by Tom Gaylord, a.k.a. B.B. Pelletier

Today, we’ll have the first part of a guest blog from reader Vince. For those who don’t know him yet, Vince is our “go-to” guy for fixing all sorts of strange vintage airguns. In this post, he tells us the tale of a wild idea he just had to try.

If you’d like to write a guest post for this blog, please email us.

Over to you, Vince!

by Vince

“Nitro” is da bomb, right? I mean, in current usage, “Nitro” anything means hot, fast, powerful and overall bad. This normally benign element sure shows its alter-ego when combined in properly mischievous proportions with oxygen to form nitrous oxide. More fun can be had by mingling it with oxygen, carbon, and hydrogen in various arrangements to come up with nitromethane, nitroglycerin, nitrocellulose or TNT (trinitrotoluene). So, yeah, “Nitro” IS da bomb — in every sense of the word.

Now, when Crosman started producing the Nitro Piston series of air rifles — well, it sends the imagination reeling, doesn’t it? That is, at least, until we come back to reality and realize all they’re doing is using something called a gas spring, which uses pressurized nitrogen to exert pressure on a piston-rod and cylinder assembly. Push the rod in, and it pops right out again, with different degrees of enthusiasm, per the individual design of the particular gas spring.

The advantages of the gas spring in an airgun application are numerous. Because there’s no metal coil spring inside, the gun doesn’t FEEL like there’s a metal coil spring inside. No twang, sproing, buzz or anything else of that nature — and no twisting or torquing reaction as the spring extends and slightly unwinds. Because gas doesn’t fatigue, a properly functioning gas spring will never take a set or get weaker with time. This also means you can leave it cocked for as long as you want with absolutely NO effect on spring life.

What’s not to love?

Well, specifically, those two little words…”properly functioning.” Yes, the gas will never fatigue, but sometimes it leaves home and never comes back. And if the gas spring DOES leak, there’s nothing left to do except go get another one. And almost certainly, it means going back to the manufacturer — and praying that they still have them available.

You see, gas springs are something of a specialty item. They kinda have to be designed around a specific application. There are universal gas springs out there, but the chances of finding one with parameters comparable to your airgun is gonna be difficult. Unlike a coil spring you can’t just get a longer one and cut it to length. You can’t tell what sort of rate a gas spring has (or had) just by measuring things, like you can with a coil spring. I believe you can still get custom coil springs made on a case-by-case basis, but making a gas spring is a bit more involved. Heck, you can make a crude coil spring yourself using a paper clip and a pencil. Sure, it won’t be good for much — but it shows that the basic process for making one is, well, pretty basic.

That’s why I’m not terribly tempted by all these Nitro Piston (of any sort) air rifles that are out there. Will you be able to get it working 50 or 75 years from now? I certainly won’t, cause I’ll probably be gone by then. But that’s beside the point. I’ve got future generations in mind here! I don’t want little Billie- or Betsy-Bob cussin’ out their great granddaddy simply because he bought a gas spring rifle they can’t fix. Heaven knows they’ll probably have enough reason to do that anyway. Why add fuel to the fire?

That’s when I got to thinking. How about gas-springing a spring gun? When the gas stuff craps out, I (or whoever) will easily be able to cram in all the old conventional spring stuff and the gun will be back in business. After examining the Crosman gas guns (for some reason this makes me think of the “fart gun” from Despicable Me), it seemed obvious that they’re based on the ubiquitous Quest platform. That rifle, as we all know (except for those of us who don’t) goes back to the old BAM B18/B19 air rifle. Which, in turn, was a near-clone of the old steel-barreled Gamo series of the time (Shadow, 220, 440, 890, etc.).

Seems to me that a proper pickin’ of replacement parts ought to let ANYONE with a Quest variant (which are as numerous as the stars in the sky) or a Gamo 220 variant to gas ’em up without giving up long-term serviceability. The best part is that Crosman is generally the most tinkerer-friendly airgun company out there. Not only do they sell parts — ALL parts — for many of their springers, but they’ll sell them to anyone. And they’ll let you keep your first-born, your arms and your legs, and your very soul because their prices are so reasonable.

So it is that I started combing through the parts list for the Storm and the Titan GP air rifles. My suspicion of the close relations was confirmed by Crosman’s designations for these guns — both start with C1K77. I believe C designates the gun family, the 1K means 1000fps, and the 77 points to .177 cal. In any event, the commonality of parts (especially the cocking link, trigger assembly and piston seal) tells me I’m on the right track. Things can get a little tricky, as some parts that are virtually identical might have different part numbers depending on cosmetic details (like lettering). Trusting my own judgment, I came up with a list of 5 parts that I THINK will fill the bill:

Piston………………….BT9M22-03-100B

Gas spring……………BT9M22-00-5

Plain plate…………….BT9M22-00-7

Back spring guide…..BT9M22-00-2

Tube cover…………..BT9M22-00-3

I ordered the parts and waited. As a side note, I told the customer service rep at Crosman what I was trying to do, and he seemed rather interested in my results. I think I’m gonna just send him a link to this blog. As another side note, there’s some commonality between Crosman’s part numbers (which were revamped a couple of years ago) and Stoeger’s. Of course, both guns are made by BAM in China.

A week or so later, the package arrived!

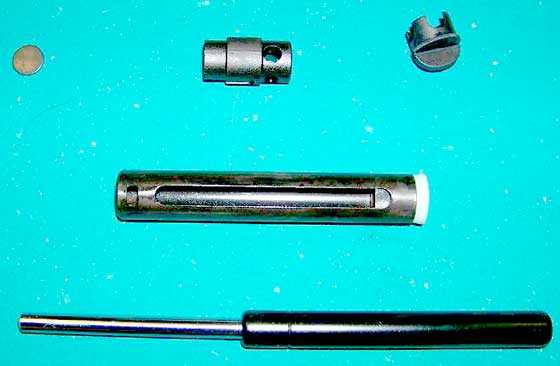

The parts received from Crosman. The camera perspective distorts the gas spring at the hottom. It’s really straight.

Picking a guinea pig is easy. I immediately turn to a tried-and-true, long-time member of my collection: a Gamo 220.

My Gamo 220 was the guinea pig.

The Gamo 220 is a bit of a mule, frankly. All the 1000 fps Gamos of that period used essentially the same powerplant with a 25mm bore, a 100mm stroke, and the same 29 lbs./in. spring. The Shadow, which was the first decent airgun I ever bought, had a nice-to-hold, if utilitarian, synthetic stock and the low-grade rear sight. The significantly more expensive 440 had a nice-looking wood stock with Gamo’s “better” micro-metric rear sight (which, incidentally, is actually inferior to the lower grade one). The upscale 890 was a sightless 440 that came with a scope.

The 220, price-wise, sat in the middle — with a completely unadorned, mud-brown and slippery wood stock with about as much aesthetic appeal as an old shoe. It lacks the utilitarian friendliness of the Shadow and the visual appeal of the 440/890. It really was the least-appealing of the Gamo magnum breakbarrel lineup. Why do I have one?

Because.

As a result, it periodically becomes a test-bed for projects when I don’t want to mar up a NICE gun. Projects like this one.

The first thing I do is baseline the rifle for accuracy and power. In the accuracy department, it didn’t disappoint — a 0.30-inch 5-shot group at 36 feet. That’s about what I remember for the gun. Power-wise, however, was a different kettle of fish. I used RWS Basic pellets for velocity and averaged only 814 fps with a spread of 22 fps. The spread isn’t too bad, but the velocity stinks and represents a measly 10 ft-lbs of power. Oh, well. Frankly, I don’t even remember what guts are in this thing.

The gun comes apart in pretty much standard Gamo/Quest fashion, starting with the three stock-to-action screws. Once the action is out of the stock, you go to the rear of the spring tube, where the big bolt comes out first.

The big bolt comes out first. Then, the pin is drifted out, but only after the end cap is restrained.

The pin is next, but the rear retainer has to be suitably restrained in order to contain the approximately 2 inches and 60 lbs. of mainspring preload typical for these Gamo’s. Or not, as the preload in this gun turned out to be less than an inch. What happened? We’ll find out soon enough.

Next step is removing the trigger, which means the barrel has to be broken open so the trigger can slide backwards a bit.

Break the barrel to put slack in the cocking linkage. The slotted bar that runs back to the trigger is the link for the anti-beartrap device.

Then, the cocking link gets pulled down, freeing it from the piston and allowing you to disengage the anti-beartrap link.

The cocking link can be disengaged from the piston, then the anti-beartrap link disconnects from the cocking linkage.

At this point, the piston just slides out. So — what’s up with that low power and lack of preload?

Wow! That mainspring sure is short. And that rear guide AIN’T Gamo.

Oh, yeah — that’s right. I detuned this thing with a Crosman 500X spring. Incidentally, that spring is part #B12-1-00-4A, for anyone who wants a real pleasant detune on a similar Gamo or a Quest variant. That’s why velocity was so low and why I could cock it with my pinkie! That also explains the lack of preload.

But the guide? Near as I can tell, it was a custom guide I picked up somewhere. It’s dimensionally close enough to the normal Gamo parts that I can be sure it isn’t affecting power.

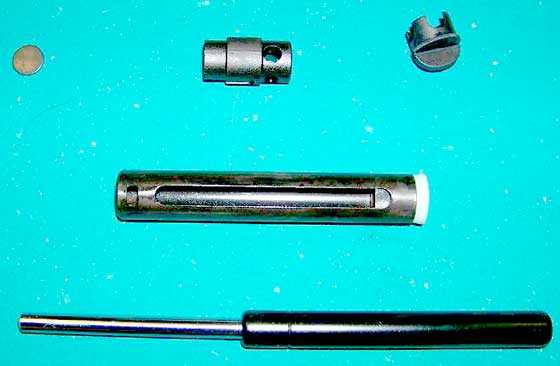

The spring guide in my 220 (top) and a regular Gamo spring guide.

As a matter of curiosity, I looked at the two pistons side-by-side.

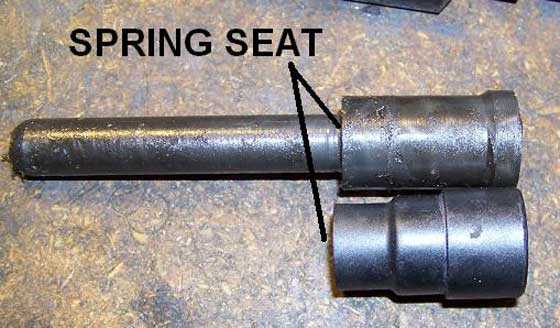

The new piston that goes with the gas spring (bottom) has a slightly shorter stroke than the old piston.

The upper one is the original — and it’s a little shorter, but it appears that, for whatever reason, the gas spring wants a slightly shorter stroke than the coil spring. Also — although it’s hard to tell from the pictures — the inside of the old piston has a flat surface for the top hat, while the newer one has a shallow hole meant to locate the rod end of the gas spring. You will see why this is needed in the next installment.

That’s where we are going to leave this story for now. Vince has the old parts out, and the new parts ready to install. We’ll see what happened in the next installment.

Although I am not a big sproinger fan, I find this very interesting because I have been thinking of doing this with a 10 meter sproinger using a low power gas spring.

And as soon as that very rich relative I am unaware of dies, I will do that and a few other projects I have in mind.

Great blog Vince. Can’t wait for part 2.

I was thinking of converting my TF 87 to a gas spring some time in the future. Do you think the Benjamin Trail Xl might offer some hope in this regard??

Pete

The big question is the stroke of the powerplant and whether or not the gas spring will bottom out. I don’t have specs on the TF87, but the stock Crosman and Gamo guns have a 100mm stroke. If the TF87 is a revamped TF99 (and I suspect it is), then it might then have the same 100mm stroke as the ’99… in which case in may be possible.

The gas spring conversion on this gun does shorten the stroke a smidgen… but I suspect there’d be a workaround.

I was looking at the Crosman website this morning for some parts manuals and happened to notice their new products for 2013. They have some stuff that looks interesting. I am still waiting for the release of the MAV 177 however. I am hoping that some of these new products are actually released this year. I am particularly interested in their version of a 1911 style blowback pistol. They also show an AR style break barrel.

VInce,

Very interesting blog so far. I agree with your point about long-term viability of a gas spring. The only exception I know of are the Theoben gas spring rifles; they can be resealed by just replacing some orings. Those guns also have a Schrader valve so the gas spring can be recharged once the gun is reassembled. This cannot be done with the self-contained gas springs.

Paul in Liberty County

Which is probably why Theobens cost so much… But what the heck? That rebuildability (is that a word?) is what makes them worth it!

/Dave

Vince…

An interesting project you have there.

I only have one “nitro piston” gun. I would not have that one except for curiosity. I wanted to know how they feel.

So my experience with “ram” guns so far has been a 100% fail rate…. it’s a leaker with very little shooting time.

twotalon

Vince,

What a great idea for a story! I have the TF 99 that I ordered from Pyramyd AIR with the nitro conversion. They ship the old parts that they remove, so should the nitro piston fail I can go back to the spring. So far I have 2 different guns with the nitro piston and both cock and shoot very well. Accuracy is good for the type of shooting I do. A new pair of eye glasses may change my mind since I cannot see the sights well at all. Maybe someone has a suggestion for shooting with poor eyesight.

Jeff…

Poor eyesight and what you can do about it gets to be a bit of a wide subject. Depends a lot on how your eyesight is poor.

Sometimes it may be just a matter of getting new glasses, sometimes not.

How much “auto focus ” your eyes have is a big issue. From how close to how far they focus is the “gotcha”. ….even with glasses.

I started having trouble when my autofocus stopped working through as much distance as it used to. I needed bifocals for normal use. Then it got worse and I needed trifocals . Then the cataract surgery..NO autofocus at all because of the fixed focus of the plastic implants. This required trifocals to give me three overlapping focus distances. But none of them is right for open sight shooting.

I would need a seperate set of shooting glasses made up for open sights to focus at the front sight distance.

There are other problems that can cause eyesight to be bad as well. Depends on what is wrong, and how (or if) it can be compensated for.

twotalon

Thanks twotalon,

Issue is that when shooting I cannot see the front sight unless I hold the rifle like a pistol, and on pistols my arms are not long enough. Now I have to shoot left handed since that is my better eye and I am right handed. I have been wearing bifocals for 31 years because of other issues. Funny but I have to take them off to use a scope as I cannot get them to clear up. Thanks for the advice as I need a new prescription so I will talk to doc about a separate pair of glasses for shooting.

Jeff

Jeff..

Sounds like you have gone farsighted. You may only need new glasses for everything, and not special shooting glasses. Depends if your eyes still have a good range of focus if the new prescription moves the focus range back where it belongs. If your focus range is not adequate, then that extra set of glasses may be in order. Let the eye doc tell you what the deal is.

twotalon

twotalon,

Yep diffidently am nearsighted. It has been getting worst, so may be time for the trifocals in a really large lens so I can actually use them. This is the year for a new pair of glasses and I will take your advice to heart and talk to doc about this.

Thanks for the advice

Jeff

Jeffrey K,

This may help in your preparation for a visit to your eye doctor:

http://www.bullseyepistol.com/wong7.htm

This may help your eye doctor help you:

http://www.bullseyepistol.com/wong1.htm

kevin

Kevin,

Thank you very much! This is excellent reading and most certainly will help. I now understand more of how my eyes are working when sighting. Doc and I will diffidently be going over this as I really want to shoot to the best of my ability. It is one of the few things I really enjoy in life.

Jeff

Jeffrey,

I wonder if any eye doctors will let you bring a pellet rifle into the office in order to fit a pair of glasses to a real situation?

-Chuckj

Chuck,

I really doubt that! I will however set up a dowel with sights so he can see what I am working against. I have a long piece of clothes rod that is 1 1/2 that I can mock up sights on. With the way people are protesting guns up here I would be seeing the back of the police car if I tried that.

Jeff

Jeff…

How about rifle /pistol shooting glasses…. bifocals with a vertical line instead of horizontal. Look through one side for your rifle shooting, the other side for pistol.

I have seen some glasses that were botched so badly that they started to resemble this. Great quality control.

twotalon

twotalon,

Well that is a new thought. The way I break glasses I may end up building a set like that. Or maybe go to a monocle like Colonel Klink on my dominant eye for shooting.

Jeff

Jeff…

That only works with German guns.

twotalon

Darn it now I have to go buy one if I want to shoot.

Oh well another reason to buy another gun. Maybe a P1 or P3 this time.

Jeff..

34 or 48?

Maybe a HW ?

twotalon

Jeffrey,

I wear progressive lenses and while they aren’t ideal for everything, they’re a good compromise. I have CSS (Can’t See S… uhhh yeah…) along with CRS….

btw… Don’t forget to shave your head for the Colonel Klink look…

/Dave

Dave,

No problem with having to shave since the genetics is taking care of that very quickly. I feel your pain as my progressives are no different than my normal bifocals. I will wait and see what happens this next doctors visit.

Jeff

Between 6 diopter prism, astigmatism, and distance correction, my regular lenses are rather limited (look too far off center and lose the astigmatism correction — see double with one eye).

The last time I had money for new glasses (fall 2010) I picked up extra inserts for an old set of Gargoyle (I think) shooting glasses, and had my “sunglass” [distance both eyes] put in — since all the rifles have been scoped [except the USST Daisy 953 with the peep]. I’d planned to have a second insert fitted for pistol shooting with right eye set for something just over 30 inches. Can’t use my reading glasses as they are set at about 15 inches, and my left regular lens is set for 18-24 inches for computer monitor.

Wulfraed,

That is my problem. I see find up to 18 inches, however pass that a big blur. The low power is to help sharpened my close vision, but it interferes if too far. My distant side is too close to the rear sight. I have the same issue driving as too close or too far to read my gauges. It is worst in my car since the gauges are in 2 different areas and the windshield hud. This will be a very interesting appointment this time. Maybe time for trifocals.

Jeff

I think you will just need to know the distance from your shooting eye to the front post, while you have the rifle shouldered properly.

Gene

You are correct. That is what the article stated as being a substitute for bring in a firearm. I am currently making an appointment with a really good eye doctor nearby that is willing to help with my issues.

Getting older just really sucks when it comes to vision. Seems like I just get a good prescription then 3 months later they are blurry.

Jeff

Hey Vince,

you probably know this but that trigger and anti-beartrap mechanism is a dead ringer for what I found on my Crosman Nitro when I did the accuracy upgrade blog a while ago. Wouldn’t surprise me if the piston is the same, as well! I never disassembled the compression chamber as there was no need to get at the gas spring or the piston in trying to make the Nitro a bit more accurate.

Looking forward to the rest of the blog!

Fred DPRoNJ

Yes, that’s what I tried to lay out. The Crosman Nitro is built on the old Quest platform, which in turn is based on the old BAM B18/B19, which in turn is a close copy of the older Gamo.

What an awesomely splendid article. Thank you Vince. This is the sort of information i like to see when i go searching around the airgun blogs, there being 2 main blogs i always check, Pyramyd AIR and Another Airgun. For me in the UK it’s a lot easier to come across old BSA’s and interchange parts, so finding information about Crosman and Gamo compatibility is an absolute bonus to my day.

I have never personally ever used a gas spring gun so i don’t really know the advantages and disadvantages of this system, and if i ever wanted to it seems Theoben and Wiehrauch are most abundant rifles around, and most expensive. But it’s nice to know that i could rip out a broken coil spring and replace it with a cheaper sealed gas spring and visa-verse. TTFN

best wishes wing commander Sir Nigel Tetlington-Smythe

What a great blog. I love the way you write, it’s easy to read and understand yet has plenty of detail all while being funny, pleasant and colorful. It’s like listening to an old buddy telling one of his great stories.

I don’t know if you guys remember but I did the same thing with a IZH-60 last year. My experience wasn’t very successful, I hope this one goes better. My gas spring was a direct swap like this one and took all the buzzing and sproing the IZH had but the recoil feels harsher, it seems too powerful for the small and light weight rifle. Maybe it need more break in time I’m not sure I have 100 pellets down the barrel yet.

But my Canadian detuned Trail NP is still a joy to shoot. The weight of the rifle seems to have played a great role in this.

J-F

J-F

Being new to airguns, does the nitro piston really need a break in period? I ask since one of the advantages I read somewhere is that it shouldn’t weaken the same as a spring can. Oh I know if it develops a leak it will start getting weaker like the ones that hold up a trunk lid, however does it really need a break in period for the piston? I can see the seals and such needing one, maybe this is just my ignorance talking here. I really want to know as I have a project in mind that would use the new pistol nitro piston from the Benjamin Trail NP pistol when it comes out.

Jeff

Jeff,

I have owned several gas spring rifles and tested several more and in my experience, they don’t need a break-in. None of the brand new guns ever gained velocity or lost it, or became smoother as they were fired.

The only thing I did see several times with the older Theoben rifles that had Schraeder valves for the owner to adjust, was that they became even nicer to shoot when the gas pressure was reduced. That was especially true for a Beeman Crow Mannum and a Theoben Fenman.

B.B.

B.B.

Thanks for confirming this about the nitro piston for me. My thought is that if your use to the way it cocks as to pressure, it will always be the same. With my detuned Benjamin Titan I just got from Crosman it is smooth thru out the entire cocking sequence. I don’t expect it to ever change unless the piston has a failure. I love the way my feels since it shoots well and the trigger is very nice on mine.

Jeff

Vince,

Info and fun in the same post! You’ve got us all curious now!

-Chuckj

Vince,

Nice writing style and good info! Looking forward to part 2!

Do you still have that spare Daisy 1894? I’m still interested if it’s not too dear. Shoot me an email if you do. dmagee1(at)hotmail(dot)com.

/Dave

I sent you a reply about it on the 4th. I was waiting to hear if you still wanted it.

Never got the email, Vince. Didn’t see it in the trash file or the blog either. Are you sure you sent it to me? If you don’t want to post your email address, try again with the address above, or try the same address only gmail.

/Dave

Just did

Vince,

I’m sorry you have gas. There is this little pill called beano……

/Dave

LOL- Enjoyed the joke!

Vince, You did make a great point about gas springs becoming obsolete. I doubt that the problem will cause the air-gun industry to standardized a few versions to keep them available.

Regards,

Herb

Can anyone tell me how to post responses to this blog? Of course, if you read this, you’ll be convinced I’m stupid. But I’ve tried posting several times in the past few days, with no apparent success. This time, I’m using a different eMail address – just 2C if my other eMail addr is a prob.

Well, Mike. As you can see, you’ve made it to the big time. Actually, depending on the content of your response, the Blog software may put you into the spam folder. Edith, the wife of BB who is the real brains here (just fishing for brownie points, Edith), runs the blog as well as numerous other software and computer aspects, has to go and check the spam folder and may not have done so for a while since she apparently has gone to the Shot Show with BB.

Some things you need to know – if you put links to competitors in your blog, it will go to the spam folder. If you are offering to sell or buy something, it could treat the message as spam, your old e-mail address might be a common one used by spammers and so on. Edith will see what the problem is and mark you as a “safe” replier and your problem with reponses being posted should be a thing of the past.

Fred DPRoNJ

You just posted to me the other day.

Matt61

Thx, Matt61. I’ve got a cerebral handicap when it comes to websites ‘n blogs ‘n stuff. Thx 4 giving me a ‘heads up’. I had no clue whether my post attempt made it or not. I’m not sure I know how to go back ‘n look 2C if something I said on the blog actually stuck. Glad 2 hear it did. I love BB’s blog – I just don’t ride the internet much and don’t have much experience messin’ around with keyboards ‘n bits ‘n bytes. I liked getting an eMail notification of your reply to me here. I was wondering if my reply via eMail would end up on the blog – or if it would just be sent to you??? Gotta be careful with my language if it ends up there on the blog 4 the world 2C (LOL). Well, I quickly found out that clicking “REPLY” to the eMail notice didn’t go anywhere at all – it just bounced back.

I think I’m getting the hang of it now. Thank-you very much, Matt61.

This is a different “Mike”.

NOT me.

Mike

B.B.

All right, time to tell the results of my test.

So far so good – technology demonstrator does what it’s meant to do – it demonstrates. Speed is the same up to 1 m/s, groups didn’t change much in size and consistency and now I’m able to aim it right. However it’s still heavy as all seven sins together and hard to cock due to somewhat short lever and awkward angle. I’ll postpone the next test until I’ll arcweld an extension handle onto cocking lever and pump up some more nitrogen into springs – let’s say 65 kilos each. Then we’ll see who’s who 🙂

I’ve bought a good-condition perfect-shooting FWB 300 and now it’s riding to me. I hope I’ll have it for my birthday – to re-polish, re-blue and rebuild the stock back to its out of the factory condition. I also finally received a package from Oberndorf – with breech clap cover, handle and spare seal kit for my FWB C62 – a true short-range CNC drill in my arsenal.

duskwight

It seems like getting the accuracy as you have done is the hard part. I’m surprised that your cool-looking stock is not more ergonomic, but that shouldn’t be hard to change. What is the source of the difficulty with cocking? Is it the double-spring set-up? Otherwise, given a spring and a more or less standard cocking geometry, the results should be comparable to other airguns.

Well, since you’re a wolf hunter, I will defer to your observations about wolf behavior. But never rule out the unlikely. I was watching a YouTube video the other day about a guy in Alaska with a pet wolverine. These things can fight off entire wolf-packs and full-grown bears! But there he was sticking his hand into the the wolverine’s mouth to massage its gums (which the wolverine likes) and kissing the wolverine right on the mouth! It made me shudder to watch, and it reminded me about the line in Mad Max about losing one’s face. He communicated with the wolverine with a high-pitched squealing that made him sound like a complete freak. Apparently, he had bottle-fed the wolverine from birth, and the animal had imprinted on him. But still…

Matt61

Matt,

Trouble is 2 things – gas spring’s force starts to act from the very beginning of the cocking cycle and starting angle is a bit too shallow, so it’s not exactly hard to cock, but more on the unconvenient side. And do not forget that right now I’m acting against 100 kg of spring force (D-350 anyone?) with a “underbelly” lever that is not so effective in terms of force multiplication and ergonomics as underbarrel lever or barrel-lever.

And wolverines – they live in the northern parts of my country. Besides it’s very well “armed”, wolverines are also very intelligent and daring beasts. And I’ve heard stories of domesticated wolverines too – they are indeed easily domesticable (well, since they are essentially “weasels on steroids” it must be so).

I once talked to Siberian shaman and he told me that wolverine must be my spirit beast, a sort of totem, with most power at dusk. Well, I’m stubborn, territorial and I tend to learn fast, so that’s at least partly true and I’m a duskwight 😉

duskwight,

Isn’t it interesting what we learn by doing things instead of just talking about them? Now you know one of the gas spring’s drawbacks — it’s hard to cock. But I think you have made the world’s first dual opposed piston gas spring air rifle, so you’ve got that going for you!

B.B.

B.B.

Did I? I’m not sure, but I may have read somewhere that some JW prototypes were built using gas springs.

We’ve got a saying “Stupid head gives no rest to man’s feet”, in my case it’s arms 🙂 Doing it indeed brought me more knowledge than reading and studying from books. And one more thing – I thought that the prototype will be a “work” rifle, but now I understand that its sole purpose was is serve as a testbed and a thing to do my homework. The “work” rifle is still ahead – but it would not happen without this heavy and cumbersome technology demonstrator.

duskwight

Vince, thanks for definitively warning me away from the gas spring. They had always made me uneasy for reasons that I had not really put my finger on. And your title reminds me of a logo for the British diving superstar Paul Daley. For one endorsement, he wore a little blue speedo with “British Gas” printed on the rear end. Heh, heh. The marketers must have been the same ones who came up with the Air Arms Twice. Anyway, I just had my first airgun session (using springers) after coming back from firearms shooting, and I feel cleansed. If it wasn’t for the cultural and historical interest, I probably wouldn’t bother with firearms at all.

B.B. thanks for the info about mailing handguns through private carriers. At some point, I will want the detail servicing of my SW1911 which is a real beauty. Vince, the postal regulations about mailing handguns are pretty absolute. If it is possible to do somewhere in their regulations, it is probably not even worth it.

Mike, were you the one who told me that when loading the SMLE with a stripper clip, the rounds would seat properly even if the were not with my snap caps? That turned out to be exactly right, and mysterious too. The rounds in the stripper clip have their rims overlapped over and under for alternating rounds. How that is somehow converted in the act of loading so that the rim of every round is in front of the one below it is completely inconceivable to me. Maybe some kind of interrupter mechanism?

Just saw The Hobbit last night, and enjoyed it immensely. What stood out is that Bilbo’s wasp-waisted sword looks exactly like my Roman Gladius. So, I’m a Hobbit? Or, given the black baked on finish of the sword, maybe an orc?

Snap. Crack.

The black crack.

Grip grab.

Pinch nab.

And down to goblin town

You go my lad.

Also of interest were the kung fu dwarves. Never undersell your basic dwarf. Entertaining as it is, how this story with its fairy tale character ensemble ever caught on to the wider population is a mystery to me.

Matt61

“We, dwarves are natural sprinters – very dangerous on a short distance!” (c)

Yes, they align properly when you load or “Strip” them into the rifle.

Mike

Take into consideration that what’s-his-name is turning what had been ONE book into a three-part movie. The book itself is only slightly longer than each part of the “Lord of the Rings” trilogy.

The whole thing about some orc leader seeking to end the dwarf royal line is totally filler for the movie, as was (as my memory insists) the short meeting of elves and Saruman and the critter-wizard. They’re apparently trying to put in foreshadowing of the later LotR trilogy. The Hobbit itself basically splits into three parts: the trip to the dragon cave (wherein the ring and swords are discovered while passing through a nasty forest), sneaking into the cave to learn the dragon’s weakness (relatively short section), and the finale — wherein a local human village takes the brunt of the dragon’s wrath and, after defeating the dragon, demands a major share of the dwarf’s gold.

Oh good. The blog is accessible again. Sure has been down a lot in the last few days. Guess it misses its’ mommy.

kevin

Kevin,

Edith and I were in the casino this afternoon and were not monitoring the blog as we normally do. Some piece of code reset some parameters in one of the servers, no doubt.

We were at the Pawn Stars shop today and I remarked to Edith that there were more guns in the cases than I had ever seen in the past. But about 10 minutes after we arrived everyone was asked to leave as they were about to film an episode. So the cases were dressed for the filming and those guns are probably not really for sale.

SHOT Show opens tomorrow,

B.B.

Tom,

“….the cases were dressed for the filming…” Your filming career is showing through.

I’m envious. If I got passes to the SHOT Show the night before the opening would undoubtedly make me feel like I did on Christmas Eve when I was ten years old.

Hope you have time to make it to the Tracking Point booth.

kevin

Kevin,

Why? What is there?

B.B.

Tom,

Tracking Point is an Austin, Texas based company that is introducing their new lock and launch, precision guided technology in a rifle + scope combination at the SHOT Show. If it works, this changes the game for long range shooting even with a mediocre civilian on the trigger. Star Wars stuff.

http://www.prnewswire.com/news-releases/1000-yards-made-easy-trackingpoint-launches-worlds-first-precision-guided-firearms-at-shot-show-186783921.html

kevin

Kevin,

Okay, I’ll have a look.

B.B.

Tom,

Only if you can make the time. I know this type of stuff isn’t on your radar and you’ve already got a full plate.

Sure would be interested in YOUR opinion though.

kevin

B.B.,

Unfortunately, I will not be able to attend the SHOT Show this year. Enjoy!

Victor

Victor,

Sorry about that. I had to miss it in 2011 and I know what a pain it is.

B.B.

Vince,

Excellent blog! I will be bookmarking this one!

Thanks!

Victor