by Tom Gaylord, a.k.a. B.B. Pelletier

My rifle is actually a BSA Super Meteor.

Today I’ll tell you the rest of the story. And, what a story it is! I had no plans for this part of the BSA Meteor report to go as long as it did. Circumstances just led me to this point. All I did was faithfully chronicle what happened.

When we left the Meteor yesterday, I’d removed the piston body, but the piston head was still stuck inside the spring tube in the forward part we call the compression chamber. The best access is through the air transfer port — a hole 0.125 inches in diameter. I had a pin punch that fit the hole, and I hoped it would need only a couple taps to come loose, but it was far tighter than I’d thought. The pin punch went in as far as it would go (about 1.5 inches), and the head was still out of reach from the other end. I needed a longer punch.

The air transfer port provided the best way to get to the stuck piston head. With the barrel removed, it was easy to insert a pin punch through the hole and tap the piston head out of the compression chamber.

I flipped the spring tube straight up, with the transfer port on the lower end, and poured Kroil (penetrating oil) on it to loosen the head. This is similar to freeing a stuck piston in an old tractor, except that this is smaller and a lot easier to work on. I left the Kroil in the spring tube overnight; and by the next morning, none had passed the piston head. The piston was stuck tight!

My shooting partner, Otho, made me a 12-inch pin punch from music wire that was exactly 0.125 inches in diameter. I met him out at the rifle range, where he gave me the new punch. All it took was a couple taps with a ball peen hammer and the head came right out. The Kroil on the walls of the spring tube made removal that much easier once the head got to the place where the oil covered the walls.

What came out of the gun was surprising, as it didn’t look like a Meteor piston head was supposed to look. But it did appear to be factory-made. Experience has taught me to, “Make haste slowly,” as Benjamin Franklin once said, so I studied the piston head and thought about the project for a day.

Looking on the internet, I found one other person who had the same problem — the head separating from the piston. And his gun was filthy dirty inside, just like this one. When he described his piston head, it turned out to be exactly like the one in my gun and also is not a head that’s normally seen in a Meteor. Then a happy thing happened.

New blog reader Dag Evert told me my rifle looks like a blend of different Marks to him. He sees some Mark IV and some Mark V characteristics in my gun, and he told me that he has seen 3 different piston heads in these rifles. For some reason, the guy on the internet thought someone had substituted a BSA Scorpion piston head in his rifle.

The piston head of a normal Mark IV Meteor has a large o-ring near the front of the head that is backed by a buffer washer. The head is either keyed to a slot in the end of the piston or there’s the newer (cheaper) kind of piston head that’s held on the piston by an E-type circlip. That kind can separate from the piston just like mine did.

My piston head appeared to have leather around the sides. I had to destroy the leather material to find out if I’m right about the composition, but I also don’t care for the weak way this head attaches to the piston. According to what I’ve read, it’s actually very weak! I would like to replace it with a new piston that uses a more conventional head that won’t separate from the piston while inside the gun.

This is what the Meteor piston head looked like when it came from the rifle. This is an enlarged and enhanced photo, so you can see the separation of the o-ring and buffer washer; but when looked at in normal light at normal size, this head looked like the sides were all leather. The shallow groove in the end of the head is for the E-type circlip that holds it fast to the piston.

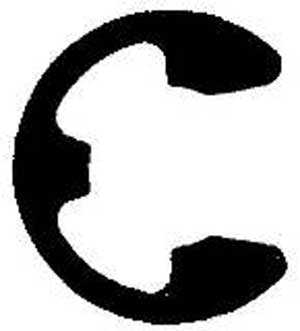

This is an E-type circlip that’s used to hold the piston head to the Meteor piston.

John Knibbs in the UK has an entire rebuilt piston with a new head that’s ready to go, but the price is 45 British pounds, which is about $72.00. Add shipping to that, and it comes out to around $80 — which is more than the rifle cost. Of course, I have to either fix the rifle or sell it for parts, and I do want to fix it. So, I’m going to have to spend some money. I don’t want to make parts for this gun if I can get around it…because most of our readers can’t make parts, either.

John Knibbs sells this BSA Meteor piston assembly complete with new piston head. This is everything needed to fix my rifle, but the cost is high.

I kept searching for something that was less expensive. I had a perfectly good piston, so all I needed was a new piston head. Instead of being attached with a circlip, as mine is, I wanted one that had a more positive attachment so it wouldn’t separate again.

At this point, I wasn’t entirely sure that the head in my gun was the same as what was being offered on the internet. It was time to take my piston head apart, and that probably meant destroying the soft parts. But since this head wasn’t going back in the rifle again, I saw it as no loss.

The first step was to remove the rear washer behind the buffer material. It should have been free to come off, and it was.

Whatever material the buffer washer was made of, it was completely gone by this time. The simple act of pulling off the metal washer behind it caused the washer to begin to disintegrate. It wasn’t the leather I thought it was.

The o-ring was so flattened by years of compression inside the chamber that it looked like something else. I cut it off to show that it is really a conventional o-ring.

With the o-ring cut off, you can see that this piston head is the usual one found on a Meteor. But the method of attachment to the piston by a single circlip is far too weak for reliable operation.

What I needed was a piston head with all the parts that attached to the piston with something more positive than just a circlip. And with more searching on the internet I found what I needed. On T.R. Robb’s website, I found an adjustable piston head for BSA Meteors that comes with the buffer washer, 2 o-rings and a nut to fasten the head to the piston.

This adjustable piston head comes with everything needed to fix my Meteor piston. Note how the fastening nut is tightened by a rod inserted from the side. The soft parts are included with this item.

Best of all, the cost for this piston head shipped to the U.S. is just 17.25 British pounds, which is only $27.51. That’s affordable in my book. I ordered one, and hopefully it’s on it’s way.

The fact that such a piston head exists tells me that others have had this same problem. That, by itself, is reassuring to know.

Last word

Before I end today’s report I want to draw your attention to the old piston head once more. Notice that the top of the head is bare metal. That’s the part that rests against the end of the compression chamber. But it doesn’t slam against it — or at least it’s not supposed to. If it did, it would hammer the gun apart in a relatively short time.

No, the compressed air in front of the piston head cushions the head from striking the top of the compression chamber when the gun is working right. Hopefully, all that’s needed to get this rifle working right again is a new piston head with fresh seals and some cleaning and lubrication of the gun’s other parts.

The piston heads I’ve seen are the normal keyhole type(in both mk3, mk4 and mk5) the circlip type you show, in a mk4, and a shortstroke circlip head from a 7,5joule mk5. The shortstroke head had two buffers fitted between the head and piston.

I think it is a bit difficult to draw conclusions for us who only see a small amount of these guns, it seems like the factory has used a lot of different parts in several combinations, and as we know, there has been made very many of them.

The circlips I have seen do not look like the E-clip you show, but more like a small coil of spring. Have to agree that Its a weakness in the design.

Dag,

I was just guessing about the type of circlip, as mine is missing.

The groove is too shallow to hold the clip, plus circlips are not meant for dynamic jobs like this. They are more for holding pins from sliding out of place — not for holding against push-pull forces.

If I had a keyed piston head I would just replace the soft parts.

B.B.

As long as there is no wear in the breech pivot hole, pin, or forks, these types of BSA’s are fairly easy and cheap to fix. When wear starts around the breech as is pretty common with ones that get years off use, it’s usually better to use them for spares. By omitting the buffer washer and adapting the piston head people in the UK can get these nearer 12 ft/lb, the Meteor was only ever a 9 ft/lb air rifle at best. I must check out T R Robbs website myself, to see if the adjustable piston head allows that. Having just recently longstroked my BSA Mercury i would like to do the same with my Meteor, It looks a lot easier with an adjustable piston head.

Thanks for some great blogs.

TTFN

Best wishes, Wing Commander Sir Nigel Tetlington-Smythe

B.B.,

I now have enough information that I know what to expect when I open up my Meteor MK IV. I suppose, however, that I should consider simply parting it out and leaving it at that, too.

What I like about the Meteor is it is adult-sized yet lightweight, easy handling, and it balances well for me. It is easy cocking, too. Certainly working on it would be an invaluable lesson in working on airguns for me as well.

But even if I were to get mine in fine working order, the trigger would still be single-stage (which I do not prefer) and very heavy, my guess is in the neighborhood of 12 pounds.

The terrible trigger obviously would negatively affect accuracy, but in general do these Meteors have a reputation for being accurate? If so, fixing it would be a worthwhile learning experience for me and also might produce for me a gun that is accurate as well.

On the other hand, if Meteors are only moderately accurate at their best, working on it might be an exercise in turd-polishing.

Kevin, Dag, and others, are Meteors generally regarded as accurate out to 20 – 25 yards?

Michael

Michael,

Dag sent me a photo of a 25-meter group he fired. It is about one inch in size, I think. I hope to be able to show you some groups from this rifle soon enough.

B.B.

That would agree with my experience as well. When I do my part, my Meteor Mk IV will hold to about 3/4″ to 1″ at 20 yards, with the right pellets.

The only complaint I have with mine is that the rifle is very hard to cock the first time after it has sat for more than a day or so. Once things start to move, it works great until it sits again. After reading this blog, I’m tempted to pull mine apart and see if I can tell what’s binding/sticking.

Neil

Neil,

I would bet the problem is that o-ring sticks after sitting a long time. If you take the gun apart, perhaps some moly-based grease in the compression chamber will keep it free? I plan to try that myself.

B.B.

I really (once again) admire your patience. I’m not sure many of us would have the patience to do such repairs.

J-F

J-F,

It isn’t patience. It’s the reality that if I don’t do something, I’m out what the gun cost me. And, once I discovered how easily it comes apart, I was intrigued.

By easily, I don’t mean to imply that the BSA is simple or straightforward. This is not a job I would recommend for most people who are unfamiliar with spring guns.

But thus far I have been very lucky and the rifle has cooperated.

B.B.

BB,

that buffer washer looks like the same material the English used in their motorcycle clutches in the 50’s and perhaps earlier – cork. My DOT-Villiers clutch was like that. It didn’t work any better than that buffer washer did, apparently.

Fred DPRoNJ

Fred,

Here’s a laugh for you. I just checked my order and found I have ordered the wrong piston head! I ordered the one for the old Scorpion pistol, which they have bundled with the Meteor head on their website. I failed to toggle the correct button when I ordered, and the wording is so vague that it includes both parts in the description. But when it gets to the order it specifies which one has been requested, and I asked for the wrong one.

I sent them a detailed message with my order, telling them what I wanted to do with the part, so they should have caught my mistake (I hope Pyramyd AIR would have!), and I just sent them another email describing my mistake. They haven’t contacted me about the order yet, so we’ll see how their customer service works.

B.B.

BB,

If you get the Scorpion piston head I will buy it from you. I was going to post yesterday that the inside of the Meteor looks just like the inside of a Scorpion pistol. I rebuilt two of the Scorpion pistols. They are my favorite break barrel pistol. I sold a 22 Scorpion but bought another one so I could use the pistol bushing and seal. On one of the Scorpions the bushing behind the piston seal was crumbled. On the other the bushing had the consistency of soft candle wax.

David Enoch

David,

TRRobb still hasn’t contacted me, so I have no idea what’s happening, but if I get the Scorpion head, it’s yours.

If you have 2 Scorpions, how about a guest blog on one? Or loan it to me and I’ll do it.

B.B.

Hope you don’t mind a couple of quick off-topic questions:

Does Pyramyd have any plans to stock the Shoebox Max compressors? They’re a lot less pricey than the Freedom8 for almost identical results. My pumping/pump rebuilding days are coming to an end dangitall!

Secondly can you explain how exactly a single-shot tray on a multi-shot gun makes it more accurate? Whether tray or magazine, the pellet enters the same breech pushed by the same bolt, so I don’t understand the accuracy claims-what am I missing here?

Thank you!!

I’ve been wondering about the single shot tray too!

J-F

Dangerdongle,

I will ask.

B.B.

Everyone,

Single-shot trays mean that the pellets aren’t subjected to moving around in a magazine, where they can get bent. Since you handle each one, presumably you can be gentler.

B.B.

Nice simple little rifles, but not a powerhouse, built to a price. Now in its Mk 8 guise apparently. Recently rebuilt a Mk 5 – BB’s notes all rang true. Had to use a very thin spring washer to stop the play in the breach which lead to loose groups. Shot repeatably after that. Trigger can be adjusted with care to give a easy enough let off.

Request a review of an Original model 50b??

CB,

The Original model 50 would be a German Diana model 50. I have owned one and tested it years ago, but I don’t have one at present. What is a 50b?

B.B.

Exactly the same, except it has a clip-on peep sight attachment. Recently acquired one and after a bit of maintenance has settled down nicely. I particularly like its sleek “Mauser”-like appearance and above all its surprising accuracy even with open sights. I asked purely because there is not that much info on the Internet and am interested in finding out more.

CB,

If you have one, how about sharing it with the rest of us through a guest blog? 😉

B.B.

B.B.

Very nice job. A man must be his own gunsmith sometimes.

I wonder why Mr.Robb’s new piston head didn’t come with a buffer, like FWB’s. And I bet the rounded edge steals some performance from the rifle. I think making it straight edge with a shallow PU ring on the very end to minimize dead volume could hotrod this vet rifle a bit, as well as making its working cycle a bit smoother. Well, but that’s all just my theoretical musings.

duskwight

Must be his own gunsmith? No he doesn’t. 🙂

Matt61

Duskwight,

Robb’s piston does include the buffer and 2 o-rings. The picture just doesn’t show them.

B.B.

That’s quite a mess in there, and the technical work is worthy of Derrick himself. The finding of the missing part reminds me of an entertaining movie called My Bodyguard from a long time ago. A disaffected person has assembled a motorcyle out of junk piece by piece except for one part and is in despair. His friend who knows nothing about motorcycles takes to wandering junkyards looking for the piece. He comes up with one part after another which is dismissed and thrown away, until one day the friend comes up with the missing part! Fade out, fade in, they are riding gloriously along on the motorcycle in tandem shouting with laughter. But then bullies close in and the motorcycle gets kicked around and thrown in a lake. This inspires soul-searching and deep personal problems connected with a firearm way back when. The pair finally gets it together and are walking the motorcycle out of the lake when the bullies reappear, interpose themselves and say, “Where do you think you’re going with that?” For the rest, see the movie. Bwa ha ha. You’ll thank me. Anyway, with all the work going into this gun, I wouldn’t be surprised if it shoots like a champ.

By the way, “Make haste slowly” long predates Benjamin Franklin and goes back to the Romans–Festina lente. It is always wise to pay attention to what the Romans said as Benjamin Franklin knew.

FredDPRofNJ, as far as I know the SW J frame is their smallest frame revolver designed for concealment. The point of the passage wasn’t the gun. It was the practice sessions once a month. That will really accomplish something. And this woman, who is supposed to be smart enough to be a mole lurches from one disaster to another. In a taxi in a bad part of town, the driver is giving her a hard time, and she says, “I have a gun” to which the cabbie responds by smiling and saying, “So, do I, sister.” The woman’s collaborator and boyfriend throws her over to retribution by the CIA. You can see in her choice of firearms training that she doesn’t know what is coming off.

Matt61

I would have wrote this rifle off as a total loss and simply tossed it in the trash. This is why I don’t like “old guns”. You never know what condition they are in. If something breaks often the parts if any could be found are more expensive than the trash gun, so not worth fixing plus you are out the money you spent on somebody else’s worn out gun. But if I buy one new and it falls apart like chinese guns are prone to doing I have a warranty so I can send them back to what ever company outsourced their product to get it made as cheaply and poorly as possible along with some carefully selected words about the shoddy product they are foisting off on us.

has any one tryed a nitro piston upgrade on a wood stock bsa meteor

not sure on wat mk it is a .177cal tired of looking for springs

Peter,

To my knowledge the Meteor has never been fitted with a gas spring (of which a Nitro Piston is but one type). As for steel mainsprings for BSA Meteors, contact T.R.Robb in England. The website link is given in this report. They will sell you a spring and you’ll have it in about 10 days.

B.B.

Tony here from California. I just rebuilt and converted both of my BSA Super Meteor .177 caliber air rifles, Mark IV and V, to nitro piston power plants. I purchased the gas pistons from CustomAirSeals.com in Australia. I have put about 300 rounds through each gun without any problems with the rifles. I had to use a screw with blue Loctite and several stacked washers and fasten it into the second hole forward from the back of the gun in the dovetail mount area making sure it did not protrude in the piston tube area which prevents the 11mm to 20mm scope conversion mount from sliding rearward with the increased impact.

Tony,

Welcome to the blog.

What are the cocking efforts of the rifles with the new springs?

B.B.

Not sure about the cocking weight of this nitro piston, but it’s not much different from the coil spring that it replaced. The kickback from the new powerplant is very manageable. Took down a couple of crows without any effort using the .177 7.9g Crosman Hollow Point Premiers. They dropped like a brick from a tall lamp post. See advertisement information below posted by CustomAirSeals from the eBay listing:

BSA METEOR GAS RAM MK3-MK5 KIT

BSA METEOR MK3-MK5 GAS RAM KIT

DROP IN KIT NO MODIFICATIONS REQUIRED

SUITABLE FOR MK3-MK5 METEOR .177 OR .22

MUZZLE ENERGY IS 9-10 FT/LBS WHICH PRODUCES THE BEST POWER ACCURACY RATIO

TRANSFORMERS THE METEOR INTO A SMOOTH AND ACCURATE SHOOTER

IN ONE COMPLETE PACKAGE NO OTHER PARTS REQUIRED

EASY TO INSTALL IN MINUTES

PISTON AND SEALS NOT INCLUDED

Tony Papilli

Dare to be different.

Another pic

Another pic with scope mount stop screw

Signetring54,

Fine job on the stop. The springers and gas rams can put a thumping to scope mounts, for sure! 🙂

Chris

P.S.,… If posting anything old or new in the future, best results and most replies will come from the most current blog. Why? Unless using the Comments RSS at the top right, very few people will ever see this. The RSS allows you to view new comments from any blog, no matter how old. Off topic on the most current is fine, so jump right in,…..