rifling

What’s wrong with solid “pellets”?

by Tom GaylordWriting as B.B. Pelletier This report covers: Diabolo pellet The couch coach solution Tradeoffs Summary Today’s report was engendered by yesterday’s report about the AirForce Texan big bore air rifle. Many of you have been discussing the advantages of solid pellets over diabolos Today I’d like to look at this question a little … Read more

Rifling revolutionized!

by Tom GaylordWriting as B.B. Pelletier This report covers: Outside the box Rosenthal award Rifling How it works Outside rifling? Accuracy Range increased by orders of magnitude! Trouble brews What is to come? Rumors are flying! Summary Outside the box I’m sure you have heard the phrase, “Think outside the box.” Many organizations don’t really … Read more

The Invention of Rifling: Part 1

The history of airguns This report covers: Nobody knows when rifling was invented What is rifling? The first rifling Gunpowder leaves dirt in the bore Minie Ball Trapdoor Springfield development Ballard rifling Airgun rifling Nobody knows when rifling was invented I’ve been reading about guns for 56 years and the one subject that has always … Read more

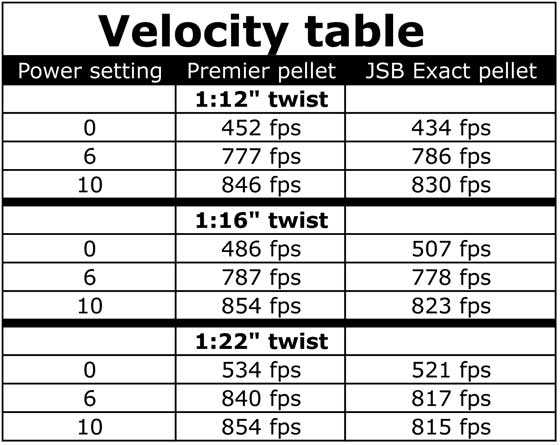

How does rifling twist rate affect velocity and/or accuracy? Part 13

by Tom Gaylord, a.k.a. B.B. Pelletier Part 1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Part 10 Part 11 Part 12 This is the summary report in this series. I’ll give you my thoughts on how this test went, and I expect you to comment, as … Read more

How does rifling twist rate affect velocity and/or accuracy: Part 12

by Tom Gaylord, a.k.a. B.B. Pelletier Part 1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Part 10 Part 11 Today, I’ll report on the final test in this series. This isn’t the final report — just the final test, which is the barrel with the 1:12″ … Read more

How does rifling twist rate affect velocity and/or accuracy? Part 10

by Tom Gaylord, a.k.a. B.B. Pelletier Part 1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Today, we’ll begin looking at the effects of the rifling twist rate on the accuracy of our test AirForce Talon SS rifle in .22 caliber at 50 yards. If you’re prone … Read more