by B.B. Pelletier

A few weeks ago, I sent my Falke model 90, a new acquisition, to blog reader Vince. As you all know, Vince is a wizard with old airguns. I asked him to get it running again and to take note of it while he was fixing it so you could see the work in this report.

Vince then took the rifle to Mac for testing, and we have a separate multi-part blog on that.

If you’d like to write a guest post for this blog, please email us.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

by Vince

It’s not my Falke! Honest. It’s B.B.’s. It just wound up in my lap because, I suspect, he’d been hitting the painkillers a bit hard after all he’s been through. Whatever the reason, he decided to risk the well being of this rare (and completely non-functional) vintage airgun to the sledge-hammer-weilding knuckle-dragger writing this article. And, was I one to take advantage of B.B.’s momentary lapse of rational judgment and dig into a gun I might never get a chance to see otherwise?

Well, duh!

The understanding is, of course, that he expects a blog out of it, which is a bit of a shame for you guys. He also sent me his old TS45 air rifle that he believes to be the long-lost cousin of “Pointy,” the unnamed sidelever I blogged a little while ago. That’ll probably provoke yet another blog, so consider yourself forewarned.

I decided, in an act of mercy, to subject B.B.’s readers only to my experiences servicing the rifle. A more in-depth review with description and shooting impressions will have to come from B.B.’s friend Mac, in whose far more capable hands the gun now resides.

From the 1950s, the Falke model 90 underlever spring rifle is a rare classic. It was made in Germany.

So, Tom sent me the .22 caliber Falke 90, explaining that when he bought it he didn’t realize that it didn’t work. Turns out he was quite right — the rifle wouldn’t even cock. The sear simply wasn’t catching. I looked in the triggerguard area and saw a sear engagement screw.

Circle indicates the sear adjustment screw.

Just on a hunch, I backed it waaay out, cocked the gun again, and CLICK! The piston caught and held.

Ha! This is gonna be easy!

A little quick background — from a design standpoint, at least, the tap-loading Falke is sort of related to the Anschütz-built Hakim air rifle that B.B. blogged a while ago. I’ve some experience with those and found that they definitely prefer soft pellets to hard. So, I loaded up a Gamo Match pellet (which works OK in the Hakim), close the tap and pull the trigger. Pfffft!

Hmmm. Sounds like the pellet jammed and never left the tap. This can happen when there’s a severe mismatch between the port in the tap and the barrel, especially with harder pellets. I cocked it again, verified that the pellet was still in the loading tap (it was) and pulled the trigger once again. Pfffffffffffft

Well, maybe not so easy after all. Whatever’s going on, a complete teardown is gonna be in order one way or the other. So, I might as well jump right in. After removing all necessary screws, the action popped out of the stock

Separated from the stock, the Falke action shows robust construction of machined steel parts.

Since it still had a pellet in it, the first thing I wanted to do was yank out the loading tap so I could extract it. I flipped over the action and…uh, there’s something funny going on here. I see the rest of the mechanism that operates the loading tap automatically when the gun is cocked.

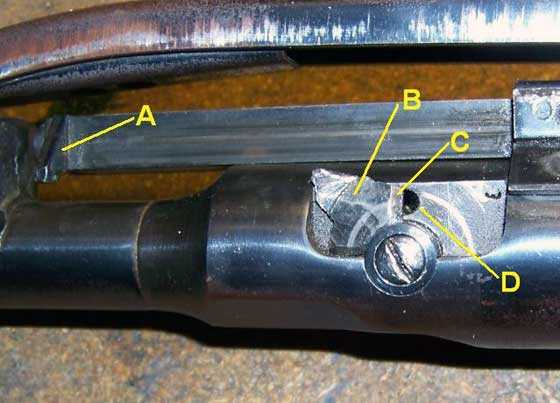

The Falke, like the Hakim and a variety of other tap-loaders, automatically opens the tap when the gun is cocked. On this gun, the protruding tab “A” slides backwards during the cocking stroke and catches the tip of lever “B.” It continues rearward until lever “B” has been rotated 90 degrees, opening the tap. There are a few things wrong. First, the bevelled section (“C”) on the lever is supposed to be facing inward toward the action. It’s upside-down. Second, the lever is really beat up. Lastly, hole “D” is not supposed to be empty; there’s a spring-and-detent ball or plunger that’s supposed to be in there.

Now I know that someone — even less skilled and experienced than I — has been in here already. I can’t WAIT to see the other surprises!

Stay tuned for part 2 on Wednesday.

Ah the Falke! About the only time that Germany actually had to copy as UK design, the Airsporter Mk1 from BSA. ormally we copied their guins, i.e. the Webley MkIII a copy of the DIana 45. They produced a very good variation on the original with lots of new features. Looking forward to seeing inside this one.

For those interested theres a Falke Forum to look at http://www.network54.com/Index/98508

Vince,

An under lever with no lever under the barrel? Please show us how this gun cocks.

Thanks

Pete

Pete,

Like the Hakim, Whiscombe, Air Arms Pro Sport and certain BSAs, the underlever is tucked into the forearm.

B.B.

Morning Vince,

I’m with Pete and am wondering about the leverage that the linkage provides. Looks like it might provide more leverage than the traditional under the barrel lever, but does it?

Bruce

Bruce,

No, it doesn’t provide greater leverage. It’s about the same as a conventional underlever.

B.B.

Vince,

What great writing, and what a teaser – no way I’m missing tommorow’s blog!

Alan in MI

Alan in MI,

I’m with you on this one. Great build up. What could be next???

Victor

Vince, I’m looking forward to your usual, colorful storytelling on this gun!

Let us know where you find that ball detent and spring, I hope not in the compression chamber!

Again withthe cliff-hanger?! Will Dudley Vince Do-Right never save the lovely Miss Falkelina?

That’s it… I mean it seems like a nice rifle and a great blog about how to fix but “Stay tuned for part 2 on Wednesday” that’s just cruel.

Now I’ll end up staying in front of the computer until midnight to read the rest. Thanks a lot 😛

I can’t wait to see the rest of this blog.

I just acquired some old airguns to try my hand at fixing them thanks to you (if I fail I’m blaming you and BB).

Rifle #1 is a Slavia 618 with a mirror smooth bore that will make a wonderful plinker if I can find a rear sight to go on it, the old one was replace with along with a nice lube job from the previous owner but the new rear sights broke during shipping so I’ll have to find a rear sight and find a way to fix it.

Rifle #2 is a Japanese rifle engraved TSA inside an eagle looking bird, it makes really harsh noises when cocking but can still shoot and hit what I’m aiming at, as no front or rear sights but has a very short dovetail on the back of the action so I was thinking of maybe putting a cheap red dot on it.

Rifle #3 is a (probably) an IZH-38 the front post globe was cut but it still cocks and fires fine I wanted to just lube it.

Then IF I’m able to not trash these I’ll give my first airgun a hand me down Relum Telly a try.

Any advice or bits of info on any or all of the first 3 rifles would be appreciated.

If you don’t want to put it here you can email me at : docgadget@gmail.com

J-F

J-F,

Well, for starters, you need to know about Numrich Gun Parts Corporation, where open sights abound. They buy millions of new, unused parts from manufacturers and sell them to guys just like you.

http://www.gunpartscorp.com/

As far as the rest of the guns are concerned, I’m not sure I know what they are, so I can’t really address them intelligently. The Japanese copied several British designs in the past, and I suspect that is what you have, but if I can’t see it, how can I tell?

Finally, you need to get a copy of the Blue Book of Airguns, which has a lot of information about what is what.

B.B.

J-F,

I just did a search on the Gun Parts web sight and found thousands of rear sights to choose from.

B.B.

I do own the latest version of the blue book and the Japanese rifle isn’t there and there isn’t much info on the IZH either other than “current values not yet determined”.

I’ll have a look at the website you suggested. But the issue to me is more of HOW to fix it to the barrel than finding the actual thing. I could use the one I have left from the IZH-60 as I scoped the rifle and removed all sights on it. I’ll take my time on these as I don’t want to risk breaking anything.

Thanks again,

JF

BB I remember the Numrich catalogues back before internet sales existed.

I always loved looking through those great big books.

The IZH 38C is a wonderful little rifle, and it’s on my list of ones I’m sorry I sold. It’s father was the IJ22, and it’s direct descendant is the 512. These guns have no spring guide per se. Rather, they have a spring that fits relatively tightly into the piston. If I recall correctly, the sear acts on a protruding nub on the bottom of the piston. It’s geometry is relatively critical, and relies on a degree of “stiction” to keep it engaged. As a caution, avoid using moly on the trigger and sear until you FULLY understand how the piston is held in place. A mirror polish on the mating surfaces should be sufficient to start with.

I’ve owned several IZH guns of varying ages over the years, and I can say unequivocally that they make very fine barrels, equally up to the high standard of their 46M pistol.

The little Slavia is a good gun to start with, since they are relatively simple and quite elegant.

I know nothing of the Japanese TSA. Maybe post a picture or two on the vintage forum to see if you can solicit some more information. I’d love to see it.

Thank you for all the info.

Sadly I can’t take pics right now as my 2 cameras (the good one for macro and zoomed pics and the “cheaper” one that can be used underwater) are with my parents on a kayak trip in the Florida keys, so no pics until they return at the end of the month… 🙁

JF

J-F

If you don’t mind, some info on 38.

There are at least 4 types of this rifle. 2 lever-opened but with different barrels, 1 “leverless” without dovetail and 1 “leverless” with a dovetail welded onto upper cylinder.

Different barrels mean that there are at least 2 types of barrel – 13-mm 6-groove and 12-groove hammer-forged polys or conventional rifling. Later are 6-groove “almost polys”. There is also a possibility to find a “mix” model fitted with brass liner 15-mm barrel, from old stock for Izh-22. Barrels are mostly excellent. So maybe some photos of your rifle can solve that mystery.

Stock can be of several types. Most common is mold glass-shiny cherry-brown plastic, IMO it’s a sort of polyethilene. Then some cherry-browns with white inserts right above the trigger (older stuff). Then some wood (birch, like all Soviet mass-production) stock and modern black glass-filled plastic stuff, same as used on AK-74 and AK-74M assault rifles.

It has a bit heavy and “dumb” trigger, and overall build is a bit brutal (Soviet school, comrade, that’s a Soviet school!) but that can be cured. Correcting angles and polishing surfaces can do miracles to that rifle: cocking, trigger etc. If you need info to tune it, just tell me – there’s a whole lot of manuals and pics and a bit of experience on my side.

duskwight

Vince:

This rifle has it all going on.I look forward to your next reports.

The discreet cocking lever really appeals to me.

I kinda like an air rifle that doesn’t look like an air rifle if you know what I mean.

Call me ‘Shallow Hal’ in this respect.lol

DaveUK

Vince

I hope the other side of “lever B” looks better than this side. It looks absolutely buggered from here, to put it into the Queens’ english.

You may have unknowingly shown your hand. You revealed the fact that the rifle is now in the hands of the venerable Mac, which means the servicing of the gun was a resounding success as usual. Now we all know the ending, so much for the cliffhanger.

Slinging Lead:

My compliments.Spoken like a true Englishman 🙂

DaveUK

DaveUK

What’s news on that side of the pond?

Any new guns or airgun exploits?

Brian:

No new guns but plenty of new pellets,a barrel cleaning kit and a laser dot sight.

JSB Exacts,RWS super H Points,H&N Diabolo Spitzkugeln pointed and a couple of dozen Prometheus Dynamic domeheads.

So many to try,so little time.

All were presents for Christmas and birthday basically.

It was only a cheap laser dot sight so I strapped it to my pistol crossbow and the cleaning rod kit I am not sure about.

That was also cheap so I’m a bit loath to start rodding around my Weihrauch with it.

Never mind,it is the thought that counts 🙂

DaveUK

Same here, a cheap Birmingham Small Arms red-green-blue dot sight for Xmas which now resides on top the 2240 pistol. It actually holds aim well and works a treat! (the Chinese factory even got the B before the S & A on the logo, ha ha ha)

And lot’s of pellets too!

DaveUk,

What kind of pistol crossbow do you use. I have yet to find good reviews on any that I have found.

rikib

rikib:

Mine is a ‘Perfectline’ self cocking Pistol with an 80Ib pull.

I have seen the same model marketed under different names though.

‘Self cocking’ is also misleading,’easier cocking’ would be more appropriate.

It’s ok for short range target practice but make sure you have a good backstop.That bolt will travel and can do serious damage.

DaveUK

I don’t know the significance of the Falke. Is it something special?

Victor, I agree with all you said about follow-through, but how do you do it? Is it a matter of holding form, maintaining eye contact with the target? These are things I’ve experimented with. Your Karate regimen is intense. I thought your accident curtailed your activity–unless you did this before the accident, but then how would you have had time to do this and shoot? Also, why? I can see how shooting, for all its effort, can be fun, but this sounds miserable. There are a couple schools of thought about martial arts training that go far back in history and probably generalize to other forms of athletic performance. One is to focus in a single-minded way on the skills themselves. The other is to work on the whole person and have this accumulated development add its weight to the activity. There are points in favor of both, but I’ve found the second to be more fun. 🙂

Fred ProNJ, thanks for the tip. So, the graph is so easy that everyone knows about it. I have Excel and can figure out how to do what you described.

PeteZ, I’ve heard about the fork design and the way it stabilizes a bicycle, but I’m not sure how this effect compares with the role of inertia in stabilizing the bike at speed. Incidentally, I live in the bike capital of the U.S., and I’ve seen people texting with both hands and looking down at their screen while riding and riding a tandem bicycle alone and from the rear seat. I wonder if this sheds light on the physics. 🙂

Mike, apparently basketball star Isaiah Thomas was fond of kneeing people in the leg, so it’s a sports move as well.

Matt61

If you read the article I referenced, you’ll see that the author tested the gyroscopic stability idea, and found it contributed very little. Sure you can ride no-handed, texting, and even standing on your hands on the seat. The actual physics of what keeps the bike restoring to the vertical in response to a small side thrust remains the same. You just apply the compensation with different muscles.

FredPRONJ: Did the bicycle link work for you?

pete

Hey Pete,

yes, the link worked and I’ll be reading the article on the plane to Charlotte tomorrow. Business trip. There is an expert in the world of motorcycle frame builders, Tony Foale, who states that balancing and leaning of a motorcycle (actually single tracked vehicles) are more dependent on gravity and having the contact patch of the front wheel moving side to side to maintain balance, as opposed to centrifugal force and, in initiating a turn by getting the bike to lean, again the force of gravity as opposed to gyroscopic precession. For the rest of you, when you want to turn or lean right, you turn the handlbars so the wheel points left. I always held that the gyroscopic force of precession forces the front wheel to flop 90 deg in the opposite direction, thus forcing the bike to lean that way. Foale says this is a minor force and by turning the wheel, you’re steering away from balance causing the bike to fall over in the opposite direction. I’m anxious to read if the article agrees with him. By the way, this is also how helicopters turn – gyroscopic precession.

Pete, other studies have been done that show you can’t turn a single tracked vehicle without turning the front wheel -body english doesn’t do it. The geometry of the fork to the contact patch determines how stable or unstable the vehicle is (we refer to it as rake and trail). This is what keeps the bike self-correcting when you ride without hands so as to maintain the vertical upright position. Sorry to have run on like this all but as you can see, this has been a pet project of mine since I started riding motorcycles.

Thanks again, Pete, for the link.

Fred PRoNJ

I remember something about a difference between low-speed and high-speed turns as well, something like you turn the wheel the way you want to turn at low speeds and opposite at high-speeds. Somehow, I managed to ride a bike without being able to figure it all out, but there is a lot of neat physics at work :).

PeteZ,

When I digest this article, could you find me something about the same that explains magnetism :)? The more explanations I get, the more I think we just don’t know how it works.

Matt 61

You say you are from the bike capital of the world. Do you live in Portland Oregon?

Matt61,

Following through is exactly about holding form and focus. The shot is not over for a least a second or two after the gun is fired. You continue to consciously aim and hold your form. The best way that I know to understand follow through is to think of the alternative. In pistol shooting, or archery, lack of follow through is VERY obvious. When you don’t follow through, you literally drop the pistol or bow almost at the instant that you let the shot or arrow go – almost meaning a fraction of a second before. That’s why archers will keep their arm up, only allowing the bow to continue it’s natural motion following the release. They don’t actually hold the bow, but allow the tension of the pull to keep it up. Upon releasing, it just falls forward, BUT the arm stays up for a couple of seconds. In my mind, the shot is not over UNTIL I SAY IT IS, and NOT the gun.

Another important lesson is to NOT practice when you’re really tired. When you’re tried, it’s harder to follow through. When you practice not following through, you learn bad habits, and there are numerous bad things that you might do when you’re desperate to get a shot off. This is also why you should stop practicing when you know you’re having a bad day. Rest, and a fresh perspective, will change EVERYTHING. Remember, the miracle happens when you change your attitude about the problem.

Yes, our training was extremely intense. On the first day of any students training, they are warned that nothing that they may have done in the past will have prepared them for what they are about to embark upon. Doesn’t matter if you were a boxer or a ballerina, this particular training will introduce new challenges and require a discipline that will take things to a whole new level. Yes, I did this before the accident. My ability to survive a head on collision, of a combined speed of 75 miles per hour, and no seat belt, is attributed to my conditioning. If you watch the movie GI Jane, you’ll get an idea of how mercilessly “fair” it was to everyone, including women. The payoff was beautiful form, and a body that reacted quicker than you could think. I swear that I could get up much faster than gravity could bring me down. No, fun had nothing to do with this training. In fact, a smile cost at least 25 push-ups.

At a minimum, the benefits of good martial arts training is that you always have presence of mind under the high stress of conflict. It’s no different than training to use that pistol that you bought your wife for self-defense. It’s a HUGE mistake to buy your wife a pistol, and then not make sure that she’s completely confortable with it. In the event of a real gun battle, she needs to be the one who is in control. Being trained to protect yourself, by any means, will save your life, even if that means just being able to get out of harms way.

Yes, I did both Karate and shooting at the same time. However, because a lot of money was being invested in me as a shooter, I did eventually have to decided between the two around the time of the Olympic tryouts.

Thanks for the good questions. I haven’t competed in decades, so I’m having to somewhat reach way back into a mindset from another lifetime.

Victor

B.B.

It seems to me that except loading system this Falke has something in common with BSA Stutzen. Can you post some larger pictures of its trigger assembly please?

Thank you.

duskwight

duskwight,

There are 35 more detailed photos coming on this rifle, as Vince takes it apart and repairs it.

Then Mac will also send some photos.

B.B.

B.B.

Wow! That’s great! All I need is patience then.

duskwight

You are right, it is very similar. The Stutzen is basically an Airsporter in a nice stock, and the Falke is more or less a copy if the Airsporter. The whole BSA Airsporter line used the loading tap arrangement right up until BSA developed the rotating breech (which Gamo now uses on its CFX models).

Vince,

Another good one. I like seeing the rare ones brought back into working order, and the best thing is that since they were’t working before and sometimes not even in good condition, you can actually shoot them rather than treat them as artifacts.

The XM-25 is a success on the battlefield!

Three have been deployed in Afghanistan for combat tests in nine engagements with the enemy, and it is being described as a “game changer.”

In one engagement, an enemy machine gunner was “so badly wounded or so freaking scared that he dropped [his] weapon” and ran, said Lt. Col. Christopher Lehner, Program Manager Individual Weapons…

“No longer can the enemy shoot at American forces, then hide behind something,” said Brig. Gen. Peter Fuller of Program Executive Office Soldier. “This is a revolutionary weapon. This is a game-changer.”

The XM25 has a target acquisition system that calculates range with the push of a button. The data is transferred to an electronic fuse, enabling the 25mm round to explode over the target and rain shell fragments on the enemy.

It’s a little hard to tell from the article, just what the XM-25 is. It’s a smart grenade gun.

On arrival the XM-25 gave infantry squads the capability to precisely target bad guys hiding behind walls, in irrigation ditches, or among rocky escarpments. The Heckler & Koch-made XM-25 pairs a barrel-mounted targeting computer and a 25mm programmable air-bursting round that’s fed precise range information just before being fired. A Soldier can simply push a button to range an enemy firing position, dial in one more meter, and the round will explode precisely where the bad guy is sitting.

http://airgun-video.foxnews.com/v/4438880/xm-25-rifle-in-action/

kevin

You mentioned that you bought a Diana mod. 26 a couple of years ago. I wondered what you paid for it and what kind of shape it was in? I just bought one on an auction website, but I just wanted the scope. It was a Beeman Blue Ribbon SS-1, which are very hard to find. I would like to sell the rifle, but can’t find pricing info.

Hector,

I may have mentioned that a friend of mine bought a Diana 26. I did not.

A 26 in good condition should sell for about $150-200, depending on cosmetics and the presence of the box.

B.B.