by B.B. Pelletier

Annoucement: There’s a new article on Pyramyd Air’s website. “How to mount a scope” includes a short intro and avery comprehensive video guide for mounting scopes on just about any airgun.

On to today’s blog.

With all the interest you guys have in tuning springers, I thought this would help. BG_Farmer has expressed curiosity about the spring selection process. Actually, there are aftermarket springs that are much higher quality than factory springs, and I would use good ones whenever I could, but you have to know if they fit.

So, although I’m writing this about the HW 55T, it applies to any mainspring in any gun.

Step 1. The spring guide

The mainspring must fit the spring guide as close as possible to reduce vibration and to lengthen spring life. When the gun’s cocked, the coils compress around the guide, which prevents them from kinking. The piston rod fits inside the guide and passes through (usually) to contact the sear.

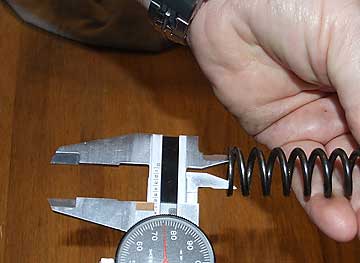

If you have your new spring on hand, you can just try the fit; if not, you must measure the inside of the old spring with a caliper. It takes practice, but many calipers have the ability to measure both outside and inside diameters. Measure the spring at both ends, because the dimensions will seldom be the same. If the factory mainspring fits the guide loosely, as many do, you’ll have to make an educated guess how much smaller you can go. Remember, as a coiled spring is compressed, both the inside and the outside diameters increase a little.

Step 2. Inside the piston

As the piston compresses the spring, it begins to fill the inside of the piston. The spring guide is also entering the bottom of the piston and traveling toward the top as the piston goes to the rear. So the mainspring ends up sandwiched between the spring guide and the inner wall of the piston. And it expands slightly as it compresses. Do not fit the spring to the piston tightly while it is not compressed or it will not fit well when the gun is cocked.

Step 3. Compressed spring length

Determining the length of the fully compressed mainspring takes only simple arithmetic. First, count the number of coils in the spring. Start at the top where the spring begins and go straight down the side to the bottom. Don’t be surprised if there’s a fraction of a coil remaining after all complete coils have been counted (include that fraction in your count).

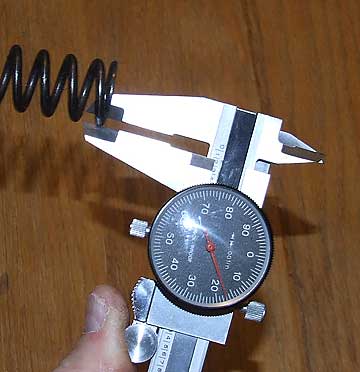

Next, with your calipers, measure the wire diameter of the mainspring. Again, this takes a little practice, so do it several times until you get the smallest diameter.

Now, multiply the number of coils by the wire diameter to get the length of a fully compressed spring.

Wayne’s HW 55T mainspring has 31.75 coils with a wire diameter of 0.109″. Multiply those numbers and you get a compressed length of 3.46″. The spring I hope to use for the tune has just less than 32 coils of wire with 0.118″ diameter. That works out to a compressed length of 3.776″. The new spring is 0.316″ longer than the spring that was in the gun when it’s fully compressed. Will there be enough room for it? Perhaps not, but I can always cut off a coil to make it fit. I would have to flatten the end of the spring at the cut, but that would reduce the length even more.

Now, both ends of the spring are ground flat, and my methods didn’t take that into account, so both springs are a little shorter than calculated. That may be handy to know in just a moment.

Step 4. How long can the spring be?

Determining the total possible length that’s available for the mainspring is easy with a Weihrauch rifle. Install the trigger in the end cap and slide the piston through the end cap until it cocks the trigger. The maximum spring length is the distance from the face of the end cap to the inside top of the piston, minus the thickness of the spring guide base and the base of any top hat guide, if there is one. In our case, there’s a top hat, so its base thickness is also subtracted from the total.

I measured the total available length at 3.947″. The spring guide rim is 0.10″ thick and the rim of the top hat is 0.120″ thick so the total space available is 3.947″ minus 0.220″, which leaves 3.727″ The new spring is probably too long to allow the gun to cock. I’ll have to cut off one coil for the fit.

Is this method exact? No. It can be off several thousandths for each measurement. Because the measurements are so close and also because I said the springs are really a trifle shorter than I calculated, I will try the spring as it is. I don’t think it will allow the gun to cock, but testing will tell for sure. If I have to, I’ll remove one coil. I’ll let you know.

Good morning B.B.

What can be done with a two springs rifles? Should/can it be replace with a single spring?

Thanks

J-F

J-F,

That depends on the rifle. If it’s Whiscombe, the answer is no. If it’s an FWB 300, then yes.

B.B.

BB,

You know I alwas read the blog, but getting a mention makes my day.

Isn’t going from .109″ to .118″ going to make the rifle harsher to shoot? On the other hand, I’m thinking that if the larger spring fits the guides (one or both?), the original must have been fairly loose, which could explain the cant?

BG_Farmer,

That’s not too large an increase – I hope! I have a smaller second-choice spring in the wings if the first one is too hard to cock.

The original spring fit both guides well, as does the new spring. The coils are not necessarily wound exactly the same so some difference is possible.

B.B.

BB,

I find that it’s much easier to measure the OD of the spring guide than to get the ID of the spring–especially on a ground end. As you mentioned, the spring changes diameter slightly as it’s compressed–this way you don’t have to make that educated guess.

Derrick

B.B.

Thanks so much, this is soooo interesting to see the inside of this great air rifle.. You do it all with such confidence…. It gives me hope that some day, I can try to open up the rusty old win 422 and play with it..

I also bought a new Tech Force 97 about 6 months ago, and it didn’t work out of the box, so I sent it back to the factory… It just got back.. It’s a .22 cal. I ran 30 shots over the crony and it is real bad.. with 11.9gr hobby: lo 365fps high 633fps avg 410fps, with JSB Exacts: lo 260fps, high 504fps avg 376. The first run of the RWS super point 14.5gr were; lo 463, high 798 avg 625fps….ONLY A 334FPS DIV!!!

So since, it’s a very cheap under lever, with almost all metal parts, I thought this also might be one to tear into, and try to fix myself…especially with the factory giving such poor service…

Do you think it’s a good one to start out on the road to “tunnersville” on?

Wayne,

Ashland Air Rifle Range

Wayne,

Go for it. The worst thing that can happen is that it won’t work. And since it doesn’t really work now, you’ll just be out your time. I just want to see some pics of you working on it in your recliner!

Derrick

Wayne,

Yes, try your hand but be careful. The 97 isn’t a real friendly design to work on.

Also, sometimes Chinese rifles need longer to break in. As in 3000 to 4000 shots. Then they can be really smooth and nice.

But I’d tune it if I were you.

B.B.

Derrick & B.B.

Yes… 4,000 shots seems like a waste of time and pellets, it's not that fun to shoot ( it's not a s410!!!).. so let's open her up for the experience… I'll need you guys over my shoulder..

So where do I find a set of tools for working on air rifles? And a work bench to fit over my recliner? Just kidding, but really, what quality of tools are required to not mess up screw heads and the like…

Then it sounds like I would need an inventory of parts to pick from, or a place to get them.. JM kits? How much work space do you need?

Wayne,

AARR&R

BB,

I know you have it under control, just wanted to see if I understand something.

Wayne,

Except for the spring length and piston stroke, the 97 (QB36-1) action is supposed to be identical to the 36-2 I wrote up, here:

/blog/2008/04/from-clunk-to-thunk-a-beginner-customizes-a-chinese-qb36-2/

You could probably use the same spring and seal, although the e3650 might be too long. The trigger is the PITA part of assembly, but I can do it blind-folded in 10 seconds, now:).

I had never opened one up before, and it came out well: go for it!

Wayne,

I’ve been thinking of getting an inexpensive springer to study, so you can be my guinea pig. The 13 part spring-gun tuning series on the blog will probably answer most of your questions about getting started.

Matt61

Some general spring information:

Spring rate is determined by a number of factors besides wire diameter.

The rate is proportional to the wire diameter to the 4th power, but it inversely proportional to the overall diameter to the 3rd power. It is also inversely proportional to the number of coils.

So a spring with a larger diameter, a lot of coils, and a thick wire might not be any stiffer than a spring that looks a lot wimpier.

BB

This is great insight into tuning! I am sure I will try my hand. I already have a cheapo caliper. Can you explain the method you use to cut and flatten the end of a spring? Thanks

Ton

B.B.,

I love your tech articles. No matter what the subject, you always have a new insider secret to offer up. It is much appreciated.

Here is a site

http://www.msdspring.com/springcalculator/default.asp

that has a spring force calculator where you can enter sping ID or OD, number of coils, wire dia, free length, etc. Then you enter the various lengths (cocked and un-cocked)you want it to calculate force for, and it will pop those numbers out. It also gives you the force at full coil bind. Its fun to play with and it will help predict what happens if you add a washer or cut off a coil or go to a heavier wire dia.

One thing it has really opened my eyes about is that sometimes you can increase the spring force by 25% but the velocity only goes up a few percent and it makes the gun shoot harshly. The whole balance of the powerplant seems to get upset. The greed for speed bites back!

Keep it coming!

Lloyd

Wayne,

The easiest spring rifle to learn the basics of a tune-up would have to be a Weihrauch 50/Beeman R7. Something break-barreled with a unitized Rekord trigger.

Oh, you’ll want about 4200 square feet and enough power to run the 4-axis CNC machines.

Derrick

Derrick

BB

Great blog as usual. I just finished catching up on all the blogs and comments I missed while on vacation. It’s amazing the volume of reading, blogs and comments that accumulate in 3 weeks. I spent 3 weeks in Hawaii, one of those on beautiful Maui

Joe B. – you live in a wonderful part of the world. I’m jealous. Sorry I didn’t think to contact you while I was there!

Volvo – I’m an old rocketeer too! I still have about 15 rockets I built in the 1970’s. Yes, Big Bertha is one of them! I actually built a newer one a couple years ago, the original was launched so much the body tube delaminated! They are still a hoot to launch, I’m going to build another rocket this winter.

Critter Controller – Are you still searching for a Crosman 357gw Kit? Contact me by e-mail – rundeen@twcny.rr.com

BB – Finally got around to shooting the new TX200 seriously. Received it early summer, but life got in the way. Walnut stock, Leapers 4-16, accushot rings. What a wonderful gun! Absolutely the best in my collection. JSB exact heavys do 5 shots in one 1/4 inch hole at 10m. Under 1/2″ at 25yards with a breeze! Loading is a little awkward(diffferent) compared to the 2 CFX’s that I have been shooting. But otherwise everything else is marvelous. No vibration, no twang, excellent trigger, amazing. Yes, it is expensive but worth every penny! See you at Roanoke next week

Joe

Actually, you’re never quite sure what’s gonna happen when you add a washer. Typically, when a spring is new it gets stressed just a bit past its yield point the first time you cock it – which is why it ‘takes a set’. From then on (theoretically), it is only getting stressed right UP to the yield point, but not past it. In actuality it doesn’t work out quite that neatly, but that’s the general idea.

If you add a washer you increase the stress on the spring, and it might again get stressed past its yield point and just take another set. And you wind up pretty much where you started.

Vince,

Good point about new springs taking that initial “set” after being cocked once or twice. Most of the springs in the higher powered guns appear to be stressed right to the yield point and operating in a near-failure mode. Of course, that’s a relative term. A car valve spring that operates well within its safe stress limit will see 100 million cycles in its life, whereas an air gun spring might be stressed to its yield point and 50,000 cycles will be an acceptable life.

Lloyd

Ton,

I use a Dremel tool to cut the spring. Then the last coil is heated red hot and collapsed against the next coil. The end is them ground flat. Use a heavy heat sink to prevent heat migration up the spring. The end is then tempered for toughness.

B.B.

Lloyd,

Thanks for the link.

B.B.

“I spent 3 weeks in Hawaii, one of those on beautiful Maui

Joe B. – you live in a wonderful part of the world. I’m jealous. Sorry I didn’t think to contact you while I was there!”

Hi Joe,

That’s OK…at least you missed the VOG. What part of the island did you stay on?

You definitely shoulda come up to Kula. This house is grand: 3.3 acres of bi-coastal views, indoor swimming pool/outdoor jacuzzi, big organic garden and gourmet food, archery range, plenty room to unlimber airguns and airsoft guns, etc. In fact, if you want to buy it, it’s now on the market. Asking price is is 2.25 mil. Think of the retirement bennies!

Ho-ho. Anyway, glad you had fun on Maui. I always get a kick out of our TV ads here that offer prizes like: a whole week in Las Vegas!

Regards,

Joe B. on Maui

BB

Thanks for the info on cutting springs!

Ton

Joe B. on Maui

Fantastic. That sounds worth all of the asking price. How idyllic. My place in Waikiki where I grew up is much more restricted.

Matt61

Derrick,

That’s what I expected, I’ll throw out the raised bed business, and move my airgunsmithing shop in there.. so I can rebuild the $50 rusty win 422 and Tech force 97..

I’ll have half naked women bringing my parts and tools to the Lazyboy workbench… Is that how you guys do it?

You still didn’t say if I need special tools, I guess regular auto grade will work.. Is there any special things. I guess a spring compressor.. and two ton press, for that heavy duty one in the win 422.. That is for sure a Magnum… The whole gun must weigh 3 lbs.. Maybe I should set up shop in Maui, what do you think Joe? Is that where to get the best half naked workers.. I can see this gunsmithing shop is going to be a big tax deduction…. Great idea guys…

Wayne,

Ashland Air Rifle Range

B.B. & All 30/30 fans,

I spent the afternoon, shooting the Marlin 336RC, and testing the new Hornady "Leverevolution" 160gr plastic tipped ammo.. This is supposed to do better at long distance, and be safer to feed and fire in the lever action models..

But, I found them to be harder to group at 100 yards, and not any better than the Remington 30-30 win. 170 gr. at 150 or 200 yards… both about 6" to 8" 5 shot groups. I did have to aim about 10" higher than at 100 yards with the 170 gr. and only 3" higher with the Hornady, but the groups were very close to the same…

The best groups came with the Federal "power-shock" 170 gr. I got a 5" group at 200 yards in the bench rest… and 3 out of 5 on the 150 yard, 5" "shoot and see" from the sitting Field Target position. The Federal Power-shock were only $14 for 20, while the Hornady are $22 for 20.. I'm taking the Federals 170 gr. on the Elk hunt this Saturday…

B.B. a point for reloading.. the guy at the sports shop where I was buying ammo, said he has weighed bullets (taken them apart and weighed powder and bullet) from the box and had a large difference, especially with Remington.. he said that the Federal had the least variance.. I had just proved it at the range, and was buying more…

I'll bring the Ruger .270, as well, but I'm so in love with Marlin 336RC… I shot 80 rounds this afternoon, and I wanted to shoot more…

Wayne,

Matt61,

So, you grew up in Waikiki. That was very subtle, Matt.

Wanna tell us about it?

Please?

Joe B. on Maui

“Maybe I should set up shop in Maui, what do you think Joe? Is that where to get the best half naked workers..?”

Hi Wayne…Yes, that’s pretty much it. Except we only employ fully naked college coeds. The older ones cost much more and, you know, how much experience does it take to bring beer and sandwiches during breaks from such brutal labor?

Hard plastic-tipped .30/30 rounds are safer than lead or silver tips? Man, who woulda thought…?

–Joe B. on, well, Maui

BB – completely different topic – on the early 50’s model 25 I recently bought, the hole for the upper stock-to-receiver screw was stripped. As you know, this was just a hole drilled in the plastic. To repair it I filled the enlarged hole with a ‘plastic-weld’ epoxy, redrilled it, and reinstalled the screw. It’s not visible at all when the gun is together.

Might sound like a stupid question – but did I just negatively impact the gun’s value?

Joe in NY,

Glad to hear from a fellow Rocketeer. Rocket scientist may have been a stretch. I was trying to add some levity but I doubt I succeeded. We are grown men and women who like to play with pellet guns, some seem to take it a tad too serious.

I sold a Joe in NY a .25 Patriot. Any chance that was you? Joe being such an unusual name and New York such sparsely populated state….

I have not been to Maui in about ten years; with the economy I’d guess it would be another ten before I go back. I’m Jealous. I may need to change my alias to Vega.

Volvo

Joe B.

Well then it’s a deal, you’ll handle personal matters for surfin sure…

Derrick,

Do you think the 3 acres will be big enough for my gunsmithing shop..I know I’ll be expanding when I’m done with win 422, and need it by the time I get to the Tech Force 97…

I’ll get the check off right away…Gota plan ahead ya know..

Wayne

BB,

Kindly include how do you temper the spring after cutting with the dremel. We use pretty much the same procedure of heating and grinding it flat. Thanks.

Lloyd, thanks for spring calculator link.

David

David,

Tempering steel is a subject that takes a book to reveal – not a blog comment. The alloy used makes all the difference in the world.

This is not something I can discuss as well as the best resources on the internet, so I will leave it to them. Start with Dennis Quackenbush’s website, which has an excellent discussion n steel.

http://www.quackenbushairguns.com

B.B.

Vince,

The collector value is gone, but not everyone is a collector. What you did restored the gun to shootability and I’m sure BB gun repairmen would have done the same.

B.B.

How to calculate spring force?

John,

The amount of weight a spring can lift is how the force is measured.

B,.B.

The IGS Side Release Valve can be found on the Euroline range of gas springs. It can also be found on custom made gas springs where a SRV was specified.

You should keep in mind that this type of release can also be activated by other persons, therefore it is suitable for prototypes or when the gas spring is fitted in an area which cannot be easily accessed by the end user.

The advantage of this type of release is that the force can be released after the gas spring has been fitted on the application. It makes adjusting the force a very easy process.

On the right you can find a video we have done to help a customer adjust the force using SRV gas springs.

Please note that the grub screw used to activate the internal valve can be completely removed once you are happy with the force.

Please note that this is work in progress and the video will be improved as soon as we can find the time to make it again.