Air Venturi Avenge-X classic wood.

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Part 9

This report covers:

- Watch the film

- Loosen the barrel screws

- Remove the .177 bolt

- Install the new bolt

- Barrel locating pin

- Proof of the pudding

- Test

- I’m done!

- Summary

I don’t know if you remember this but today is the day Billy Joe MacAllister jumped off the Tallahatchie bridge.

Today I change the caliber of the Air Venturi Avenge-X I’m testing from .177 to .22. Besides all the tuning options the Avenge-X offers, you can change the caliber of the rifle in less than 10 minutes.

Watch the film

And you can do this the easy way by just watching the film Pyramyd AIR has provided. It’s 4 minutes long and well done. Cory shows you how the swap is done and I found his instructions so simple that I did the swap almost as fast! But my rifle was scoped, so the first thing was to remove that.

The scope has to come off to get access to the two barrel screws.

Loosen the barrel screws

With the scope off I had access to the two screws that hold the barrel in the receiver.

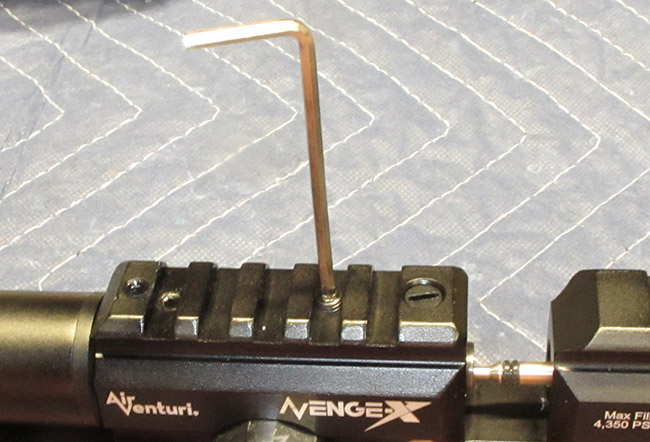

The Allen screws in the Picatinny rail are loosened to remove the barrel.

In the film Cory recommends removing one screw and just loosening the other, so that’s what I did.

Remove barrel

Once the two screws have been dealt with, the barrel is removed. In the video Cory tells you to hold onto the barrel band because the band has an o-ring inside that creates resistance. Twisting the barrel helps overcome it.

Remove the .177 bolt

Once the barrel is out, remove the .177 bolt. There is a small hole at the bolt’s base that the smaller Allen wrench fits through to assist in loosening the bolt threads.

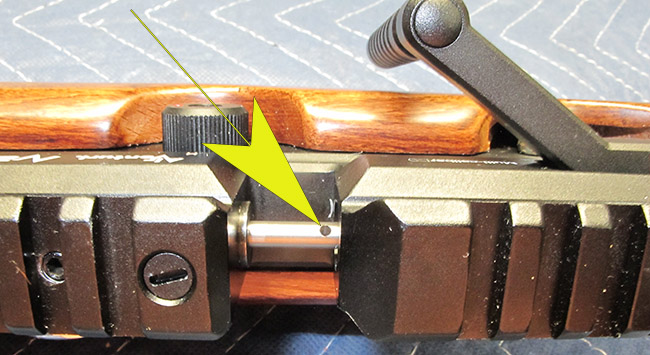

Stick the smallest Allen wrench through the bolt hole (arrow) and loosen the bolt threads. Then unscrew it the rest of the way by hand.

There is a bellville spring washer at the rear of the bolt that puts some tension on when the bolt is closed. This washer comes out with the bolt. In the video Cory tries to pull the bolt through the receiver with this washer on, but I took it off before the bolt came out of the receiver. That way it didn’t get lost.

The .177 bolt and bellville washer out of the receiver. The bolt will be replaced but the washer goes back into the rifle with the new bolt.

Install the new bolt

The new barrel comes with a new bolt of the appropriate size. I’m installing the .22 barrel, so that’s also the bolt size that’s being installed. The bellville washer goes back in the same way it came out. Hand tighten the bolt until you feel resistance, then use the Allen wrench to snug it down.

Barrel locating pin

The receiver has a small barrel locating pin that fits into the rear of the barrel when it slides in.

The barrel locating pin (arrow) is what locates the barrel shroud so it is perfectly aligned.

The hole in the rear of the barrel shroud (arrow) allows the locating pin to align the barrel perfectly.

As the barrel is pulled back the alignment pin does its job.

The alignment pin does its job.

The final step is to install and tighten the two Allen screws that hold the barrel tight to the receiver. And the job is done.

That’s as simple and quick as it is. It takes maybe 7 minutes the first time you change barrels and less than five minutes from then on. The photography added more time than the caliber change.

Proof of the pudding

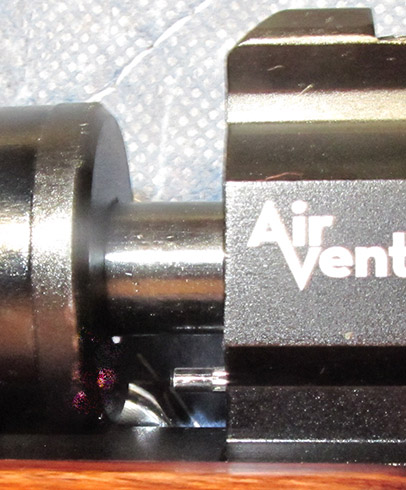

After the caliber swap is finished the scope goes back on.

The scope goes on and the rifle is tested for function.

Test

After the caliber swap the rifle should be tested for functioning. The scope will probably have to be adjusted a bit, since it was taken off the rifle. This isn’t an accuracy test — just a function test that prepares the rifle for what comes next. I left all power settings where they were.

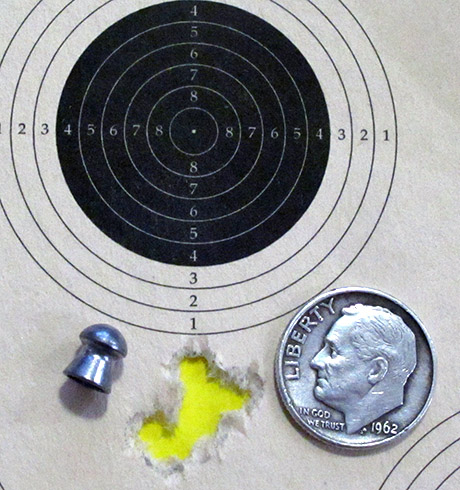

I tested the rifle at 10 meters and used a 10-shot magazine. I loaded Benjamin Bullseyes and shot at the center of a bull. The first shot hit a little over an inch below the aim point and in line, left and right. That’s close enough for me; no scope adjustment necessary. I shot the other nine pellets and produced a group that measures 0.42-inches between centers. The bolt fed all the pellets from the magazine fine, so the Avenge-X is ready to be tested in .22 caliber.

From 10 meters the rifle put ten Benjamin Bullseyes into 0.42-inches between centers.

I’m done!

The rifle is now converted to .22 caliber and ready to be tested. I first need to find a great pellet and then tune for it, so the next test will be one that looks at different pellets.

Summary

The Air Venturi Avenge-X rifle is easy to change calibers. That’s one more feature we can add to its bag of tricks.

B.B.

I hear the PCP guys at the range chatter on about having to “index” their barrels after a barrel change.

What is that?

-Yogi

Let me guess Yogi, they were shooting a particular Swedish made air rifle?

Ian

Yes, and when they are “indexed”, they shoot 1/2 moa at 200 yards.

-Y

or less….

45Bravo,

Not just applicable to FX products.

I bet there will be Avenger owners that will remove the indexing pin ;^)

shootski

45Bravo,

The ability of Swedish airguns to be adjusted and fine tuned is what allows then to go from very good to exceptionally good accuracy… especially at longer ranges.

My Swedish airguns consistently out shoot my British and German ones.

Hank

Yogi,

Not a clue, but I have only changed barrels/calibers in AirForce rifles, so it’s probably something I haven’t seen.

BB

B.B.,

Don’t you own a multi barrel (4 calibers) Whiscombe JW 75?

Best i can remember he indexed all his barrels before welding on the locking bar or installing them in the fixed barrel JW 80s…

shootski

shootski,

I sold the JW 75. John never told me that he indexed any of his barrels. He may have but I never heard it from him.

BB

B.B,

Oh!

FYI: https://www.yumpu.com/en/document/view/31607557/jw-70-us-ag-may1995pdf-whiscombe

shootski

Yogi,

If those barrels are anything like the ones we have here there is no pin to indicate the proper position maybe just a dimple with a dab of paint and the barrel is rotated by trial and error to find the point where it shoots best.

Siraniko

My guess is that the alignment pin that BB showed us is used for indexing. I have a Diana Chaser Kit that changing to a different length barrel (pistol to rifle but not a caliber change) is easy to do. The indexing is accomplished via two dimples drilled in the top surface of the barrel aligned with the two set screws that hold the barrel in place. It isn’t difficult to position the barrel so that the dimples are directly below the threaded holes in the receiver for the set screws. Taking one set screw out and using a flashlight works for me. Then the convex shape of the bottom of the set screws conforms with the concave shape of the dimples. So that when the set screws are being tightened, the barrel moves very slightly into its intended indexed position. I hope that makes sense.

Thanks for the well done report BB. I’m looking forward to the next one.

Yogi,

What Siraniko said.

I index (markings on two mating parts to provide a reference for repeatable precision reassembly.) all my Quackenbush barrels to the receiver (breech) since they are threaded. The theory is that the barrel will shoot to the same POI (Point Of Impact) on reinstalling.

In simple terms a way to remove another potential variable.

shootski

Yogi,

No barrel is drilled perfectly straight so they have a bias as to which way they throw the projectile.

The best thing is to index the bore such that the biased path of the projectile up, vertically, in the same plane as gravity.

The indexing pin in the Avenge-X barrel is to ensure that the transfer port is correctly aligned. I expect (hope) that the manufacturer has properly indexed the bore at the same time.

I wrote a guest blog on the subject a while ago…

https://www.pyramydair.com/blog/2022/11/in-pursuit-of-sub-moa-barrel-indexing/

Hank

Vana2,

(as well as READERSHIP that cares about tiny 10 shot groups or first shot X ring hits)

That was a REALLY well done and IMPORTANT Guest Blog; with some valuable and outstanding comments from the Readership as well!

From my experience, observations of more knowledgeable airgun folks than i; it seems that on the hardware side of the search for accuracy the design and fabrication of the barrel is considered by most airgunners as the Holy Grail of PRECISION.

Second only in importance is the correct and optimized installation of those great barrels.

Your Guest Blog should be bookmarked by those that are trying to shoot smaller than 3-4 MOA (3/4″-1″/19mm-25.5mm) 10 shot groups at more than 25 yards/meters or in the market for a new tiny group shooter.

There are some really great FOUNDATIONAL Blogs LOST in this vast collection of reports most of which have limited long-term value beyond the archival.

Too bad the great blogs aren’t filed in a “foot stomp/wink-wink” folder.

shootski

Is this the evolution of the dual caliber Beeman spring rifles that are still being sold? Is this a step up from their system of grub screws and sleeves or is it something different? How long do you think the system will maintain its integrity?

Brent,

This method of barrel attachment has been around for a long time and will likely be for quite some time. Most airgun manufacturers use this method. Most airguns that come in multiple calibers use a very similar method.

Will it maintain its integrity? Very likely. There are some very nice airguns out there that use it and have used it for very many years.

It would seem that Nova’s listening to Tyler was a very good decision on their part. The modifications they have made to the Liberty since its inception has seemingly made a very impressive air rifle.

Snowpeak has also listened well to shooters around the world in making and modifying their products. Sometimes we even know what we are talking about. 😉

RidgeRunner,

They (copy artists extraordinary) must have read Hank’s Guest Blog but didn’t trust average airgun buyers to read and heed his instructions.

I still think a bunch of folks are going to wack or cut off that DANG pin!

Or maybe use their trusty/rusty VISEGRIPS® for a quick extraction…

shootski

aka, Visegrip jockey

shootski,

It sounds like quite a few “slightly used” (and somewhat abused) Avenge-X air rifles will be coming to the market soon.