not for the sort of screws we encounter on airguns.

This Bergeon set of flat-bladed screwdrivers is made in Switzerland. The are great for watches and eyeglasses but not so good for airguns.

Then I thought — Amazon! If anyone has them Amazon surely will. Well, they don’t! Was I searching for the wrong thing? Would a set of gunsmith’s screwdrivers be more appropriate? Not only no — heck no! Their “gunsmith screwdriver sets” are the same Chinese sets I have three of right now. Dozens of littly bitty blades that attach to a magnetic driver handle that possibly has a ratcheting switch. And they all come in a nice plastic box. The set of 48 “screwdrivers” retails for $19.95.

Those are not screwdrivers. Like I say, I have three sets on my pegboard and several more with twisted and broken blades in various tool drawers. I expect to pay $19.95 for one screwdriver — not 4 dozen!

Wait a minute, BB. Amazon has an expensive set of gunsmith screwdrivers made by a company called Chapman. BB knows that because he owns them. Yes they are expensive and no, they are no good. I have bent and broken many of their blades. And — guess what? They don’t have any LARGE flat blades! I’ve been there, done that, got the T-shirt and wore it out.

Phillips

You see, when you look for flat-blade screwdrivers what everyone wants to sell you are Phillips screwdrivers. Everybody has them and they are so eager for you to have them, too. Well, ever since reader JerryC told us about Vessel Phillips screwdrivers from Japan, I have a wonderful set that I use all the time. Well, then, BB, surely Vessel makes flat-blade screwdrivers, as well. They do and don’t call me ….. nope, I’m not gonna go there. Their flat-bladed screwdrivers are all smaller than what I need.

Okay, sez I — eBay! That’s where I usually find things I want when I can’t buy them new. Since it seems no one is making large flat-bladed screwdrivers these days — at least not the sizes I need, perhaps they made them in the past.

And, I was right — sort of. In the listing of the vintage screwdrivers on eBay the tip of what they call a LARGE flat bladed screwdriver measures 3/8-inch, or 9.525mm across the tip. Folks, I have blades that size in piles! I need a LARGE flat-bladed screwdriver!

Denny told me nobody was making large slotted screws like that anymore. Well then, I guess Weihrauch is nobody!

I used to have what I consider to be a large flat-bladed screwdriver. The width of the blade was greater than one-half inch or 12.7mm. I used that one so much I broke the handle off and, like a dummy, I threw it away. Surely I can buy another screwdriver just like it? No, I can’t and don’t call me … nope, nope, nope!

However, while writing this report I discovered a pawn shop find that I was supposed to fix — a few years ago. Every time I go into a pawn shop I look for large flat-bladed screwdrivers. I found this guy in one. And I guess I need to order another case of round tuits to get that handle fixed.

Now, THAT’S a large flat-bladed screwdriver!

Pin punches

I just filled half a report on one type of tool I can’t find — the large flat-bladed screwdriver. Tell us, BB — how bad does this get? Well, the only other hand tool I used for the HW 50S disassembly/assembly yesterday was a pin punch. A SOLID pin punch for pushing SOLID pins. Try to order a set of those! My Craftsman set is 40 years old and the tiny 1/16-inch punch has broken, as they will for all shade tree mechanics like BB Pelletier.

My set of Craftsman pin punches is 40 years old and the tip of the smallest one is broken.

So once more I venture out into the fray, only to discover that what “they” want to sell me are roll pin punches. But I don’t want roll pin punches because most airguns don’t use roll pins. I want solid pin punches.

Well, BB, if it’s just your 1/16-inch punch that’s broken you do know you can buy just one that size? Yes, I’m aware of that. But all the other punches in my set have mushroomed tips or they are bent (don’t ask). I need a new set, and no, I won’t throw the old punches away — not even the broken one. There’s always something…

My point here is, if solid straight pins are still being used in manufacturing (along with slotted screws that have large heads) why aren’t the tools to work on them more available? Yes, I’m aware that straight pin punches come in the sets that include punches for roll pins. That’s what I had to order. I don’t need those roll pin punches but who knows? Maybe someday I will.

Figured it out!

Then it hit me. The reason I can’t find any vintage large flat-bladed screwdrivers or solid straight pin punches is because people aren’t selling them. They are keeping their good tools, just like I’m keeping mine. I suppose when someone passes away their heirs might sell off the tools, but you have to be quick to get them, because everyone wants them.

I don’t know. That’s just what occurs to me. Do you guys notice the same thing, or am I just being a crybaby? Are you able to buy good hand tools these days?

The FAT Wrench is all you should need. That and a good set of allen key keys is all you need. Except that little cut off tool to pop out the 4 squares.

What size is the front trigger guard screw. Well it is an M-7, good luck finding one. McMaster-Carr, forget about it.

Even Euro hardware stores have no M-7 Hex headed screws/bolts.

-Y

I agree, it is hard to find quality tools for some specific tasks in todays world where everything is disposable.

Like you, I have either scavenged older tools or made some of my own by modifying an existing tool to perform a task it was not designed to do.

No one makes a tool to remove the ring that holds the face seal that seals the co2 cartridge in the many co2 pistols out there.

Like your tool to push the parts from the insides in yesterdays article about the HW, those of us that NEED those special tools are few and far between, but it makes our life so much easier.

On a different subject, about the Jelly hog, this video was posted a few days ago shooting ballistic gel with very powerful firearms, but filming them in extreme slow motion.

The results are very cool.

Enjoy!

Ian

https://www.youtube.com/watch?v=nsJGJHkJolI

Ian,

Monday. 😉

BB

BB-

For $10-15 you can get a 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 7/8, and 1″ wide xl screwdriver set.

The trick is to buy a paddle bit (wood bits) set and grind the points off. These bits have 1/4″ hexagonal shafts and will fit a drill or a 6-in-1 screwdriver handle. The drill bits are a hair shy of 1/8″ thick, and because they are cheap and plentiful, you can grind to fit.

Does this make sense?

That’s not a bad idea. Especially if you are right about them fitting into a screwdriver handle without falling out.

Of course, I don’t think I have ever seen a 1″ diameter screw on an airgun, so the larger sizes may not be used but so what. I can see applications for more than slotted screws.

Great suggestion Prof!

There’s pretty good steel in those spade bits! I’ve repurposed them into all manner of specialty tools.

BB,

From my early gunsmithing days of restoring vintage single-shot shotguns, I learned to always look for lots of old flat-blade screw drivers (pawn shops are a great place to find them); then, when I had a need for a particular size of screwdriver, I ground down one of the old ones till it was a proper fit. Not counting the screw drivers that come in kits (and are mostly small ones), I’ve got dozens of flat-blade screw drivers here…and I can always use a few more! 😉

Blessings to you,

dave

Well what I should of said was the problem is not the tools needed for the rifles fasteners, but the fasteners themselves! Why not use grade 5 or 8 hex headed bolts? Stronger, easy to manipulate, easy to torque to specs.

Instead they give use slot heads that are soft metal, in the case of Hatsan putty metal….

At least you can get into these guns, unlike the ill fated SIG rifle.

-Y

Yogi,

The hex-headed bolt was Denny’s suggestion.

BB

I’ll make this response quick so that you can get back to work on your HW50. Do you have a bench grinder? Get one of your old, yet serviceable flat screwdrivers and carefully grind the blade into a workable size. I’d give it a try any how. As always. Orv.

Orv,

I have several flat-bladed screwdrivers that are purpose-ground and filed.

BB

Good morning, when I first got into airgunning again, I found this Birchwood Casey kit on clearance, it has large thick and thin hollow-ground flat bits that are good with the screws on my R7 and R9. They can be further shaped if needed. It is 90% of what I have needed. I still need a set of really long, thin ones for getting into the trigger guard holes for trigger adjustment screws.

Some of my vintage Dianas have a slotted nut that requires a flat bit with a U-shaped cutout. I have no bench grinder, so I asked my gunsmith to make me one. He charged me $20.

The Crosman Mark I and II pistols I like to rehab and reseal have roll pins, so I have a set of roll pin punches from Wheeler. But the set comes with a tiny hammer….

I still need to fabricate a large flat screwdriver blade or tool to remove the nut inside the piercing cap without making a mess of the threads in there.

And for other guns, I still need a set of solid punches, brass and steel. Oh, and a proper vise, and a spring compressor ….

RG,

They are all out there if you look for them. You just have to shuck out the bucks. 😉

RidgRunner,

You got that right, completely correct.

As I cruised around ebay looking for large flat-blade screwdrivers, I discovered two categories: new ones for very serious professionals at very serious prices, and quite old ones that were in various conditions, with the better ones at very serious prices. I saw a really nice vintage Irwin for $50 + shipping.

Sometimes I would find a well-made vintage one that the seller had removed the rust from and redressed the business end to make it precise again. They were quite pricey as well because of the labor. (And why not? A rusty $3 screwdriver at a pawnshop that someone then put an hour of labor into.) I saw one that was made like new again for $30 + shipping.

My lesson? I need to start haunting pawns shops again. :^)

Michael

It’s one of those cases where if someone made the tools, almost no one would buy them.

That said, a “Weinrauch Factory Toolkit” would probably be a steady, if slow seller. Just a case of someone willing to tie up the necessary capital.

You read FM’s mind; sell the tool sets as accessories to the airguns, with a detailed repair and maintenance manual to go with them. That’s FM’s Wishful Thinking thought for today.

Selling a kit like that would lead to warranty returns and repairs for the makers, because I believe most people shouldn’t touch their airgun or a tool!

But they could be sold exclusively through folks that sell spare parts and springs as an accessory after the initial sale….

Much better would be an after market person making a hex screw kit to fit the HW stock screws. We have pellet samplers, aftermarket springs and seals, setback triggers. Why not a hex headed stock screw set???

-Yogi

PS that would make all those other tools irrelevant!

Tom,

In the section Phillips 6th paragraph 1st sentence: “However, while writing this report I discovered a pawn shop find that I was supposed to fix — a few years ago.” What were you going to fix? Or do you go there hoping for a bargain to fix?

In my case we ended up making our own screwdriver from a steel rebar.

Siraniko

Siraniko,

I meant that I was a lazy boy for not fixing the handle of this screwdriver yet. I talked to Denny yesterday and he promised me some walnut scraps so I could remedy the situation.

BB

BB

Years ago before the era of computerized weaving machines, loom fixers ground the tips of old screwdrivers to get precise fit for screw slots. Good luck finding anything new. As suggested by OhioPlinker, maybe Weihrauch should fill this niche.

Deck

Deck,

Already in process. 😉

BB

BB,

I have a toolbox (Black & Decker Workmate ShopBox) that is devoted to tools for my airguns. When I scour around and find a tool that fits one of my airguns, into that particular toolbox it goes. In there is a bag full of Hex keys that came with scopes, mounts, airguns, etcetera I have collected over the years. In my garage are bins of tools that were owned by my grandfather and father. I can usually find the correct tool for whatever job I am doing. If I do not have it, I find it somehow, somewhere.

Stanley FatMax Punch Pin Set

P.S. There are some nice gunsmith screwdrivers out there.

RR,

I already have one dedicated airgun toolbox. I guess I need a second one. 😉

BB

BB,

A man cannot have too many tools.

Another axiom.

A man has got to have a pickup.

If he has so many tools that he/she does not know where they are or what to use them for, THEY HAVE TO MANY TOOLS. Seriously, metric hex head set and a FAT WRENCH is all you need.

-Y

BB,

There is no market for special tools aside from commercial manufacturing industries. Suggest you call the tool manufacturers like Snap-On, Craftsman, Apex for help. Have the specifications of the screw slot on hand.

Look up ‘Slotted Insert Bits’ online. Might get lucky? Don’t know the size of that screw.

Slotted power insert bits

Bob,

I have over a hundred of those. They are the ones I complained about bending and breaking.

BB

I have custom tool kits put together for a lot of my stuff – especially for my airguns.

To get around the cheap and/or wierd sized hardware I’ll often upgrade to good quality cap screws.

Large flat blade screwdrivers are not readily available so I just re-forge (with a propane torch and hammer) a large shafted screwdriver to the width needed and file to shape; harden it then temper (light straw color) in oil and I’m good to go. Takes 15 minutes.

Hank

Have you ever done a guest blog on that sort of thing? With lot of pictures?

Roamin,

Don’t think it would be much of a guest blog.

The dedicated tool kits aren’t anything special. Just a (freezer weight) ZipLok bag with various screwdriver bits, Allen keys, custom punches (made fron old twist drill shanks), bits of bent and/or formed coat hangers for special uses needed for maintenance.

Think that heat treating steel (annealing, hardening and tempering) is kinda beyond the scope/intrest of most airgunners. Lots of info on the blacksmithing sites on that.

We could talk off-line if you’d like.

Cheers!

Hank

I think something simple like making a custom tool as you described would be very useful, especially for folks who tinker with vintage guns or like to mod guns and need a custom tool. Alternatively, I can go to blacksmithing sites. Is there one you would recommend?

Roamin,

I’m always making/modifying tools and jigs to make things easier to do. Most are simple to address a specific need for what I’m doing at the moment. Shims, wedges, magnets, a gob of grease, a spot of hot melt glue, bits of wire and other stuff are all McGivered into use as required. Hard to do a blog on that kinda stuff as without seeing the need/application a bit of bent wire doesn’t mean much.

I do blacksmithing (and lots of other things) on the fly but I’m not into it as a hobby. Sorry, don’t have a specific site to recommend.

I thought of doing a guest blog on my spring compressor. Still might, but it seems to be such a simple/easy thing to make.

Cheers,

Hank

Hank,

Make me one?

I do not have the tooling to make one.

Seriously, do a guest blog and then make one for me!

-Yogi

Sorry Yogi, too many other projects on the go to take on another one and its right in the middle of the fishing and shooting season… I’ve no spare time at all!

You’d be better off buying a commercially made spring compressor anyway – It would be less expensive than cost of materials and shipping for me to make you one.

There’s lots of DIY articles/videos available so I don’t think a guest blog is needed.

Hank

Roamin,

Was thinking about your blog request and what makes something “simple” like that difficult to do.

It’s not the tool that’s hard to explain, it’s the thinking/designing that can’t be photographed.

As a designer with direct experience in multiple fields I see/think of things from a different perspective than would an accountant or doctor or chef.

Design and metal working is a heavy subject (no pun intended). It would take quite a series of blogs to orient and teach even the basics to people without a background in tools and tinkering.

Just saying.

Hank

BB,

I have two names for you…Brownell’s and Starrett. First, Brownell’s makes all kinds of gunsmithing tools, and their screwdrivers and screwdriver bits are custom made for people like us working on airguns and firearms. I use these all the time on my airgun repairs and don’t have any problems with stripped screws or broken screwdrivers. Second, Starrett makes high quality machinist tools. They have a set of steel, ground and hardened pin punches that are exactly what you are looking for. With these two sources, you should be fine. Brownells can only be purchased on their website, no ebay or Amazon.

Jeff

Jeff,

Yes, I was told to go to those tool houses by Denny, as well.

Sorry I was short with you this morning but I was adjusting the HW 50S for a Monday blog. Please don’t tell anyone what I was doing!

BB

Tom,

Snap-on makes a variety of 3/8 flat screwdrvers that are all over ebay: GSHD8R, SGD153B, and others. They are for marine and aircraft plug fasteners.

Michael

BB-

I’ve had good service from Proto punches over the years. My most recent purchases seem as good as those from years ago. Of course, pins (roll, spring or straight) are always started moving with a taper punch and the largest hammer practicable. Once the pin is started, then use the pin punch. The other necessary tools are a rock solid bench and Kroil.

For large screws— as others have already stated, get at it and make your own. A bench grinder with a fast cutting wheel and a light touch is all you need. I’ve been working from a couple of 5 gallon buckets of MAC Tools warranty turn-ins purchased at a garage sale 25 years ago. Most were the very large ‘mechanics’ pry bars with the incidental screwdriver tip. Again, for a stubborn screw— a sturdy bench and vise holding the workpiece, Kroil and bump, don’t pound, the screwdriver with a big hammer.

BB

Let me know if this tool works. It appears to be a 13 mm flathead driver by PB Swiss used in the industrial camera industry. I know zero about tools. Been involved in Global Sourcing for Software Technology for over 35 years. Fun research over coffee this morning. Retails for about 18.50 USD

Kind Regards

JDA001

JDA001,

Now THAT is a screwdriver! Thanks,

BB

How about B-square and Grace drivers? Also get the little grinding jig from Brownells that reshapes the tips of broken drivers on your drill press. What the poster above said:You can take garage and flea market sourced quality drivers and regrind them to fit any slot and then heat treat them properly with a propane torch and oil. I do this all the time. Second hand tools make up the majority of the tools in my shop from large metal lathes ,several ton arbor presses, grinders and hundreds of hand tools of all kinds.

Well I was shocked and ashamed for them to think that Chapman bits

Are no longer good. I have a set from the 1980? time period. Let’s just say back then they really really made great tools.

All their Flathead screwdrivers have parallel sides rather than tapered.

They also come with both a conventional handle as well as a ratcheting handle. Also included back then was a ton of knowledge in written form. Mine were a gift from a friend in Colorado,….. With a Marksman model 70

.22 break barrel. Let’s just say that air gun eventually cost me nearly six figures.

Put me down for plus one on starrett.

They have made some of the finest things a machinist can own in Massachusetts and as far as I know still do.

Hey Frank, I just wanted to say “thanks again” for that Haenel model 1; she’s a great little rifle, and she sees quite a bit of use here; I use her as my go-to offhand plinker; she’s sighted in dead-on at 15 yards, and in the 7-foot (to plink away the .22 hulls around the bench) to 15-yard range she shoots pretty flat, and accurately enough to be interesting…plus a lot of fun. 😉

Blessings to you,

dave

Screwdriver tests: https://www.youtube.com/watch?v=xtZ2jh_J7XE

Gordon Buck

Cool. None of those are gunsmithing screwdrivers, though.

I’m a fan of the wheeler gunsmithing tools. Have used my sets for decades. The assortment of flat blades has always been adequate for me. Their pin punches are also top notch. Doesn’t surprise me that on amazon these sets received a 5 star rating from over 500 buyers:

https://www.amazon.com/Wheeler-Engineering-89-Piece-Gunsmithing-Screwdriver/dp/B07YVJ2YPR/ref=sr_1_26?keywords=wheeler+gunsmith+tools&qid=1689351730&refinements=p_89%3AWheeler&sr=8-26

My Lucky Screwdriver, made Mom stop on the railroad tracks to pick it up over 65 years ago. It has held up to my abuse all that time. No idea who made it.

Don

I keep trying to tell BB to stay off those junk tool sites. https://www.starrett.com/metrology/product-detail/565A

Probably one of the best and not that expensive,

Tom (and Pyramyd Air),

Off topic (I know, I know), but it matches Ian’s guest blog a couple of days ago. And please, please do not make this a big side-track to today’s topic of tools and air guns.

First, a disclaimer: I have long owned a Barra Cowboy Series 1866 air rifle and like it very much. I bought it from Pyramyd AIR. Furthermore, the below is based on actual numbers interpreted by me. I could have interpreted them incorrectly.

I was window shopping here at Pyramyd AIR when I found what appears to be some AI created hacking of PA’s product reviews, what used to be called “astroturfing.” Three products by Barra, their Cowboy Series 1866, 1866 Junior, and 1866 Rosie, have a combined 3584 user reviews with a combined 5 and 4 star reviews making up 95% of them. A suspiciously high (in my opinion) number of them are annonymous. PA’s user reviews are typically quite detailed. Many of these seem comparably vague and general to me. A lot of them are of the “What I liked: ‘Good to teach my boy about shooting.'” Many have what seems an artificially “”folksy” language style such as, “Boy likes the gun, I’m happy.”

/product-all-reviews/m/barra-cowboy-series-1866-177-bb-pellet-air-rifle/5007

/product-all-reviews/m/barra-1866-junior-air-rifle/5741

/product/barra-1866-rosie-air-rifle?m=5742#Reviews

I strongly suspect Pyramyd AIR is the victim of an AI hack job.

Again, please do not make this a big tangent from today’s topic of tools and air guns.

Michael

Michael, very interesting.

It looks like a lot of them have the statement, “This review was originally published on barraairguns.com”, in blurry fine print on the left as the user “By:” entry. Maybe that is the source?

Mike

Mike,

Huh. I didn’t notice that. These could be legit reviews, it just all seems just slightly sideways to me.

Michael

Absolutely sideways! But we have a trail to follow. Why does PA have reviews from the manufacturer’s site?

Mike

Dunno. Perhaps Pyramyd AIR wasn’t aware they had been uploaded, or perhaps they OKed it.

This one looks like a contender with a 16 mm blade width…

https://www.amazon.com/PB-Swiss-102-Slotted-Screwdriver/dp/B001D2ODNY

dgwren,

That one is great but cowabunga — the price!

BB

Here is what I use.

Uh, Jeff?

Vaporware? 😉

BB

B.B.,

https://www.wihatools.com/products/extra-heavy-duty-screwdrivers-softfinish?_pos=11&_fid=8e3c37b64&_ss=c

shootski

In my experience, Wiha makes excellent tools. Their Phillips head drivers are close to Vessel quality.

For any Canadian readers looking for the HW30 or HW50 (or you know, extra copies), the .177 wood-stocked models are in stock at Italian Sporting Goods. They aren’t listed with the S-suffix and the images show the old-style stocks.

Cheers,

Nathan

BB,

They must’ve packaged the hi-output kit instead of the low one by mistake. I still do believe the 7.5J HW50S will be your new favorite.

Fish

Fish,

Monday.

BB

We have had this tool talk before.

If you noticed, Hi-Torque screws and fasteners are not straight slots. Unfortunately, the harder you make something the more brittle it becomes. Straight slot screws that become overtightened require a very precision designed tip to prevent stripping out of the slot, no tapered blades, and extremely hard screwdrivers and bits will fracture under high torque. They were intended for longevity of use, not high torque.

So obviously it is important to use the correct blade for the screws slot, so it distributes the load evenly and stays in place. Ones with small ridges or a sand blasted looking tips work better.

Another alternative is to apply some valve polishing or grinding compound for a better grip and maintaining enough pressure for it to remain in the slot.

Square shank screwdrivers can be pushed down very hard, and a wrench applied to the shank for increased torque. This will destroy a brittle tool.

But this is all nice to know information. You still need a screwdriver with the proper size and material and the one you need is probably a special one used by the company.

Sometimes you can use a small Cresent wrench on the blade itself.

Good luck on your search, but if all else fails perhaps this info may help with what you have to work with.

I have a problem myself. My old shipmate friend just punched out two people in the memory care home and was asked to depart for good. This reputation will unfortunately follow him when looking for a new home.

May need a “Silence of the Lambs” rig? 🙁

BB

Again, not a tool guy but please find attached, a 1/16 solid steel punch from Tekton price about 6.00 USD

I’m having a better time finding the wrong tools then trying to find a Diana Smoothbore for my dart shooting 🙂

Kind Regards

JDA001

I’m on the lookout for you. I can either post on the most current blog, or if you give us your private email address, I can let you know if I find one. Most folks disguise their actual email in some manner in the hopes of minimizing getting new spam.

Roamin Greco

Thank You and appreciate the help. I’ve been researching airgun dart shooting and it looks like the Germans and English were doing this for a while in the late 19 early 20 Century, The research indicates they were able to achieve accuracy to about 15 yards. I will be happy with a consistent one inch / ten shot group at 5 meters.

Kind Regards

Joe

I finally saw a breakbarrel on ebay that seller confirmed is a smoothbore. I posted a question about it on today’s blog. It’s a Haenel XXXX. I think it’s overpriced and the shipping is too high. But it is something.

Why do wider screwdrivers have longer shafts? It a bit (HA!) awkward to use a long screwdriver on jobs that require precise movement.

As mentioned above Stanley makes punch sets. I have 3 – 1/32, 2/32 and 3/32. Also, I have several large flat head Stanley screw drivers of different lengths. I have found all to be very robust. I use a large rubber head hammer for the punches. You may find what you need at an auto supply store. Bill

If you guys are looking for the best punches out there:

https://www.amazon.com/PB-Swiss-Tools-Parallel-rainbow/dp/B008PE1FYS

Looks like PB Swiss may be the specialty tools of choice

Kind Regards

JDA001

Speaking of tools, every serious airgunner should have a chronograph. If you look on Amazon right now you can find a chronograph that has indoor LED lights and a tripod with it for less than $62. Just saying.

BB,

Aside from having an amazingly entertaining YouTube channel, the guy who does Hand Tool Rescue makes the screwdrivers you want. It’s not a gunsmithing screwdriver design, but they’d probably get the job done. You might only need the medium.

https://www.handtoolrescue.com/

1) Grace USA sells screwdrivers for gunsmiths. The are high quality, but costly. Their line of screwdrivers should cover pretty much any scree a gunsmith might encounter.

2) If in doubt, write an email to Weihrauch and they will tell you which screwdriver they use for assembly.

The Chapman set I have had has been the best fitting set for flathead screws . They are engineered to break before they strip screw slot ifI you torque to tightly. Yes you have to pay for new bits but that’s a lot easier than trying to replace a screw on a vintage airgun.

Glenn

The Chapman set I have had has been the best fitting set for flathead screws . They are engineered to break before they strip screw slot if you torque to tightly. Yes you have to pay for new bits but that’s a lot easier than trying to replace a screw on a vintage airgun.

Glenn