Another twist on rifling

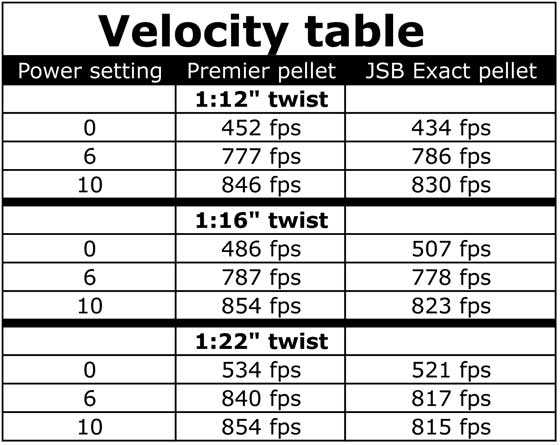

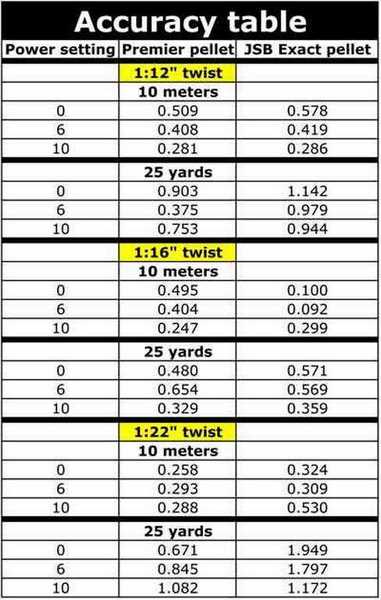

by Tom Gaylord, a.k.a. B.B. Pelletier I thought I’d provide some thoughts on how this blog has helped me become a better shooter. We just finished the Twist-rate test last week, and I wanted to share with you some things from that test that have impacted my shooting. Swaged bullets I’ve been using the output … Read more